Open or closed 3D printer?

Posted by frax3d

|

Open or closed 3D printer? December 27, 2015 12:21PM |

Registered: 8 years ago Posts: 14 |

Hi all,

I have a question and would like to hear the advice and experience of the community. Maybe this is not the correct section to post it, if it’s not correct please let me know and I will move it.

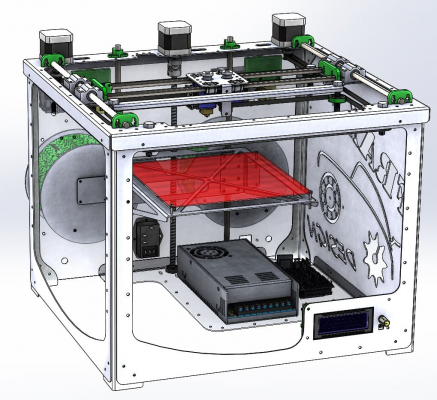

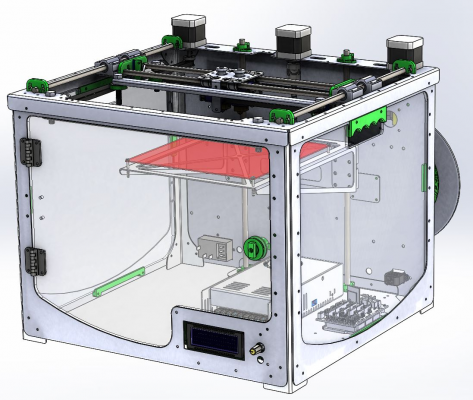

The point is that I design OpenSource 3D printers (I have already published a post on this forum to show the Frax3D printer). But now I wanted to close the structure to keep the printing temperature stable and controlled. In addition, I have also added some clamps on the side so that it can be transported easily. Here is the image of before and now.

My question is whether it’s really important to close the 3D printer. I did some tests and I haven’t noticed big changes ... Also many printer models (not just cheap rep-rap printers, but even some others like Ultimaker) have a structure with some of the faces and the roof open.

This brings me to my next question. Now I have changed the design and have all sides closed, but I don’t see how close the roof ... Do you think this is gonna be a problem? Do you think of any efficient way to close it considering that I want to be able to use both direct and Bowden extruder?

Thanks so much for your help.

You can see more info on my website

I have a question and would like to hear the advice and experience of the community. Maybe this is not the correct section to post it, if it’s not correct please let me know and I will move it.

The point is that I design OpenSource 3D printers (I have already published a post on this forum to show the Frax3D printer). But now I wanted to close the structure to keep the printing temperature stable and controlled. In addition, I have also added some clamps on the side so that it can be transported easily. Here is the image of before and now.

My question is whether it’s really important to close the 3D printer. I did some tests and I haven’t noticed big changes ... Also many printer models (not just cheap rep-rap printers, but even some others like Ultimaker) have a structure with some of the faces and the roof open.

This brings me to my next question. Now I have changed the design and have all sides closed, but I don’t see how close the roof ... Do you think this is gonna be a problem? Do you think of any efficient way to close it considering that I want to be able to use both direct and Bowden extruder?

Thanks so much for your help.

You can see more info on my website

|

Re: Open or closed 3D printer? December 27, 2015 03:04PM |

Registered: 11 years ago Posts: 5,780 |

If you're going to print with ABS you need to enclose the printer and ensure that the temperature inside the enclosure is at least 45C or your ABS prints will warp and delaminate. If you're only going to print with PLA you don't need to enclose the printer at all. I'm not sure about other filament materials, but enclosing a printer often makes it quieter and less smelly, so designing for enclosure is a good thing to do. It turns out that frames that are designed for easy enclosure (by simply attaching rectangular panels) are often the most rigid designs, and rigidity is good. Your machine looks like very rigid construction, so I don't think you're going to have any problems there.

You will need to make a box type cover to put on top of that machine if you're going to print with ABS.

I redesigned and built my printer to be enclosed for ABS printing and easy service. You can see what I did by following the link in my sig, below. Most of what I did is easily applicable to other printer architectures. I feed the filament down through the top of the enclosure into the direct extruder. You can mount a Bowden tube extruder on top and feed the filament down. It's going to make the printer taller, but that's usually less of a problem than expanding the footprint.

Though you can convert (as I did for the first generation of my printer), a printer that will be used for ABS really should be designed for it. That means designing it to be enclosed and warm which usually means keeping the electronics out of the warm build chamber. The ability to enclose and the location of the electronics and cables (out of the heat, yet accessible) should be planned in advance. In most printer designs, enclosure and placement of electronics appear to be an afterthought. Since warm air rises, I figured the best place for the electronics was at the bottom of the printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You will need to make a box type cover to put on top of that machine if you're going to print with ABS.

I redesigned and built my printer to be enclosed for ABS printing and easy service. You can see what I did by following the link in my sig, below. Most of what I did is easily applicable to other printer architectures. I feed the filament down through the top of the enclosure into the direct extruder. You can mount a Bowden tube extruder on top and feed the filament down. It's going to make the printer taller, but that's usually less of a problem than expanding the footprint.

Though you can convert (as I did for the first generation of my printer), a printer that will be used for ABS really should be designed for it. That means designing it to be enclosed and warm which usually means keeping the electronics out of the warm build chamber. The ability to enclose and the location of the electronics and cables (out of the heat, yet accessible) should be planned in advance. In most printer designs, enclosure and placement of electronics appear to be an afterthought. Since warm air rises, I figured the best place for the electronics was at the bottom of the printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Open or closed 3D printer? December 27, 2015 06:37PM |

Registered: 8 years ago Posts: 14 |

Hi digital dentist,

Thanks for your comments My printer is designed for working with both PLA and ABS and I also did some testing with flexible filaments and works fine. The design was created for being closed on the sides, but with the roof open (I have been told that is more important to prevent the air flow than not just the temperature, but maybe I’m wrong). The reason for the roof open is because I want to be able to use any type of extruder so I don’t want any limitation.

My printer is designed for working with both PLA and ABS and I also did some testing with flexible filaments and works fine. The design was created for being closed on the sides, but with the roof open (I have been told that is more important to prevent the air flow than not just the temperature, but maybe I’m wrong). The reason for the roof open is because I want to be able to use any type of extruder so I don’t want any limitation.

I have thought about making a box type cover on the top, but usually these things are made with acrylic or methacrylate so it will be very fragile and probably expensive …

Your printer looks very rigid too, and perfectly closed, good job. The problem is that is also very big for me ... I’m using a CoreXY system so the design can be more compact and fast. I have also thought about using some aluminum profiles like you and make like a box on the top, but I’m not really sure if it will look good on my printer …

You are totally right about the electronics, probably the best place is the bottom. I have them on the bottom too, but unfortunately them are inside the warm build chamber … maybe I will need to create a second floor to keep it separated … What do you think?

Thanks a lot for your help

Thanks for your comments

My printer is designed for working with both PLA and ABS and I also did some testing with flexible filaments and works fine. The design was created for being closed on the sides, but with the roof open (I have been told that is more important to prevent the air flow than not just the temperature, but maybe I’m wrong). The reason for the roof open is because I want to be able to use any type of extruder so I don’t want any limitation.

My printer is designed for working with both PLA and ABS and I also did some testing with flexible filaments and works fine. The design was created for being closed on the sides, but with the roof open (I have been told that is more important to prevent the air flow than not just the temperature, but maybe I’m wrong). The reason for the roof open is because I want to be able to use any type of extruder so I don’t want any limitation.I have thought about making a box type cover on the top, but usually these things are made with acrylic or methacrylate so it will be very fragile and probably expensive …

Your printer looks very rigid too, and perfectly closed, good job. The problem is that is also very big for me ... I’m using a CoreXY system so the design can be more compact and fast. I have also thought about using some aluminum profiles like you and make like a box on the top, but I’m not really sure if it will look good on my printer …

You are totally right about the electronics, probably the best place is the bottom. I have them on the bottom too, but unfortunately them are inside the warm build chamber … maybe I will need to create a second floor to keep it separated … What do you think?

Thanks a lot for your help

|

Re: Open or closed 3D printer? December 28, 2015 03:56AM |

Registered: 12 years ago Posts: 2,470 |

Since warm air rises up a printer without a top cover is more or less useless. Yes, preventing draft helps, especially with ABS (the other way a round for PLA), but if the heat escapes you will never be able to print anything even slightly larger with ABS.

Don't bother for PLA or PET(G), but i found that Nylon and most elastic materials warp less if you have a real enclosure. Again small parts are usually no problem, but anything beyond 1-2cm might already prove difficult with ABS.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Don't bother for PLA or PET(G), but i found that Nylon and most elastic materials warp less if you have a real enclosure. Again small parts are usually no problem, but anything beyond 1-2cm might already prove difficult with ABS.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Open or closed 3D printer? December 28, 2015 05:28AM |

Registered: 8 years ago Posts: 3,525 |

You have the best and easiest configuration for fully enclosed, it's a cube and the motors and electronics can be kept out of the enclosure. I noticed big improvements with an enclosure but it was harder to do with an i3 than a corexy. You can also then vent fumes out of the area where your printer is located by fitting a tube preferably venting to the outside.

A small fan helps to circulate air around especially to blow the air from the top of the enclosure downwards. I found a low wattage hairdryer is a good heater as long as the air is diffused and not blowing directly at your print/motors/electronics.

A small fan helps to circulate air around especially to blow the air from the top of the enclosure downwards. I found a low wattage hairdryer is a good heater as long as the air is diffused and not blowing directly at your print/motors/electronics.

|

Re: Open or closed 3D printer? December 28, 2015 09:44AM |

Registered: 8 years ago Posts: 14 |

OK so it’s clear. It’s better to close the printing area for ABS and I need to find a way of closing the roof …

Then I need to find a place where to keep the electronics (and I guess the power supply) out of the warm chamber.

But I have one more question, for PLA is better to have some ventilation (usually a fan) and keep the printed object cool, right? Do you think it will work if the chamber is warm? Or I need to find a method to cool the chamber when using PLA?

Thanks for the info

Check out the new Frax3D Printer

Then I need to find a place where to keep the electronics (and I guess the power supply) out of the warm chamber.

But I have one more question, for PLA is better to have some ventilation (usually a fan) and keep the printed object cool, right? Do you think it will work if the chamber is warm? Or I need to find a method to cool the chamber when using PLA?

Thanks for the info

Check out the new Frax3D Printer

|

Re: Open or closed 3D printer? December 28, 2015 10:33AM |

Registered: 11 years ago Posts: 5,780 |

If you print on blue painter's tape you can get PLA to stick fine at room temperature. In that case, the enclosed printer won't heat up enough to cause any problems. You can leave the top off or the door open if you're concerned about heat from the electronics, motors, and extruder building up.

The "floor" and the back wall of the build chamber in my printer are both pieces of 1" thick PIR foam cut to fit tightly into the openings in the frame. There is nothing holding either in place except friction. The top piece is also PIR and has screws that hold it into the ends of the frames corner pieces. The 1/8" polycarbonate side panels are held in place by magnetic strips that come in mating pairs. They close the build chamber up almost air tight yet allow easy access to the machine for adjustments and maintenance. The magnetic strip has adhesive but I found that it didn't like to stick to aluminum very well, so I applied some contact cement. I started with all sides and top being polycarbonate and then monitored the temperature in the chamber during a few test prints. I added insulation panels until the temperature got to 45C- the current configuration. I could get things warmer without adding any more heat by swapping another PIR foam piece or two for polycarbonate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The "floor" and the back wall of the build chamber in my printer are both pieces of 1" thick PIR foam cut to fit tightly into the openings in the frame. There is nothing holding either in place except friction. The top piece is also PIR and has screws that hold it into the ends of the frames corner pieces. The 1/8" polycarbonate side panels are held in place by magnetic strips that come in mating pairs. They close the build chamber up almost air tight yet allow easy access to the machine for adjustments and maintenance. The magnetic strip has adhesive but I found that it didn't like to stick to aluminum very well, so I applied some contact cement. I started with all sides and top being polycarbonate and then monitored the temperature in the chamber during a few test prints. I added insulation panels until the temperature got to 45C- the current configuration. I could get things warmer without adding any more heat by swapping another PIR foam piece or two for polycarbonate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Open or closed 3D printer? December 28, 2015 12:16PM |

Registered: 8 years ago Posts: 14 |

45ºC it’s quite good for an ambient temperature (what bed and extruder temperature are you using?). I’m sure it will be complicated to get any hotter without any external heater (probably using a hairdryer as DjDemonD suggests could be a good idea, it seems easy and cheap, but maybe you will create air flows on you printing area …).

The thing is that I want to create a printer that can work with “almost” any available material. So it needs to be hot with ABS and “cold” with PLA. Maybe a good solution is some kind of roof that can be easily removed or opened? What do you think?

And talking about fan, I’m pretty sure I know the answer but I would like to ask if you think is important to have a layer fan for the PLA. And also ask where you are connecting these fans. Directly to the power supply or using Arduino so you can turn On and Off?

Thanks again for the help

Check out the new Frax3D Printer

The thing is that I want to create a printer that can work with “almost” any available material. So it needs to be hot with ABS and “cold” with PLA. Maybe a good solution is some kind of roof that can be easily removed or opened? What do you think?

And talking about fan, I’m pretty sure I know the answer but I would like to ask if you think is important to have a layer fan for the PLA. And also ask where you are connecting these fans. Directly to the power supply or using Arduino so you can turn On and Off?

Thanks again for the help

Check out the new Frax3D Printer

|

Re: Open or closed 3D printer? December 28, 2015 12:37PM |

Registered: 11 years ago Posts: 5,780 |

I have a 450W bed heater and 40W heater in the extruder. I run the bed at 105C for printing ABS and the enclosure heats to 45C in about 15 minutes- usually by the time the first few layers of a print have finished. You can use an unused 2nd extruder I/O on the controller board to regulate the enclosure temperature if you use a heater for that purpose. Just add a thermistor and SSR and treat it like a second extruder- run PID autotune.

A print cooling fan for PLA is a good idea, and you want it controlled by the controller board because it is not needed all the time and can cause problems if it runs at full speed all the time. Slic3r has settings to control the print cooling fan including min and max speeds (PWM values). It is mostly needed when printing small surface area layers- you want the plastic to cool quickly so the next layer has a solid surface to print on.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A print cooling fan for PLA is a good idea, and you want it controlled by the controller board because it is not needed all the time and can cause problems if it runs at full speed all the time. Slic3r has settings to control the print cooling fan including min and max speeds (PWM values). It is mostly needed when printing small surface area layers- you want the plastic to cool quickly so the next layer has a solid surface to print on.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Open or closed 3D printer? December 30, 2015 04:24AM |

Registered: 8 years ago Posts: 3,525 |

I find with pla the enclosure isn't really needed so open the door with pla. I leave mine closed but that's because my printers are in an outbuilding and the ambient air temperature is 5-10 deg C. If the printer was indoors at 20 deg C I'd leave the door open. A controllable print/layer fan is required for pla where the layers are small ie have a short layer time so not much time to cool.

For abs close the door and you might reach 45 deg C without additional heating. If not then use a hairdryer or other such gentle heating. I have 2 layer fans a 4cm one which is switchable with a simple inline switch and a very small 2cm fan for small abs layers also.

Whilst it's best to keep the electronics out of the enclosure if they have to be inside then use a small fan and a duct to bring cold air from outside into the enclosure and blowing across the controller board. As long as it's not too much airflow it won't cool your enclosure too much, certainly not a match for my hairdryer. This small inwards airflow will push air out of any fume vent also.

The motors are not going to be a problem at 45 deg C as long as you set your current to just enough to get smooth accurate movement and not too much to generate excess heat, most steppers are rated up to 130 deg C. If you kill one then its cheap enough to replace.

You have to build it, monitor the enclosure temperature, get printing and experiment - your setup will be unique and have its own positives and problems. Good luck once you gone enclosed you'll never go back.

For abs close the door and you might reach 45 deg C without additional heating. If not then use a hairdryer or other such gentle heating. I have 2 layer fans a 4cm one which is switchable with a simple inline switch and a very small 2cm fan for small abs layers also.

Whilst it's best to keep the electronics out of the enclosure if they have to be inside then use a small fan and a duct to bring cold air from outside into the enclosure and blowing across the controller board. As long as it's not too much airflow it won't cool your enclosure too much, certainly not a match for my hairdryer. This small inwards airflow will push air out of any fume vent also.

The motors are not going to be a problem at 45 deg C as long as you set your current to just enough to get smooth accurate movement and not too much to generate excess heat, most steppers are rated up to 130 deg C. If you kill one then its cheap enough to replace.

You have to build it, monitor the enclosure temperature, get printing and experiment - your setup will be unique and have its own positives and problems. Good luck once you gone enclosed you'll never go back.

|

Re: Open or closed 3D printer? December 31, 2015 07:09AM |

Registered: 8 years ago Posts: 14 |

Hi all,

I have been doing some testing about closing it and I’m quite sure it will work. I have created a fix closed windows on the sides and a door that can be open for easy access on the front. I have used printed parts to close it, even the look and the hinges.

I need to design a roof …

Right now the testing are with a future printer, so I can’t check the temperature yet because is not finish … I will let you know how it’s going

Here you have some images:

You have more info on my web, but it’s just in Spanish …

Thanks for your help

Check out the new Frax3D Printer

I have been doing some testing about closing it and I’m quite sure it will work. I have created a fix closed windows on the sides and a door that can be open for easy access on the front. I have used printed parts to close it, even the look and the hinges.

I need to design a roof …

Right now the testing are with a future printer, so I can’t check the temperature yet because is not finish … I will let you know how it’s going

Here you have some images:

You have more info on my web, but it’s just in Spanish …

Thanks for your help

Check out the new Frax3D Printer

|

Re: Open or closed 3D printer? January 04, 2016 08:19AM |

Registered: 8 years ago Posts: 312 |

|

Re: Open or closed 3D printer? January 04, 2016 08:16PM |

Registered: 8 years ago Posts: 14 |

Hi Lykle,

Thanks for the Info. I have been googling for this patent but I don’t really understand what is involved … Do you think mi printer will be affected by it?

And talking about this. Are all the RepRap printers following the patents? Because there are lots of closed chamber printers … All mi work is always released as OpenSource, but I guess that I need to follow the patens anyway, right?

What do you think I should do?

Thanks for your help.

Check out the new Frax3D Printer

Thanks for the Info. I have been googling for this patent but I don’t really understand what is involved … Do you think mi printer will be affected by it?

And talking about this. Are all the RepRap printers following the patents? Because there are lots of closed chamber printers … All mi work is always released as OpenSource, but I guess that I need to follow the patens anyway, right?

What do you think I should do?

Thanks for your help.

Check out the new Frax3D Printer

|

Re: Open or closed 3D printer? January 04, 2016 09:45PM |

Registered: 11 years ago Posts: 5,780 |

If you're really concerned about it, talk to a lawyer. Otherwise, fugeddaboudit.

If every garage tinkerer had to worry about violating someone's patent, they'd spend all their time researching patents and none of it actually tinkering. How do you know that anything in your printer doesn't violate someone's patent? Are you going to do patent searches for every little thing? Maybe someone has a patent on the way you choose to connect your frame pieces together or even on a rectangular shaped frame. Judging by recent stupid patents (rounded corners on a rectangular shape, by apple) you're very probably violating several patents when you build a printer. Are you going to let that stop you?

Edited 1 time(s). Last edit at 01/05/2016 07:29AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If every garage tinkerer had to worry about violating someone's patent, they'd spend all their time researching patents and none of it actually tinkering. How do you know that anything in your printer doesn't violate someone's patent? Are you going to do patent searches for every little thing? Maybe someone has a patent on the way you choose to connect your frame pieces together or even on a rectangular shaped frame. Judging by recent stupid patents (rounded corners on a rectangular shape, by apple) you're very probably violating several patents when you build a printer. Are you going to let that stop you?

Edited 1 time(s). Last edit at 01/05/2016 07:29AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Open or closed 3D printer? January 06, 2016 05:46PM |

Registered: 8 years ago Posts: 14 |

Hahaha you are totally right digital dentist. I can´t be worried with this right now. I need to focus all my energy improving the printer and showing it to the world so anyone can help mi to improve it.

Thanks again for your help

Check out the new Frax3D Printer

Thanks again for your help

Check out the new Frax3D Printer

|

Re: Open or closed 3D printer? January 11, 2016 01:01PM |

Registered: 8 years ago Posts: 112 |

Quote

Srek

Since warm air rises up a printer without a top cover is more or less useless. Yes, preventing draft helps, especially with ABS (the other way a round for PLA), but if the heat escapes you will never be able to print anything even slightly larger with ABS.

Don't bother for PLA or PET(G), but i found that Nylon and most elastic materials warp less if you have a real enclosure. Again small parts are usually no problem, but anything beyond 1-2cm might already prove difficult with ABS.

PETG is awesome. warps way less then ABS and is stronger, non toxic. adheres well to PEI Bed, doesnt shrink

Makerparts.ca

Your Canadian source for V-Slot Extrusion, CNC and 3D Printing Parts and Accessories.

we are proud to be an official Openbuilds distributor.

Sorry, only registered users may post in this forum.