Extruder Questions

Posted by Ithacacian

|

Extruder Questions April 10, 2008 10:33PM |

Registered: 16 years ago Posts: 37 |

Hello,

During the extruder exerciser test, I noticed that upon startup, the value (ostensibly room temperature) for the thermistor temperature is about 10 deg. C low. This is with the 10nF cap at C3 suggested in the wiki, using the standard RRRF thermistor. I didn't bother to go about changing the numbers for R_z or the other parameters which relate to the physical thermistor and circuit properties. I haven't done the heater profile yet, though that shouldn't make a difference on what the thermistor is reading. My question is whether playing with the cap value in the preferences, to see what value gives you a proper room temperature, is acceptable. I did this, changing it to 13nF, which gave 21 deg. C (as opposed to 11 deg. C with 10nF), about right, but now running the extruder exerciser, set to 80, it tops out at 71, jumping to 75 momentarily and back again periodically. Set to 10nF, it would top out at 62, jumping to 65 and back again. Once I get to this point, the heater LED will pulse on for about 3 seconds, stay off for 1-2 seconds, then pulse back on, apparently a maintenance routine. Increasing the set temperature any further has no effect.

Could the R_z and beta values vary by any significant amount for differing setups, assuming the same hardware? Does the resistance of the nichrome wire factor in to any of these changeable parameters? Mine's at about 8.3R at room temperature.

Even at 10nF, when the thermistor read 62, I could get it to extrude. so I don't think that's an accurate reading of the temperature, which leads me to believe its a parameter issue.

Also, when attempting to print the minimug object, it tried to print with the z=0 at the top (on McWire). What is this? Is Darwin geared to handle this differently?

On a separate note, we're ostensibly trying to build a pellet feed extruder head prototype for our design project, even though we've spent all our time trying to get the repstrap built. We read Adrian's posting about his initial findings to that end. It seemed like the main challenge was casting an effective auger to reduce heat transfer up the screw (and maybe figuring out how to use the existing motor, if you want to go that direction). I've been playing around with that with a 3/4" wood auger bit. The main difficulty stems from the fact that you can't make a two-part halving mold out of something completely rigid, as the profile of each half is not monotonic (picture the extending flutes jutting forward axially to strike a cutting edge). Plaster of paris, wax, etc. won't get the job done. Even playing around with how Adrian first did it, wrapping coil around a shaft, there's very poor resolution with most readily available casting compounds. So we've been playing around with semi-flexible compounds, which can be sort of unwound around the bit and realigned to cast. Sculptors often use expensive silicone based compounds, but we've been playing around with 100% builders silicone with various quick-drying mechanisms. Initial results show it takes some skill to get a decent cast, but I think we might be able to get it. This of course would eliminate the main impediment to an augur type bit, having to create it on a lathe.

It seemed Adrian's design was promising for many reasons and needn't be very complicated. Casting simply shaped components out of JBWELD instead of relying on printed parts also seems to be a major advantage.

Edited 1 time(s). Last edit at 04/10/2008 10:55PM by Ithacacian.

During the extruder exerciser test, I noticed that upon startup, the value (ostensibly room temperature) for the thermistor temperature is about 10 deg. C low. This is with the 10nF cap at C3 suggested in the wiki, using the standard RRRF thermistor. I didn't bother to go about changing the numbers for R_z or the other parameters which relate to the physical thermistor and circuit properties. I haven't done the heater profile yet, though that shouldn't make a difference on what the thermistor is reading. My question is whether playing with the cap value in the preferences, to see what value gives you a proper room temperature, is acceptable. I did this, changing it to 13nF, which gave 21 deg. C (as opposed to 11 deg. C with 10nF), about right, but now running the extruder exerciser, set to 80, it tops out at 71, jumping to 75 momentarily and back again periodically. Set to 10nF, it would top out at 62, jumping to 65 and back again. Once I get to this point, the heater LED will pulse on for about 3 seconds, stay off for 1-2 seconds, then pulse back on, apparently a maintenance routine. Increasing the set temperature any further has no effect.

Could the R_z and beta values vary by any significant amount for differing setups, assuming the same hardware? Does the resistance of the nichrome wire factor in to any of these changeable parameters? Mine's at about 8.3R at room temperature.

Even at 10nF, when the thermistor read 62, I could get it to extrude. so I don't think that's an accurate reading of the temperature, which leads me to believe its a parameter issue.

Also, when attempting to print the minimug object, it tried to print with the z=0 at the top (on McWire). What is this? Is Darwin geared to handle this differently?

On a separate note, we're ostensibly trying to build a pellet feed extruder head prototype for our design project, even though we've spent all our time trying to get the repstrap built. We read Adrian's posting about his initial findings to that end. It seemed like the main challenge was casting an effective auger to reduce heat transfer up the screw (and maybe figuring out how to use the existing motor, if you want to go that direction). I've been playing around with that with a 3/4" wood auger bit. The main difficulty stems from the fact that you can't make a two-part halving mold out of something completely rigid, as the profile of each half is not monotonic (picture the extending flutes jutting forward axially to strike a cutting edge). Plaster of paris, wax, etc. won't get the job done. Even playing around with how Adrian first did it, wrapping coil around a shaft, there's very poor resolution with most readily available casting compounds. So we've been playing around with semi-flexible compounds, which can be sort of unwound around the bit and realigned to cast. Sculptors often use expensive silicone based compounds, but we've been playing around with 100% builders silicone with various quick-drying mechanisms. Initial results show it takes some skill to get a decent cast, but I think we might be able to get it. This of course would eliminate the main impediment to an augur type bit, having to create it on a lathe.

It seemed Adrian's design was promising for many reasons and needn't be very complicated. Casting simply shaped components out of JBWELD instead of relying on printed parts also seems to be a major advantage.

Edited 1 time(s). Last edit at 04/10/2008 10:55PM by Ithacacian.

|

Re: Extruder Questions April 11, 2008 10:53AM |

Registered: 16 years ago Posts: 37 |

Upon further reflection, the issue with the z-axis makes sense. Darwin starts high and goes low. McWire starts low and goes high. The following post has some discussion on the matter:

[forums.reprap.org]

Zach says to plug the motor in backwards. Is this exactly how it sounds? i.e. if the harness would fit in the plug like that, just taking it out as is and reversing direction? Or are there power wires that need to stay where they are?

Thanks

Edited 1 time(s). Last edit at 04/11/2008 11:11AM by Ithacacian.

[forums.reprap.org]

Zach says to plug the motor in backwards. Is this exactly how it sounds? i.e. if the harness would fit in the plug like that, just taking it out as is and reversing direction? Or are there power wires that need to stay where they are?

Thanks

Edited 1 time(s). Last edit at 04/11/2008 11:11AM by Ithacacian.

|

Re: Extruder Questions April 11, 2008 03:15PM |

Admin Registered: 17 years ago Posts: 1,487 |

if you have the Arduino electronics, the connector will fit in backwards, no big deal. it's a keyed connector, but not as strong as to prevent you from putting it in backwards. reversing it simply reverses the direction of rotation.

if you have the PIC electronics, it should have told you to wire it up specially.

if you have the PIC electronics, it should have told you to wire it up specially.

|

Re: Extruder Questions April 13, 2008 07:43PM |

Registered: 16 years ago Posts: 37 |

Just fyi for anyone building the mcwire with pic electronics, I switched the wires doing a complete reverse (as instructed on the stepper wiring page for the pic) and its working fine. There wasn't anything special to wiring "backwards."

On a separate note, I'm still having the same problem with the thermistor temperature not reading correctly. With the correct C3, it reads 10 low at room temperature, and can't go above 65. Messing with C3 allows me to get the requisite temperature for the software to be able to print a part for CAPA, but that's really annoying and certainly an impediment to expanding into different materials. Does anyone have any idea what this could be? I've tried two separate thermistors, both had the exact same behavior. Here's the debug temperature reading, using the correct C3 of 10nF:

Java 3D WARNING : reported GLX version = 1.2

GLX version 1.3 or higher is required

The reported version number may be incorrect. There is a known

ATI driver bug in glXQueryVersion that incorrectly reports the GLX

version as 1.2 when it really is 1.3, so Java 3D will attempt to

run anyway.

DEBUG: Opening port /dev/ttyUSB0 [0.000s/-1208128939786ms]

Experimental: JNI_OnLoad called.

Stable Library

=========================================

Native lib Version = RXTX-2.1-7

Java lib Version = RXTX-2.1-7

RXTX Warning: Removing stale lock file. /var/lock/LCK..ttyUSB0

Received data packet when expecting ACK

sendMessage error - retrying

DEBUG: CAPA extruder vRefFactor set to 7 [0.543s/543ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [1.198s/655ms]

DEBUG: CAPA extruder vRefFactor set to 8 [1.198s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [1.774s/576ms]

DEBUG: CAPA extruder vRefFactor set to 9 [1.774s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [2.353s/579ms]

DEBUG: CAPA extruder vRefFactor set to 10 [2.353s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [2.922s/569ms]

DEBUG: CAPA extruder vRefFactor set to 11 [2.922s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [3.502s/580ms]

DEBUG: CAPA extruder vRefFactor set to 12 [3.502s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [4.078s/576ms]

DEBUG: CAPA extruder vRefFactor set to 13 [4.079s/1ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [4.661s/582ms]

DEBUG: CAPA extruder vRefFactor set to 14 [4.661s/0ms]

DEBUG: CAPA extruder re-ranging temperature (faster): [5.234s/573ms]

DEBUG: CAPA extruder vRefFactor set to 13 [5.234s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [5.806s/572ms]

DEBUG: CAPA extruder vRefFactor set to 14 [5.806s/0ms]

DEBUG: CAPA extruder re-ranging temperature (faster): [6.381s/575ms]

DEBUG: CAPA extruder vRefFactor set to 13 [6.381s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [6.958s/577ms]

DEBUG: CAPA extruder vRefFactor set to 14 [6.958s/0ms]

DEBUG: CAPA extruder current temp 8.864886064942482 [7.531s/573ms]

DEBUG: CAPA extruder current temp 8.864886064942482 [17.668s/10137ms]

DEBUG: CAPA extruder temperature set to 0.0C, which is not the standard temperature (110.0C). [18.765s/1097ms]

DEBUG: CAPA extruder heater set to 52/59 limit 4/3 [23.069s/4304ms]

DEBUG: CAPA extruder re-ranging temperature (faster): [27.827s/4758ms]

DEBUG: CAPA extruder vRefFactor set to 13 [27.827s/0ms]

DEBUG: CAPA extruder heater set to 52/59 limit 2/1 [27.872s/45ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [28.426s/554ms]

DEBUG: CAPA extruder vRefFactor set to 14 [28.426s/0ms]

DEBUG: CAPA extruder heater set to 52/59 limit 4/3 [28.473s/47ms]

DEBUG: CAPA extruder current temp 10.774553376596828 [29.029s/556ms]

DEBUG: CAPA extruder current temp 14.428999476252727 [39.178s/10149ms]

DEBUG: CAPA extruder current temp 18.55466270270722 [49.327s/10149ms]

DEBUG: CAPA extruder current temp 22.096190244627962 [59.470s/10143ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [69.619s/10149ms]

DEBUG: CAPA extruder vRefFactor set to 15 [69.619s/0ms]

DEBUG: CAPA extruder heater set to 52/59 limit 5/3 [69.667s/48ms]

DEBUG: CAPA extruder current temp 26.333148883345984 [70.223s/556ms]

DEBUG: CAPA extruder current temp 29.56486298400489 [80.363s/10140ms]

DEBUG: CAPA extruder current temp 32.76194777422677 [90.511s/10148ms]

DEBUG: CAPA extruder current temp 36.47928651470983 [100.649s/10138ms]

DEBUG: CAPA extruder current temp 40.10405516305332 [110.791s/10142ms]

DEBUG: CAPA extruder current temp 43.46085934584477 [120.949s/10158ms]

DEBUG: CAPA extruder current temp 46.3220803110018 [131.105s/10156ms]

DEBUG: CAPA extruder current temp 48.431687961497516 [141.250s/10145ms]

DEBUG: CAPA extruder current temp 51.97034898271454 [151.391s/10141ms]

DEBUG: CAPA extruder current temp 53.26823635535561 [161.532s/10141ms]

DEBUG: CAPA extruder current temp 56.07753561685803 [171.670s/10138ms]

DEBUG: CAPA extruder current temp 60.94988790205514 [181.816s/10146ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [191.957s/10141ms]

DEBUG: CAPA extruder current temp 66.90213026302501 [202.093s/10136ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [212.227s/10134ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [222.362s/10135ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [232.497s/10135ms]

DEBUG: CAPA extruder current temp 66.90213026302501 [242.631s/10134ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [252.766s/10135ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [262.906s/10140ms]

DEBUG: CAPA extruder current temp 66.90213026302501 [273.061s/10155ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [283.197s/10136ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [293.353s/10156ms]

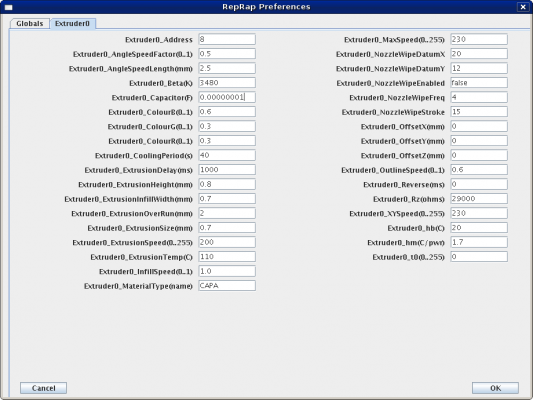

Changing C3 to match room temperature (instead of the 9 deg. C it was reading with C3 = 10nF), results in a higher temperature limit, but the same behavior. I have attached a screenshot of my extruder preferences and a picture of my board. Thanks for any help anyone can provide.

On a separate note, I'm still having the same problem with the thermistor temperature not reading correctly. With the correct C3, it reads 10 low at room temperature, and can't go above 65. Messing with C3 allows me to get the requisite temperature for the software to be able to print a part for CAPA, but that's really annoying and certainly an impediment to expanding into different materials. Does anyone have any idea what this could be? I've tried two separate thermistors, both had the exact same behavior. Here's the debug temperature reading, using the correct C3 of 10nF:

Java 3D WARNING : reported GLX version = 1.2

GLX version 1.3 or higher is required

The reported version number may be incorrect. There is a known

ATI driver bug in glXQueryVersion that incorrectly reports the GLX

version as 1.2 when it really is 1.3, so Java 3D will attempt to

run anyway.

DEBUG: Opening port /dev/ttyUSB0 [0.000s/-1208128939786ms]

Experimental: JNI_OnLoad called.

Stable Library

=========================================

Native lib Version = RXTX-2.1-7

Java lib Version = RXTX-2.1-7

RXTX Warning: Removing stale lock file. /var/lock/LCK..ttyUSB0

Received data packet when expecting ACK

sendMessage error - retrying

DEBUG: CAPA extruder vRefFactor set to 7 [0.543s/543ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [1.198s/655ms]

DEBUG: CAPA extruder vRefFactor set to 8 [1.198s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [1.774s/576ms]

DEBUG: CAPA extruder vRefFactor set to 9 [1.774s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [2.353s/579ms]

DEBUG: CAPA extruder vRefFactor set to 10 [2.353s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [2.922s/569ms]

DEBUG: CAPA extruder vRefFactor set to 11 [2.922s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [3.502s/580ms]

DEBUG: CAPA extruder vRefFactor set to 12 [3.502s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [4.078s/576ms]

DEBUG: CAPA extruder vRefFactor set to 13 [4.079s/1ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [4.661s/582ms]

DEBUG: CAPA extruder vRefFactor set to 14 [4.661s/0ms]

DEBUG: CAPA extruder re-ranging temperature (faster): [5.234s/573ms]

DEBUG: CAPA extruder vRefFactor set to 13 [5.234s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [5.806s/572ms]

DEBUG: CAPA extruder vRefFactor set to 14 [5.806s/0ms]

DEBUG: CAPA extruder re-ranging temperature (faster): [6.381s/575ms]

DEBUG: CAPA extruder vRefFactor set to 13 [6.381s/0ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [6.958s/577ms]

DEBUG: CAPA extruder vRefFactor set to 14 [6.958s/0ms]

DEBUG: CAPA extruder current temp 8.864886064942482 [7.531s/573ms]

DEBUG: CAPA extruder current temp 8.864886064942482 [17.668s/10137ms]

DEBUG: CAPA extruder temperature set to 0.0C, which is not the standard temperature (110.0C). [18.765s/1097ms]

DEBUG: CAPA extruder heater set to 52/59 limit 4/3 [23.069s/4304ms]

DEBUG: CAPA extruder re-ranging temperature (faster): [27.827s/4758ms]

DEBUG: CAPA extruder vRefFactor set to 13 [27.827s/0ms]

DEBUG: CAPA extruder heater set to 52/59 limit 2/1 [27.872s/45ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [28.426s/554ms]

DEBUG: CAPA extruder vRefFactor set to 14 [28.426s/0ms]

DEBUG: CAPA extruder heater set to 52/59 limit 4/3 [28.473s/47ms]

DEBUG: CAPA extruder current temp 10.774553376596828 [29.029s/556ms]

DEBUG: CAPA extruder current temp 14.428999476252727 [39.178s/10149ms]

DEBUG: CAPA extruder current temp 18.55466270270722 [49.327s/10149ms]

DEBUG: CAPA extruder current temp 22.096190244627962 [59.470s/10143ms]

DEBUG: CAPA extruder re-ranging temperature (slower): [69.619s/10149ms]

DEBUG: CAPA extruder vRefFactor set to 15 [69.619s/0ms]

DEBUG: CAPA extruder heater set to 52/59 limit 5/3 [69.667s/48ms]

DEBUG: CAPA extruder current temp 26.333148883345984 [70.223s/556ms]

DEBUG: CAPA extruder current temp 29.56486298400489 [80.363s/10140ms]

DEBUG: CAPA extruder current temp 32.76194777422677 [90.511s/10148ms]

DEBUG: CAPA extruder current temp 36.47928651470983 [100.649s/10138ms]

DEBUG: CAPA extruder current temp 40.10405516305332 [110.791s/10142ms]

DEBUG: CAPA extruder current temp 43.46085934584477 [120.949s/10158ms]

DEBUG: CAPA extruder current temp 46.3220803110018 [131.105s/10156ms]

DEBUG: CAPA extruder current temp 48.431687961497516 [141.250s/10145ms]

DEBUG: CAPA extruder current temp 51.97034898271454 [151.391s/10141ms]

DEBUG: CAPA extruder current temp 53.26823635535561 [161.532s/10141ms]

DEBUG: CAPA extruder current temp 56.07753561685803 [171.670s/10138ms]

DEBUG: CAPA extruder current temp 60.94988790205514 [181.816s/10146ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [191.957s/10141ms]

DEBUG: CAPA extruder current temp 66.90213026302501 [202.093s/10136ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [212.227s/10134ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [222.362s/10135ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [232.497s/10135ms]

DEBUG: CAPA extruder current temp 66.90213026302501 [242.631s/10134ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [252.766s/10135ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [262.906s/10140ms]

DEBUG: CAPA extruder current temp 66.90213026302501 [273.061s/10155ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [283.197s/10136ms]

DEBUG: CAPA extruder current temp 62.793388799193906 [293.353s/10156ms]

Changing C3 to match room temperature (instead of the 9 deg. C it was reading with C3 = 10nF), results in a higher temperature limit, but the same behavior. I have attached a screenshot of my extruder preferences and a picture of my board. Thanks for any help anyone can provide.

|

Re: Extruder Questions April 14, 2008 10:31AM |

Registered: 16 years ago Posts: 622 |

|

Re: Extruder Questions April 14, 2008 10:48AM |

Registered: 16 years ago Posts: 37 |

Do you have a mouser part# for the thermistor you ordered, Demented? I saw your post here:

[forums.reprap.org]

Also, did you go about calculating new R_z, beta, etc. or did you use the values calculated by someone else? Either way, do you have them for reference? Thanks,

[forums.reprap.org]

Also, did you go about calculating new R_z, beta, etc. or did you use the values calculated by someone else? Either way, do you have them for reference? Thanks,

|

Re: Extruder Questions April 15, 2008 01:20PM |

Registered: 16 years ago Posts: 622 |

I believe the mouser part number is

527-DKF104N5

I'm not completely sure but it shouldn't matter too much.

Steve used this thermistor from digi-key

615-1020-ND

I used the Rz and Beta values:

Rz: 337254

Beta: 3960

Steve ended up using similar values. I've played around with my rz and beta values and they didn't make as huge a difference as you would think as long as you stay in the same order of magnitude. Just get it ball-park and that should give you something to work with.

Demented

527-DKF104N5

I'm not completely sure but it shouldn't matter too much.

Steve used this thermistor from digi-key

615-1020-ND

I used the Rz and Beta values:

Rz: 337254

Beta: 3960

Steve ended up using similar values. I've played around with my rz and beta values and they didn't make as huge a difference as you would think as long as you stay in the same order of magnitude. Just get it ball-park and that should give you something to work with.

Demented

|

Re: Extruder Questions April 15, 2008 02:26PM |

Registered: 16 years ago Posts: 447 |

Yeah, the DigiKey thermistors are inexpensive but they're also 5% tolerance. You can't use the spec'd beta and Rz values as-read. Each one is slightly off spec, so you'd need to go through the whole measurement process for each.

I ended up buying 5 of them, calculating their individual beta and Rz values, and taping them to scraps of paper with the values scribbled on them. Still, at $0.80 a piece, it was worth the trouble.

I ended up buying 5 of them, calculating their individual beta and Rz values, and taping them to scraps of paper with the values scribbled on them. Still, at $0.80 a piece, it was worth the trouble.

Sorry, only registered users may post in this forum.