Terrible part warping with ABS, uneven bed temperature

Posted by icefire

|

Terrible part warping with ABS, uneven bed temperature February 28, 2016 09:48AM |

Registered: 8 years ago Posts: 168 |

So what I have achieved so far is being able to print small and medium size parts with very good print quality. However, when printing large parts in ABS the parts tend to warp so badly that they become utterly unusable. That is, if I don't interrupt the print due to the enormous warp.

I am using the MK2B PCB heated bed running at 12V in combination with a 4mm glass plate (simple glass, not borosilicate if this is important for thermal conductivity).

Measuring with an infrared thermometer shows that there are differences of about 5-6 °C in different areas of the heated bed. Furthermore the thermometer measures max. 98°C on the glass surface while the setting in Slic3r is 112°C. It is a pain to get more heat.

In order to reduce part deformation, I am using ABS sludge on the glass. Parts stick like hell on the glass, making it next to impossible to separate large parts from the glass once the print is finished. And even in such cases there is small visible deformation on the edges:

I used to create a 10mm skirt around the part to improve adhesion.. then I used a large plastic bag to cover the printer, preventing the heat to escape, but I'd like to tacke the underlying problem. I am thinking of putting a 3mm aluminum plate between the pcb bed heater and the glass to make the heat spread more evenly.

The alternative would be to change the PSU to 24V and buy the original Kapton heater for the Mendelmax 2.0

Or is there any other bed heater I could use for my setup? What would you suggest?

Thanks!

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

I am using the MK2B PCB heated bed running at 12V in combination with a 4mm glass plate (simple glass, not borosilicate if this is important for thermal conductivity).

Measuring with an infrared thermometer shows that there are differences of about 5-6 °C in different areas of the heated bed. Furthermore the thermometer measures max. 98°C on the glass surface while the setting in Slic3r is 112°C. It is a pain to get more heat.

In order to reduce part deformation, I am using ABS sludge on the glass. Parts stick like hell on the glass, making it next to impossible to separate large parts from the glass once the print is finished. And even in such cases there is small visible deformation on the edges:

I used to create a 10mm skirt around the part to improve adhesion.. then I used a large plastic bag to cover the printer, preventing the heat to escape, but I'd like to tacke the underlying problem. I am thinking of putting a 3mm aluminum plate between the pcb bed heater and the glass to make the heat spread more evenly.

The alternative would be to change the PSU to 24V and buy the original Kapton heater for the Mendelmax 2.0

Or is there any other bed heater I could use for my setup? What would you suggest?

Thanks!

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Terrible part warping with ABS, uneven bed temperature February 28, 2016 09:56AM |

Registered: 10 years ago Posts: 14,672 |

Personally, I would never heat ordinary glass to ABS temperatures without an aluminium heat spreader between the bed heater and the glass, otherwise you risk cracking the glass. With a heat spreader, I see no reason to use borosilicate glass, in fact ordinary float glass conducts heat a little better than borosilicate.

In my experience, you still need to use a bag over the printer if you want to print ABS parts more than 1 or 2cm tall, otherwise your prints are likely to delaminate.

To get more heat, you need to turn up the PSU voltage a little. If you are using a LED/CCTV supply then there is a voltage adjustment pot at the end of the terminal block. But beware of turning up the voltage if you are using Arduino/RAMPS electronics, because the 5V regulator on the Arduino is likely to overheat if you have any LCD displays etc. drawing power from 5V.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

In my experience, you still need to use a bag over the printer if you want to print ABS parts more than 1 or 2cm tall, otherwise your prints are likely to delaminate.

To get more heat, you need to turn up the PSU voltage a little. If you are using a LED/CCTV supply then there is a voltage adjustment pot at the end of the terminal block. But beware of turning up the voltage if you are using Arduino/RAMPS electronics, because the 5V regulator on the Arduino is likely to overheat if you have any LCD displays etc. drawing power from 5V.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Terrible part warping with ABS, uneven bed temperature February 28, 2016 10:31AM |

Registered: 8 years ago Posts: 168 |

I am using a computer PSU at 12 V. If I go for 24V I'd probably need a LED PSU or maybe a second computer PSU which would be a pretty clumsy solution.

However, I would try using an aluminum plate because it would be much easier to leave everything as it is now. How thick should the aluminum sheet be? I would go for 3mm but it bothers me if it is too thick the aluminum plate would act as a passive cooler...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

However, I would try using an aluminum plate because it would be much easier to leave everything as it is now. How thick should the aluminum sheet be? I would go for 3mm but it bothers me if it is too thick the aluminum plate would act as a passive cooler...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Terrible part warping with ABS, uneven bed temperature February 28, 2016 02:02PM |

Registered: 10 years ago Posts: 14,672 |

I suggest 1.5 or 2mm for a 200 x 200mm bed. You want it to be thick enough to spread the heat, but thin enough so that it bends to the (flat) shape of the glass, not the other way around. Thicker aluminium will also increase the time it takes to heat up, but won;t significantly affect how hot the bed ends up.

There is no need to go to 24V if the bed is only about 200mm square. You can use a 12V 25A LED PSU turned up to 14V, and a separate 5V regulator to power the 5V rail if you are using Arduino/RAMPS.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

There is no need to go to 24V if the bed is only about 200mm square. You can use a 12V 25A LED PSU turned up to 14V, and a separate 5V regulator to power the 5V rail if you are using Arduino/RAMPS.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Terrible part warping with ABS, uneven bed temperature March 03, 2016 06:42PM |

Registered: 10 years ago Posts: 35 |

Unless you enclose your print volume and heat it evenly to 50C, ABS will not print reliably. I've been working through all of the other issues with ABS for about 3 years. Printbite, Sitall, or a chemical treatment for your print bed, 110 bed temp minimum, and and enclosed/heated chamber are all required for ABS. You might get by on occasion with less. A well calibrated and maintained printer are assumed to be a given.

Don

Don

|

Re: Terrible part warping with ABS, uneven bed temperature March 04, 2016 12:10AM |

Registered: 8 years ago Posts: 112 |

Your problem is that your printing with ABS.. its not a safe plastic. Try Petg it doesnt shrink/ warp nearly as much as ABS and its safer

Makerparts.ca

Your Canadian source for V-Slot Extrusion, CNC and 3D Printing Parts and Accessories.

we are proud to be an official Openbuilds distributor.

Makerparts.ca

Your Canadian source for V-Slot Extrusion, CNC and 3D Printing Parts and Accessories.

we are proud to be an official Openbuilds distributor.

|

Re: Terrible part warping with ABS, uneven bed temperature March 04, 2016 04:01AM |

Registered: 12 years ago Posts: 1,450 |

Most PCB heaters give out an even amount of heat over the whole area of the bed, but heat is removed unevenly - more at the edges where air rises round them. To make matters worse, the temperature is measured only at one point - if that point is covered by a print then it will get hotter for the amount of heat energy and un-insulated areas further from the thermistor will be cooler. If the print over the thermistor and has good insulation such as sparse infill, the difference may be substantial.

If you don't have a heat spreader you can often get some improvement by not printing anything within about 25mm of the thermistor. Otherwise:

Mike

If you don't have a heat spreader you can often get some improvement by not printing anything within about 25mm of the thermistor. Otherwise:

- Use an adequate heat spreader.

- Keep the build environment warm. An enclosure is best but avoiding drafts and not using fan cooling of the print will help a lot.

- Get more out of the heater. If you can't increase the voltage then putting some insulation under the bed should help.

Mike

|

Re: Terrible part warping with ABS, uneven bed temperature March 04, 2016 07:58AM |

Registered: 11 years ago Posts: 5,780 |

A couple months ago I looked at the bed of our Taz printer at the makerspace with a FLIR camera. That bed is a piece of glass with a silicone heater bonded to it. We saw a 20C variation in temperature across the surface of the bed, including a cool spot at the center of the bed, about 74mm in diameter, as well as the usual temperature drop off around the edges and at the corners.

Glass is a thermal insulator and will not spread heat evenly. That's why people usually layer glass on top of aluminum. The topic of glass vs aluminum beds has been beaten to death.

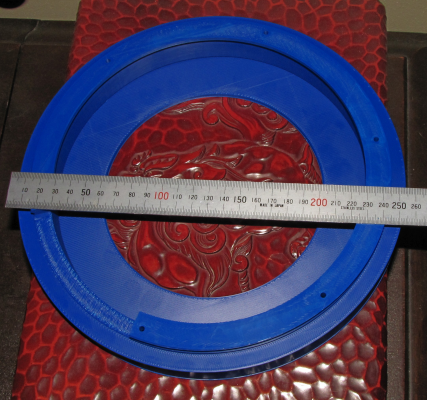

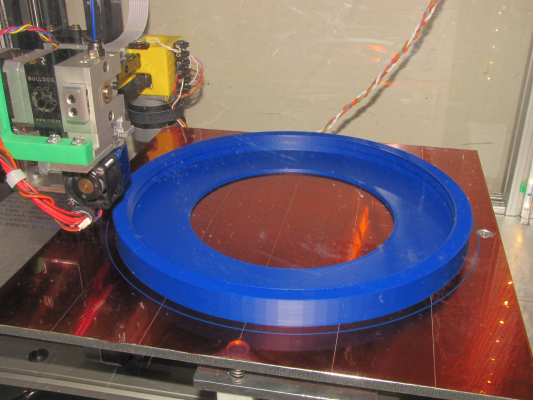

Here's what you can do with a flat aluminum bed, 317 x 305 x 6.35 mm cast tooling plate in this case:

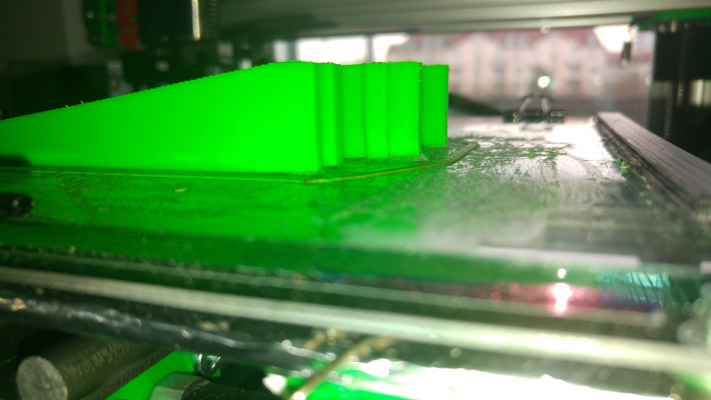

Note- the photo shows two threaded parts screwed together. Here's the larger one printing:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Glass is a thermal insulator and will not spread heat evenly. That's why people usually layer glass on top of aluminum. The topic of glass vs aluminum beds has been beaten to death.

Here's what you can do with a flat aluminum bed, 317 x 305 x 6.35 mm cast tooling plate in this case:

Note- the photo shows two threaded parts screwed together. Here's the larger one printing:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.