Base for vertical Leadscrew

Posted by DjDemonD

|

Base for vertical Leadscrew January 11, 2016 11:30AM |

Registered: 8 years ago Posts: 3,525 |

Does anyone have a design for a base for a vertically mounted TR8 leadscrew? Assuming the screw will be driven by a pulley so no motor to attach it to. Is there a closed ended bearing of some type that can be used? It seems insufficient to just have the end of the screw running on metal/printed plastic even if the end were smoothly finished and lubricated.

I have two applications in mind, one is a single motor z axis for an i3, but simplified compared to the one circulating on thingiverse, the other is a z axis for a corexy - again pulley and belt driven.

I have two applications in mind, one is a single motor z axis for an i3, but simplified compared to the one circulating on thingiverse, the other is a z axis for a corexy - again pulley and belt driven.

|

Re: Base for vertical Leadscrew January 11, 2016 12:52PM |

Registered: 12 years ago Posts: 2,470 |

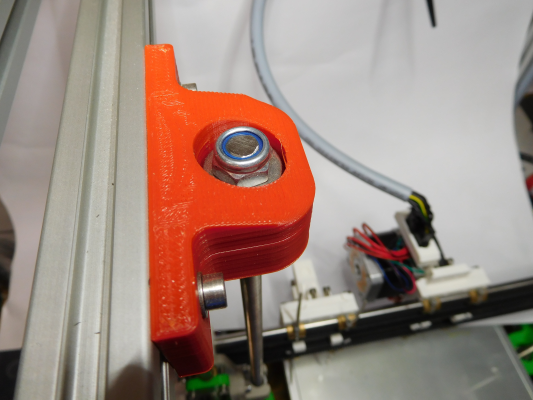

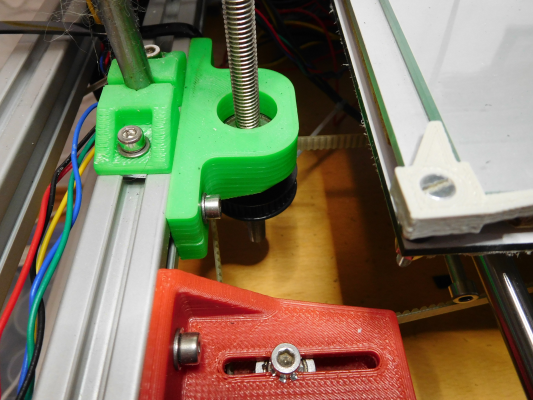

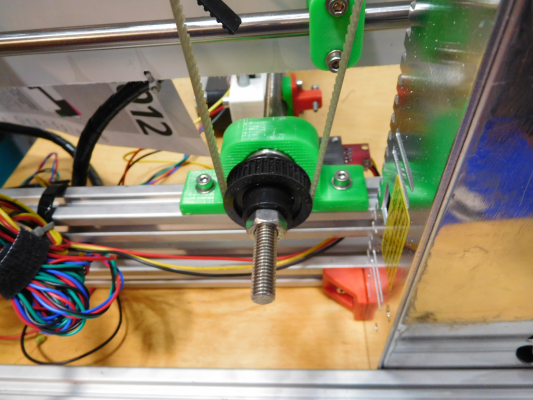

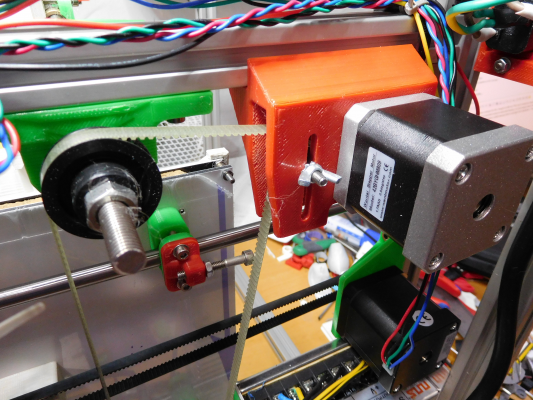

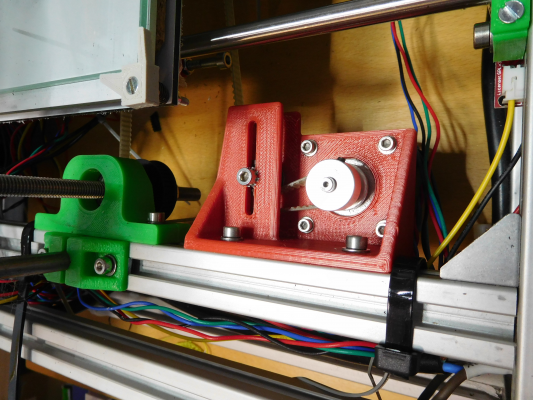

I have actually done a design for this, though for M8 not TR8, but it should be transferable.

At the top the screw is mounted using an axial ball bearing, so it just hangs down from it.

At the lower end it goes through a radial bearing that is mounted from the bottom. The pulley is mounted in a way that the whole screw is tightened slightly, that way it never bends but will always be straight.

I use an axial bearing at the top since the load is the weight of the X assembly plus the tension on the screw, while at the bottom i only use a radial bearing since it mostly has to cope with the pull of the belt and in axial direction only with the tension force.

Please check the attached images or my blog [b.bonkers.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

At the top the screw is mounted using an axial ball bearing, so it just hangs down from it.

At the lower end it goes through a radial bearing that is mounted from the bottom. The pulley is mounted in a way that the whole screw is tightened slightly, that way it never bends but will always be straight.

I use an axial bearing at the top since the load is the weight of the X assembly plus the tension on the screw, while at the bottom i only use a radial bearing since it mostly has to cope with the pull of the belt and in axial direction only with the tension force.

Please check the attached images or my blog [b.bonkers.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Base for vertical Leadscrew January 11, 2016 01:15PM |

Registered: 9 years ago Posts: 100 |

I've been looking into that recently for my own printer design, this is what I've deduced.

The most common way of mounting leadscrews vertically, for our types of application, seems to be with a fixed bearing mount at the bottom, and a floating mount at the top (ie, the floating mount has a little bit of play in it, the fixed bearing block usually has 2 radial bearings spaced slightly apart to provide some lateral support). Of course once you get into higher loads I believe you are supposed to use thrust bearings as well as radial bearings at the base, but that is probably overkill for us. This page discusses the main mounting options, and their limitations and benefits http://www.cncroutersource.com/leadscrew.html

Of course, as you implied, the screw will just drop through the bearing unless you secure it somehow, you are not supposed to just rest it on the motor shaft (as most 3D printers do) because the stepper bearings are not designed for load in that direction, however the loads are so light on something like an i3 that this is not an issue. So where you don't have a motor beneath the screw to support it, the simplest method to secure it is with a lockable collar like this, however the more rigorous solution is to machine the end of the leadscrew so the end has a thinner diameter that will pass through the bearing, but the wider screw cannot. If you are in Europe then Motedis and Dold (use Google translate, if you don't speak German) both do pre-machined 16x4 leadscrews (and the matching end bearings), but for a TR8 I believe your only option is to machine it yourself, or use a collar.

The most common way of mounting leadscrews vertically, for our types of application, seems to be with a fixed bearing mount at the bottom, and a floating mount at the top (ie, the floating mount has a little bit of play in it, the fixed bearing block usually has 2 radial bearings spaced slightly apart to provide some lateral support). Of course once you get into higher loads I believe you are supposed to use thrust bearings as well as radial bearings at the base, but that is probably overkill for us. This page discusses the main mounting options, and their limitations and benefits http://www.cncroutersource.com/leadscrew.html

Of course, as you implied, the screw will just drop through the bearing unless you secure it somehow, you are not supposed to just rest it on the motor shaft (as most 3D printers do) because the stepper bearings are not designed for load in that direction, however the loads are so light on something like an i3 that this is not an issue. So where you don't have a motor beneath the screw to support it, the simplest method to secure it is with a lockable collar like this, however the more rigorous solution is to machine the end of the leadscrew so the end has a thinner diameter that will pass through the bearing, but the wider screw cannot. If you are in Europe then Motedis and Dold (use Google translate, if you don't speak German) both do pre-machined 16x4 leadscrews (and the matching end bearings), but for a TR8 I believe your only option is to machine it yourself, or use a collar.

|

Re: Base for vertical Leadscrew January 11, 2016 01:54PM |

Registered: 8 years ago Posts: 1,671 |

I'm using these [www.ebay.co.uk]

|

Re: Base for vertical Leadscrew January 11, 2016 02:07PM |

Registered: 9 years ago Posts: 1,873 |

This isn't much help for you, but I described the blocks that I made for exactly the use case you describe in this thread They are in use now, and I've been very pleased with the way it turned out.

Edited 1 time(s). Last edit at 01/11/2016 02:08PM by JamesK.

Edited 1 time(s). Last edit at 01/11/2016 02:08PM by JamesK.

|

Re: Base for vertical Leadscrew January 11, 2016 02:49PM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Base for vertical Leadscrew January 11, 2016 04:05PM |

Registered: 8 years ago Posts: 1,671 |

dont forget about these ones [www.ebay.co.uk]

depending on where & what you have to bolt it to it might be useful, even for smooth rod supports.

depending on where & what you have to bolt it to it might be useful, even for smooth rod supports.

|

Re: Base for vertical Leadscrew March 01, 2016 11:15PM |

Registered: 9 years ago Posts: 31 |

|

Re: Base for vertical Leadscrew March 02, 2016 10:01AM |

Registered: 8 years ago Posts: 1,671 |

I found a new use for the J head hotend plate...I used it to mount one of the self aligning bearings, thee hole and the slot in the plate allowed me to position the bearing just where I needed it, waiting on the horse shoe type to see how that aligns with my hole spacings, as I no longer need them to mount the hotend, I hope I can use in another way.

Edited 1 time(s). Last edit at 03/02/2016 10:03AM by MechaBits.

Edited 1 time(s). Last edit at 03/02/2016 10:03AM by MechaBits.

|

Re: Base for vertical Leadscrew March 03, 2016 05:59AM |

Registered: 8 years ago Posts: 3,525 |

Quote

3DLTech

I don't believe the ebay pillowblock bearing are suitable for the axial loads you are suggesting for this application. I made a similar design to JamesK but I 3D printed my thrust bearing housings.

No I agree they probably aren't but then in an i3 neither are the bearings in the motors, so I am swapping one less-than-ideal approach for another, albeit better in the sense that it will enable me to have a single motor z axis on this printer. I figure if I have to replace a bearing from time to time, they are cheap enough.

Sorry, only registered users may post in this forum.