|

Re: Making PCB's with a diodelaser March 04, 2015 02:07AM |

Registered: 9 years ago Posts: 125 |

|

Re: Making PCB's with a diodelaser March 04, 2015 04:41AM |

Admin Registered: 16 years ago Posts: 13,891 |

@Tady - your focus isn't optimal - see the width difference in X and Y ... and what's your focal distance?

Shorter distances gives better focussing and so higher energy densities.

I'm using soap, warm water and a smooth brush to remove the carbonized residues.

And my speeds with roughly 1-2Watts are around 20-50mm/s, what's between 1200 and 3000 mm/min ...

Edited 1 time(s). Last edit at 03/04/2015 04:44AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Shorter distances gives better focussing and so higher energy densities.

I'm using soap, warm water and a smooth brush to remove the carbonized residues.

And my speeds with roughly 1-2Watts are around 20-50mm/s, what's between 1200 and 3000 mm/min ...

Edited 1 time(s). Last edit at 03/04/2015 04:44AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 04, 2015 04:53AM |

Registered: 9 years ago Posts: 9 |

yes a saw the difference in widths... well i using a microscope lens for cfocusing.. i saw on the net a guy that did the same thing ... the focal distance is about 120mm (it is veryy big but that is where the sopt is the smallest). i don't have alot of experience with laser optics so i din't know witch lens to buy.... i only bought the diode (chinese to-3 package) and i made a watercooled housing and i used a lens from an microscope... it worked prefectly for engraving wood and plastics but now i want to etch PCB's and i hit a bump...

can you advise me on what focal lenses to buy?

thank you for your info!

can you advise me on what focal lenses to buy?

thank you for your info!

|

Re: Making PCB's with a diodelaser March 04, 2015 06:36AM |

Admin Registered: 16 years ago Posts: 13,891 |

... my focal distances are between 20mm and 45mm! - if bigger, then the 'spot' changes to a 'line', regardless, which optics I'll use.

Search at ebay for "445nm lens" or "collimator" - here are some samples from ebay German (found with "445nm linse"):

[www.ebay.de]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Search at ebay for "445nm lens" or "collimator" - here are some samples from ebay German (found with "445nm linse"):

[www.ebay.de]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 04, 2015 06:52AM |

Registered: 9 years ago Posts: 9 |

|

Re: Making PCB's with a diodelaser March 05, 2015 01:25AM |

Registered: 9 years ago Posts: 9 |

i got a new lens for the laser... for testing i took it out of an videocamera lense... my initial thought was that i has to have an IR filter but it seems it does not. anway i didn't have alot of time yesterday but i did a quick test... the power output seem to be higher now! it burned the paint like it was nothing ... my focus point is abou 25mm i think (didn't measure). now i need to make something to blow the fumes away so they don't stick to the lense

|

Re: Making PCB's with a diodelaser March 05, 2015 03:53AM |

Admin Registered: 16 years ago Posts: 13,891 |

... not blowing! - the fumes are toxic and carcinogenic, so you'll need an activated charcoal filter and/or exhausting the air through the next window ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 05, 2015 05:43AM |

Registered: 9 years ago Posts: 9 |

|

Re: Making PCB's with a diodelaser March 06, 2015 01:52AM |

Registered: 9 years ago Posts: 9 |

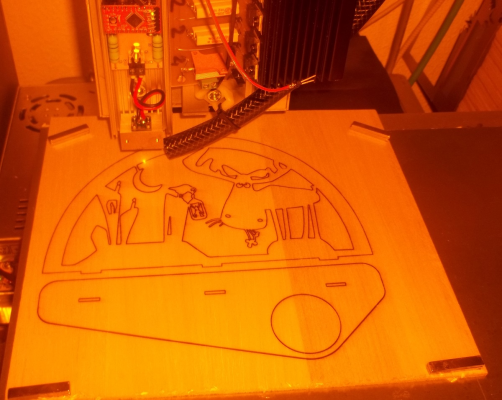

Success  The new lens works flawlessly

The new lens works flawlessly  This is a picture of a test pcb in the attachment. And i'm very happy with the results

This is a picture of a test pcb in the attachment. And i'm very happy with the results  Thank you Viktor for all of the information! The only thing now is to make an suction system for the fumes!

Thank you Viktor for all of the information! The only thing now is to make an suction system for the fumes!

Thank you!

The new lens works flawlessly

The new lens works flawlessly  This is a picture of a test pcb in the attachment. And i'm very happy with the results

This is a picture of a test pcb in the attachment. And i'm very happy with the results  Thank you Viktor for all of the information! The only thing now is to make an suction system for the fumes!

Thank you Viktor for all of the information! The only thing now is to make an suction system for the fumes!Thank you!

|

Re: Making PCB's with a diodelaser March 06, 2015 02:41AM |

Admin Registered: 16 years ago Posts: 13,891 |

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 31, 2015 11:55AM |

Registered: 9 years ago Posts: 6 |

Victor, I'am planing to create cartesio like reprap whit drill, 1W blue laser and 3d.

Idea is to make proto pcb's and cahssis for them. And found your writeings which werw

intresting.

I'am going trough all possible PCB process, try to get bought correct low power laser

at once, for best possible, GREEN process.

I have some GREEN IDEA's to test, and if you any other like to test them

before me, I'am intrested to hear results. No guaranteen those work out !

Instead of black paint you used ( assume it's acryllic ) you could try Johnsson Floor Wax

in yellow bottle, pour it to PCB and put vertical position and let extra flow away,

wax should be ready for laser printing whitin 30 minutes, then develop at acid normaly.

WAX can be removed WARM WATER !!!!

Other GREEN material that could work out nicesly is schellac, put 95% some alcohol

and 5% schellac flakes. Paint board let it dry. Laser print and let it dry. Then go foward nornaly

at acid bath. Shellac can be removed by aseton,... ext,.. Then you can put tin bath and

shellac to protect tin.

Shellac protects board and can be soldered trough. Any way shellac

has same water content tha air so dose not protect PCB:s used outside or humidity.

That I do not know is it nessesary to reamove shellac painting after acid bath or not

it should be tested separetly.

Above wild ideas are build ideas used in art's, ancient decoration of metal.

At home you try to avoid chemical's as much as possible.

Creating soldering mask for SMD components at GREEN technology is chalange,

at moment dry film sounds good but it's not enough green. Is there any protective paint

that can be burned away 1W laser,... or could sellac work as solder mask / i think fil is

too thin,... or could some normal epoxy be cured by laser and eccsess wiped off by

aseton,... not so green eighter,..

I will try these methods, ideas, when I get my RepRap done, it's in desing

phase and all ideas welcome for accurate, low budjet CNC,LASER PRINTER/CUTTER

& 3d printer. At moment cartesio is ground, merlin or teacup who knows, N23 4,5 A servos,

15mm HTB5 belt,...

yours,

[boy007.dy.fi]

Edited 1 time(s). Last edit at 03/31/2015 12:13PM by boy007.

joni

[boy007.dy.fi]

e-mail: the@boy007.dy.fi

Idea is to make proto pcb's and cahssis for them. And found your writeings which werw

intresting.

I'am going trough all possible PCB process, try to get bought correct low power laser

at once, for best possible, GREEN process.

I have some GREEN IDEA's to test, and if you any other like to test them

before me, I'am intrested to hear results. No guaranteen those work out !

Instead of black paint you used ( assume it's acryllic ) you could try Johnsson Floor Wax

in yellow bottle, pour it to PCB and put vertical position and let extra flow away,

wax should be ready for laser printing whitin 30 minutes, then develop at acid normaly.

WAX can be removed WARM WATER !!!!

Other GREEN material that could work out nicesly is schellac, put 95% some alcohol

and 5% schellac flakes. Paint board let it dry. Laser print and let it dry. Then go foward nornaly

at acid bath. Shellac can be removed by aseton,... ext,.. Then you can put tin bath and

shellac to protect tin.

Shellac protects board and can be soldered trough. Any way shellac

has same water content tha air so dose not protect PCB:s used outside or humidity.

That I do not know is it nessesary to reamove shellac painting after acid bath or not

it should be tested separetly.

Above wild ideas are build ideas used in art's, ancient decoration of metal.

At home you try to avoid chemical's as much as possible.

Creating soldering mask for SMD components at GREEN technology is chalange,

at moment dry film sounds good but it's not enough green. Is there any protective paint

that can be burned away 1W laser,... or could sellac work as solder mask / i think fil is

too thin,... or could some normal epoxy be cured by laser and eccsess wiped off by

aseton,... not so green eighter,..

I will try these methods, ideas, when I get my RepRap done, it's in desing

phase and all ideas welcome for accurate, low budjet CNC,LASER PRINTER/CUTTER

& 3d printer. At moment cartesio is ground, merlin or teacup who knows, N23 4,5 A servos,

15mm HTB5 belt,...

yours,

[boy007.dy.fi]

Edited 1 time(s). Last edit at 03/31/2015 12:13PM by boy007.

joni

[boy007.dy.fi]

e-mail: the@boy007.dy.fi

|

Re: Making PCB's with a diodelaser March 31, 2015 12:38PM |

Admin Registered: 16 years ago Posts: 13,891 |

Hi joni,

I've done much more with coating and removing it than posted here ... some of the work was under NDA's or closed for different reasons, but most for testing with different methodes with or without lasers.

Some of the tests and developments were with wax, ceramic and metallic coatings, UV-resins, different etching processes, EDM or ultrasonic 'milling' and some more nanotech-related works with potential for future developments, which I didn't want to disclosure now.

So yes, there are much more interesting and/or DIY-able methodes around, which will develop with time -- but here I'm mostly focussed on laser-etching/engraving

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I've done much more with coating and removing it than posted here ... some of the work was under NDA's or closed for different reasons, but most for testing with different methodes with or without lasers.

Some of the tests and developments were with wax, ceramic and metallic coatings, UV-resins, different etching processes, EDM or ultrasonic 'milling' and some more nanotech-related works with potential for future developments, which I didn't want to disclosure now.

So yes, there are much more interesting and/or DIY-able methodes around, which will develop with time -- but here I'm mostly focussed on laser-etching/engraving

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 31, 2015 12:48PM |

Registered: 9 years ago Posts: 6 |

|

Re: Making PCB's with a diodelaser March 31, 2015 05:25PM |

Admin Registered: 16 years ago Posts: 13,891 |

... 'normal' wax is only working with CO2-lasers for its high transparency -- VIS or NIR diodes needs material with very high absorption rates ... but you can try with high loads of graphite or dark pigments.

Black shellack would be better than wax for use with diodes, but I didn't test it until now ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Black shellack would be better than wax for use with diodes, but I didn't test it until now ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser April 11, 2015 04:49AM |

Registered: 9 years ago Posts: 6 |

hi,

What kind of laser could workout, is there idea you like me to try

while doing [reprap.org]

I'am now open to ideas and can test some of them.

One idea is that laser light is guided trough optical cable,..

What you think these laser's:

[stores.ebay.com]

or

[stores.ebay.com]

And about drill ?

[www.ebay.com]

All ideas welcome, due building new one I have possibility test totaly new structure's and system's.

What kind of laser could workout, is there idea you like me to try

while doing [reprap.org]

I'am now open to ideas and can test some of them.

One idea is that laser light is guided trough optical cable,..

What you think these laser's:

[stores.ebay.com]

or

[stores.ebay.com]

And about drill ?

[www.ebay.com]

All ideas welcome, due building new one I have possibility test totaly new structure's and system's.

|

Re: Making PCB's with a diodelaser April 11, 2015 10:47AM |

Admin Registered: 16 years ago Posts: 13,891 |

... you can start with 405nm-diodes with 300mW or more or with 445nm-diodes with 1Watt or more - the more power, the better.

Modules with more diodes and internal beam-shaping/combining to feed them through a fiber are usefull too, but 10-fold the price of single diodes!

Small high-speed mill-drills can be used too, but here you'll need precise/expensive bearings for good results, what's driving the price up to some hundred USD ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Modules with more diodes and internal beam-shaping/combining to feed them through a fiber are usefull too, but 10-fold the price of single diodes!

Small high-speed mill-drills can be used too, but here you'll need precise/expensive bearings for good results, what's driving the price up to some hundred USD ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser June 01, 2015 04:01PM |

Registered: 8 years ago Posts: 1 |

Hi,

This is very interesting topic, thank you all for sharing.

I am new in laser world. As I see in this topic, 1W or 2W laser diode is sufficient to burn the black paint, then copper will be etched with acid as normal, it is not enough powerful to etch away copper.

But my dream is to make pcb drilling and cutting machine. Can anyone guide me where to start?

I have found some CO2 cutting machine on ebay, but not sure it can cut or drill the pcb or not.

[www.ebay.com]

[www.ebay.com]

[www.ebay.com]

Any idea.

Thank you very much.

This is very interesting topic, thank you all for sharing.

I am new in laser world. As I see in this topic, 1W or 2W laser diode is sufficient to burn the black paint, then copper will be etched with acid as normal, it is not enough powerful to etch away copper.

But my dream is to make pcb drilling and cutting machine. Can anyone guide me where to start?

I have found some CO2 cutting machine on ebay, but not sure it can cut or drill the pcb or not.

[www.ebay.com]

[www.ebay.com]

[www.ebay.com]

Any idea.

Thank you very much.

|

Re: Making PCB's with a diodelaser June 01, 2015 07:17PM |

Admin Registered: 16 years ago Posts: 13,891 |

... for engraving copper you'll need a Q-switched pulsed NdYAG-laser with around 60Watts averaged power (some ten kilowatts pulsed).

The biggest problem here is to stop exactly when the copper is removed -- otherwise this excessive power will blow/explode the underlying resin and damage the traces.

When testing this in 1994, we've only engraved 90% of the copper and etched the thinned traces ... not much difference to only engraving the coating with a blue diode and etch the complete copper layer ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The biggest problem here is to stop exactly when the copper is removed -- otherwise this excessive power will blow/explode the underlying resin and damage the traces.

When testing this in 1994, we've only engraved 90% of the copper and etched the thinned traces ... not much difference to only engraving the coating with a blue diode and etch the complete copper layer ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser June 04, 2015 02:58PM |

Registered: 9 years ago Posts: 125 |

I think he wanted to cut the PCB itself with the laser.Quote

VDX

... for engraving copper you'll need a Q-switched pulsed NdYAG-laser with around 60Watts averaged power (some ten kilowatts pulsed).

The biggest problem here is to stop exactly when the copper is removed -- otherwise this excessive power will blow/explode the underlying resin and damage the traces.

When testing this in 1994, we've only engraved 90% of the copper and etched the thinned traces ... not much difference to only engraving the coating with a blue diode and etch the complete copper layer ...

|

Re: Making PCB's with a diodelaser June 04, 2015 05:25PM |

Admin Registered: 16 years ago Posts: 13,891 |

... I've understand so

Copper is one of the most 'laser-reflecting' materials and needs enormous amounts of power to get something impressed.

The base material of PCB's is another problem - here you have to deal with the translucency of the epoxy and embedded glass fibers, what's too is far away from the abilities of the smaller/weaker lasers ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Copper is one of the most 'laser-reflecting' materials and needs enormous amounts of power to get something impressed.

The base material of PCB's is another problem - here you have to deal with the translucency of the epoxy and embedded glass fibers, what's too is far away from the abilities of the smaller/weaker lasers ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser June 05, 2015 11:55AM |

Registered: 9 years ago Posts: 6 |

|

Re: Making PCB's with a diodelaser June 05, 2015 12:11PM |

Admin Registered: 16 years ago Posts: 13,891 |

... yes, my 6x445nm-diode head is meant for combining the blue diodes for up to 12 Watts @445nm and 6x or 12x 9Watt-IR-diodes for up to 100 Watt @975nm on a spot of 0.3mm ... but this is not for engraving, but an SLM-application

You can combine different visible wavelengths for better overall absorption for different coloured materials, but for better engraving/finer spots it's better to source stronger single lasers and select proper materials for this wavelength ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

You can combine different visible wavelengths for better overall absorption for different coloured materials, but for better engraving/finer spots it's better to source stronger single lasers and select proper materials for this wavelength ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser June 05, 2015 12:25PM |

Registered: 9 years ago Posts: 6 |

ok, difrent wavelenght laser should have own optics and then combineing them at object surface, that could solve optical problems whit laser and spot size?

Hardware might come too complex.

What you suggest as method to combine multiple led's together?

Have you any source for fibers to be used as laser light guide,...

Hardware might come too complex.

What you suggest as method to combine multiple led's together?

Have you any source for fibers to be used as laser light guide,...

|

Re: Making PCB's with a diodelaser June 05, 2015 05:49PM |

Admin Registered: 16 years ago Posts: 13,891 |

... you have to focus every wavelength separate - here the biggest problem is to get the spot sizes uniform and as small as possible.

When combining in a bundle or beam-array with low enough focal distances to be usefull (below 60mm FL), you'll need special optics, what's not available on the free market yet - I've used small (0.2mm to 1.5mm diameter) GRIN-lenses for IR and visible wavelengths successfully, but this are custom made optics, so count in several thousand USD only for the optical setup without the lasers

For 'overlapping' the beams you'll need wavelength- and beam-combining optical parts -- here yo can look into the laser-show market ... especially the new crap laser-scanners, sold for cheap at ebay, could be an interesting source for beam combiners or dicroic windows. But then you have to adjust the different wavelengths very precise to combine the foci on a precise spot.

I have different glass fiber types - the cheap thick ones used for light feeding/illumination, which I've found in electronic shops.

... and fine/precise ones, used for laser and medical applications, that can only be found with specific laser or medical related projects or from old scientific gears ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

When combining in a bundle or beam-array with low enough focal distances to be usefull (below 60mm FL), you'll need special optics, what's not available on the free market yet - I've used small (0.2mm to 1.5mm diameter) GRIN-lenses for IR and visible wavelengths successfully, but this are custom made optics, so count in several thousand USD only for the optical setup without the lasers

For 'overlapping' the beams you'll need wavelength- and beam-combining optical parts -- here yo can look into the laser-show market ... especially the new crap laser-scanners, sold for cheap at ebay, could be an interesting source for beam combiners or dicroic windows. But then you have to adjust the different wavelengths very precise to combine the foci on a precise spot.

I have different glass fiber types - the cheap thick ones used for light feeding/illumination, which I've found in electronic shops.

... and fine/precise ones, used for laser and medical applications, that can only be found with specific laser or medical related projects or from old scientific gears ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser September 21, 2015 10:00AM |

Registered: 9 years ago Posts: 346 |

|

Re: Making PCB's with a diodelaser September 21, 2015 10:29AM |

Admin Registered: 16 years ago Posts: 13,891 |

... my solutions were 30% / 30% -- 37% / 35% should be good too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser September 21, 2015 02:19PM |

Registered: 9 years ago Posts: 346 |

Thanks VDX!

Expensive stuff, 18€ for the HCL and 6.5€ for the H2O2, both 1L and both with delivery to the door.

Here in Brazil I can only buy 2L HCL per month and the seller registers my identity number. If I understand correctly he even registers me with the police. Also there was some extra costs for "safe delivery"...

On the other hand, if I still was living in Europe the various flavors of secret intelligence would probably have kept a record anyways

Edited 1 time(s). Last edit at 09/21/2015 02:21PM by LarsK.

Expensive stuff, 18€ for the HCL and 6.5€ for the H2O2, both 1L and both with delivery to the door.

Here in Brazil I can only buy 2L HCL per month and the seller registers my identity number. If I understand correctly he even registers me with the police. Also there was some extra costs for "safe delivery"...

On the other hand, if I still was living in Europe the various flavors of secret intelligence would probably have kept a record anyways

Edited 1 time(s). Last edit at 09/21/2015 02:21PM by LarsK.

|

Re: Making PCB's with a diodelaser September 21, 2015 06:18PM |

Admin Registered: 16 years ago Posts: 13,891 |

... yes, 'dangerous' chemicals, that can be used for terrorist actions, are under observation

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser October 12, 2015 05:59AM |

Registered: 8 years ago Posts: 19 |

Hey, mate, i know your pain of getting HCL handy.

Actually, you can avoid this by using more available chems:

Peroxyde (3% is ok) 100ml

Ordinary Salt (NaCl) 5gr

Limonic acid (30gr) or strong vinegar (4-5 spoons).

Dissolve salt in peroxyde and add vinegar.

Due to chemical interchange reaction in acid solution, Cl iones will do the job.

Unfortunatelly, the solution is degrading, you have to use it right away.

FeCl is better - you can store it, but the solution above is much cleaner at home.

Actually, you can avoid this by using more available chems:

Peroxyde (3% is ok) 100ml

Ordinary Salt (NaCl) 5gr

Limonic acid (30gr) or strong vinegar (4-5 spoons).

Dissolve salt in peroxyde and add vinegar.

Due to chemical interchange reaction in acid solution, Cl iones will do the job.

Unfortunatelly, the solution is degrading, you have to use it right away.

FeCl is better - you can store it, but the solution above is much cleaner at home.

|

Re: Making PCB's with a diodelaser January 15, 2016 06:29PM |

Admin Registered: 16 years ago Posts: 13,891 |

... the last laser-job was again not for PCB's, but cutting some "Elk-bows" out from 4mm-poplar- and 3mm-balsa-plywood

- balsa plywood cutting:

- balsa ready:

- older poplar-plywood and cardboard:

Edited 1 time(s). Last edit at 01/15/2016 06:30PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

- balsa plywood cutting:

- balsa ready:

- older poplar-plywood and cardboard:

Edited 1 time(s). Last edit at 01/15/2016 06:30PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.