Reprap2: Mendel circuit material

Posted by Annirak

|

Reprap2: Mendel circuit material November 23, 2008 03:51PM |

Registered: 15 years ago Posts: 401 |

|

Re: Reprap2: Mendel circuit material December 02, 2008 06:54PM |

Registered: 16 years ago Posts: 161 |

As to the use of conductive epoxy, I believe that. firstly, its' resistance is too high for it to be practical for use on conductors more than a few inches long. One reference (which I can no longer locate)gave resistance values per meter in units I never really understood, but Copper was 17, Solder was 150 and silver bearing epoxy was 380. Conductive epoxy is also expensive, currently $1.70US/gram, not including shipping. Probably cheaper in bulk, but still several orders of magnitude more expensive than solder.

|

Re: Reprap2: Mendel circuit material December 03, 2008 09:54AM |

Registered: 15 years ago Posts: 401 |

|

Re: Reprap2: Mendel circuit material December 03, 2008 10:19AM |

Admin Registered: 17 years ago Posts: 1,915 |

Having Reprap print circuits has been discussed to death literally for years now at Reprap. Adrian has made 3 mm rods of Fields metal and tried to print with them. I've run regular solder through an extruder and printed it on an HDPE circuit. We've talked about conductive inks and many other options.

Why not use "no clean" solder paste. It's made to be either painted onto pcb's with a stencil or applied with a dispenser (using a positioning robot) and is used industry-wide for attaching surface mount chips to pcb's.

Why not just use your reprap machine to paint the circuit board pattern with a solder paste and then reflow the stuff by passing your hot extruder tip over it slowly without extruding plastic. That should do the trick, don't you think?

I priced some of the stuff just now and it looks like you can get it for about $30/lb.

Edited 1 time(s). Last edit at 12/03/2008 10:20AM by Forrest Higgs.

Why not use "no clean" solder paste. It's made to be either painted onto pcb's with a stencil or applied with a dispenser (using a positioning robot) and is used industry-wide for attaching surface mount chips to pcb's.

Why not just use your reprap machine to paint the circuit board pattern with a solder paste and then reflow the stuff by passing your hot extruder tip over it slowly without extruding plastic. That should do the trick, don't you think?

I priced some of the stuff just now and it looks like you can get it for about $30/lb.

Edited 1 time(s). Last edit at 12/03/2008 10:20AM by Forrest Higgs.

|

Anonymous User

Re: Reprap2: Mendel circuit material December 03, 2008 03:27PM |

Forrest Higgs Wrote:

-------------------------------------------------------

....

>

> Why not use "no clean" solder paste. It's made to

> be either painted onto pcb's with a stencil or

> applied with a dispenser (using a positioning

> robot) and is used industry-wide for attaching

> surface mount chips to pcb's.

.....

I think the surface tension of the solder will be a problem. It will bead up on the surface. What were your results when you attempted to print solder on HDPE?

-------------------------------------------------------

....

>

> Why not use "no clean" solder paste. It's made to

> be either painted onto pcb's with a stencil or

> applied with a dispenser (using a positioning

> robot) and is used industry-wide for attaching

> surface mount chips to pcb's.

.....

I think the surface tension of the solder will be a problem. It will bead up on the surface. What were your results when you attempted to print solder on HDPE?

|

Re: Reprap2: Mendel circuit material December 03, 2008 03:44PM |

Admin Registered: 17 years ago Posts: 1,915 |

d0ubled Wrote:

-------------------------------------------------------

>

> I think the surface tension of the solder will be

> a problem. It will bead up on the surface. What

> were your results when you attempted to print

> solder on HDPE?

>

I didn't have beading problems. Molten solder didn't seem to have much surface tension at all. It tended to splatter rather than bead.

-------------------------------------------------------

>

> I think the surface tension of the solder will be

> a problem. It will bead up on the surface. What

> were your results when you attempted to print

> solder on HDPE?

>

I didn't have beading problems. Molten solder didn't seem to have much surface tension at all. It tended to splatter rather than bead.

|

Re: Reprap2: Mendel circuit material December 03, 2008 06:42PM |

Registered: 15 years ago Posts: 401 |

Forrest Higgs Wrote:

-------------------------------------------------------

> Having Reprap print circuits has been discussed to

> death literally for years now at Reprap. Adrian

> has made 3 mm rods of Fields metal and tried to

> print with them. I've run regular solder through

> an extruder and printed it on an HDPE circuit.

> We've talked about conductive inks and many other

> options.

I can't imagine that there is some magical solution that I will come up with that has not already been discussed. I come at this problem from what I expect to be a slightly different perspective. I'm an electronics designer and I want the ability to prototype my own PCBs or, better yet, print designs right into parts, in 3D.

> Why not use "no clean" solder paste. It's made to

> be either painted onto pcb's with a stencil or

> applied with a dispenser (using a positioning

> robot) and is used industry-wide for attaching

> surface mount chips to pcb's.

>

> Why not just use your reprap machine to paint the

> circuit board pattern with a solder paste and then

> reflow the stuff by passing your hot extruder tip

> over it slowly without extruding plastic. That

> should do the trick, don't you think?

>

> I priced some of the stuff just now and it looks

> like you can get it for about $30/lb.

The reason that I am not satisfied with any of the offered solutions is that my goals are different. I want to be able to connect to a BGA and QFN package surface mount device with .65 and .5mm pitch, respectively. Either of these will be very difficult to do with paste melting or field's metal.

This is why I keep coming back to conductive polymers and thick films. Laser sintering looked good, but high energy lasers and the general population don't mix well, so I don't think this is a good solution for reprap.

-------------------------------------------------------

> Having Reprap print circuits has been discussed to

> death literally for years now at Reprap. Adrian

> has made 3 mm rods of Fields metal and tried to

> print with them. I've run regular solder through

> an extruder and printed it on an HDPE circuit.

> We've talked about conductive inks and many other

> options.

I can't imagine that there is some magical solution that I will come up with that has not already been discussed. I come at this problem from what I expect to be a slightly different perspective. I'm an electronics designer and I want the ability to prototype my own PCBs or, better yet, print designs right into parts, in 3D.

> Why not use "no clean" solder paste. It's made to

> be either painted onto pcb's with a stencil or

> applied with a dispenser (using a positioning

> robot) and is used industry-wide for attaching

> surface mount chips to pcb's.

>

> Why not just use your reprap machine to paint the

> circuit board pattern with a solder paste and then

> reflow the stuff by passing your hot extruder tip

> over it slowly without extruding plastic. That

> should do the trick, don't you think?

>

> I priced some of the stuff just now and it looks

> like you can get it for about $30/lb.

The reason that I am not satisfied with any of the offered solutions is that my goals are different. I want to be able to connect to a BGA and QFN package surface mount device with .65 and .5mm pitch, respectively. Either of these will be very difficult to do with paste melting or field's metal.

This is why I keep coming back to conductive polymers and thick films. Laser sintering looked good, but high energy lasers and the general population don't mix well, so I don't think this is a good solution for reprap.

|

Re: Reprap2: Mendel circuit material December 04, 2008 02:11AM |

Registered: 15 years ago Posts: 401 |

|

Re: Reprap2: Mendel circuit material December 23, 2008 12:51PM |

Registered: 16 years ago Posts: 37 |

I've been curious why people have gone about the first generation of PCB-making as an extension of the quite difficult process of extrusion. It would be much simpler to capitalize on the RepRap's ability as a positioning table to use it as a mini-mill to etch 1oz FR1 boards with a 1/64" or 1/32" end mill. There's a nice piece of software used in MIT's Fab Lab called cad.py which governs this (http://fab.cba.mit.edu/about/fab/), and generally circuits are made there either by this method on a Roland Modela, or on a vinylcutter. You have the added advantage of using the RepRap for other light milling tasks i.e. foam or wax, and people have even used the Modela successfully for simple 3D scanning tasks in 2.5D. Cad.py outputs a number of CAD formats, and you'd have to get one of them talking with the RepRap (and of course create a swappable milling head with collet).

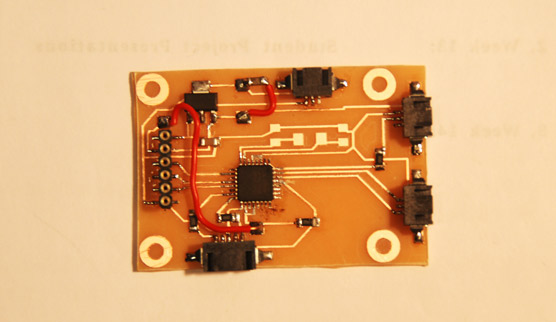

Here's an example board done with a 1/64" bit. The method works best for surface mount, though I've gotten through hole to work as well (even bi-layer through-hole):

Here's an example board done with a 1/64" bit. The method works best for surface mount, though I've gotten through hole to work as well (even bi-layer through-hole):

|

Re: Reprap2: Mendel circuit material December 23, 2008 01:25PM |

Admin Registered: 17 years ago Posts: 1,915 |

>

> It would be much simpler to capitalize on the RepRap's ability as a

> positioning table to use it as a mini-mill

>

I'm doing that.

Looking at your board, you milled most of the copper off of it. Given that a end mill like the one that I'm using...

[www.northbaytechnical.com]

...has a service life of anywhere between 2500-6000 inches of milling through copper, the cost of replacement end mills could become quite substantial.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

> It would be much simpler to capitalize on the RepRap's ability as a

> positioning table to use it as a mini-mill

>

I'm doing that.

Looking at your board, you milled most of the copper off of it. Given that a end mill like the one that I'm using...

[www.northbaytechnical.com]

...has a service life of anywhere between 2500-6000 inches of milling through copper, the cost of replacement end mills could become quite substantial.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Reprap2: Mendel circuit material December 23, 2008 02:04PM |

Registered: 15 years ago Posts: 251 |

Greetings all,

Here's another (somewhat speculative) idea for creating printed-circuit boards:

Although the conductivity of conductive plastics (incl. conductive epoxies and similar coatings) sounds too low to build high-power or high-frequency circuits, they might serve as a substrate upon which we could selectively deposit higher-conductivity materials, e.g. copper, via electroplating. Plated through holes were produced in a manner similar to this, before surface-mount largely displaced the need for holes. (Vias may still be done via plating; does anybody know?)

-- Larry

Here's another (somewhat speculative) idea for creating printed-circuit boards:

Although the conductivity of conductive plastics (incl. conductive epoxies and similar coatings) sounds too low to build high-power or high-frequency circuits, they might serve as a substrate upon which we could selectively deposit higher-conductivity materials, e.g. copper, via electroplating. Plated through holes were produced in a manner similar to this, before surface-mount largely displaced the need for holes. (Vias may still be done via plating; does anybody know?)

-- Larry

|

Re: Reprap2: Mendel circuit material December 23, 2008 02:11PM |

Admin Registered: 17 years ago Posts: 1,915 |

>

> Here's another (somewhat speculative) idea for creating printed-circuit boards:

>

I've toyed with that notion. I can't see anything that would keep it from working.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

> Here's another (somewhat speculative) idea for creating printed-circuit boards:

>

I've toyed with that notion. I can't see anything that would keep it from working.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Reprap2: Mendel circuit material January 01, 2009 06:23PM |

Registered: 15 years ago Posts: 401 |

Larry_Pfeffer Wrote:

-------------------------------------------------------

> (Vias may still be done via plating; does

> anybody know?)

Vias are, generally, plated. For hobbyist work, there are rivets that serve a similar purpose.

Electroplating is certainly viable but, again, it eliminates the 3D aspect of the production, and introduces a need for a chemical bath. In addition, electroplating isn't exactly the most energy conservative production technique.

I think we may end up going with electroplating, but I hope not.

I've been talking to a rep at 3M about conductive plastics. They have a conductive thermoplastic polyurethane which fits the bill and have offered to send me samples. I'm trying to build my own very simple granule extruder so that I can experiment with the granules when they come in. This is why I've been working on a standalone head controller; it's going to start off as a plain thermal controller but later expand to a full-on head controller with the addition of a motor driver.

-------------------------------------------------------

> (Vias may still be done via plating; does

> anybody know?)

Vias are, generally, plated. For hobbyist work, there are rivets that serve a similar purpose.

Electroplating is certainly viable but, again, it eliminates the 3D aspect of the production, and introduces a need for a chemical bath. In addition, electroplating isn't exactly the most energy conservative production technique.

I think we may end up going with electroplating, but I hope not.

I've been talking to a rep at 3M about conductive plastics. They have a conductive thermoplastic polyurethane which fits the bill and have offered to send me samples. I'm trying to build my own very simple granule extruder so that I can experiment with the granules when they come in. This is why I've been working on a standalone head controller; it's going to start off as a plain thermal controller but later expand to a full-on head controller with the addition of a motor driver.

|

Re: Reprap2: Mendel circuit material January 01, 2009 10:25PM |

Registered: 15 years ago Posts: 251 |

Annirak Wrote:

-------------------------------------------------------

> I've been talking to a rep at 3M about conductive

> plastics. They have a conductive thermoplastic

> polyurethane which fits the bill and have offered

> to send me samples.

Annirak,

Can you please post the name of the specific material, and any links to its technical specs? (especially melting point, heat deflection temp, and bulk resistivity)

Thanks much,

-- Larry

-------------------------------------------------------

> I've been talking to a rep at 3M about conductive

> plastics. They have a conductive thermoplastic

> polyurethane which fits the bill and have offered

> to send me samples.

Annirak,

Can you please post the name of the specific material, and any links to its technical specs? (especially melting point, heat deflection temp, and bulk resistivity)

Thanks much,

-- Larry

|

Re: Reprap2: Mendel circuit material January 02, 2009 12:00AM |

Registered: 15 years ago Posts: 401 |

Hi Larry,

Apparently, there are no actual datasheets for 3M's conductive plastics. In fact, when I contacted them originally, the rep didn't know any more about them than I did from the website. He found me this information:

That's all I've got until I have the pellets in hand.

Brendan

Apparently, there are no actual datasheets for 3M's conductive plastics. In fact, when I contacted them originally, the rep didn't know any more about them than I did from the website. He found me this information:

Quote

- conductivity: ~1400 ohms

- softening point: 175 - 205 C

- recommended extrusion temperature: 190 - 215 C

- product dimensions: typical 1/8" pellets

- special handling information: too much shear can offset the conductive

properties; you can cool like typical pellets, does not require special

handling. You may want to pre-dry prior to extrusion (2 hours - 80 C) since this is

an aromatic polyurethane.

That's all I've got until I have the pellets in hand.

Brendan

|

Re: Reprap2: Mendel circuit material January 02, 2009 12:54AM |

Admin Registered: 17 years ago Posts: 1,915 |

How much of this stuff are they sending you?

The "conductivity" value is weird. conductivity is usually figured in siemens/meter.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

The "conductivity" value is weird. conductivity is usually figured in siemens/meter.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Reprap2: Mendel circuit material January 02, 2009 04:49AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes 1400 ohms is not a reasonable conductivity or resistivity for a conductor.

Conductivity of copper is 59.6 x 10^6 S/m and resistivity is 16.8 x 10^-9 Ohm/m. I am worried whether low melting point metals will be conductive enough but they are at least only one order of magnitude from copper.

[www.hydraraptor.blogspot.com]

Conductivity of copper is 59.6 x 10^6 S/m and resistivity is 16.8 x 10^-9 Ohm/m. I am worried whether low melting point metals will be conductive enough but they are at least only one order of magnitude from copper.

[www.hydraraptor.blogspot.com]

|

Re: Reprap2: Mendel circuit material January 02, 2009 12:12PM |

Registered: 15 years ago Posts: 401 |

|

Re: Reprap2: Mendel circuit material January 10, 2009 04:00PM |

Registered: 15 years ago Posts: 401 |

|

Re: Reprap2: Mendel circuit material January 10, 2009 05:51PM |

Admin Registered: 17 years ago Posts: 1,915 |

They're going to give you some samples though, right? Plunking down $1000 just to see if this stuff works is a bit beyond what I want to get involved with. :-s

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Reprap2: Mendel circuit material January 10, 2009 08:20PM |

Registered: 15 years ago Posts: 401 |

|

Re: Reprap2: Mendel circuit material -- conductive plastics, resistivity January 10, 2009 10:21PM |

Registered: 15 years ago Posts: 251 |

Brendan, et al,

First off, if the shipping cost is an issue, let me know and I can help out with that. (Certainly don't let shipping cost constrain the sample size -- get as much as you can!)

I did a bit of searching, and I *think* I understand the odd units given for conductivity. I think this value is a surface resistance -- the value of ohms/square, based on an unspecified (to us, at least) nominal thickness (the size of the square doesn't matter.) There are apparently a couple standards for surface resistivity (or conductivity), such as ASTM D-257 and S11.11 These are (from what I gather) generally applied to anti-static (or similarly high resistance) products, that are often used in a thin films. Some background on these test standards is in [archive.evaluationengineering.com]

Strangely (to me), neither if these test standards standardizes the thickness of the test piece, nor do they normalize the result into a bulk resistivity (or conductance), so that it can be used to calculate the resistance of a different thickness. IMHO, this isn't the best way to set up (or report) such tests.

I just measured a (silvery colored) anti-static bag, and it's 0.003 inches thick (one layer, not two.) So that's ~7.6e-5 meters. Iff this thickness is ~representitive of what was used on this (unnamed) 3-M plastic, then we'd have a bulk resistivity of 1400 ohms (per any-sized square @7.6e-5 meters thick.) Iff the material is ansiotropic (same resistive properties, independent of direction -- which is not always the case with plastics filled with conductive fibers.) Then the bulk resistivity would be ~0.1 ohm x meters or (10 ohm x cm)

Comparing this to resistivities of some metals [en.wikipedia.org] it's not very conductive, but compared to insulators, it's pretty good. (Comes in about the range for Si, Ge, (assumed undoped.)

FYI, there are some data and part numbers for some 3M conductive plastics on this link: [solutions.3m.com]

See the table near the end. The surface resistance numbers bracket the 1400 ohms you mentioned; in fact one of the materials, "Polyester Urethane 4931" has a very similar surface resistivity, 1500 ohms/square. I *wish* they'd say what thickness they used in their measurement!

However I hope the material you're getting samples of is something new and (fingers crossed) substantially more conductive.

By the way, I have some conductive fiber (nylon thread with carbon infused into the surface), and it works quite well as a strain-gage sensor, particularly for high strains (e.g. beyond what one can do with conventional strain gages.)

Please post any new info about this new(?) 3M material.

-- Larry

First off, if the shipping cost is an issue, let me know and I can help out with that. (Certainly don't let shipping cost constrain the sample size -- get as much as you can!)

I did a bit of searching, and I *think* I understand the odd units given for conductivity. I think this value is a surface resistance -- the value of ohms/square, based on an unspecified (to us, at least) nominal thickness (the size of the square doesn't matter.) There are apparently a couple standards for surface resistivity (or conductivity), such as ASTM D-257 and S11.11 These are (from what I gather) generally applied to anti-static (or similarly high resistance) products, that are often used in a thin films. Some background on these test standards is in [archive.evaluationengineering.com]

Strangely (to me), neither if these test standards standardizes the thickness of the test piece, nor do they normalize the result into a bulk resistivity (or conductance), so that it can be used to calculate the resistance of a different thickness. IMHO, this isn't the best way to set up (or report) such tests.

I just measured a (silvery colored) anti-static bag, and it's 0.003 inches thick (one layer, not two.) So that's ~7.6e-5 meters. Iff this thickness is ~representitive of what was used on this (unnamed) 3-M plastic, then we'd have a bulk resistivity of 1400 ohms (per any-sized square @7.6e-5 meters thick.) Iff the material is ansiotropic (same resistive properties, independent of direction -- which is not always the case with plastics filled with conductive fibers.) Then the bulk resistivity would be ~0.1 ohm x meters or (10 ohm x cm)

Comparing this to resistivities of some metals [en.wikipedia.org] it's not very conductive, but compared to insulators, it's pretty good. (Comes in about the range for Si, Ge, (assumed undoped.)

FYI, there are some data and part numbers for some 3M conductive plastics on this link: [solutions.3m.com]

See the table near the end. The surface resistance numbers bracket the 1400 ohms you mentioned; in fact one of the materials, "Polyester Urethane 4931" has a very similar surface resistivity, 1500 ohms/square. I *wish* they'd say what thickness they used in their measurement!

However I hope the material you're getting samples of is something new and (fingers crossed) substantially more conductive.

By the way, I have some conductive fiber (nylon thread with carbon infused into the surface), and it works quite well as a strain-gage sensor, particularly for high strains (e.g. beyond what one can do with conventional strain gages.)

Please post any new info about this new(?) 3M material.

-- Larry

|

Re: Reprap2: Mendel circuit material March 11, 2009 08:17PM |

Registered: 15 years ago Posts: 401 |

Well,

I have the 3M plastic sample in-hand. The granules are quite small. I need to get the extruder proto up and running now, but I have to move in a couple of weeks, so stuff is getting packed. Looks like I'll have to wait a little longer to try out the conductive urethane.

As a first glance, though, I took one 1/8" pellet and jabbed multi-meter probes into it. The resistance was <1k. It's on the border of what might be useable in digital circuits. I hope that goes down when I make a proper connection.

I will update as possible.

I have the 3M plastic sample in-hand. The granules are quite small. I need to get the extruder proto up and running now, but I have to move in a couple of weeks, so stuff is getting packed. Looks like I'll have to wait a little longer to try out the conductive urethane.

As a first glance, though, I took one 1/8" pellet and jabbed multi-meter probes into it. The resistance was <1k. It's on the border of what might be useable in digital circuits. I hope that goes down when I make a proper connection.

I will update as possible.

Sorry, only registered users may post in this forum.