Anti-ooze valve for extruder

Posted by LoboCNC

|

Anti-ooze valve for extruder October 17, 2017 12:46AM |

Registered: 10 years ago Posts: 564 |

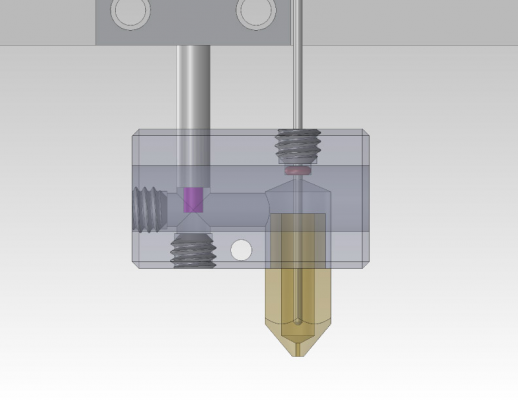

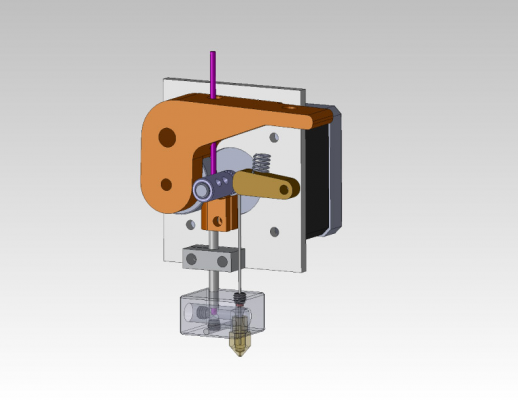

I know the idea of an anti-ooze valve for the extruder nozzle has been discussed here before, but I haven't seen much beyond hand drawn sketches. The idea I am thinking about, illustrated in the photos, involves a stainless steel wire that is used to plug the extruder orifice from the inside. The wire pierces the heater block and is sealed with a silicone o-ring. My idea is to actuate it directly off of the extruder drive gear. The brown cam in the second image has a friction fit against the drive gear, and is lightly spring-loaded downward. When extruding normally, the magenta filament is driven downward into the heater block while the cam is drive upward and ultimately disengages the drive gear. During retraction, however, the cam is engaged and pushed downward, and it shoves the wire down to seal the orifice. This mechanism would require no modifications to any standard firmware.

Any opinions as to whether this will work or not?

Any opinions as to whether this will work or not?

|

Re: Anti-ooze valve for extruder October 17, 2017 04:10AM |

Registered: 12 years ago Posts: 1,450 |

A couple of possible pitfalls occur to me - probably not insolvable but may need some engineering.

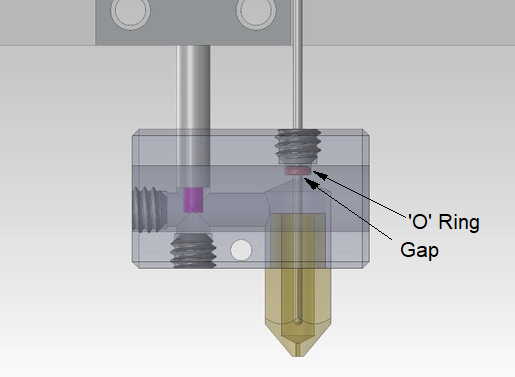

Firstly, I assume that the bit I have marked 'O' Ring in the diagram is silicone. Although silicone does work at PLA/ABS extruding temperatures I am less sure that it retains the proper elasticity.

More importantly, most filaments contain quite a bit of small particulates such as course dye materials, crystallized un-polymerised plastic and crispy crunchy bits of caramelized organic contaminants. While these are usually too small to block the nozzle, they may well accumulate in the gap around the pin.

One thought though, using the identical arrangement but with the pin fixed so that the 'O' ring and gap don't exist, but having the nozzle sprung and floating so that when the filament is retracted the nozzle also retracts and seats against the pin. The above problems of the 'O' Ring and gunge-blockage still exist but the mechanicals would have been simplified.

Mike

Firstly, I assume that the bit I have marked 'O' Ring in the diagram is silicone. Although silicone does work at PLA/ABS extruding temperatures I am less sure that it retains the proper elasticity.

More importantly, most filaments contain quite a bit of small particulates such as course dye materials, crystallized un-polymerised plastic and crispy crunchy bits of caramelized organic contaminants. While these are usually too small to block the nozzle, they may well accumulate in the gap around the pin.

One thought though, using the identical arrangement but with the pin fixed so that the 'O' ring and gap don't exist, but having the nozzle sprung and floating so that when the filament is retracted the nozzle also retracts and seats against the pin. The above problems of the 'O' Ring and gunge-blockage still exist but the mechanicals would have been simplified.

Mike

|

Re: Anti-ooze valve for extruder October 17, 2017 09:44AM |

Registered: 7 years ago Posts: 363 |

I wonder how that zig-zag path you've got the material passing throuh will affect pressure and neccesary torque to push the filament through. Of course the concept could work quite well if you decide to create a prototype.

I disagree with having a floating nozzle. It could very easily introduce mechanical play affecting print accuracy/quality.

I disagree with having a floating nozzle. It could very easily introduce mechanical play affecting print accuracy/quality.

|

Re: Anti-ooze valve for extruder October 17, 2017 11:35AM |

Registered: 10 years ago Posts: 564 |

Quote

leadinglights

One thought though, using the identical arrangement but with the pin fixed so that the 'O' ring and gap don't exist, but having the nozzle sprung and floating so that when the filament is retracted the nozzle also retracts and seats against the pin. The above problems of the 'O' Ring and gunge-blockage still exist but the mechanicals would have been simplified.

Mike

Are you thinking that with a floating nozzle, you'd just rely on the positive pressure of extrusion to extend the nozzle away from the valve pin? That would be incredibly cool if you could get it to work. Making the nozzle float with some sort of o-ring supported linear joint would be really tricky, though, given that the seal friction will be fairly high and the extrusion pressure might be fairly low at times. I'd be afraid it wouldn't always be fully extended.

However, if the nozzle were mounted on a flexible diaphragm, this would eliminate the friction and also could integrate the spring function. Perhaps even a use something like one of those bimetallic jumping discs that snaps to one of two discrete positions. This would also eliminate the problem of sliding seals getting gunked up. (Although the constant clicking with every retraction would drive you insane.)

With my original idea, if the silicone o-ring failed to work, I could instead try a using a PTFE plug with a small hole drilled into it - essentially a square cross-section o-ring. This might act as more of a wiper to keep any gunk inside the heater block.

Edited 1 time(s). Last edit at 10/17/2017 11:44AM by LoboCNC.

|

Re: Anti-ooze valve for extruder October 17, 2017 11:42AM |

Registered: 10 years ago Posts: 564 |

Quote

obelisk79

I wonder how that zig-zag path you've got the material passing throuh will affect pressure and neccesary torque to push the filament through. Of course the concept could work quite well if you decide to create a prototype.

I'm not too worried about the zig-zag path. My current printer (UDIO printer) uses a right-angle extruder which has given me no problems at all in the year or so I've been using it. Normally I'd be worried about the relatively large volume of melted material inside the heater block because this causes more oozing, but with the valve, it shouldn't matter.

|

Re: Anti-ooze valve for extruder October 17, 2017 01:17PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Anti-ooze valve for extruder October 17, 2017 02:27PM |

Registered: 12 years ago Posts: 1,450 |

Whether the pin pushes any filament through the nozzle or not would depend on if the filament retract was effective before the pin closed off the nozzle.

In the case of the floating nozzle, since the lifting of the nozzle to meet the pin is done by retracting the filament, I think there would be nothing in the nozzle to be pushed out. Incidentally, the nozzle being lifted would help it to clear the print in the case of multi filament printers.

Regarding obelisk79's concern that the nozzle would wobble, I think it is easy to engineer around that problem - LoboCVC's thought about the diaphragm spring sounds like a very good way of de-wobbling as well as helping with the sealing.

Mike

In the case of the floating nozzle, since the lifting of the nozzle to meet the pin is done by retracting the filament, I think there would be nothing in the nozzle to be pushed out. Incidentally, the nozzle being lifted would help it to clear the print in the case of multi filament printers.

Regarding obelisk79's concern that the nozzle would wobble, I think it is easy to engineer around that problem - LoboCVC's thought about the diaphragm spring sounds like a very good way of de-wobbling as well as helping with the sealing.

Mike

|

Re: Anti-ooze valve for extruder October 17, 2017 02:33PM |

Registered: 10 years ago Posts: 564 |

Quote

o_lampe

Wouldn't the pin push filament through the nozzle each time it closes the channel? What would be the chamber pressure after unretract? There could be a gap in the filament.

If you would guide the pin sideways into the nozzle, you could again use a straight melting path.

I'm envisioning that the pin will be inserted as the filament is being retracted, so filament should be being sucked out of the orifice and the pin seats against the inside end. Note that the pin doesn't actually go into the orifice. I'm thinking of using a 0.8mm dia wire for the pin to seal against a 0.4mm or 0.5mm diameter orifice.

|

Re: Anti-ooze valve for extruder October 17, 2017 02:37PM |

Registered: 7 years ago Posts: 363 |

Quote

o_lampe

Wouldn't the pin push filament through the nozzle each time it closes the channel? What would be the chamber pressure after unretract? There could be a gap in the filament.

If you would guide the pin sideways into the nozzle, you could again use a straight melting path.

Minimizing pin travel would reduce ooze from the mechanism as well as the reduced nozzle pressure from a simultaneous retract yes?

I have no background in engineering, but I would imagine that the melted plastic, being rather viscous in liquid form, would actually create a very brief moment of negative nozzle pressure during retract, during which time the pin could seat in the nozzle. I am also assuming that ooze becomes more of an issue once pressure stabilizes after retract and gravity can work its mojo (technical term

).

).

|

Re: Anti-ooze valve for extruder October 17, 2017 02:45PM |

Registered: 7 years ago Posts: 363 |

Quote

LoboCNC

I'm not too worried about the zig-zag path. My current printer (UDIO printer) uses a right-angle extruder which has given me no problems at all in the year or so I've been using it. Normally I'd be worried about the relatively large volume of melted material inside the heater block because this causes more oozing, but with the valve, it shouldn't matter.

Gotcha, thanks for the link Lobo!

Since that thing prints upside down, do you even notice much of an ooze problem?

|

Re: Anti-ooze valve for extruder October 17, 2017 03:05PM |

Registered: 10 years ago Posts: 564 |

Quote

obelisk79

Since that thing prints upside down, do you even notice much of an ooze problem?

Actually, it turns out that ooze, and pretty much all other 3D printing factors, have little to do with gravity. The viscodynamic and thermal forces are far greater than the weight of the filament. Printing upside down, even bridging, looks pretty much the same as printing right-side up. Oozing, in particular doesn't care about gravity. The biggest factor I've found is the volume of melted plastic in the heater block. I'm not sure if it is related to thermal expansion of the filament, or maybe some amount of outgassing that happens in the heater block, but larger melted volumes of filament will cause much more oozing than smaller volumes.

|

Re: Anti-ooze valve for extruder October 18, 2017 09:22AM |

Registered: 7 years ago Posts: 363 |

Quote

LoboCNC

Actually, it turns out that ooze, and pretty much all other 3D printing factors, have little to do with gravity. The viscodynamic and thermal forces are far greater than the weight of the filament. Printing upside down, even bridging, looks pretty much the same as printing right-side up. Oozing, in particular doesn't care about gravity. The biggest factor I've found is the volume of melted plastic in the heater block. I'm not sure if it is related to thermal expansion of the filament, or maybe some amount of outgassing that happens in the heater block, but larger melted volumes of filament will cause much more oozing than smaller volumes.

Thanks for the info. Perhaps thermal expansion is more to blame, wouldn't outgassing potentially cause inconsistent flow from the nozzle?

|

Re: Anti-ooze valve for extruder October 18, 2017 12:36PM |

Registered: 10 years ago Posts: 564 |

Quote

obelisk79

Quote

LoboCNC

Actually, it turns out that ooze, and pretty much all other 3D printing factors, have little to do with gravity. The viscodynamic and thermal forces are far greater than the weight of the filament. Printing upside down, even bridging, looks pretty much the same as printing right-side up. Oozing, in particular doesn't care about gravity. The biggest factor I've found is the volume of melted plastic in the heater block. I'm not sure if it is related to thermal expansion of the filament, or maybe some amount of outgassing that happens in the heater block, but larger melted volumes of filament will cause much more oozing than smaller volumes.

Thanks for the info. Perhaps thermal expansion is more to blame, wouldn't outgassing potentially cause inconsistent flow from the nozzle?

Maybe. It also could be phase-change expansion as more filament up the feed tube starts to melt. Any of these processes, though, produce an amount of oozing proportional to the interior volume of the heater block.

|

Re: Anti-ooze valve for extruder October 20, 2017 04:38PM |

Registered: 7 years ago Posts: 249 |

This is very similar to valve gates used in industrial injection molding hot manifolds.

The only thing I would add is an additional plug to the horizontal feed line (through hole), so it can be cleaned in the event of a clog due to baked filament.

Obviously, if the hot end is cold, operating the valve would be avoided.

The only thing I would add is an additional plug to the horizontal feed line (through hole), so it can be cleaned in the event of a clog due to baked filament.

Obviously, if the hot end is cold, operating the valve would be avoided.

|

Re: Anti-ooze valve for extruder October 20, 2017 04:55PM |

Registered: 10 years ago Posts: 564 |

Quote

leadinglights

Whether the pin pushes any filament through the nozzle or not would depend on if the filament retract was effective before the pin closed off the nozzle.

In the case of the floating nozzle, since the lifting of the nozzle to meet the pin is done by retracting the filament, I think there would be nothing in the nozzle to be pushed out. Incidentally, the nozzle being lifted would help it to clear the print in the case of multi filament printers.

Regarding obelisk79's concern that the nozzle would wobble, I think it is easy to engineer around that problem - LoboCVC's thought about the diaphragm spring sounds like a very good way of de-wobbling as well as helping with the sealing.

Mike

I thought of another idea relating to the flexible diaphragm idea that would simplify things. Instead of mounting the nozzle on a diaphragm, leave it rigidly mounted to the heater block but mount the top end of the valve pin to a diaphragm or bellows on the top side of the block. You'd use the same extrude/retract pressure differential to actuate the pin, but you'd never have to worry about the nozzle position varying with the pressure. All I have to do now is figure out how to make a tiny 1mm throw diaphragm good for about 2000 PSI.

|

Re: Anti-ooze valve for extruder October 21, 2017 09:54AM |

Registered: 8 years ago Posts: 312 |

afaik, the retraction does not suck the molten filament up into the heat block.

It simply relieves some of the pressure, but there is no negative movement of the molten plastic.

So yeah, closing the needle will have a pulse effect of pushing some filament out.

That can be used, by retracting early and closing the valve slowly, using the pushed out material to finish the track.

That would take a lot of control and precision in the needle valve.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

It simply relieves some of the pressure, but there is no negative movement of the molten plastic.

So yeah, closing the needle will have a pulse effect of pushing some filament out.

That can be used, by retracting early and closing the valve slowly, using the pushed out material to finish the track.

That would take a lot of control and precision in the needle valve.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: Anti-ooze valve for extruder October 21, 2017 03:37PM |

Registered: 10 years ago Posts: 564 |

Quote

Lykle

afaik, the retraction does not suck the molten filament up into the heat block.

It simply relieves some of the pressure, but there is no negative movement of the molten plastic.

So yeah, closing the needle will have a pulse effect of pushing some filament out.

That can be used, by retracting early and closing the valve slowly, using the pushed out material to finish the track.

That would take a lot of control and precision in the needle valve.

I believe you are correct - I just spent 10 minuted manually feeding and retracting filament, and the retraction will arrest the flow but not reverse it. How much additional material gets pushed out by the valve pin, though is the big questions. I think it will depend on the shape of the pin and the shape of the chamber just inside the orifice. I suspect it will be just a fraction of a mm of extruded filament, which should be fairly easy to compensate for with some of the advanced retraction/ooze control slicing parameters. Could be more though. Only one way to find out...

|

Re: Anti-ooze valve for extruder October 22, 2017 05:26PM |

Registered: 10 years ago Posts: 564 |

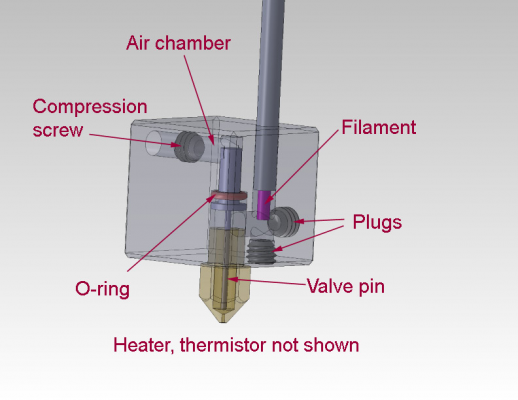

OK, here's another version of the anti-ooze valve that eliminates the complex extruder motor driven actuation and instead uses the differential extrude/retract pressure to operate the valve, as leadinglights suggested. It uses compressed air in a small chamber in the heater block to push the valve pin against the inside of the orifice during retraction, when the inner pressure filament pressure is zero. During extrusion, the high extrusion pressure will push the valve pin upward against the air-spring. A sealed compression screw can be used to compress the air in the air chamber to the proper level. It still has an o-ring seal, which could be problematic, but at least this something I have a hope being able to fabricate.

|

Re: Anti-ooze valve for extruder February 07, 2018 02:27PM |

Registered: 6 years ago Posts: 3 |

hello LoboCNC, i am not sure how far along you are but please check the following patents before investing a lot of money in this project. the design you mention is already in use in a fairly popular machine, the only difference is that the filament in yours feeds parallel to the valve pin. as you guessed the o-ring seal is the weakest point as it generally last only about 500hrs in this harsh environment, sometimes more sometimes less. The issue in the particular head i am referring to is that it fails due to pressure then the filament is allowed to escape through the orifice or at the thread area in that location. I have two of these machine and it is a common issue acknowledged by the manufacturer. Maybe a particularly strong o-ring with high temp resistance will do the trick. Not sure how well ptfe will perform but it could limit what materials you can print with as already observed. You may not be working on this for any financial gain so this message may not be applicable to you, i was not sure. In either case i am sure you can complete the project and your head will print well if implemented correctly, but for retail purposes you may face a road-block unless you are able to design it as such that you do not infringe on any of the patent claims and that would require a pretty good lawyer. I hope this is useful, i design 3D printers and innovative parts too so I would hate for you to get in trouble over patent infringement law.

[www.google.com]

[www.google.com]

Best,

Moh

[www.google.com]

[www.google.com]

Best,

Moh

|

Re: Anti-ooze valve for extruder February 07, 2018 02:53PM |

Registered: 10 years ago Posts: 564 |

Quote

aimdy

hello LoboCNC, i am not sure how far along you are but please check the following patents before investing a lot of money in this project. the design you mention is already in use in a fairly popular machine, the only difference is that the filament in yours feeds parallel to the valve pin. as you guessed the o-ring seal is the weakest point as it generally last only about 500hrs in this harsh environment, sometimes more sometimes less. The issue in the particular head i am referring to is that it fails due to pressure then the filament is allowed to escape through the orifice or at the thread area in that location. I have two of these machine and it is a common issue acknowledged by the manufacturer. Maybe a particularly strong o-ring with high temp resistance will do the trick. Not sure how well ptfe will perform but it could limit what materials you can print with as already observed. You may not be working on this for any financial gain so this message may not be applicable to you, i was not sure. In either case i am sure you can complete the project and your head will print well if implemented correctly, but for retail purposes you may face a road-block unless you are able to design it as such that you do not infringe on any of the patent claims and that would require a pretty good lawyer. I hope this is useful, i design 3D printers and innovative parts too so I would hate for you to get in trouble over patent infringement law.

[www.google.com]

[www.google.com]

Best,

Moh

Thanks for the heads-up. I hadn't actually made any progress on this, and I doubt I would have sought to commercialize it, but still good to know what's been patented. The patent looks to be specifically for dual-extrusion, but that wouldn't stop someone from trying to sue you. I'm always a little disappointed when I see some idea I've had has already been patented, but on the other hand, I also take it as confirmation that the idea has some merit.

|

Re: Anti-ooze valve for extruder February 08, 2018 10:46AM |

Registered: 7 years ago Posts: 270 |

There's (was?) printer made in Australia with valve in the nozzle. From what I recall it was causing all sorts of issues.

Found it: https://www.wiltronics.com.au/Robox-3Dprinting/nozzle-valve-system/

From their description though, it looks like needle valve is not used during retractions:

Printing head costs $2500 which could mean that users see some value in such design....LAST EDIT: used, like new CEL-Robox on Amazon goes for $300 so maybe not

Edited 6 time(s). Last edit at 02/08/2018 11:14AM by newbob.

Found it: https://www.wiltronics.com.au/Robox-3Dprinting/nozzle-valve-system/

From their description though, it looks like needle valve is not used during retractions:

Quote

When they want to pause printing, or switch nozzles, the current nozzle is plugged completely with a small needle, stopping the flow of filament and producing a perfect ‘end’ to the line or layer of print. This also facilitates the ability of the printer to manage the pause and resume function, another CEL-Robox innovation.

Printing head costs $2500 which could mean that users see some value in such design....LAST EDIT: used, like new CEL-Robox on Amazon goes for $300 so maybe not

Edited 6 time(s). Last edit at 02/08/2018 11:14AM by newbob.

|

Re: Anti-ooze valve for extruder February 08, 2018 11:33AM |

Registered: 10 years ago Posts: 564 |

Quote

newbob

There's (was?) printer made in Australia with valve in the nozzle. From what I recall it was causing all sorts of issues.

Found it: https://www.wiltronics.com.au/Robox-3Dprinting/nozzle-valve-system/

From their description though, it looks like needle valve is not used during retractions:

Quote

When they want to pause printing, or switch nozzles, the current nozzle is plugged completely with a small needle, stopping the flow of filament and producing a perfect ‘end’ to the line or layer of print. This also facilitates the ability of the printer to manage the pause and resume function, another CEL-Robox innovation.

Printing head costs $2500 which could mean that users see some value in such design....LAST EDIT: used, like new CEL-Robox on Amazon goes for $300 so maybe not

Too bad they don't have an illustration showing the guts of their nozzle system. It'd be interesting to see if the issues you mention are fundamental, or if they have to do with their particular implementation.

|

Re: Anti-ooze valve for extruder February 08, 2018 12:09PM |

Registered: 6 years ago Posts: 3 |

this is the machine i was referring to. you can see here a basic cartoon of what happens in the heater block

[www.cel-robox.com]

this shows the needle valves (pin) as well from outside the heater block in the dual material head

[cel-uk.com]

they offer a single material head, with 2 nozzles for .3mm and .8mm and a dual material head with .4mm nozzles.

The main issue is as I mentioned in my initial post. The machine's proprietary software and slicer provides calibration tools so the machine knows how to precisely calibrate the pin movements. Additional issues may result from the user not properly calibrating their machines. Also as the machine is closed source the manufacturer provide firmware updates, which is one way fine tuning of the pin behavior can be implemented. On a well calibrated machine the user should have no problem other than the longevity of the o-rings.

[www.cel-robox.com]

this shows the needle valves (pin) as well from outside the heater block in the dual material head

[cel-uk.com]

they offer a single material head, with 2 nozzles for .3mm and .8mm and a dual material head with .4mm nozzles.

The main issue is as I mentioned in my initial post. The machine's proprietary software and slicer provides calibration tools so the machine knows how to precisely calibrate the pin movements. Additional issues may result from the user not properly calibrating their machines. Also as the machine is closed source the manufacturer provide firmware updates, which is one way fine tuning of the pin behavior can be implemented. On a well calibrated machine the user should have no problem other than the longevity of the o-rings.

|

Re: Anti-ooze valve for extruder February 08, 2018 12:28PM |

Registered: 10 years ago Posts: 564 |

Quote

aimdy

this is the machine i was referring to. you can see here a basic cartoon of what happens in the heater block

[www.cel-robox.com]

this shows the needle valves (pin) as well from outside the heater block in the dual material head

[cel-uk.com]

they offer a single material head, with 2 nozzles for .3mm and .8mm and a dual material head with .4mm nozzles.

The main issue is as I mentioned in my initial post. The machine's proprietary software and slicer provides calibration tools so the machine knows how to precisely calibrate the pin movements. Additional issues may result from the user not properly calibrating their machines. Also as the machine is closed source the manufacturer provide firmware updates, which is one way fine tuning of the pin behavior can be implemented. On a well calibrated machine the user should have no problem other than the longevity of the o-rings.

In their animation, it looks like the seal moves with the valve pin, which seems a little odd. Also, with the rocking motion, they might be getting a little bit of side loading of the pin which would certainly not help with the sealing. I guess I'll just have to try out my idea and see how it works. BTW, I think the general idea of a pin valve sealing a nozzle at the orifice is fairly common in other dispensing devices, so I suspect any patents would only apply to particular implementations.

|

Re: Anti-ooze valve for extruder February 08, 2018 12:55PM |

Registered: 6 years ago Posts: 3 |

Oh that is not the seal, the seal is further down and actually inside the heater block, while the part shown is mechanical to help adjust the length of the pin during manufacturing i supposed. The seal is not shown on the animation. There are several existing patents making the use of this sort of pin technology in various other industries so you are correct; you will need to investigate their specific claims to determine what the limitations are.

[www.quora.com]

Here is what the maker had to say on the topic (see the comments to the article)

[www.cel-robox.com]

So you should not have any issues since you are just making a proof of concept for yourself. Best of luck and keep us updated on your progress.

[www.quora.com]

Here is what the maker had to say on the topic (see the comments to the article)

[www.cel-robox.com]

So you should not have any issues since you are just making a proof of concept for yourself. Best of luck and keep us updated on your progress.

|

Re: Anti-ooze valve for extruder February 08, 2018 01:07PM |

Registered: 6 years ago Posts: 1,007 |

I doubt the needle valve can be patented as it is a well known and used type of valve to meter and control various type of fluids. The inventor and patent are history now.

Even applied in a 3D printer as it is already used in extrusion, injection molding.

What is innovative in this patent is the two heads rocking to take position although the idea is similar to the old turret production lathe, combined with this needle nozzle.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Even applied in a 3D printer as it is already used in extrusion, injection molding.

What is innovative in this patent is the two heads rocking to take position although the idea is similar to the old turret production lathe, combined with this needle nozzle.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Anti-ooze valve for extruder February 08, 2018 01:36PM |

Registered: 7 years ago Posts: 270 |

This idea reminds me of reading about attempts to embed wire in the filament. I think both cope with similar issue which is how to breach melting chamber and keep plastic from escaping through the breach.

Here's video from 2010.

When I was contemplating this myself I thought of diamond head type of nozzle with one of the filament holes replaced with a needle.

Here's video from 2010.

When I was contemplating this myself I thought of diamond head type of nozzle with one of the filament holes replaced with a needle.

|

Re: Anti-ooze valve for extruder February 18, 2018 09:10AM |

Registered: 7 years ago Posts: 270 |

Quote

LoboCNC

OK, here's another version of the anti-ooze valve that eliminates the complex extruder motor driven actuation and instead uses the differential extrude/retract pressure to operate the valve, as leadinglights suggested. It uses compressed air in a small chamber in the heater block to push the valve pin against the inside of the orifice during retraction, when the inner pressure filament pressure is zero. During extrusion, the high extrusion pressure will push the valve pin upward against the air-spring. A sealed compression screw can be used to compress the air in the air chamber to the proper level. It still has an o-ring seal, which could be problematic, but at least this something I have a hope being able to fabricate.

To push the pin up using pressure you'll need melted plastic press on part of the plunger, larger the surface area means bigger gasket and mechanism would be harder to clean/keep aligned once contaminated. I like the original cam idea better. Another negative is changing melt chamber volume when using pressure to produce mechanical energy.

What I find intriguing is the idea of offset chamber where filament is pressing on the wall as it's being fed which may speedup melting due to better heat transfer.

Edited 3 time(s). Last edit at 02/18/2018 03:03PM by newbob.

|

Re: Anti-ooze valve for extruder February 18, 2018 11:45AM |

Registered: 10 years ago Posts: 564 |

Quote

newbob

What I find intriguing is the idea of offset chamber where filament is pressing on the wall as it's being fed which may speedup melting due to better heat transfer.

I hadn't thought about that. My inverted printer (inverted printer thread) uses a right-angle feed into the hot end which does the same thing. It works pretty well - maybe faster melting is part of the reason.

As for the o-ring seals getting gunked up with filament, yeah, that's a real worry, but I'll just have to try it to see how much of a problem it is.

|

Re: Anti-ooze valve for extruder February 19, 2018 08:29AM |

Registered: 6 years ago Posts: 1,007 |

Quote

newbob

Quote

LoboCNC

OK, here's another version of the anti-ooze valve that eliminates the complex extruder motor driven actuation and instead uses the differential extrude/retract pressure to operate the valve, as leadinglights suggested. It uses compressed air in a small chamber in the heater block to push the valve pin against the inside of the orifice during retraction, when the inner pressure filament pressure is zero. During extrusion, the high extrusion pressure will push the valve pin upward against the air-spring. A sealed compression screw can be used to compress the air in the air chamber to the proper level. It still has an o-ring seal, which could be problematic, but at least this something I have a hope being able to fabricate.

To push the pin up using pressure you'll need melted plastic press on part of the plunger, larger the surface area means bigger gasket and mechanism would be harder to clean/keep aligned once contaminated. I like the original cam idea better. Another negative is changing melt chamber volume when using pressure to produce mechanical energy.

What I find intriguing is the idea of offset chamber where filament is pressing on the wall as it's being fed which may speedup melting due to better heat transfer.

And what pressure do you think it will have to act upon ? If there is no leak, a 1 bar in the "air chamber" at room T° will become how much at let say 200° ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.