Confused about using Gino/Silicone pads for my heated bed

Posted by Cyber Akuma

|

Confused about using Gino/Silicone pads for my heated bed August 10, 2015 10:29PM |

Registered: 8 years ago Posts: 28 |

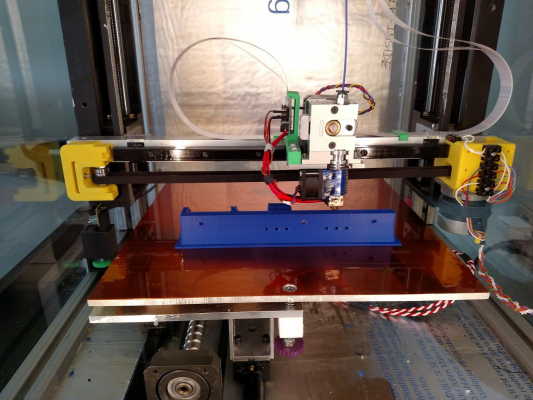

Ok, so I recently got a Wanhao Duplicator I3, and one of the changes I am planning to make to it before I start printing is to add a glass bed.

I hate the idea of using binder clips, and saw that many people use Gino (or some other brand) Silicone pads normally meant for computer CPU/GPUs instead. I am a little confused about two things however.

First of all if you should use one big pad or cut it into squares. There seems to be debate on both sides about this and I wanted to hear what others opinions about it were. I heard that using a single pad is not a good idea because it makes it harder to remove the glass and it's harder to get it flat or make sure no air bubbles get trapped under it. But on the other hand I am worried about heat not transferring evenly if you cut it into squares, especially since there seems to be no general consensus on how they squares should be arranged or how many to use.

And second, are these pads supposed to be sticky or adhesive? I assumed the whole point was that it was a sticky substance that on top of being a heat-transfer medium would stick like tape the glass to the metal heated printbed, but now I am hearing that some or even all pads might not be sticky, and can't seem to get a clear answer.

Can anyone offer any advice?

I hate the idea of using binder clips, and saw that many people use Gino (or some other brand) Silicone pads normally meant for computer CPU/GPUs instead. I am a little confused about two things however.

First of all if you should use one big pad or cut it into squares. There seems to be debate on both sides about this and I wanted to hear what others opinions about it were. I heard that using a single pad is not a good idea because it makes it harder to remove the glass and it's harder to get it flat or make sure no air bubbles get trapped under it. But on the other hand I am worried about heat not transferring evenly if you cut it into squares, especially since there seems to be no general consensus on how they squares should be arranged or how many to use.

And second, are these pads supposed to be sticky or adhesive? I assumed the whole point was that it was a sticky substance that on top of being a heat-transfer medium would stick like tape the glass to the metal heated printbed, but now I am hearing that some or even all pads might not be sticky, and can't seem to get a clear answer.

Can anyone offer any advice?

|

Re: Confused about using Gino/Silicone pads for my heated bed August 12, 2015 03:17PM |

Registered: 9 years ago Posts: 1,873 |

I haven't tried it, but just intuitively, if you cut the pad into squares (and assuming the squares have a smaller total area than that of the glass) then the gaps between the squares will form an air gap which will be an excellent heat insulator - exactly the opposite of what you want. The binder clips may seem clunky but one of the major advantages of printing on glass is the ease with which you can remove the bed for cleaning, or to have multiple pieces of glass with different surface treatments for different filaments, or even just so that you can start the next print while the previous one cools down. If you bond the glass to the heater then you throw those advantages away.

I've ordered some supaclips to try out, but they haven't arrived yet. I'm hoping they give a lower profile while retaining the ease of removal advantages.

I've ordered some supaclips to try out, but they haven't arrived yet. I'm hoping they give a lower profile while retaining the ease of removal advantages.

|

Re: Confused about using Gino/Silicone pads for my heated bed August 13, 2015 10:30PM |

Registered: 8 years ago Posts: 28 |

Removing the glass isn't really a conscern, especially since I plan to put a PEI sheet on top of it, so unless it utterly breaks I don't plan to remove it. I am more conscerned with it actually sticking well and transferring heat better, since strips/sqaures can cause air pockets that would insulate the heat.

Do I need to use something else to stick the pad to the berd and glass, or will the pad itself stick?

I am trying to avoid using clips, because I want to try to maximize heat transfer and every millimeter I can get out of the print bed, as well as avoid the risk of the nozzle crashing into the clips.

Edited 1 time(s). Last edit at 08/13/2015 10:32PM by Cyber Akuma.

Do I need to use something else to stick the pad to the berd and glass, or will the pad itself stick?

I am trying to avoid using clips, because I want to try to maximize heat transfer and every millimeter I can get out of the print bed, as well as avoid the risk of the nozzle crashing into the clips.

Edited 1 time(s). Last edit at 08/13/2015 10:32PM by Cyber Akuma.

|

Re: Confused about using Gino/Silicone pads for my heated bed August 13, 2015 11:14PM |

Registered: 9 years ago Posts: 517 |

I am trying out those silicone pads on a new printer I am building. The people who suggested them to me gave me the recommendation of using the biggest pads you can get, but when you lay them out, leave a small gap between them for expansion. I have a 300x200mm bed and used 6 100x100mm pads. No problems with air gaps and does a pretty good job getting the heat through.

|

Re: Confused about using Gino/Silicone pads for my heated bed August 18, 2015 10:37PM |

Registered: 8 years ago Posts: 28 |

|

Re: Confused about using Gino/Silicone pads for my heated bed August 18, 2015 10:41PM |

Registered: 9 years ago Posts: 517 |

|

Re: Confused about using Gino/Silicone pads for my heated bed August 27, 2015 08:38AM |

Registered: 8 years ago Posts: 28 |

Damn..... it's been out of stock on Amazon for nearly a week now, they said they don't even know if they will get it IN stock again. Went out of stock just as I was about to order it last weekend.

[www.amazon.com]

... A lot of the 3D printer guides refer to them as "Gino Pads" even though that is just one brand of manufacturer, is there any particular reason to choose Gino over other brands? I can't finish my printer bed without this pad and when trying to search for it by it's ASIN number "B007PPEW52" all I get are linkbacks to that Amazon page. Any other brands you can recommend that are good? And actually flat without deformities that would make my bed unlevel?

[www.amazon.com]

... A lot of the 3D printer guides refer to them as "Gino Pads" even though that is just one brand of manufacturer, is there any particular reason to choose Gino over other brands? I can't finish my printer bed without this pad and when trying to search for it by it's ASIN number "B007PPEW52" all I get are linkbacks to that Amazon page. Any other brands you can recommend that are good? And actually flat without deformities that would make my bed unlevel?

|

Re: Confused about using Gino/Silicone pads for my heated bed August 27, 2015 08:53AM |

Registered: 9 years ago Posts: 517 |

Quote

Cyber Akuma

is there any particular reason to choose Gino over other brands?

Is there any particular reason to choose Kleenex over other brands? I think Gino has just been picked up as a generic name like Kleenex or Xerox or other similar items. I ended up ordering pads off of eBay. They came from China or Hong Kong so took longer to get here. Ordered 100mm x 100mm pads and just placed them close to each other with a small gap to allow for any expansion.

|

Re: Confused about using Gino/Silicone pads for my heated bed August 27, 2015 10:05AM |

Registered: 11 years ago Posts: 5,780 |

I have noticed that many people at the makerspace have problems getting ABS prints to stick to kapton tape without adding glue, etc. When I ask what they did, they tell me they wiped the bed with acetone before printing and the parts just wouldn't stick. Then I ask them to show me the acetone and they bring out a bottle of nail polish remover. Nail polish remover is cheap (you can buy a small bottle for $2) and contains some acetone. The problem is that it contains glycerin and other greasy crap intended to keep the acetone from drying your skin. Where do you think that stuff ends up when you wipe a print bed with it? Acetone means acetone, not nail polish remover. A 1 qt can of acetone will cost about $7 and last a year. How much cheaper do things have to get?

People are constantly trying to shave a $ or two out of their printers and everything associated with them. Why not spend a few more $ and get what actually works and you won't have to waste so much time and energy trying other things that don't. All the effort you're going through to get even heating at the lowest possible cost is being applied to a thermal insulator- no matter what you do, you won't get even heating because the bed plate is an insulator. If you're not going to remove the bed plate, why not use a thermally conductive plate instead of glass? 1/4" cast aluminum tooling plate is flat and thermally conductive. Apply some Kapton tape or PEI and you have the best bed money can buy. It might cost $10 more than the glass/silicone thing, but it will work more reliably and without slathering it with sloppy stuff to try to get prints to stick.

This part is about 9" diameter, ABS, and finished perfectly, without lifting from the bed, warping, or delaminating. The bed is 1/4" cast aluminum tooling plate covered with 5 mil kapton tape. Nothing on the tape but a clean surface- just wipe with acetone (NOT fingernail polish remover) before printing.

Here is another:

You need a good leveling scheme to take full advantage of the flat surface of the plate. 3 point leveling is the way to go.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

People are constantly trying to shave a $ or two out of their printers and everything associated with them. Why not spend a few more $ and get what actually works and you won't have to waste so much time and energy trying other things that don't. All the effort you're going through to get even heating at the lowest possible cost is being applied to a thermal insulator- no matter what you do, you won't get even heating because the bed plate is an insulator. If you're not going to remove the bed plate, why not use a thermally conductive plate instead of glass? 1/4" cast aluminum tooling plate is flat and thermally conductive. Apply some Kapton tape or PEI and you have the best bed money can buy. It might cost $10 more than the glass/silicone thing, but it will work more reliably and without slathering it with sloppy stuff to try to get prints to stick.

This part is about 9" diameter, ABS, and finished perfectly, without lifting from the bed, warping, or delaminating. The bed is 1/4" cast aluminum tooling plate covered with 5 mil kapton tape. Nothing on the tape but a clean surface- just wipe with acetone (NOT fingernail polish remover) before printing.

Here is another:

You need a good leveling scheme to take full advantage of the flat surface of the plate. 3 point leveling is the way to go.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Confused about using Gino/Silicone pads for my heated bed August 27, 2015 11:28AM |

Registered: 8 years ago Posts: 28 |

Actually, for ashesion I am planning to laminate a PEI sheet on top of the Borosilicate Glass using 3M 468MP tape. I already have the PEI, glass, and tape.... just need a pad to put the glass on the printbed. Really, I am doing the opposite of trying to cut every cost I can, since if I was I would just use binder clips instead of a silicone pad. (I have actual acetone as well, I use it to make ABS juice for my other printer that dosen't have a heated bed when I want to print small ABS parts on it... or I would if I had a container that woulden't melt from acetone to make the juice in... but there would be no point in putting acetone or gluestick or hairspray on a PEI sheet).

The printer is a Wanhao Duplicator i3, it already came mostly pre-assembled. I don't have enough expirence with 3D printing yet, especuially i3 models, to make changes to it's fundamental design like converting the bed to a three-point leveling system, just small tweaks here and there.

The printer is a Wanhao Duplicator i3, it already came mostly pre-assembled. I don't have enough expirence with 3D printing yet, especuially i3 models, to make changes to it's fundamental design like converting the bed to a three-point leveling system, just small tweaks here and there.

|

Re: Confused about using Gino/Silicone pads for my heated bed September 01, 2015 08:01AM |

Registered: 8 years ago Posts: 28 |

Seems I can't find ANY pads in the rigth size regardless of brand...

The glass I am putting on my bed is 200x250mm, so I was looking for pads at least that big or bigger. Most of them are in the 100x100 range... or very thick like 5mm or 7mm.

The few handful that I could find are shipping form Hong Kong and estimated to take until mid October to arrive!

The glass I am putting on my bed is 200x250mm, so I was looking for pads at least that big or bigger. Most of them are in the 100x100 range... or very thick like 5mm or 7mm.

The few handful that I could find are shipping form Hong Kong and estimated to take until mid October to arrive!

|

Re: Confused about using Gino/Silicone pads for my heated bed September 01, 2015 11:51AM |

Registered: 11 years ago Posts: 5,780 |

One of the people at the makerspace had a FLIR camera on their phone a couple days ago. We looked at the beds of the Solidoodle 3 and the Taz Lulzbot 3. The Solidoodle has an aluminum bed and the Taz a glass bed. The Solidoodle's heat profile was warmest at the center and then gradual reduction in temperature going away from the center with the edges of the plate maybe 10C cooler than the center of the bed. The Taz had a cool spot at the center and then several other cool spots distributed over the surface of the bed- by cool I mean 20C or more less than the warmest areas.

Glass is a lousy material for a heated bed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Glass is a lousy material for a heated bed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Confused about using Gino/Silicone pads for my heated bed September 01, 2015 12:41PM |

Registered: 8 years ago Posts: 45 |

Anybody know if this, aluminium flat bar. The same as tooling plate for flatness. Aluminium Flat Bar

|

Re: Confused about using Gino/Silicone pads for my heated bed September 01, 2015 01:04PM |

Registered: 8 years ago Posts: 28 |

|

Re: Confused about using Gino/Silicone pads for my heated bed September 01, 2015 02:47PM |

Registered: 11 years ago Posts: 5,780 |

Quote

3DS-QUAD

Anybody know if this, aluminium flat bar. The same as tooling plate for flatness. Aluminium Flat Bar

If it doesn't say cast/milled tooling/jig plate, it isn't. It is most likely extruded and not particularly flat.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Confused about using Gino/Silicone pads for my heated bed September 01, 2015 02:54PM |

Registered: 11 years ago Posts: 5,780 |

Quote

Cyber Akuma

The glass is for an even flat surface, not for heat conductivity.

Right. But you apply heat to get prints to stick. If prints don't stick, it doesn't matter how flat the bed is.

What you need is bed flatness and thermal conductivity so there are no cool spots that will let go of the print. That's what cast tooling plate is good for.

Edited 1 time(s). Last edit at 09/01/2015 02:55PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.