Lead Screw Backlash

Posted by Shachar85

|

Lead Screw Backlash August 31, 2015 07:10AM |

Registered: 8 years ago Posts: 63 |

Hi

I'm in advanced stage of designing 3D printer. I was thinking maybe to change my Y axis lead screw to ballscrew.

I really prefer the lead screw, because I like my design so far, but I'm afraid of it's backlash.

Can anyone tell me how much backlash can I expect having when using the lead screw?

(Or at least an estimation - 0.1-0.2 mm or more like 1mm?)

Thanks for any help in that matter

I'm in advanced stage of designing 3D printer. I was thinking maybe to change my Y axis lead screw to ballscrew.

I really prefer the lead screw, because I like my design so far, but I'm afraid of it's backlash.

Can anyone tell me how much backlash can I expect having when using the lead screw?

(Or at least an estimation - 0.1-0.2 mm or more like 1mm?)

Thanks for any help in that matter

|

Re: Lead Screw Backlash August 31, 2015 07:20AM |

Registered: 9 years ago Posts: 722 |

Hi,

It depends of the nut employed.

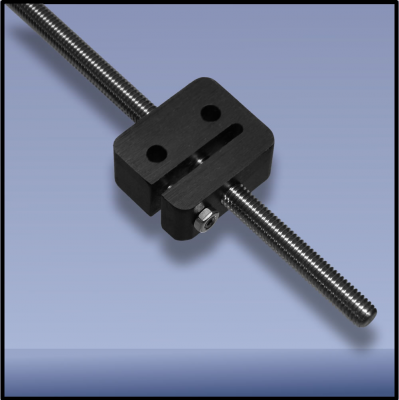

Some Derlin nuts have a play compensation :

You must find a way to avoid the play, with a spring system or whatever.

++JM

It depends of the nut employed.

Some Derlin nuts have a play compensation :

You must find a way to avoid the play, with a spring system or whatever.

++JM

|

Re: Lead Screw Backlash August 31, 2015 07:20AM |

Registered: 11 years ago Posts: 5,780 |

You can get anti backlash nuts for lead screws.

There are different grades of ball screw. If you want something that doesn't have much backlash you may have to get a precision ground ball screw ($$$).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There are different grades of ball screw. If you want something that doesn't have much backlash you may have to get a precision ground ball screw ($$$).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Lead Screw Backlash August 31, 2015 07:32AM |

Registered: 8 years ago Posts: 63 |

Thanks for the answers, but I know there are solutions for the backlash

My question is how bad can the backlash be if I ignore it? I mean - maybe I don't need such precise printer after all

I'm going to use this lead screw:

[www.banggood.com]

My question is how bad can the backlash be if I ignore it? I mean - maybe I don't need such precise printer after all

I'm going to use this lead screw:

[www.banggood.com]

|

Re: Lead Screw Backlash August 31, 2015 09:56AM |

Registered: 11 years ago Posts: 5,780 |

It depends entirely on the quality of the prints you find acceptable. Backlash is likely to cause some surface finish defects and possibly some accuracy issues if you're trying to do precision work (gears that mesh, boxes with tightly fitting lids, threaded parts that screw together). If you're going to print Yoda heads and tugboats it doesn't matter much.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Lead Screw Backlash August 31, 2015 10:09AM |

Registered: 9 years ago Posts: 722 |

Hi again,

Sometimes, I must admit, dentists are right

We can't awnser your question. Which screw ? Which nut ?

Which manufacturer ? Which manufacturing tolerance ?

it could be +-0.02 or +-0.2mm for a low quality item.

Ask your provider, he will know better than us.

If you use a 0.5 of bigger nozzle, the initial play does not realy matter.

But if you want to use 0.3 or 0.25 nozzles for your parts,

then the backlash will matter soon;

Shachar85, event if the initial backlash is negligeable,

keep in mind the wear must grow with use.

An anti backlash system allows you to use your components longer

before to have to replace them. It worth the money and it's no big deal.

++JM

Sometimes, I must admit, dentists are right

We can't awnser your question. Which screw ? Which nut ?

Which manufacturer ? Which manufacturing tolerance ?

it could be +-0.02 or +-0.2mm for a low quality item.

Ask your provider, he will know better than us.

If you use a 0.5 of bigger nozzle, the initial play does not realy matter.

But if you want to use 0.3 or 0.25 nozzles for your parts,

then the backlash will matter soon;

Shachar85, event if the initial backlash is negligeable,

keep in mind the wear must grow with use.

An anti backlash system allows you to use your components longer

before to have to replace them. It worth the money and it's no big deal.

++JM

|

Re: Lead Screw Backlash August 31, 2015 10:54AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Lead Screw Backlash August 31, 2015 11:42AM |

Registered: 8 years ago Posts: 150 |

|

Re: Lead Screw Backlash August 31, 2015 04:46PM |

Registered: 11 years ago Posts: 335 |

You can hit essentially zero backlash just by lightly spring-loading two nuts. This strategy is sometimes used in machine tools but is limited by rigidity and force constraints. A 3d printer has fairly tame loads so there aren't many drawbacks.

Leadscrews are generally a poor choice when you are looking for high accelerations. If you look at motor sizing calculations you will discover that that each gram of screw is equivalent to ~10g of extruder mass.

The extruder is relatively easy to accelerate because a small motor can apply a large force through the mechanical advantage of a timing pulley or screw. The screw itself must be directly attached to the motor shaft so you get no mechanical advantage and it really slows things down.

This gets exponentially worse for short-lead screws. Accelerating a screw from 0 to 1200RPM is going to take a hell of a long time compared to the equivalent timing belt.

Edited 1 time(s). Last edit at 08/31/2015 04:47PM by 691175002.

Leadscrews are generally a poor choice when you are looking for high accelerations. If you look at motor sizing calculations you will discover that that each gram of screw is equivalent to ~10g of extruder mass.

The extruder is relatively easy to accelerate because a small motor can apply a large force through the mechanical advantage of a timing pulley or screw. The screw itself must be directly attached to the motor shaft so you get no mechanical advantage and it really slows things down.

This gets exponentially worse for short-lead screws. Accelerating a screw from 0 to 1200RPM is going to take a hell of a long time compared to the equivalent timing belt.

Edited 1 time(s). Last edit at 08/31/2015 04:47PM by 691175002.

|

Re: Lead Screw Backlash September 01, 2015 03:00AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Lead Screw Backlash September 01, 2015 03:33AM |

Registered: 9 years ago Posts: 722 |

Hi,

That's true Olaf. But first of all, a screw is a reduction.

The larger pitch, the less reduction, the lower definition, the higher speed.

All is linked. But acceleration will still be faster with a belt if you use a regular nema 17 motor.

There's not a lot of stepper motors types that can reach 1200RPM.

A nema17 can't or will loose 90% of its torque along the way.

Acceleration on a screw can be realy fast if you use a brushless servo motor.

That's the best motor choice for a screw transmission indeed.

Otherhand, a direct belt transmission cannot provide a good resolution.

A regular 1.8° nema 17 can provide only a 0.2mm by full step through a 20T GT2 pulley.

That's not that much, and that can induce some artefacts on some prints.

I guess Shachar85 built a screw-style printer for resolution first.

And you can print pretty well without speed. See the digital dentist's printer for example.

But screw backlash can reduce that benefits to zero.

Shachar85, a ballscrew can help to hold strongest machining forces,

but it won't help you that much to prevent backlash,

except if you're ready to spend a lot of money into a C0 screw.

To buy a derlin backlash free nut or to spring load two nuts will be simpler an cheaper.

++JM

Edited 1 time(s). Last edit at 09/01/2015 03:35AM by J-Max.

That's true Olaf. But first of all, a screw is a reduction.

The larger pitch, the less reduction, the lower definition, the higher speed.

All is linked. But acceleration will still be faster with a belt if you use a regular nema 17 motor.

Well, all you say may be different, depending of the motor.Quote

691175002

You can hit essentially zero backlash just by lightly spring-loading two nuts. This strategy is sometimes used in machine tools but is limited by rigidity and force constraints. A 3d printer has fairly tame loads so there aren't many drawbacks.

Leadscrews are generally a poor choice when you are looking for high accelerations. If you look at motor sizing calculations you will discover that that each gram of screw is equivalent to ~10g of extruder mass.

The extruder is relatively easy to accelerate because a small motor can apply a large force through the mechanical advantage of a timing pulley or screw. The screw itself must be directly attached to the motor shaft so you get no mechanical advantage and it really slows things down.

This gets exponentially worse for short-lead screws. Accelerating a screw from 0 to 1200RPM is going to take a hell of a long time compared to the equivalent timing belt.

There's not a lot of stepper motors types that can reach 1200RPM.

A nema17 can't or will loose 90% of its torque along the way.

Acceleration on a screw can be realy fast if you use a brushless servo motor.

That's the best motor choice for a screw transmission indeed.

Otherhand, a direct belt transmission cannot provide a good resolution.

A regular 1.8° nema 17 can provide only a 0.2mm by full step through a 20T GT2 pulley.

That's not that much, and that can induce some artefacts on some prints.

I guess Shachar85 built a screw-style printer for resolution first.

And you can print pretty well without speed. See the digital dentist's printer for example.

But screw backlash can reduce that benefits to zero.

Shachar85, a ballscrew can help to hold strongest machining forces,

but it won't help you that much to prevent backlash,

except if you're ready to spend a lot of money into a C0 screw.

To buy a derlin backlash free nut or to spring load two nuts will be simpler an cheaper.

++JM

Edited 1 time(s). Last edit at 09/01/2015 03:35AM by J-Max.

|

Re: Lead Screw Backlash September 01, 2015 04:02AM |

Registered: 9 years ago Posts: 483 |

You can make zero backlash nuts quite inexpensively using this method. I build a CNC router using this technique and I can't measure any backlash. It uses .375" two start Acme leadscrew. I also used the technique on a macro slide for my camera. It uses stainless 5mm all-thread for the leadscrew and can make 1 micron steps, plus or minus .5 microns. Both applications are lower speed than a 3d printer.

|

Re: Lead Screw Backlash September 01, 2015 07:49AM |

Registered: 11 years ago Posts: 5,780 |

The motor with the screw shaft that was linked previously appears to be very small and incapable of delivering much torque. If you're going to be driving your printer's relatively massive Y axis at anything approaching an acceptable print speed, you're going to need a motor with higher torque. I used the Oriental Motor motor sizing tools web site to calculate the torque required for driving the Y axis in my printer. You have to set some design goals and make a few assumptions about things like coefficients of friction, but you can easily calculate the motor torque required. You will need to know or estimate the mass of the Y axis parts (bed, undercarriage, bearings, lead screw), the desired print speed, the accuracy required, acceleration, etc.

[www.orientalmotor.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[www.orientalmotor.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Lead Screw Backlash September 01, 2015 10:15PM |

Registered: 11 years ago Posts: 471 |

|

Re: Lead Screw Backlash September 02, 2015 12:00PM |

Registered: 11 years ago Posts: 335 |

Quote

o_lampe

Wouldn´t the higher pitch of a lead screw outweight the acceleration issue? Saying, it doesn´t have to turn fast to achieve high speed at the gantry?

-Olaf

There are of course many workarounds, but all else being equal a belt drive will always accelerate faster than a screw just because it weighs less.

High pitch screws and servos are both good options, but if you are willing to put money into a belt system it can be competitive as well.

TBH I personally think a well chosen timing belt with servos in an H-Bot configuration is likely to outperform most screw systems in this application. If you can get 4000+ counts per revolution then step size isn't as much of a problem. The Fortus 400 uses belts and its a $200,000 machine.

|

Re: Lead Screw Backlash September 03, 2015 01:10AM |

Registered: 8 years ago Posts: 63 |

wow thanks for all the replies. I was away for few days.

I really never asked myself what I'm gonna print with it. I mean - It sure gonna be in use all the time, but didn't think about printing gears.

I had some reasons why not to use anti backlash, but I think I'm gonna use it anyway.

I was wondering - since you brought up some topics I never thought about - if belt is faster than lead screw - Could there be a problem if X axis is belt and Y axis is screw?

I really never asked myself what I'm gonna print with it. I mean - It sure gonna be in use all the time, but didn't think about printing gears.

I had some reasons why not to use anti backlash, but I think I'm gonna use it anyway.

I was wondering - since you brought up some topics I never thought about - if belt is faster than lead screw - Could there be a problem if X axis is belt and Y axis is screw?

|

Re: Lead Screw Backlash September 03, 2015 04:36AM |

Registered: 9 years ago Posts: 722 |

Hi,

No matter what kind of transmission you use. Even mixed.

For example, the prusa I3 uses belts for the XY axis and screws for the Z axis.

But, in this case, the Z axis moves only few steps ahead at each new layer,

so the screw does not slow the process at all, even with a direct drive regular nema 17 motor.

Any of X and Y axis needs fast moves with a lot of quick direction changes.

If you draw anything else than a staight line along a single axis,

both works together to draw a diagonal or a curve.

If you choose a screw for the Y axis and a belt for the X axis, for example,

the slowest drive system will teach the maximum speed for the overall machine.

If you use a regular stepper motor with a screw on one of these two axis,

it will drasticaly slow down the printing speed, even with a large pitch screw,

because the slow acceleration rates will make direction changes slower.

The only way to reach the speed a belt system can give

is to use a servo motor which is powerfull enough to conpensate the screw weight.

And maybe use a wide pitch screw too.

You understand it will be more expensive for the same purpose.

Actualy, it's more pragmatic to use the same transmission system on both XY axis,

and chose the transmission type according to the needs teached by the process.

A screw system gives more torque and hold better machining stress.

A 3D printer does not needs a huge torque and filament deposits is stressless.

Otherhand, a 3D printer needs a high speed and fast acceleration.

A screw transmission is at the oposite of what a 3D printer needs.

My advice is to don't use any screw, except if it solves design problems

or is cheaper for a specific design, or if you already own screw

and desperately wants to use it.

Some say the screw will be more precise or more durable.

Obviously it isn't. Except if you buy a C0 ballscrew

(which will exceed the price of good belt printer full kit).

You can buy quality belts and machined idler pulleys

(or use flanged mounted regular gt2 pulleys instead), and get excellent precision prints.

The print quality depends of the global quality of your printer,

no matter your transmission type. But the transmission type will influence the speed.

++JM

No matter what kind of transmission you use. Even mixed.

For example, the prusa I3 uses belts for the XY axis and screws for the Z axis.

But, in this case, the Z axis moves only few steps ahead at each new layer,

so the screw does not slow the process at all, even with a direct drive regular nema 17 motor.

Any of X and Y axis needs fast moves with a lot of quick direction changes.

If you draw anything else than a staight line along a single axis,

both works together to draw a diagonal or a curve.

If you choose a screw for the Y axis and a belt for the X axis, for example,

the slowest drive system will teach the maximum speed for the overall machine.

If you use a regular stepper motor with a screw on one of these two axis,

it will drasticaly slow down the printing speed, even with a large pitch screw,

because the slow acceleration rates will make direction changes slower.

The only way to reach the speed a belt system can give

is to use a servo motor which is powerfull enough to conpensate the screw weight.

And maybe use a wide pitch screw too.

You understand it will be more expensive for the same purpose.

Actualy, it's more pragmatic to use the same transmission system on both XY axis,

and chose the transmission type according to the needs teached by the process.

A screw system gives more torque and hold better machining stress.

A 3D printer does not needs a huge torque and filament deposits is stressless.

Otherhand, a 3D printer needs a high speed and fast acceleration.

A screw transmission is at the oposite of what a 3D printer needs.

My advice is to don't use any screw, except if it solves design problems

or is cheaper for a specific design, or if you already own screw

and desperately wants to use it.

Some say the screw will be more precise or more durable.

Obviously it isn't. Except if you buy a C0 ballscrew

(which will exceed the price of good belt printer full kit).

You can buy quality belts and machined idler pulleys

(or use flanged mounted regular gt2 pulleys instead), and get excellent precision prints.

The print quality depends of the global quality of your printer,

no matter your transmission type. But the transmission type will influence the speed.

++JM

|

Re: Lead Screw Backlash September 03, 2015 07:02AM |

Registered: 8 years ago Posts: 63 |

That was very informative.

I think i'm going to stay with my Z-axis lead screw... I don't want to redesign the whole thing, but I will definitely try to change the Y-axis to GT2 belt.

I really hope it will be easier than expected.

Thanks...again...for all the information. I really haven't put much thought of printing speed

I think i'm going to stay with my Z-axis lead screw... I don't want to redesign the whole thing, but I will definitely try to change the Y-axis to GT2 belt.

I really hope it will be easier than expected.

Thanks...again...for all the information. I really haven't put much thought of printing speed

Sorry, only registered users may post in this forum.