Pololu geared DC motor 30g prototype extruder

Posted by ipcalit

|

Re: Pololu geared DC motor 30g prototype extruder June 13, 2016 07:17AM |

Registered: 12 years ago Posts: 972 |

I reckon putting the feedback on the filament and not on the output shaft is more useful for accurate printing. But I am afraid about the additional delay that might cause to the loop (which may make it unstable).

On the other hand, filament-grinding or no-filament conditions may be inferred from anomalous conditions of the loop (error higher than a threshold?). Ideally, filament path error should be able to be used for adaptive printing (slowing down the print as needed so filament feed is maintained).

Your steel rod for filament motion sensing may have some teeth too, as we know this increases the grip, though in this case filament will be forcing rod rotation and not the other way around.

On the other hand, filament-grinding or no-filament conditions may be inferred from anomalous conditions of the loop (error higher than a threshold?). Ideally, filament path error should be able to be used for adaptive printing (slowing down the print as needed so filament feed is maintained).

Your steel rod for filament motion sensing may have some teeth too, as we know this increases the grip, though in this case filament will be forcing rod rotation and not the other way around.

|

Re: Pololu geared DC motor 30g prototype extruder June 13, 2016 07:23AM |

Registered: 8 years ago Posts: 181 |

I wanted to ensure the grip by shrink wrapping the rod using regular shrink tube for electrical isolationQuote

misan

Your steel rod for filament motion sensing may have some teeth too, as we know this increases the grip, though in this case filament will be forcing rod rotation and not the other way around.

I don't like teeth on the rod, but if the shrink wrap will not work, I'll try this approach, too.

I don't like teeth on the rod, but if the shrink wrap will not work, I'll try this approach, too.

|

Re: Pololu geared DC motor 30g prototype extruder June 13, 2016 01:08PM |

Registered: 7 years ago Posts: 78 |

There's another off-the-shelf simpler solution that I might try if the AS5600 doesn't work: the thumb wheel of a mouse is already rubber coated and has the optical encoder built-in (at least in some Logitech and Microsoft ones I dismantled). Just make some oval mounting holes to press the wheel against the filament and rewire the existing optics.Quote

rklauco

I wanted to ensure the grip by shrink wrapping the rod using regular shrink tube for electrical isolationQuote

misan

Your steel rod for filament motion sensing may have some teeth too, as we know this increases the grip, though in this case filament will be forcing rod rotation and not the other way around.I don't like teeth on the rod, but if the shrink wrap will not work, I'll try this approach, too.

|

Re: Pololu geared DC motor 30g prototype extruder June 13, 2016 01:16PM |

Registered: 7 years ago Posts: 78 |

Quote

misan

I reckon putting the feedback on the filament and not on the output shaft is more useful for accurate printing. But I am afraid about the additional delay that might cause to the loop (which may make it unstable).

How would this be different than backlash in the gearing if one adds the encoder to the output shaft? A mechanical error, such as a broken teeth, would manifest in the same way with slipping filament.

Quote

misan

On the other hand, filament-grinding or no-filament conditions may be inferred from anomalous conditions of the loop (error higher than a threshold?). Ideally, filament path error should be able to be used for adaptive printing (slowing down the print as needed so filament feed is maintained).

I think this is the key to get real benefits from closed-loop control of the extruder to most folks. Lighter extruders would otherwise appeal only to fast machines or dual/triple/quad hotends.

Quote

misan

Your steel rod for filament motion sensing may have some teeth too, as we know this increases the grip, though in this case filament will be forcing rod rotation and not the other way around.

This would be similar with the dual-gear approach of Bondtech extruders. I tried with small gears but hand carving the gears gets really old fast. It would be nice to have some off-the-shelf ones like the Mk7/Mk8 that could be paired this way. However, for just measuring the advancement of the filament, I think rklauco's way is enough.

|

Re: Pololu geared DC motor 30g prototype extruder June 13, 2016 04:27PM |

Registered: 8 years ago Posts: 181 |

My problem with any of the gears like MK7/8 etc. is the diameter.

To explain - for reasonable price I am able to get encoder with ~50-100 steps. By using the quadrupling code, I am able to get resolution of 400 impulses per revolution.

Now, if I select my preferred width of 3mm shaft and add ~1mm of heat-shrink-like sleeve, I'll end up with 4mm diameter. That means 1 revolution will move 4*3.141592654 mm of filament - 12.5664 mm. So the resulting resolution is 12.5664 / 400 = 0.0314 mm per impulse.

Now, when I almost double the diameter and use 7mm for the smaller MK8, I'll end up (using the same calculation) with resolution of 0.055 mm per impulse. As you can see, there is linear dependence of the resolution to the shaft diameter.

Now, I am using NEMA17 stepper with 11mm gear as a drive. The stepper has a resolution of 0.9 degree, but my printer is using microstepping and effectively doubles the resolution. So, using the same calculation, my printer has a resolution of 0.0432 mm per microstep

I want to keep the same or better resolution, I don't want to get below the original.

Hence my motivation to use 3mm shaft and very thin sleeve for grip.

That's why I asked for an advice regarding resolution of the extruder

To explain - for reasonable price I am able to get encoder with ~50-100 steps. By using the quadrupling code, I am able to get resolution of 400 impulses per revolution.

Now, if I select my preferred width of 3mm shaft and add ~1mm of heat-shrink-like sleeve, I'll end up with 4mm diameter. That means 1 revolution will move 4*3.141592654 mm of filament - 12.5664 mm. So the resulting resolution is 12.5664 / 400 = 0.0314 mm per impulse.

Now, when I almost double the diameter and use 7mm for the smaller MK8, I'll end up (using the same calculation) with resolution of 0.055 mm per impulse. As you can see, there is linear dependence of the resolution to the shaft diameter.

Now, I am using NEMA17 stepper with 11mm gear as a drive. The stepper has a resolution of 0.9 degree, but my printer is using microstepping and effectively doubles the resolution. So, using the same calculation, my printer has a resolution of 0.0432 mm per microstep

I want to keep the same or better resolution, I don't want to get below the original.

Hence my motivation to use 3mm shaft and very thin sleeve for grip.

That's why I asked for an advice regarding resolution of the extruder

|

Re: Pololu geared DC motor 30g prototype extruder June 13, 2016 06:50PM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

My problem with any of the gears like MK7/8 etc. is the diameter.

To explain - for reasonable price I am able to get encoder with ~50-100 steps. By using the quadrupling code, I am able to get resolution of 400 impulses per revolution.

Now, if I select my preferred width of 3mm shaft and add ~1mm of heat-shrink-like sleeve, I'll end up with 4mm diameter. That means 1 revolution will move 4*3.141592654 mm of filament - 12.5664 mm. So the resulting resolution is 12.5664 / 400 = 0.0314 mm per impulse.

Now, when I almost double the diameter and use 7mm for the smaller MK8, I'll end up (using the same calculation) with resolution of 0.055 mm per impulse. As you can see, there is linear dependence of the resolution to the shaft diameter.

Now, I am using NEMA17 stepper with 11mm gear as a drive. The stepper has a resolution of 0.9 degree, but my printer is using microstepping and effectively doubles the resolution. So, using the same calculation, my printer has a resolution of 0.0432 mm per microstep

I want to keep the same or better resolution, I don't want to get below the original.

Hence my motivation to use 3mm shaft and very thin sleeve for grip.

That's why I asked for an advice regarding resolution of the extruder

Sorry. I think my previous statements led to a confusion. I suggested the use of the mouse wheel (~25mm dia) to measure the movement of the filament instead of the steel rod, so there resolution won't be a problem. Alternatively, one print an overlay sleeve to the idler bearing using flexible filament (or heat-shrink) and just attach the magnet there to drive the AS5600 instead of relying on optical tracking.

The comment on Mk7/8 targeted a dual-gear design to get more grip as in Bondtech. While this could be used to record positional changes, the small diameter of these gears has the issues you mentioned.

|

Re: Pololu geared DC motor 30g prototype extruder June 14, 2016 03:08AM |

Registered: 12 years ago Posts: 972 |

Quote

ipcalit

How would this be different than backlash in the gearing if one adds the encoder to the output shaft? A mechanical error, such as a broken teeth, would manifest in the same way with slipping filament.

I believe so. Backslash causes one shaft movement not to propagate immediately to the other and a missing tooth would cause filament move not to be registered properly (provided there is a toothed measuring gear with a missing teeth and only one teeth engages the filament at a a time).

Now that I think about it, a missing tooth gear with only one tooth engaged a time would be a disaster as it may cause the reading to stop permanently no matter there are direction changes in filament due to retraction moves.

|

Re: Pololu geared DC motor 30g prototype extruder June 14, 2016 03:17PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Pololu geared DC motor 30g prototype extruder June 14, 2016 07:42PM |

Registered: 7 years ago Posts: 78 |

Quote

o_lampe

Why introducing another shaft for the filament encoder? Could you use the common idler gear for that as well?

That is exactly what I proposed. Just attach the encoder disk or magnet to the idler bearing. I'll try to work out a design as I got the SOI8 adapter and magnets for AS5600.

|

Re: Pololu geared DC motor 30g prototype extruder June 14, 2016 11:04PM |

Registered: 8 years ago Posts: 181 |

I have a problem with the "just attach the encoder disk or magnet to the idler bearing" part of the sentence.

As the idler bearing has to push the filament, I can't imagine something reliably be attached while not obstructing:

I'm looking forward for inspiration - try to provide some sketch or at least describe the idea how do you imagine this to happen.

As the idler bearing has to push the filament, I can't imagine something reliably be attached while not obstructing:

- the idler itself

- shaft for the bearing

I'm looking forward for inspiration - try to provide some sketch or at least describe the idea how do you imagine this to happen.

|

Re: Pololu geared DC motor 30g prototype extruder June 15, 2016 02:31AM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

I have a problem with the "just attach the encoder disk or magnet to the idler bearing" part of the sentence.

As the idler bearing has to push the filament, I can't imagine something reliably be attached while not obstructing:

I thought about some mechanism to do it reliably, but I was not able to come up with something - limits of my imagination, I think

- the idler itself

- shaft for the bearing

I'm looking forward for inspiration - try to provide some sketch or at least describe the idea how do you imagine this to happen.

I think that we can get away with supporting the bearing from one side only and avoid obstructing the shaft of the bearing. Then we can slip a sleeve over the bearing and end of the screw and attach the magnet to that sleeve.

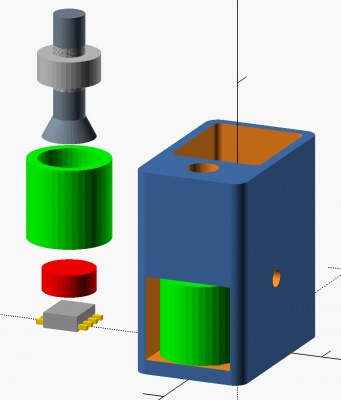

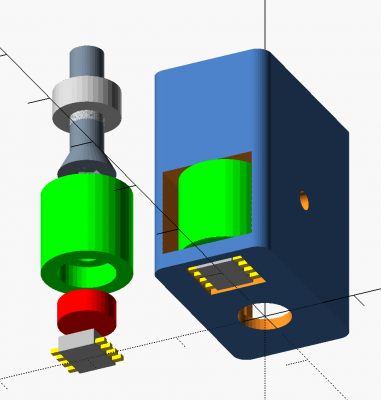

Here is a tentative illustration based on the latest Mk8 gear design, where the AS5600 is at the bottom of the stack in gray, followed by the red magnet, the green sleeve, screw and bearing.

To assemble the setup, you first insert the bearing into one end of the sleeve, place the sleeve into the housing and then insert the screw through as5600 hole in the bottom of the housing and through the sleeve and bearing. After the sleeve is secured into the housing, the magnet is inserted through the bottom followed by the AS5600.

|

Re: Pololu geared DC motor 30g prototype extruder June 15, 2016 03:49AM |

Registered: 8 years ago Posts: 181 |

So, if I understand it correctly, the actual push on the filament is done using the sleeve, not the bearing, right? Not that I have anything against it, I am just wondering if the fit will be stable over time - at least ABS would wore out quite fast due to the friction of resisting filament (my opinion only).

|

Re: Pololu geared DC motor 30g prototype extruder June 15, 2016 05:07AM |

Registered: 8 years ago Posts: 916 |

I just received my geared motor with encoder today, and have been looking at the best way to turn it into an extruder. My goodness it's tiny! So small.

Looking at the output shaft, it doesn't have a bearing, only a steel on brass bush. Are the side loads from the idler bearing considered low enough for this style of bearing surface? Would it be better to mount this motor somehow so that it only provides turning force, instead of supporting the drive gear directly?

It worries me a bit in terms of longevity, that's all.

Looking at the output shaft, it doesn't have a bearing, only a steel on brass bush. Are the side loads from the idler bearing considered low enough for this style of bearing surface? Would it be better to mount this motor somehow so that it only provides turning force, instead of supporting the drive gear directly?

It worries me a bit in terms of longevity, that's all.

|

Re: Pololu geared DC motor 30g prototype extruder June 15, 2016 05:59AM |

Registered: 11 years ago Posts: 31 |

Quote

nebbian

I just received my geared motor with encoder today, and have been looking at the best way to turn it into an extruder. My goodness it's tiny! So small.

Looking at the output shaft, it doesn't have a bearing, only a steel on brass bush. Are the side loads from the idler bearing considered low enough for this style of bearing surface? Would it be better to mount this motor somehow so that it only provides turning force, instead of supporting the drive gear directly?

It worries me a bit in terms of longevity, that's all.

I would prefer to have extra bearings, to ensure the load wasn't put onto the motor construction.. You are deforming the plastic a little, so there are sideways loading

|

Re: Pololu geared DC motor 30g prototype extruder June 15, 2016 09:40AM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

So, if I understand it correctly, the actual push on the filament is done using the sleeve, not the bearing, right? Not that I have anything against it, I am just wondering if the fit will be stable over time - at least ABS would wore out quite fast due to the friction of resisting filament (my opinion only).

It should fare pretty well as it only has compression forces against it. For now, it is just an experiment and if it turns out that it fails, we could always try brass or aluminum.

|

Re: Pololu geared DC motor 30g prototype extruder June 15, 2016 09:42AM |

Registered: 7 years ago Posts: 78 |

Quote

B4Me

Quote

nebbian

I just received my geared motor with encoder today, and have been looking at the best way to turn it into an extruder. My goodness it's tiny! So small.

Looking at the output shaft, it doesn't have a bearing, only a steel on brass bush. Are the side loads from the idler bearing considered low enough for this style of bearing surface? Would it be better to mount this motor somehow so that it only provides turning force, instead of supporting the drive gear directly?

It worries me a bit in terms of longevity, that's all.

I would prefer to have extra bearings, to ensure the load wasn't put onto the motor construction.. You are deforming the plastic a little, so there are sideways loading

Same concerns here, but it seems to be used successfully in other projects. Also, this is one of the reasons to have the encoder elsewhere and be able to swap just the motor for its $3 version if it fails.

|

Re: Pololu geared DC motor 30g prototype extruder June 15, 2016 09:44AM |

Registered: 8 years ago Posts: 181 |

Heh, you are 100% right - I almost forgot I have rapid prototyping machine on my handsQuote

ipcalit

For now, it is just an experiment and if it turns out that it fails, we could always try brass or aluminum.

I'll work on it tomorrow afternoon and try to come up with a sample - we'll see...

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 02:22AM |

Registered: 8 years ago Posts: 916 |

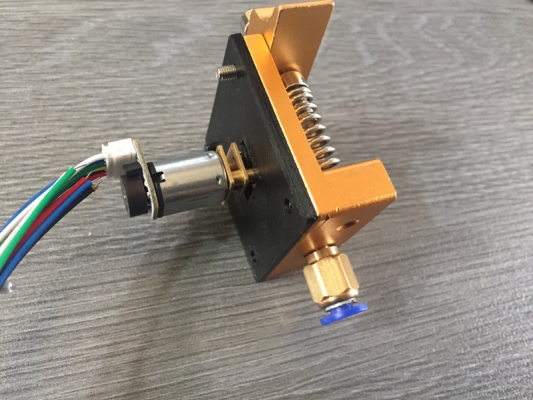

And now for something completely different:

From the "That looks ridiculous" department, I present to you the N20 to NEMA17 adapter.

This allows you to use whatever extruder body you have lying around, without having to engineer a totally new solution. You can then concentrate on the electronics, while using a known-good extruder mechanism.

You will need two M1.5 x 4 (or thereabouts) screws to mount the gearbox to the adapter plate.

Now that that's out of the way I can concentrate on the electrickery

Edited 1 time(s). Last edit at 06/16/2016 02:23AM by nebbian.

From the "That looks ridiculous" department, I present to you the N20 to NEMA17 adapter.

This allows you to use whatever extruder body you have lying around, without having to engineer a totally new solution. You can then concentrate on the electronics, while using a known-good extruder mechanism.

You will need two M1.5 x 4 (or thereabouts) screws to mount the gearbox to the adapter plate.

Now that that's out of the way I can concentrate on the electrickery

Edited 1 time(s). Last edit at 06/16/2016 02:23AM by nebbian.

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 02:56AM |

Registered: 8 years ago Posts: 181 |

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 11:08AM |

Registered: 7 years ago Posts: 78 |

Quote

nebbian

And now for something completely different:

From the "That looks ridiculous" department, I present to you the N20 to NEMA17 adapter.

This allows you to use whatever extruder body you have lying around, without having to engineer a totally new solution. You can then concentrate on the electronics, while using a known-good extruder mechanism.

Haha.. Not what I had in mind when going for the Pololu/N20 extruder. You might want to make a 10x12mm "tube" protruding from the plate that goes around the gearbox to secure it properly.

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 02:11PM |

Registered: 11 years ago Posts: 471 |

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 06:16PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 07:15PM |

Registered: 8 years ago Posts: 916 |

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 07:27PM |

Registered: 7 years ago Posts: 78 |

Quote

nebbian

Quote

ipcalit

Haha.. Not what I had in mind when going for the Pololu/N20 extruder. You might want to make a 10x12mm "tube" protruding from the plate that goes around the gearbox to secure it properly.

The plate already has this.

I would just make it a little bit longer. Also per JamesK comments, some bushing or bearing to support the other side would be beneficial. If you look at my designs, there's always some kind of support at the free end although I haven't tested these for 10h straight

.

.

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 09:23PM |

Registered: 8 years ago Posts: 916 |

Ah OK, I see the bushing now. Didn't see it before.

The reason I didn't go straight to your design was that I didn't have that tiny bearing handy, and your design doesn't have a lever to allow easy manual feeding / retraction.

I totally agree with JamesK, that unsupported sideload worries me, and it's not a design that I'd want to see go into 'production' in my printers. However as something that can be used to test the proof of concept, I think it might work for long enough to see if this system is viable.

I ran that motor last night, and even put some filament through it. It seems fast enough, even at 4.5V. It seems like it's not really designed for the loads and running time that a printer requires, however.

To be totally honest, I'd prefer to use a beefier gearbox, with a brushless motor. The brushless motor and controller are readily available on Hobbyking, I also have loads of them lying around as spares for my quadcopters. The code that is available on github which converts step and direction into controls for a brushed motor could easily be interfaced with a brushless controller as well.

However I haven't been able to find a strong, small gearbox that would do the job yet.

The reason I didn't go straight to your design was that I didn't have that tiny bearing handy, and your design doesn't have a lever to allow easy manual feeding / retraction.

I totally agree with JamesK, that unsupported sideload worries me, and it's not a design that I'd want to see go into 'production' in my printers. However as something that can be used to test the proof of concept, I think it might work for long enough to see if this system is viable.

I ran that motor last night, and even put some filament through it. It seems fast enough, even at 4.5V. It seems like it's not really designed for the loads and running time that a printer requires, however.

To be totally honest, I'd prefer to use a beefier gearbox, with a brushless motor. The brushless motor and controller are readily available on Hobbyking, I also have loads of them lying around as spares for my quadcopters. The code that is available on github which converts step and direction into controls for a brushed motor could easily be interfaced with a brushless controller as well.

However I haven't been able to find a strong, small gearbox that would do the job yet.

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 09:50PM |

Registered: 7 years ago Posts: 78 |

Quote

nebbian

Ah OK, I see the bushing now. Didn't see it before.

The reason I didn't go straight to your design was that I didn't have that tiny bearing handy, and your design doesn't have a lever to allow easy manual feeding / retraction.

I got rid of typical springs as you don't really need them - the housing material is the spring. Attached is the latest design with space for the AS5600 in OpenSCAD so you ca tweak it as you need. Loading/unloading with a DC motor could also be solved with a simple switch bypassing any controller and just applying power to the motor, but this won't work for atomic pulls.

Quote

nebbian

I totally agree with JamesK, that unsupported sideload worries me, and it's not a design that I'd want to see go into 'production' in my printers. However as something that can be used to test the proof of concept, I think it might work for long enough to see if this system is viable.

I ran that motor last night, and even put some filament through it. It seems fast enough, even at 4.5V. It seems like it's not really designed for the loads and running time that a printer requires, however.

This is exactly the idea of this thread. Try out a couple designs and see how far we can get. The motor is already in use by commercial 3D doodler pens in a direct drive design and they handle quite some abuse. The N20s are mass produced by multiple vendors so it means that there's already a different, more established and much larger market supporting them.

Quote

nebbian

To be totally honest, I'd prefer to use a beefier gearbox, with a brushless motor. The brushless motor and controller are readily available on Hobbyking, I also have loads of them lying around as spares for my quadcopters. The code that is available on github which converts step and direction into controls for a brushed motor could easily be interfaced with a brushless controller as well.

However I haven't been able to find a strong, small gearbox that would do the job yet.

That is the primary issue. We already have stepper-based NEMA11, NEMA14 and alike extruders with planetary gearboxes and Titan-like geared ones. While you could use these as high-pole count brushless, most RC hobby brushless motors lack a gearbox. Also if you go up in size, you also go up in weight, which is important if you want to get rid of Bowden for a moving extruder setup. rklauco and LoboCNC do use larger DC motors for X and Y so any progress here is valid there as well.

|

Re: Pololu geared DC motor 30g prototype extruder June 16, 2016 10:05PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Pololu geared DC motor 30g prototype extruder June 17, 2016 01:01AM |

Registered: 8 years ago Posts: 181 |

To continue the original thread - I decided to go in a bit different direction. I'll make a tiny (2-3 mm) shaft with heatshrink that will be measuring the bearing movement by simply touching it. As there is virtualy no load, the added friction will be minimal.

Yesterday I tested the MK8 and it is much smaller and has way better grip as the groove is bigger then MK7. So MK8 is a clear winner for me.

Yesterday I tested the MK8 and it is much smaller and has way better grip as the groove is bigger then MK7. So MK8 is a clear winner for me.

|

Re: Pololu geared DC motor 30g prototype extruder June 17, 2016 01:20PM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

To continue the original thread - I decided to go in a bit different direction. I'll make a tiny (2-3 mm) shaft with heatshrink that will be measuring the bearing movement by simply touching it. As there is virtualy no load, the added friction will be minimal.

Is this what you a have in mind? oO| - where "o" is the Mk8, O is the bearing, and | is the shaft for the encoder? I'm wondering whether having the encoder so far from the motor creates troubles for the PID loop. If I recall correctly most recommendations are to get the encoder as close as possible to the motor (generally on the motor itself), but here we are not dealing with high speed operations so things are a bit more relaxed.

Quote

rklauco

Yesterday I tested the MK8 and it is much smaller and has way better grip as the groove is bigger then MK7. So MK8 is a clear winner for me.

That was my impression too. The standard Mk8 has more grip than both my knurled shaft and home-made gear. I have no idea about the longevity of nebbian's 3-to-5mm printed adapter, so I used brass threaded inserts between the gearbox shaft and the Mk8.

|

Re: Pololu geared DC motor 30g prototype extruder June 17, 2016 03:57PM |

Registered: 8 years ago Posts: 181 |

Exactly what I have in mind.Quote

ipcalit

Is this what you a have in mind? oO| - where "o" is the Mk8, O is the bearing, and | is the shaft for the encoder? I'm wondering whether having the encoder so far from the motor creates troubles for the PID loop. If I recall correctly most recommendations are to get the encoder as close as possible to the motor (generally on the motor itself), but here we are not dealing with high speed operations so things are a bit more relaxed.

The difference here is that I don't really care about the movement of the motor. What I do care about is the movement of the filament. So, the best place for the encoder would be the bearing. But I am worried about the grip if the bearing has any sort of sleeve on it. So my idea is instead of providing a sleeve to the bearing, I would add a small shaft close to the bearing with very little diameter (2mm) with some sort of sleeve to improve grip between the 2mm shaft and the bearing. And, at the end of the shaft, there will be the encoder wheel.

The bearing will act like 1:1 transmission for the filament movement and, should the grip of the shaft be sufficient, I'll be able to measure quite precise movements.

There might be some sort of hysteresis within the movement - so I'll need to implement some sort of hysteresis compensation into the movement algorithm of the motor controller. But I think it's doable.

Sorry, only registered users may post in this forum.