Cycloidal Extruder Drive: A lightweight direct extruder drive unit

Posted by powdermetal

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit November 14, 2016 06:04AM |

Registered: 8 years ago Posts: 93 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit November 14, 2016 04:11PM |

Registered: 8 years ago Posts: 62 |

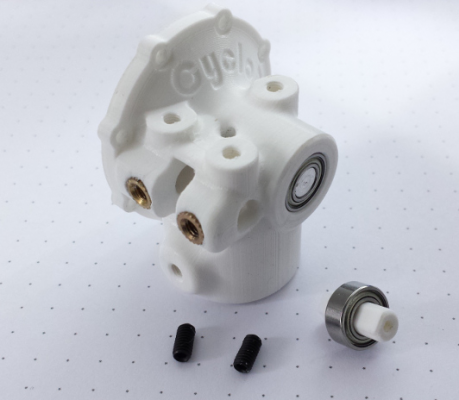

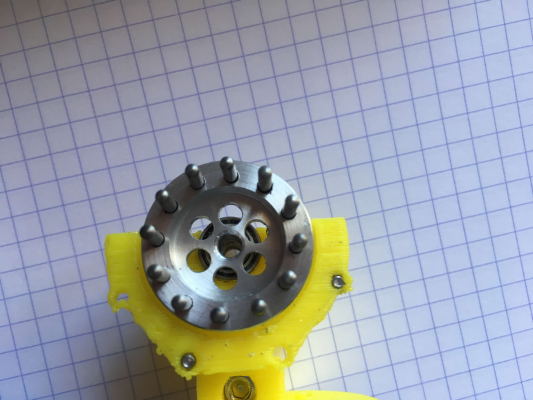

Added the Aluminium gearbox to the updated drive unit:

Some first print results (from upper to lower image):

- v04 gearbox with Aluminium gears (1.75mm PLA)

- v04 gearbox with printed gears (3mm PLA)

- my bowden setup (3mm PLA)

Actually the wavy structure from transmission errors has nearly gone. Not really surprising - gear manufacturers know, why they aim for precision...

Kewtdz & o_lampe: How are you doing with the machined POM gears?

Some first print results (from upper to lower image):

- v04 gearbox with Aluminium gears (1.75mm PLA)

- v04 gearbox with printed gears (3mm PLA)

- my bowden setup (3mm PLA)

Actually the wavy structure from transmission errors has nearly gone. Not really surprising - gear manufacturers know, why they aim for precision...

Kewtdz & o_lampe: How are you doing with the machined POM gears?

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit November 15, 2016 02:10AM |

Registered: 8 years ago Posts: 5,232 |

My POM gears worked flawlessly until I changed the effector for some other extruders I'm testing ( E3D chimera & cyclops, diamond ) The cycloid drive is sitting on my "trophy shelf" waiting for another chance.

Funny how the Bowden setup in your test has the best seam. The 1.75 sample has some signs of ringing right from the seam and the 3mm sample has diameter/extrusion variations.

Recently I had a MK8 drive gear which wobbled badly, causing uneven extrusion. Maybe you see the same with the 3mm gear?

Edited 1 time(s). Last edit at 11/15/2016 02:11AM by o_lampe.

Funny how the Bowden setup in your test has the best seam. The 1.75 sample has some signs of ringing right from the seam and the 3mm sample has diameter/extrusion variations.

Recently I had a MK8 drive gear which wobbled badly, causing uneven extrusion. Maybe you see the same with the 3mm gear?

Edited 1 time(s). Last edit at 11/15/2016 02:11AM by o_lampe.

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit November 15, 2016 08:38AM |

Registered: 7 years ago Posts: 20 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit November 15, 2016 01:57PM |

Registered: 8 years ago Posts: 62 |

Quote

o_lampe

My POM gears worked flawlessly until I changed the effector for some other extruders I'm testing ( E3D chimera & cyclops, diamond ) The cycloid drive is sitting on my "trophy shelf" waiting for another chance.

Funny how the Bowden setup in your test has the best seam. The 1.75 sample has some signs of ringing right from the seam and the 3mm sample has diameter/extrusion variations.

Recently I had a MK8 drive gear which wobbled badly, causing uneven extrusion. Maybe you see the same with the 3mm gear?

Good to hear about your POM gears: Sitting on your "trophy shelf" sounds they will get a second chance - much better than going directly to the bin...

For the overall surface appearance, there are a couple of notes:

- Each of the 3 samples was created with a different fan shroud (time is progressing). Probably my bowden shroud is the most effective one as the seam is the most consistent one.

- For the drive gear, I finally switched to E3D's Hobb Goblin for the 1.75mm drive. After using MK8 gears for quite a time, I got tired of facing new surprises with every new one: Non-sharp teeth, pitch not manufactured properly thus deformed previously cut teeth, poor runout inner bore to teeth and dimensional differences depending on supplier...

E3D's drive gears are coming from one single source and they have a professional understanding of good manufacturing practice.

Anyway, the MK8 in the 3mm was fine... - Ringing: The bowden setup works best - great stiffness of holding the heatsink in the effector plate and lowest overall mass. The 1.75mm was intended to work better than the previous v04 3mm design (being a quite a flimsy effector/hotend-mount btw), but it seems the long dangling assembly of the 1.75mm makes things worse -> easy to improve...

- And using PLA from a different supplier in the meantime.

Quote

Kewtdz

The aluminum setup really looks amazing. Also, what are the tolerances you are shooting for to be considered precision?

Unfortunately, I haven't been able to work on it yet. I've been traveling this last week and I'm hoping to pick up the material this week/early next week.

This "precision"-specification is based on tolerance stack calculations and was adjusted according to capabilities of manufacturing: Tooth profile is specified to 0.04mm (i.e. 0.02mm max. deviation from CAD-model), various bore positions to 0.02mm...

Edited 1 time(s). Last edit at 11/15/2016 02:04PM by powdermetal.

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit December 05, 2016 02:42PM |

Registered: 8 years ago Posts: 16 |

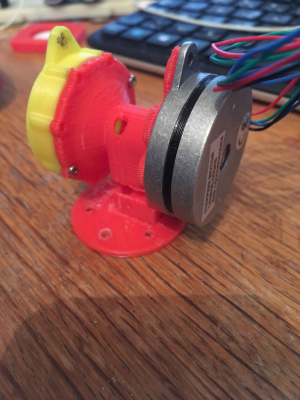

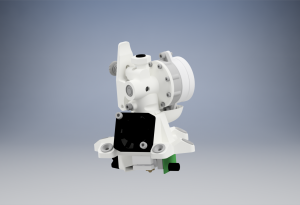

I have been quietly proceeding down the route of mounting the motor and the gearbox either side of the filament feed and it has been slow progress (mostly external issues) but I now have something to show for it.

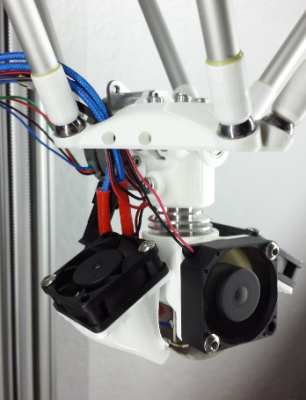

After the debacle last time when I discovered that the unit fouled the support arms, I did a little more analysis this time and I now have a unit that sits on top of the spider with the E3D sitting below - thus relieving much of the inbalance that PowderMetal was concerned about.

Still work in progress but the photos show the clearance (or lack of it in one case) with the arms at the extremes possible on my Kossel XL, 250mm dia plate.

This is still marginally too tight - but I may just live with it!

As you can see, all the other cables and bowden from the operational printer are still in place so try and discount them from the view..

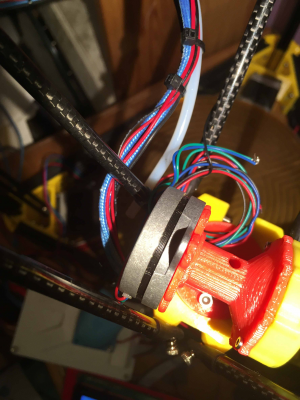

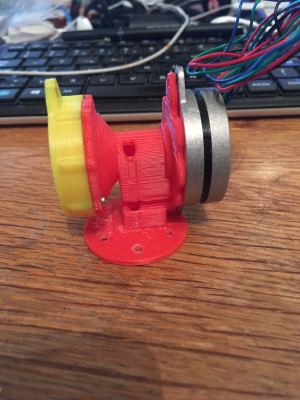

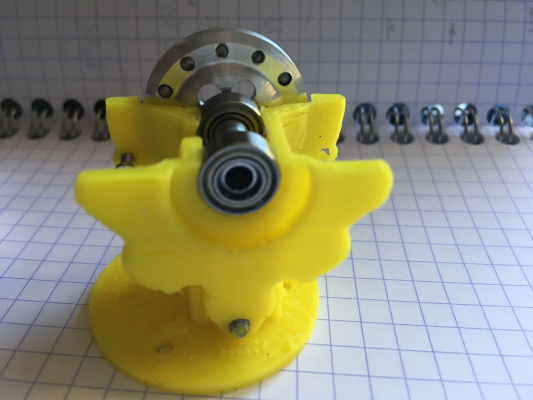

The second set of photos show the layout - sorry about the colours though! The yellow is the gearbox, now being machined in al to a slightly different design (no lugs for example) and the red is the new support mount (missing the pinch wheel assembly since this was a prototype for size testing.

The mechanism consists of an extension to the stepper in 3mm dia rod which passes through a hollow 5mm shaft which the MK8 gear runs on. So the power train is stepper->gearbox inner (3mm) ->gearbox output (5mm) -> MK8.

At the moment I think the machine work will be relatively straightforward but I will report once I have a working prototype.

Awaiting your comments.....!

Simon

After the debacle last time when I discovered that the unit fouled the support arms, I did a little more analysis this time and I now have a unit that sits on top of the spider with the E3D sitting below - thus relieving much of the inbalance that PowderMetal was concerned about.

Still work in progress but the photos show the clearance (or lack of it in one case) with the arms at the extremes possible on my Kossel XL, 250mm dia plate.

This is still marginally too tight - but I may just live with it!

As you can see, all the other cables and bowden from the operational printer are still in place so try and discount them from the view..

The second set of photos show the layout - sorry about the colours though! The yellow is the gearbox, now being machined in al to a slightly different design (no lugs for example) and the red is the new support mount (missing the pinch wheel assembly since this was a prototype for size testing.

The mechanism consists of an extension to the stepper in 3mm dia rod which passes through a hollow 5mm shaft which the MK8 gear runs on. So the power train is stepper->gearbox inner (3mm) ->gearbox output (5mm) -> MK8.

At the moment I think the machine work will be relatively straightforward but I will report once I have a working prototype.

Awaiting your comments.....!

Simon

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit December 05, 2016 04:47PM |

Registered: 8 years ago Posts: 62 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit December 06, 2016 07:31AM |

Registered: 8 years ago Posts: 16 |

Heinrich,

I will do - but some of it is still 'work in progress' and needs me to confirm it will work first!

For the 5mm shaft with the MK8 attached, the bearings are arranged as you drew them I think - one bearing either side of the Mk8 supporting the pin plate at one end.

The through shaft will have one bearing on what is now the back plate of the gearbox to support that end of the shaft.

More to come - when I have the time...

Simon

I will do - but some of it is still 'work in progress' and needs me to confirm it will work first!

For the 5mm shaft with the MK8 attached, the bearings are arranged as you drew them I think - one bearing either side of the Mk8 supporting the pin plate at one end.

The through shaft will have one bearing on what is now the back plate of the gearbox to support that end of the shaft.

More to come - when I have the time...

Simon

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit December 06, 2016 09:56AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit December 06, 2016 10:08AM |

Registered: 8 years ago Posts: 16 |

Thanks.

Centre part printed pretty well - although this was only a 0.4mm trial for sizing - SlicR using pillar supports left the outside ok, the centre 10mm tube section will I strongly suspect need a cleaning tool applied to arrive at a truly circular hole for the bearings - 'TBA'....!

Least successful part is the top mount for the stepper but I think that could be improved with a different profile next to the stepper.

Stepper shaft - yes ++......

Drive grub screw - I 'think' it will be possible to add a delicate flat to the tube to help the grubscrew bite (but the wall thickness <1mm) and it should also be possible to glue it to the shaft with the bearings and pin holder constructed as a single assembly. I plan that the tube will be silver steel (drill rod in the US) drilled through for motor shaft clearance and to minimise weight - but is will be much stronger than the equivalent in Al.

Simon

Centre part printed pretty well - although this was only a 0.4mm trial for sizing - SlicR using pillar supports left the outside ok, the centre 10mm tube section will I strongly suspect need a cleaning tool applied to arrive at a truly circular hole for the bearings - 'TBA'....!

Least successful part is the top mount for the stepper but I think that could be improved with a different profile next to the stepper.

Stepper shaft - yes ++......

Drive grub screw - I 'think' it will be possible to add a delicate flat to the tube to help the grubscrew bite (but the wall thickness <1mm) and it should also be possible to glue it to the shaft with the bearings and pin holder constructed as a single assembly. I plan that the tube will be silver steel (drill rod in the US) drilled through for motor shaft clearance and to minimise weight - but is will be much stronger than the equivalent in Al.

Simon

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit December 08, 2016 10:07AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit February 06, 2017 05:20AM |

Registered: 8 years ago Posts: 16 |

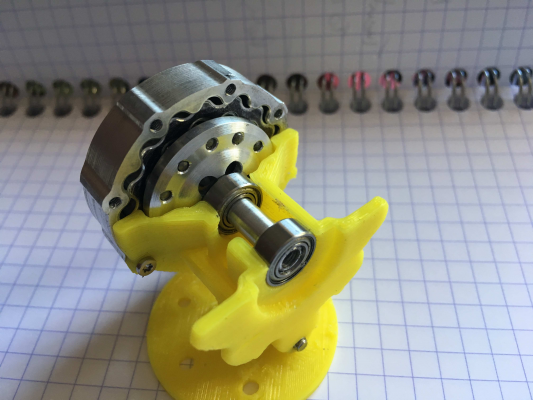

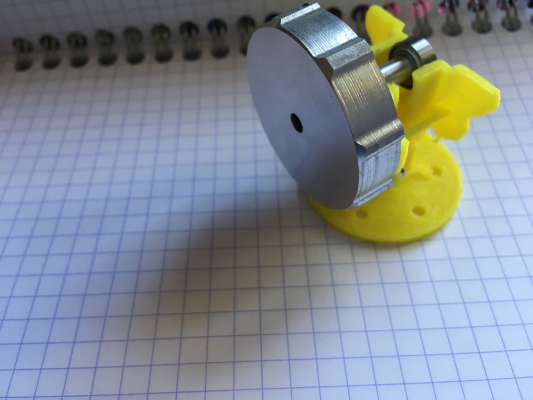

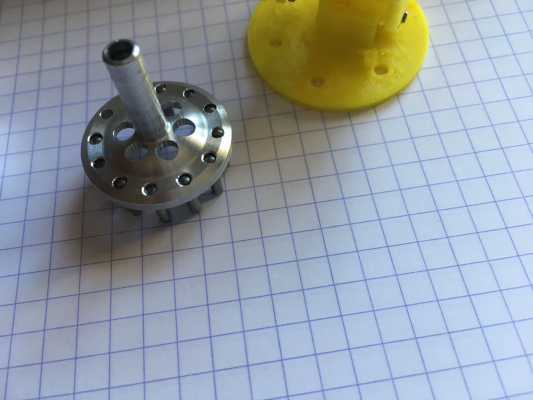

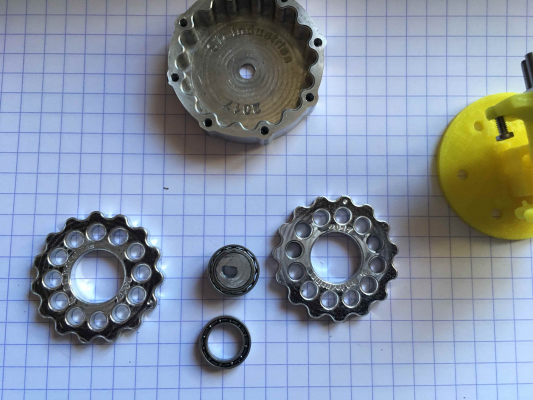

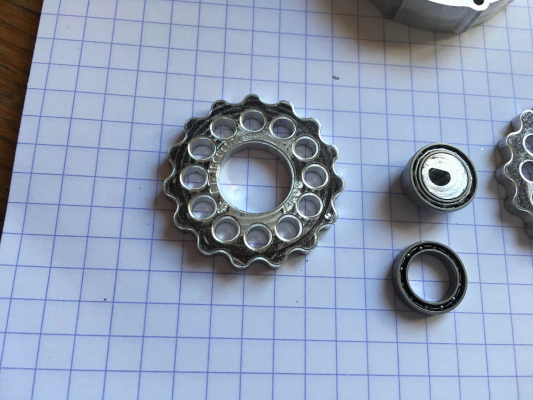

Just a short update - I have spent some time getting the CNC operational enough to machine the gear casing and the gears as well as the pin holder plate - which is now merged with the drive shaft for the extruder itself.

The good news is that I can now produce all of these elements with relative ease - but I am still tidying them up - the photos show various areas where further work is needed.Also trying to remove weight, especially where the Al can operate with substantially thinner sections. The casing needs probably about 1mm removed from it, the gears may have further lightening holes and the pin holder still has further areas to be pared away.

The excentric has been the biggest challenge - easy enough but takes a number of machining operations and I haven't yet worked out a way to automate the process.

Still to do: the through shaft to drive the eccentric, shorten the Mk8 and change the grub screw, modify the stepper and print a successful casing - this one was looking good until the feed jammed, fortuitously at the half way point allowing a convenient view of the actions.

Getting there slowly though...

The good news is that I can now produce all of these elements with relative ease - but I am still tidying them up - the photos show various areas where further work is needed.Also trying to remove weight, especially where the Al can operate with substantially thinner sections. The casing needs probably about 1mm removed from it, the gears may have further lightening holes and the pin holder still has further areas to be pared away.

The excentric has been the biggest challenge - easy enough but takes a number of machining operations and I haven't yet worked out a way to automate the process.

Still to do: the through shaft to drive the eccentric, shorten the Mk8 and change the grub screw, modify the stepper and print a successful casing - this one was looking good until the feed jammed, fortuitously at the half way point allowing a convenient view of the actions.

Getting there slowly though...

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit February 06, 2017 05:42AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit February 06, 2017 10:20AM |

Registered: 8 years ago Posts: 16 |

Well to be brutally honest, what I have made so far has been a great intellectual exercise for me as well as helping improve the setup and operations of my CNC mill and lathe. Mixing both additive and subtractive machining in the same solution is also very interesting - and trying to use the strengths of both.

The gears are now down to an 8-9 minute exercise (don't ask how many I have made so far to get that quick!) and, whilst there was no intention to do so, I can knock out another copy very easily - which is great if I decide to make further changes.....no different from 3D printing really!

Weight - again, I can't help but agree with you and even in ally, it will still be heavier - but that doesn't stop the intellectual exercise!

Eccentric - It is relatively straightforward but requires a number of separate operations - the best case so far was to machine an outer reference on a piece of square stock, install in the CNC mill using the reference to find the centre, drill the centre hole and then mill it to a 'D' shape using a 0.8mm mill. Then circular mill the 1st eccentric at the correct offset. Replace in the 4 jaw of the lather and setup the 1st eccentric to be true and then using 2 jaws alone, apply the 2nd offset. Machine using a narrow parting off type tool. Part off to length...

About 30 mins...I should probably retry in 3D since the centre drive hole is now only 3.17mm (1/8") with a flat on it - so more eccentric material and less hole up the middle..

I also contemplated using the mill Z axis and a 4th axis to turn the eccentric blank (Z goes up and down as the blank rotates) but that still requires another setup exercise with the centre hole.

Hey ho, just as well I am not into mass production......although I guess that just becomes one big injection moulding exercise.

Simon

The gears are now down to an 8-9 minute exercise (don't ask how many I have made so far to get that quick!) and, whilst there was no intention to do so, I can knock out another copy very easily - which is great if I decide to make further changes.....no different from 3D printing really!

Weight - again, I can't help but agree with you and even in ally, it will still be heavier - but that doesn't stop the intellectual exercise!

Eccentric - It is relatively straightforward but requires a number of separate operations - the best case so far was to machine an outer reference on a piece of square stock, install in the CNC mill using the reference to find the centre, drill the centre hole and then mill it to a 'D' shape using a 0.8mm mill. Then circular mill the 1st eccentric at the correct offset. Replace in the 4 jaw of the lather and setup the 1st eccentric to be true and then using 2 jaws alone, apply the 2nd offset. Machine using a narrow parting off type tool. Part off to length...

About 30 mins...I should probably retry in 3D since the centre drive hole is now only 3.17mm (1/8") with a flat on it - so more eccentric material and less hole up the middle..

I also contemplated using the mill Z axis and a 4th axis to turn the eccentric blank (Z goes up and down as the blank rotates) but that still requires another setup exercise with the centre hole.

Hey ho, just as well I am not into mass production......although I guess that just becomes one big injection moulding exercise.

Simon

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit February 06, 2017 11:18AM |

Registered: 8 years ago Posts: 5,232 |

You already changed the D-shape of the excenter, which is no longer necessary with the remote shaft, but you might also find a different shape for the whole excenter? It only has to fit in the bearing but doesn't have to be cylindric. A two-piece excenter would also work if it makes production easier/cheaper.

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit February 06, 2017 02:13PM |

Registered: 8 years ago Posts: 62 |

Hi Simon,

great job - you seem to become an expert in making those gears!

Joining the output hub with the shaft into a one-piece solution is a good idea - it saves some space in the packaging and removes potential troubles with weak press fits.

For the eccentric you may circular-mill it in one clamp by using a kind of undercut-tool, which allows to 'undercut' for the second (lower) eccentric diameter.

What will be the overall width of your setup? What's the distance from center to the most outer face?

Looking forward, how you will attach the eccentric drive shaft to the motor!

Heinrich

Edited 1 time(s). Last edit at 02/06/2017 04:23PM by powdermetal.

great job - you seem to become an expert in making those gears!

Joining the output hub with the shaft into a one-piece solution is a good idea - it saves some space in the packaging and removes potential troubles with weak press fits.

For the eccentric you may circular-mill it in one clamp by using a kind of undercut-tool, which allows to 'undercut' for the second (lower) eccentric diameter.

What will be the overall width of your setup? What's the distance from center to the most outer face?

Looking forward, how you will attach the eccentric drive shaft to the motor!

Heinrich

Edited 1 time(s). Last edit at 02/06/2017 04:23PM by powdermetal.

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit February 09, 2017 03:14PM |

Registered: 8 years ago Posts: 62 |

Aynik Technology posted a great movie on their implementation of the cycloidal gearbox combined with the Bondtech Drivegears:

This post on Aynik's website provides a good overview and interesting in-depth information.

For those of us who are not really familiar with Japanese, Google's website translation will help...

Great solution - I like the way, how the Bondtech gears have been integrated with the tensioning lever and the well accessible filament path!

Edited 1 time(s). Last edit at 02/09/2017 03:15PM by powdermetal.

This post on Aynik's website provides a good overview and interesting in-depth information.

For those of us who are not really familiar with Japanese, Google's website translation will help...

Great solution - I like the way, how the Bondtech gears have been integrated with the tensioning lever and the well accessible filament path!

Edited 1 time(s). Last edit at 02/09/2017 03:15PM by powdermetal.

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit February 10, 2017 02:48AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit February 11, 2017 01:24PM |

Registered: 8 years ago Posts: 312 |

Wow guys, that is great work.

The metal work is great and I love how the final results are looking. Great way to really stretch the boundaries.

And Simon, that is quite some speed you can generate now, making the parts. When ever I dive into the workshop I take about an hour just to get up to speed and then I am about 4 x as slow as what you are doing.

Loving it!

The metal work is great and I love how the final results are looking. Great way to really stretch the boundaries.

And Simon, that is quite some speed you can generate now, making the parts. When ever I dive into the workshop I take about an hour just to get up to speed and then I am about 4 x as slow as what you are doing.

Loving it!

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 29, 2018 05:25AM |

Registered: 8 years ago Posts: 5,232 |

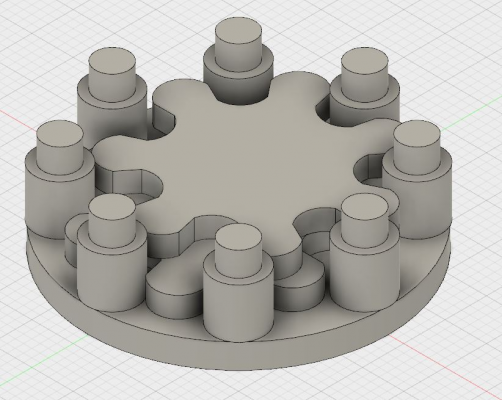

I suggested a different design for a 1:8 geared cycloid drive in the Smart Effector adapter thread, but want to discuss it here where it belongs.

As a newbie in fusion360 I failed to construct the inner gears, but the main things I wanted to point out are the 6mm bronce bushings on 4mm dowel pins.

There is only one tooth of either gear in full contact with the bushing, so I think one bushing per pin is enough.

Is it overkill or would it help to minimize friction?

PS: there are plenty of other bushing sizes available. Bronce and POM gears would work well, but POM bushings and aluminum gears, too.

Edited 1 time(s). Last edit at 01/29/2018 05:34AM by o_lampe.

As a newbie in fusion360 I failed to construct the inner gears, but the main things I wanted to point out are the 6mm bronce bushings on 4mm dowel pins.

There is only one tooth of either gear in full contact with the bushing, so I think one bushing per pin is enough.

Is it overkill or would it help to minimize friction?

PS: there are plenty of other bushing sizes available. Bronce and POM gears would work well, but POM bushings and aluminum gears, too.

Edited 1 time(s). Last edit at 01/29/2018 05:34AM by o_lampe.

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 29, 2018 05:42AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 29, 2018 05:54AM |

Registered: 8 years ago Posts: 5,232 |

Quote

MKSA

It is a nice exercise but again, what are the advantages compared to two simple gears and do they offset the extra complexity, weight, cost, size,friction, backlash .... ?

Probably a planetary gear would work fine, too. Especially with the lower gear ratio. But for the 1:16 ratio it would've been difficult to make it that compact and still have printable gears. I still believe, the gear shape and the dowel pins are the most attractive parts for DIY gearboxes.

Edited 1 time(s). Last edit at 01/29/2018 05:56AM by o_lampe.

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 30, 2018 02:54PM |

Registered: 8 years ago Posts: 62 |

Quote

o_lampe

I suggested a different design for a 1:8 geared cycloid drive in the Smart Effector adapter thread, but want to discuss it here where it belongs.

As a newbie in fusion360 I failed to construct the inner gears, but the main things I wanted to point out are the 6mm bronce bushings on 4mm dowel pins.

There is only one tooth of either gear in full contact with the bushing, so I think one bushing per pin is enough.

Is it overkill or would it help to minimize friction?

PS: there are plenty of other bushing sizes available. Bronce and POM gears would work well, but POM bushings and aluminum gears, too.

A ratio of 1:8 may be sufficient for 1.75 material. Not sure, whether this ratio is a good idea for a cycloidal reducer - let's give it a try. I have a fully parametric model of the gearbox (in NX) and can adjust parameters easily - please provide your key parameters (PCD of pins, pin diameter, eccentricity and number of pins) by a PM and I send you a model of the cycloidal disc. However take care: Some space is needed for the central bore (for the bearing) and for the holes where the output carrier's pin engage into...

Bushes are used in industrial gearboxes as well - maybe overkill here, but who knows?

Quote

MKSA

It is a nice exercise but again, what are the advantages compared to two simple gears and do they offset the extra complexity, weight, cost, size,friction, backlash .... ?

Well, ratios above 1:6 are getting hard to achieve with two simple gears - for the small gear a practical limit is approx.12 teeth as a minimum, so the second gear will become quite large. The same is true with planetary gearboxes.

Mechanical engineering has a broad range of solutions for speed reducers (some of them very well known, others less known) - depending on the application's needs, you will always find a solution.

Anyway, of course you are right: It is more complex than two simple gears.

Not so sure about the other criteria...

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 30, 2018 03:41PM |

Registered: 6 years ago Posts: 1,007 |

Quote

powdermetal

Quote

MKSA

It is a nice exercise but again, what are the advantages compared to two simple gears and do they offset the extra complexity, weight, cost, size,friction, backlash .... ?

Well, ratios above 1:6 are getting hard to achieve with two simple gears - for the small gear a practical limit is approx.12 teeth as a minimum, so the second gear will become quite large. The same is true with planetary gearboxes.

Mechanical engineering has a broad range of solutions for speed reducers (some of them very well known, others less known) - depending on the application's needs, you will always find a solution.

Anyway, of course you are right: It is more complex than two simple gears.

Not so sure about the other criteria...

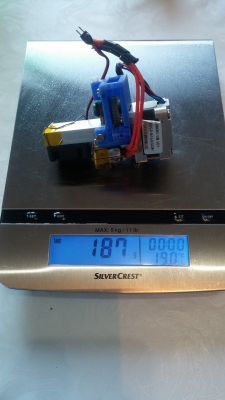

For 1.75mm, I determined that a ratio of around 5 (two gears), a Nema 14 , a good hobgear provide enough push force. A higher ratio to use a smaller motor is not worth it.

Extruder, hot end etc... I am down to less than 190g (120g for the motor) and could gain 40g using a pancake motor. Add 30g for the X Prusa carriage (not much for an other system as I use Igus bushings). Total moving mass is less than a NEMA17 motor.

Edited 2 time(s). Last edit at 01/30/2018 04:00PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 30, 2018 04:08PM |

Registered: 8 years ago Posts: 62 |

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 30, 2018 04:52PM |

Registered: 7 years ago Posts: 62 |

Not to derail the cool work going on here, but just checking that you are aware of the Nimble extruder that we sell at [zesty.tech] ?

It's weight is significantly less (~27g), and it's possibly smaller in size too:

The standard 950mm drive cable we sell weighs 58g. Assuming the full cable weight was borne by your carriage/effector (which we know it isn't) this would make the total weight around 85g we believe it works out to be more like half that, shorter drive cables weigh less obviously.

Co-creator of the Zesty Nimble, worlds lightest direct drive extruder.

[zesty.tech]

It's weight is significantly less (~27g), and it's possibly smaller in size too:

The standard 950mm drive cable we sell weighs 58g. Assuming the full cable weight was borne by your carriage/effector (which we know it isn't) this would make the total weight around 85g we believe it works out to be more like half that, shorter drive cables weigh less obviously.

Co-creator of the Zesty Nimble, worlds lightest direct drive extruder.

[zesty.tech]

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 30, 2018 05:12PM |

Registered: 6 years ago Posts: 1,007 |

Quote

powdermetal

Cool! You found your solution!

What's the rated torque of your motor and what current are you running it and what type of hobgear do you use?

Holding torque 0.13 mN @1A. 0.5 A is enough to extrude PETG at 120mm/s print speed, 0.4mm nozzle (the motor is at 60°). The hobgear is of my own, bites like a shark, casehardened steel, self cleaning in conjunction with the idler (filament detection in the making). I don't publish the details. Fed up to see how the guys in Shenzhen steal ideas and make money.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 31, 2018 12:56AM |

Registered: 6 years ago Posts: 1,007 |

briangilbert

We know about zesty and similar.

I did look at using flexible, worm gears, as many others. Then I realized it is not all that rosy. Indeed, the mass to move is not just the extruder, you have the cable and in addition it is not that flexible.

As said many times, servo brushless DC is the way to go.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

We know about zesty and similar.

I did look at using flexible, worm gears, as many others. Then I realized it is not all that rosy. Indeed, the mass to move is not just the extruder, you have the cable and in addition it is not that flexible.

As said many times, servo brushless DC is the way to go.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 31, 2018 03:01AM |

Registered: 8 years ago Posts: 5,232 |

[OT]

I would have gone for remote driven extruders too, but the stiffness of the cable was always a big questionmark. I thought of different solutions, like closed loop spectra line, but didn't find any.

Direct drive (geared ) extruders could be so much smaller with a smaller filament diameter. That's what I'm working on for my coffeemug Delta.

We've seen how much 3DP improved when we started to use 1.75 filament instead of 3mm. ( well many of us ), why did we stop there?

[/OT]

@MKSA

Your solution is quite nice, but would it fit on a Smart Effector? Maybe with a radial fan placed on top, could you center the heatsink? Or make it fit under the stepper? The radial fan could then suck in air from around the stepper, for extra cooling.

I would have gone for remote driven extruders too, but the stiffness of the cable was always a big questionmark. I thought of different solutions, like closed loop spectra line, but didn't find any.

Direct drive (geared ) extruders could be so much smaller with a smaller filament diameter. That's what I'm working on for my coffeemug Delta.

We've seen how much 3DP improved when we started to use 1.75 filament instead of 3mm. ( well many of us ), why did we stop there?

[/OT]

@MKSA

Your solution is quite nice, but would it fit on a Smart Effector? Maybe with a radial fan placed on top, could you center the heatsink? Or make it fit under the stepper? The radial fan could then suck in air from around the stepper, for extra cooling.

|

Re: Cycloidal Extruder Drive: A lightweight direct extruder drive unit January 31, 2018 05:37AM |

Registered: 6 years ago Posts: 1,007 |

Quote

o_lampe

[OT]

I would have gone for remote driven extruders too, but the stiffness of the cable was always a big questionmark. I thought of different solutions, like closed loop spectra line, but didn't find any.

Direct drive (geared ) extruders could be so much smaller with a smaller filament diameter. That's what I'm working on for my coffeemug Delta.

We've seen how much 3DP improved when we started to use 1.75 filament instead of 3mm. ( well many of us ), why did we stop there?

[/OT]

@MKSA

Your solution is quite nice, but would it fit on a Smart Effector? Maybe with a radial fan placed on top, could you center the heatsink? Or make it fit under the stepper? The radial fan could then suck in air from around the stepper, for extra cooling.

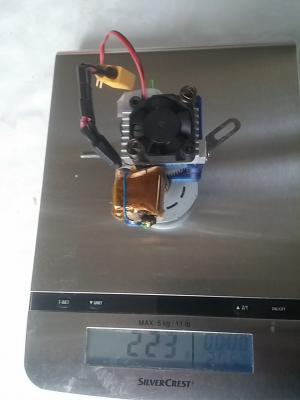

The flanges are symmetric therefore the motor can be mounted top, bottom, left or right. The heatsink and fan are mounted horizontally but can also be mounted vertically. I made both (see picture with a PM stepper instead of a Nema14) . Horizontally, I have full access to the filament path. It is also the reason why I didn't put the hobgear inside the flange as the Titan does.

One screw to attach to the carrier.

The smart effector is designed around the E3D hot end so not possible to mount it as is. Note my hot end is a lot smaller, its end is a cylinder diam 6 height 16 squeezed in a hole in the heatsink.

Note that to further reduce weight and ease the mount/dismount I use steel clips instead of screws to hold for ex the fans.

Edited 3 time(s). Last edit at 01/31/2018 05:44AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.