Vacuum hold-down for 3D build surface.

Posted by leadinglights

|

Vacuum hold-down for 3D build surface. November 11, 2016 10:54AM |

Registered: 12 years ago Posts: 1,450 |

Inspired both by ECJs idea of using overhead transparency film [forums.reprap.org] and the digital dentist's idea of using an electrostatic hold down I thought I would try out using a vacuum to hold down a thin film of material. Using thin materials for a print stage has obvious advantages such as a high likelihood of being cheap and little worry if the print is permanently stuck to the build film.

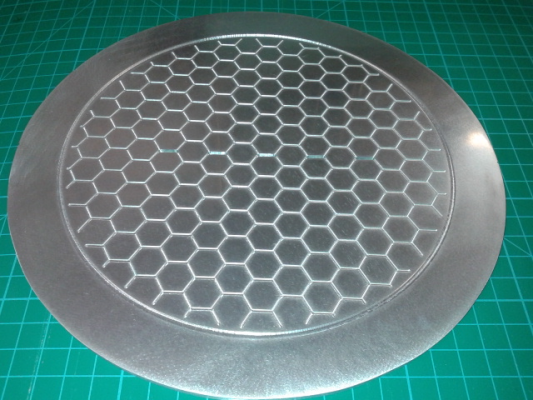

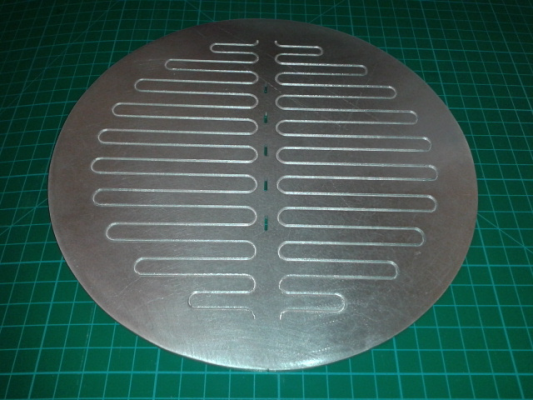

I have done some quick tests which convinced me that the idea of a vacuum stage is worth perusing and have just completed a vacuum table for this purpose. The general idea is to have a network of shallow grooves machined in the surface of an aluminium plate. Holes would be better but having them all connected to the vacuum adds complexity. The hexagonal pattern is so that there are no long unbroken lines which would allow a seam to develop in the material A circular groove is machined around the periphery in case an 'O' ring is needed. The obverse of the plate is also shown as machining the vacuum traces gives an opportunity to use the same method to make channels for embedding resistance in the plate.

Photos below show the build surface and the back side of the plate. I have also published a short video on YouTube showing the machining of the front face of the table [www.youtube.com]

So far I have been using an Aquavac for getting the vacuum - obviously impractical but available. I will experiment to see what vacuum is needed and how much leakage will occur. A simple syringe would work if no leakage - which may be possible if the outer edge of the plate is smeared with grease.

Mike

I have done some quick tests which convinced me that the idea of a vacuum stage is worth perusing and have just completed a vacuum table for this purpose. The general idea is to have a network of shallow grooves machined in the surface of an aluminium plate. Holes would be better but having them all connected to the vacuum adds complexity. The hexagonal pattern is so that there are no long unbroken lines which would allow a seam to develop in the material A circular groove is machined around the periphery in case an 'O' ring is needed. The obverse of the plate is also shown as machining the vacuum traces gives an opportunity to use the same method to make channels for embedding resistance in the plate.

Photos below show the build surface and the back side of the plate. I have also published a short video on YouTube showing the machining of the front face of the table [www.youtube.com]

So far I have been using an Aquavac for getting the vacuum - obviously impractical but available. I will experiment to see what vacuum is needed and how much leakage will occur. A simple syringe would work if no leakage - which may be possible if the outer edge of the plate is smeared with grease.

Mike

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 11:27AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 12:27PM |

Registered: 8 years ago Posts: 312 |

I love the idea!

Maybe a ring shaped groove around the circumference would be enough?

If the vacuum is strong enough it would pull the top film tight. Especially is the groove is deep enough to handle the material sagging into it.

Depends on the top material of course.

I certainly will be following this with interest.

Lykle

Maybe a ring shaped groove around the circumference would be enough?

If the vacuum is strong enough it would pull the top film tight. Especially is the groove is deep enough to handle the material sagging into it.

Depends on the top material of course.

I certainly will be following this with interest.

Lykle

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 12:29PM |

Registered: 12 years ago Posts: 1,450 |

There seems to be no visible deformation into the grooves when the material is a very thin sheet from a laminating pouch. I think that this material may be very interesting s it has a hot melt coating so may be a perfect build surface for many types of filament.

The milling on the printer was interesting, not least because I broke best quality German 1mm carbide end mills but a cheap Chinese end mill survived even cutting 5 slots each 4.5mm deep for the vacuum.

Mike

The milling on the printer was interesting, not least because I broke best quality German 1mm carbide end mills but a cheap Chinese end mill survived even cutting 5 slots each 4.5mm deep for the vacuum.

Mike

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 01:01PM |

Registered: 9 years ago Posts: 1,873 |

You didn't cut 4.5mm deep in a single pass surely? I haven't tried anything as small as 1mm, but with 1/4" mills I usually take 10 to 15 thou on each pass.Quote

leadinglights

The milling on the printer was interesting, not least because I broke best quality German 1mm carbide end mills but a cheap Chinese end mill survived even cutting 5 slots each 4.5mm deep for the vacuum.

I was a little surprised that the mill was handling the initial plunge as end mills typically have a centre that doesn't cut.

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 01:16PM |

Registered: 12 years ago Posts: 1,450 |

Now that would be a really good cutter. The slots were made 0.1mm per pass with movement in both Y and Z - each pass went down 0.1mm for an 8mm move in Y. As this was zig-zag, the cut went from 0mm each time it changed direction to 0.2mm at the end. This still broke German cutters and didn't faze the Chinese ones

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 01:20PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 01:48PM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 02:45PM |

Registered: 9 years ago Posts: 483 |

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 03:29PM |

Registered: 7 years ago Posts: 137 |

Amazing workmanship I love the Hexagonal pattern, Dunno what it is about that pattern but there is something deeply satisfying about it.

Another possible use for these builds would be to get a semi transparent high temp resin and lay down a thin film of it across the build plate with the right releasing spray you could have a removable resin cast build plate.

The Vacuum would pull it onto the plate and once you release the Vacuum you could just lift it off.

Something else that would be mostly cosmetic but you could could also lay in some LEDs and have yourself an illuminated build plate.

Edited 1 time(s). Last edit at 11/11/2016 03:32PM by Rlewisrlou666.

Out of the box thinking is easier when you never fitted in the box to begin with.

Another possible use for these builds would be to get a semi transparent high temp resin and lay down a thin film of it across the build plate with the right releasing spray you could have a removable resin cast build plate.

The Vacuum would pull it onto the plate and once you release the Vacuum you could just lift it off.

Something else that would be mostly cosmetic but you could could also lay in some LEDs and have yourself an illuminated build plate.

Edited 1 time(s). Last edit at 11/11/2016 03:32PM by Rlewisrlou666.

Out of the box thinking is easier when you never fitted in the box to begin with.

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 04:11PM |

Registered: 7 years ago Posts: 65 |

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 06:37PM |

Registered: 11 years ago Posts: 5,780 |

What sort of pump are you planning to use and how much noise does it make?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Vacuum hold-down for 3D build surface. November 11, 2016 06:41PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Vacuum hold-down for 3D build surface. November 12, 2016 05:01AM |

Registered: 12 years ago Posts: 1,450 |

I think that only a small and simple vacuum pump will be needed - if there is no leakage then a plastic syringe of about 100ml to 250ml would probably work. However, it seems a bit unlikely that a good vacuum could be held for several hours. The ideal pump is possibly a pulsing pump that only pulls when the vacuum falls below a trigger level - in a manner similar to the SU and Bendix pumps used on old cars; but sucking air instead of pumping fuel.

The materials that it would hold down include overhead transparency film and the thin material from laminating pouches. I am sure that most materials will have some problem (softening on the heat bed and being drawn into the grooves or lifting when the print wants to curl etc., but nothing that can't be kicked into shape)

Mike

The materials that it would hold down include overhead transparency film and the thin material from laminating pouches. I am sure that most materials will have some problem (softening on the heat bed and being drawn into the grooves or lifting when the print wants to curl etc., but nothing that can't be kicked into shape)

Mike

|

Re: Vacuum hold-down for 3D build surface. November 12, 2016 05:31AM |

Registered: 7 years ago Posts: 65 |

Quote

leadinglights

I think that only a small and simple vacuum pump will be needed - if there is no leakage then a plastic syringe of about 100ml to 250ml would probably work. However, it seems a bit unlikely that a good vacuum could be held for several hours. The ideal pump is possibly a pulsing pump that only pulls when the vacuum falls below a trigger level - in a manner similar to the SU and Bendix pumps used on old cars; but sucking air instead of pumping fuel.

The materials that it would hold down include overhead transparency film and the thin material from laminating pouches. I am sure that most materials will have some problem (softening on the heat bed and being drawn into the grooves or lifting when the print wants to curl etc., but nothing that can't be kicked into shape)

Mike

I have an idea here. My table was coated with silicone/PET film, that used to protect LCD screens. She is even more heat-resistant than transparencies, but it's not good to print directly. I used it as a lightweight alternative to glass. The big advantage of it is that the face coated with silicone adheres very well to smooth surfaces and could serve to seal the edges of your table. You could do a ring and paste it at the edges of transparency and i believe so the vacuum last infinitely!

There are films for laptop whose size should be sufficient for this application.

Another option would be to do a circular groove in the edge of table and populate it with silicone resin to produce a sealing ring!

|

Re: Vacuum hold-down for 3D build surface. November 12, 2016 12:22PM |

Registered: 11 years ago Posts: 5,780 |

I'd probably connect it to the air intake on a small aquarium pump and just let it run continuously.

I don't understand how you're connecting the pump to this- one side gets closed off with the plastic film... what happens on the other side?

Edited 1 time(s). Last edit at 11/12/2016 12:26PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't understand how you're connecting the pump to this- one side gets closed off with the plastic film... what happens on the other side?

Edited 1 time(s). Last edit at 11/12/2016 12:26PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Vacuum hold-down for 3D build surface. November 12, 2016 01:08PM |

Registered: 7 years ago Posts: 65 |

Quote

the_digital_dentist

I'd probably connect it to the air intake on a small aquarium pump and just let it run continuously.

I don't understand how you're connecting the pump to this- one side gets closed off with the plastic film... what happens on the other side?

I believe that an aquarium pump can not generate enough vacuum to adhere to the film with the necessary firmness. Even if there were no leaks.

|

Re: Vacuum hold-down for 3D build surface. November 12, 2016 02:42PM |

Registered: 12 years ago Posts: 1,450 |

At the moment it is a bit of an unknown. Having seen prints curl at the edge so severely that they have lifted blue paper from the build surface I am sure that it won't work always for all films. An additional problem may be that at the build stage temperatures of some materials the plastic film may become very pliable. Among the expected and known problems there are certain to be unknown unknowns as well.

On the other hand, the idea of simply slapping a 10c or 10p sheet of plastic on the table and turning on the vacuum, running off a print, turning off the vacuum and lifting the sheet and print away cleanly then either peeling the print off - or even cutting round it if the material is really sticky is altogether too appealing to abandon without giving it a good try. Just little details like not waiting for the stage to cool down - and then having to reheat it would be a major improvement.

So I don't know if an aquarium pump would work - or even if they have an accessible vacuum port, but I will look at this as a possible solution.

Mike

On the other hand, the idea of simply slapping a 10c or 10p sheet of plastic on the table and turning on the vacuum, running off a print, turning off the vacuum and lifting the sheet and print away cleanly then either peeling the print off - or even cutting round it if the material is really sticky is altogether too appealing to abandon without giving it a good try. Just little details like not waiting for the stage to cool down - and then having to reheat it would be a major improvement.

So I don't know if an aquarium pump would work - or even if they have an accessible vacuum port, but I will look at this as a possible solution.

Mike

|

Re: Vacuum hold-down for 3D build surface. November 12, 2016 02:48PM |

Registered: 12 years ago Posts: 1,450 |

Quote

the_digital_dentist

I'd probably connect it to the air intake on a small aquarium pump and just let it run continuously.

I don't understand how you're connecting the pump to this- one side gets closed off with the plastic film... what happens on the other side?

On the photo of the bottom side of the plate there are five slots visible which communicate with the top side. I will make a manifold with an 'O' ring to connect with these. Possibly too complicated for a production version, but O.K. for testing the feasibility of the idea and investigating various build stage surfaces.

Mike

|

Re: Vacuum hold-down for 3D build surface. November 12, 2016 03:02PM |

Registered: 11 years ago Posts: 5,780 |

If all the slots on the top connect to each other you should only need one hole on the back to pull all the air out from under the film.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Vacuum hold-down for 3D build surface. November 12, 2016 03:57PM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Vacuum hold-down for 3D build surface. November 13, 2016 01:56AM |

Registered: 8 years ago Posts: 312 |

|

Re: Vacuum hold-down for 3D build surface. November 13, 2016 05:15AM |

Registered: 8 years ago Posts: 5,232 |

I think using an o-ring or silicone resin around the table will cause problems. The seal has to stick out from the bed and will likely cause the foil to build folds.

Maybe a thin groove that is filled with grease/resin that is even with the bed would work.

Then, the best way to keep the foil from lifting, is a frame on top of it and some bulldog clamps.

What puzzles me is how you want to attach a heater to the bottom of the bed?

DD's suggestion of using only one drillhole would make it much easier than the row of milled slots.

Maybe a thin groove that is filled with grease/resin that is even with the bed would work.

Then, the best way to keep the foil from lifting, is a frame on top of it and some bulldog clamps.

What puzzles me is how you want to attach a heater to the bottom of the bed?

DD's suggestion of using only one drillhole would make it much easier than the row of milled slots.

|

Re: Vacuum hold-down for 3D build surface. November 13, 2016 06:54AM |

Registered: 12 years ago Posts: 1,450 |

So far the best seal is a thin smear of grease about 10mm wide around the perimeter of the plastic film. The idea of a frame with bulldog clips may make the use of a simple vacuum pump such as a syringe workable again - thank you o_lampe.

I did think that using thin wall silicone tube instead of solid silicone cord would allow the 'O' ring to flatten and not distort the film. While it does flatten nicely it also seems to act like a trumpeters lips

As far as the heater goes, on the back side of the plate (shown in the original posting) you will see two zig-zag grooves. These are for resistance wire to form a heater. Sadly, the nichrome wire that I got was the wrong resistance (I looked at the wrong row in a table) so I have sent for some 0.71mm insulated constantan wire which should work well.

New motto: First prove that it is feasible, then make it easyable.

Mike

I did think that using thin wall silicone tube instead of solid silicone cord would allow the 'O' ring to flatten and not distort the film. While it does flatten nicely it also seems to act like a trumpeters lips

As far as the heater goes, on the back side of the plate (shown in the original posting) you will see two zig-zag grooves. These are for resistance wire to form a heater. Sadly, the nichrome wire that I got was the wrong resistance (I looked at the wrong row in a table) so I have sent for some 0.71mm insulated constantan wire which should work well.

New motto: First prove that it is feasible, then make it easyable.

Mike

|

Re: Vacuum hold-down for 3D build surface. November 13, 2016 07:37AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Vacuum hold-down for 3D build surface. November 13, 2016 11:46AM |

Registered: 11 years ago Posts: 5,780 |

How do you insulate the nichrome wire from the aluminum plate?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Vacuum hold-down for 3D build surface. November 13, 2016 12:56PM |

Registered: 12 years ago Posts: 1,450 |

I was going to use PTFE shrink sleeving over 0.71mm nichrome but when I tried it out I found that the resistance was too high - 4 Ohms for each half. I have sent for some constantan, also of 0.71mm, which should have a resistance of just under 2 Ohms per half. This is enameled but I will back that up but coating the inside of the grooves with a tough silicone elastomer (Electrolube FSC) and sealing the wire in with the same. silicone.

Mike

Mike

|

Re: Vacuum hold-down for 3D build surface. November 15, 2016 02:40PM |

Registered: 12 years ago Posts: 1,450 |

First tests with grease and a vacuum of about 200mb below atmospheric pressure shows no leaks at all but we will only know if it remains good with many different materials and when hot

As there was a bit of interest in the milling of the plate, I put something on Thingiverse at [www.thingiverse.com]

Mike

As there was a bit of interest in the milling of the plate, I put something on Thingiverse at [www.thingiverse.com]

Mike

|

Re: Vacuum hold-down for 3D build surface. November 15, 2016 03:15PM |

Registered: 11 years ago Posts: 5,780 |

Quote

leadinglights

I was going to use PTFE shrink sleeving over 0.71mm nichrome but when I tried it out I found that the resistance was too high - 4 Ohms for each half. I have sent for some constantan, also of 0.71mm, which should have a resistance of just under 2 Ohms per half. This is enameled but I will back that up but coating the inside of the grooves with a tough silicone elastomer (Electrolube FSC) and sealing the wire in with the same. silicone.

Mike

PTFE is thermal as well as electrical insulation, as is the silicone elastomer. Your controller is going to be measuring the plate temperature. It will take time for the applied heat to get through the thermal resistances and heat up the bed. During that time the insulated wire is heating to ever higher temperatures. Teflon decomposes at 350C. How do you guarantee that the wire won't get to 350C?

Edited 1 time(s). Last edit at 11/15/2016 03:15PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Vacuum hold-down for 3D build surface. November 15, 2016 03:39PM |

Registered: 12 years ago Posts: 1,450 |

Quote

the_digital_dentist

Quote

leadinglights

I was going to use PTFE shrink sleeving over 0.71mm nichrome but when I tried it out I found that the resistance was too high - 4 Ohms for each half. I have sent for some constantan, also of 0.71mm, which should have a resistance of just under 2 Ohms per half. This is enameled but I will back that up but coating the inside of the grooves with a tough silicone elastomer (Electrolube FSC) and sealing the wire in with the same. silicone.

Mike

PTFE is thermal as well as electrical insulation, as is the silicone elastomer. Your controller is going to be measuring the plate temperature. It will take time for the applied heat to get through the thermal resistances and heat up the bed. During that time the insulated wire is heating to ever higher temperatures. Teflon decomposes at 350C. How do you guarantee that the wire won't get to 350C?

The wall thickness whether PTFE or silicone is 0.2mm or less, total area of the interface between the insulator and the aluminium is about 7800 mm² and a little over half of that at the wire. Long experience with heater elements tells me that 144 watts through an indifferent thermal insulator will be less than 100°C without even doing the maths - though I may look up the thermal resistances and formulae to allay any suspicions.

Mike

Sorry, only registered users may post in this forum.