Sintron All metal hotend - Mechanics mirror-inverted ?!

Posted by ianmcmill

|

Sintron All metal hotend - Mechanics mirror-inverted ?! July 31, 2015 11:27AM |

Registered: 10 years ago Posts: 153 |

Hello Community,

I have ordered an All-Metal-Extruder : [www.ebay.com]

As I have realized the same extruder goes for less then 50€ what I have paid. But this only as a side-note.

When it arrived part of the fan was broken out and one cable came loose. The vendor is very attentive and send a replace fan. So no big deal either.

But when I wanted to install the extruder some strange feeling did overcome me...

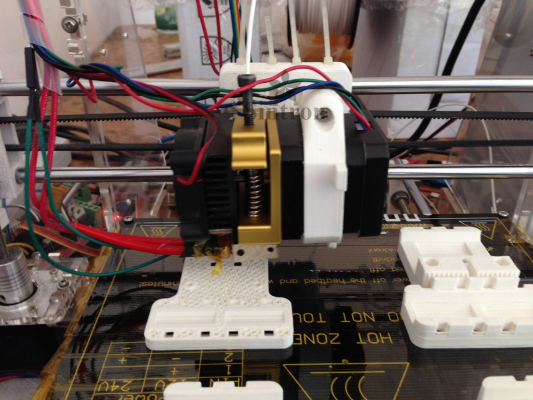

On all pictures from the vendor's ebay page the extruder is oriented as follows:

Vendor picture

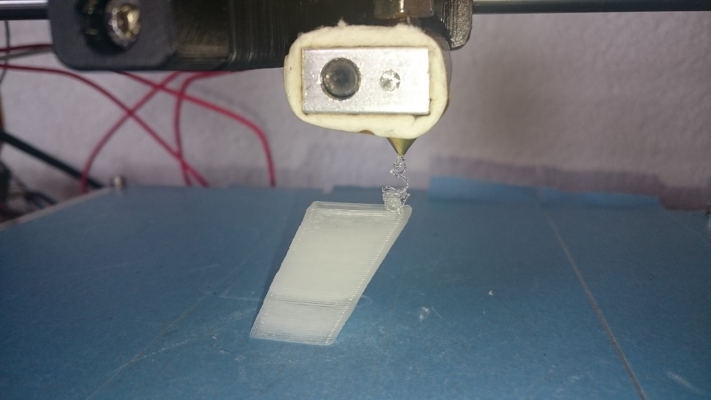

Whereas on the extruder I did receive the mechanics are mirror-inverted like this. I already attached it to my Prusa i3:

In this picture I already flipped it around so I have access to the notch to push down for inserting the filament.

Extruder I received:

I had to flip it around because of said 'notch' to be in front. If I would attach the extruder like in the vendor's picture the notch would face back. Due to the mount on the X-carriage the notch cannot be pushed down.

I am using this mount: [www.thingiverse.com]

Problem:

This all would be no big deal if the Prusa i3 was not designed as it is. The result from the flipped extruder is that the nozzle is further in the back. The distance it is positioned to the back is the distance I now miss on my print bed e.g. print area.

My print area is now reduced by about 1.5-2 cm.

Am I blind or studid? Am I doing it wrong? Any ideas??

Did they just clone the extruder from pictures on the internet (which were accidently mirrored)? Or what is the intention of an mirrored all metal extruder? Maybe the also sell mirrored Prusas??

Edited 1 time(s). Last edit at 08/01/2015 07:48AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

I have ordered an All-Metal-Extruder : [www.ebay.com]

As I have realized the same extruder goes for less then 50€ what I have paid. But this only as a side-note.

When it arrived part of the fan was broken out and one cable came loose. The vendor is very attentive and send a replace fan. So no big deal either.

But when I wanted to install the extruder some strange feeling did overcome me...

On all pictures from the vendor's ebay page the extruder is oriented as follows:

Vendor picture

Whereas on the extruder I did receive the mechanics are mirror-inverted like this. I already attached it to my Prusa i3:

In this picture I already flipped it around so I have access to the notch to push down for inserting the filament.

Extruder I received:

I had to flip it around because of said 'notch' to be in front. If I would attach the extruder like in the vendor's picture the notch would face back. Due to the mount on the X-carriage the notch cannot be pushed down.

I am using this mount: [www.thingiverse.com]

Problem:

This all would be no big deal if the Prusa i3 was not designed as it is. The result from the flipped extruder is that the nozzle is further in the back. The distance it is positioned to the back is the distance I now miss on my print bed e.g. print area.

My print area is now reduced by about 1.5-2 cm.

Am I blind or studid? Am I doing it wrong? Any ideas??

Did they just clone the extruder from pictures on the internet (which were accidently mirrored)? Or what is the intention of an mirrored all metal extruder? Maybe the also sell mirrored Prusas??

Edited 1 time(s). Last edit at 08/01/2015 07:48AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: All metal hotend - Mechanics mirror-inverted ?! July 31, 2015 01:32PM |

Registered: 10 years ago Posts: 153 |

First print failed. Need to adjust retraction and cooling.

Edited 2 time(s). Last edit at 07/31/2015 02:07PM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: All metal hotend - Mechanics mirror-inverted ?! July 31, 2015 06:51PM |

Registered: 10 years ago Posts: 814 |

|

Re: All metal hotend - Mechanics mirror-inverted ?! August 01, 2015 03:19AM |

Registered: 8 years ago Posts: 5,232 |

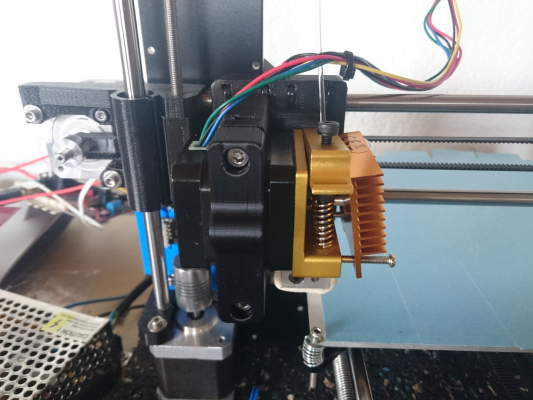

It looks like the Sintron extruder? I also used it and turned it around, like you did.

I placed the endstop for the y-axis in the front as min. endstop.

Also placed the x-endstop to the left as max. endstop.

I have no problem with adjusting the home position and the print results were excellent. ( compared to my new dual e3d-clones )

-Olaf

I placed the endstop for the y-axis in the front as min. endstop.

Also placed the x-endstop to the left as max. endstop.

I have no problem with adjusting the home position and the print results were excellent. ( compared to my new dual e3d-clones )

-Olaf

|

Re: All metal hotend - Mechanics mirror-inverted ?! August 01, 2015 03:47AM |

Registered: 10 years ago Posts: 153 |

Yes it's from Sinton. Dual extruding. Now I get it. I don't have endstops installed.

O Lampe, what settings do you have for retraction? Before I used a geared Wade extruder and those settings clearly do not fit. It oozes alot and sometimes because of this the threaded hotend runs empty and air is being extruded.

Nevertheless, when it prints, the results are okay. My setup before was a cloned e3d v6 and I don't see any differences in print quality.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

O Lampe, what settings do you have for retraction? Before I used a geared Wade extruder and those settings clearly do not fit. It oozes alot and sometimes because of this the threaded hotend runs empty and air is being extruded.

Nevertheless, when it prints, the results are okay. My setup before was a cloned e3d v6 and I don't see any differences in print quality.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: All metal hotend - Mechanics mirror-inverted ?! August 01, 2015 03:53AM |

Registered: 10 years ago Posts: 153 |

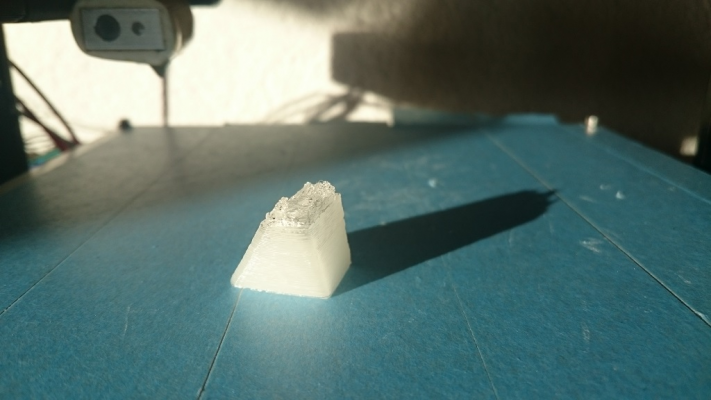

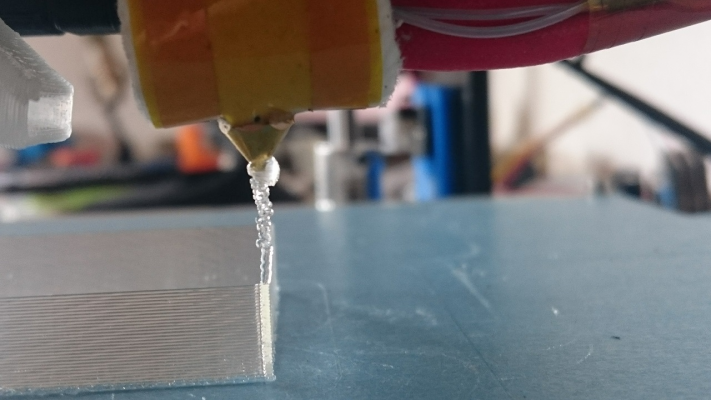

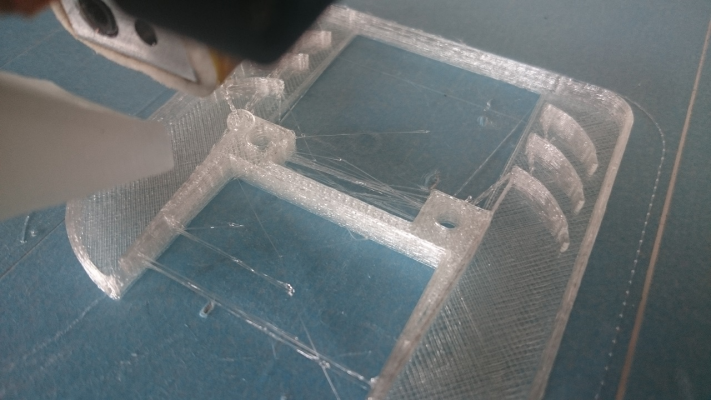

I had forgotten to set the z axis to 0 and this failed print came out. The nozzle started to print 10mm above the print bed. As of yet, this is my best fail print...

Edited 1 time(s). Last edit at 08/01/2015 03:54AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

Edited 1 time(s). Last edit at 08/01/2015 03:54AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Oozing after finished print August 01, 2015 05:17AM |

Registered: 10 years ago Posts: 153 |

I have now set retraction to 2mm at a speed of 40mm/s. Looks better as far as you can say this after one print.

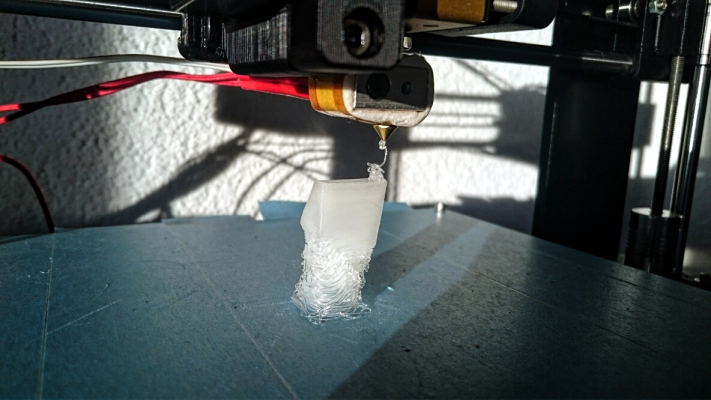

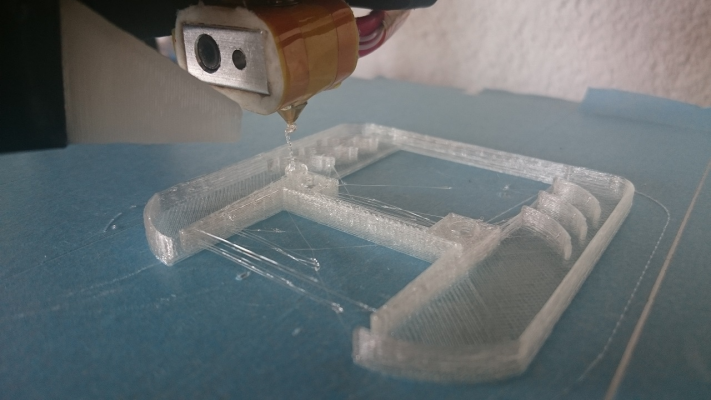

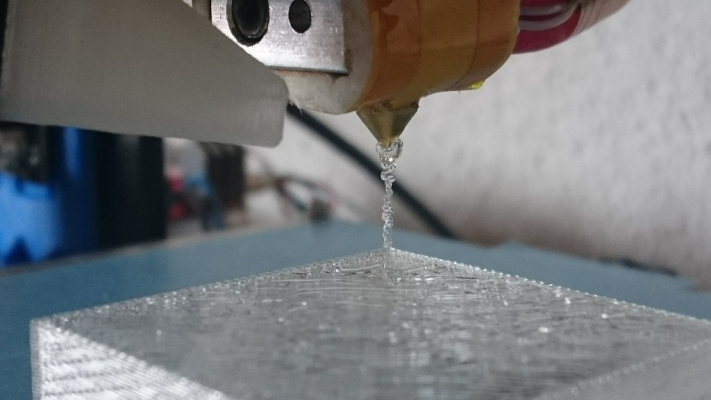

Still, when the print finishes the hotend oozes out alot like shown in this picture

I haven't had this issue with my E3D V6 clone on a Wades extruder. Any ideas?

Edited 1 time(s). Last edit at 08/01/2015 06:41AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

Still, when the print finishes the hotend oozes out alot like shown in this picture

I haven't had this issue with my E3D V6 clone on a Wades extruder. Any ideas?

Edited 1 time(s). Last edit at 08/01/2015 06:41AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: Sintron All metal hotend - Mechanics mirror-inverted ?! August 01, 2015 08:36AM |

Registered: 10 years ago Posts: 153 |

More pictures of oozing and now also with stringing. YAY. I am getting there.

Retraction settings in Slic3r.

Distance = 2mm

Speed = 40mm/s

Travel speed 80mm/s

Print temperature= 200°C in the beginning. Then set it down to 193°C.

Print interrupted because of Communication Timeout.

Board = Teensylu v0.8 - I wonder if this piece is starting to die. Would have been a wonder if cheap stuff from overseas work for over 2 years.

If I only had stuck to my former E3D V6 geared Wade extruder.

Never change a running system!

I'm starting to regret buying this piece of overpriced metal.

Edited 2 time(s). Last edit at 08/01/2015 08:39AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

Retraction settings in Slic3r.

Distance = 2mm

Speed = 40mm/s

Travel speed 80mm/s

Print temperature= 200°C in the beginning. Then set it down to 193°C.

Print interrupted because of Communication Timeout.

Board = Teensylu v0.8 - I wonder if this piece is starting to die. Would have been a wonder if cheap stuff from overseas work for over 2 years.

If I only had stuck to my former E3D V6 geared Wade extruder.

Never change a running system!

I'm starting to regret buying this piece of overpriced metal.

Edited 2 time(s). Last edit at 08/01/2015 08:39AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: Sintron All metal hotend - Mechanics mirror-inverted ?! August 01, 2015 09:36AM |

Registered: 10 years ago Posts: 153 |

Okay. I will fall back to my good old DIY wade extruder. Also it is bigger then the Sintron extruder I have a bigger print area and prints come out in higher quality.

I'll disassemble this MK8 extruder. The motor and the mk8 pulley should find another use. 50€ for a stepper and a mk8 pulley is quite the deal. Lesson learned.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

I'll disassemble this MK8 extruder. The motor and the mk8 pulley should find another use. 50€ for a stepper and a mk8 pulley is quite the deal. Lesson learned.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: All metal hotend - Mechanics mirror-inverted ?! August 01, 2015 12:47PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: All metal hotend - Mechanics mirror-inverted ?! August 03, 2015 02:53PM |

Registered: 10 years ago Posts: 153 |

Of couse I tried different retraction settings. I asked the vendor himself and he stated that they print with 2mm @ 35mm/s. I have turned it up to 40mm/s and haven't seen any improvements. I still haven't disassembled the extruder. 80mm/s is something I wouldn't have gone by myself. But I am always open to suggestions. Did some research on the interwebs and haven't found *any* information whatsoever. I am really glad you came up with your settings. Will try them tomorrow and report back.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: All metal hotend - Mechanics mirror-inverted ?! August 04, 2015 05:11AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Sintron All metal hotend - Mechanics mirror-inverted ?! August 04, 2015 05:33AM |

Registered: 10 years ago Posts: 153 |

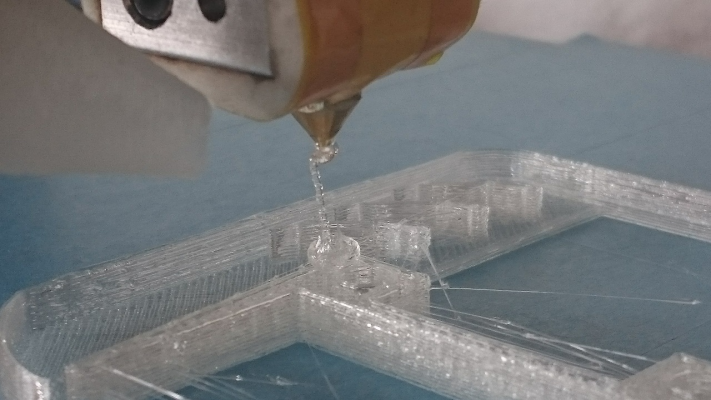

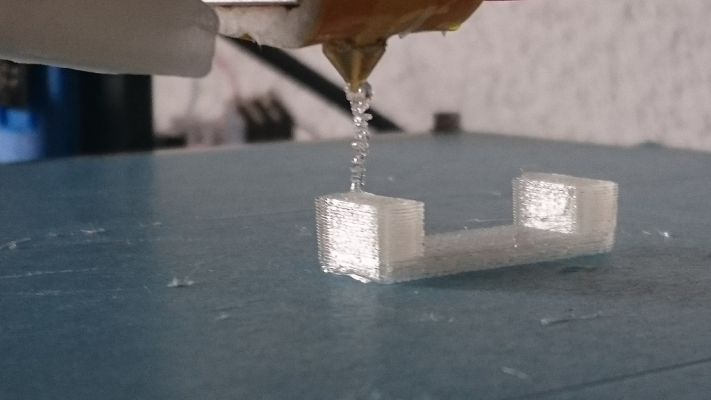

So these prints were printed with a retraction setting of 4.5mm @ 80mm/s.

In the end of the print you can clearly see that retraction settings doesn't deal with the heavy oozing. This excessive oozing might result from the preasure built up inside the hotend and as there are no retraction commands once the print is finished or as there is no PTFE inliner inside the hotend, the (PLA) plastic melts and just drips out.

A side effect of this oozing is that the hotend runs nearly empty after a print. When a new print is started it first needs to push enough plastic inside the hotend. This could be compenstated with "Extra length on restart" inside Slic3r. Comment from the developers "This setting is barely needed".

This part is oozebane-test.stl from the essential calibration set at [www.thingiverse.com]

The oozing is acceptable. Only very fine strings occur occasionally but as described above, heavy dripping once print is finished. The first layer didn't print well. Some parts of the perimeter were missing because of missing plastic inside the hotend as described above. Therefore it looks jagged.

I have had several hotends and extruders so far.

I started with a Anubis hotend on a QU-BD TwoUp. (Derivate of Ubis hotend). Took some time to heat up but printed okay. No oozing. Direct drive.

2nd was a Merlin Hotend. Nice clean surfaces. Needs extra cooling around the hotend's thread. Very delicate. Only for experienced user, which I was not at that point.

3rd was a E3D v6 clone from China. Greg's geared wade extruder. No oozing. No dripping. The heatsink needs cooling or it might happen that the filament melts to early and blocks the hotend. It came without PTFE inliner which often caused the hotend to block when printing PLA. Replaced the stock thread with a thread featuring a PTFE inliner and the blocking was gone. Very nice print results with 0.4mm nozzle. My most favourable hotend/extruder by now.

4th is the MK8 direct drive.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

In the end of the print you can clearly see that retraction settings doesn't deal with the heavy oozing. This excessive oozing might result from the preasure built up inside the hotend and as there are no retraction commands once the print is finished or as there is no PTFE inliner inside the hotend, the (PLA) plastic melts and just drips out.

A side effect of this oozing is that the hotend runs nearly empty after a print. When a new print is started it first needs to push enough plastic inside the hotend. This could be compenstated with "Extra length on restart" inside Slic3r. Comment from the developers "This setting is barely needed".

This part is oozebane-test.stl from the essential calibration set at [www.thingiverse.com]

The oozing is acceptable. Only very fine strings occur occasionally but as described above, heavy dripping once print is finished. The first layer didn't print well. Some parts of the perimeter were missing because of missing plastic inside the hotend as described above. Therefore it looks jagged.

I have had several hotends and extruders so far.

I started with a Anubis hotend on a QU-BD TwoUp. (Derivate of Ubis hotend). Took some time to heat up but printed okay. No oozing. Direct drive.

2nd was a Merlin Hotend. Nice clean surfaces. Needs extra cooling around the hotend's thread. Very delicate. Only for experienced user, which I was not at that point.

3rd was a E3D v6 clone from China. Greg's geared wade extruder. No oozing. No dripping. The heatsink needs cooling or it might happen that the filament melts to early and blocks the hotend. It came without PTFE inliner which often caused the hotend to block when printing PLA. Replaced the stock thread with a thread featuring a PTFE inliner and the blocking was gone. Very nice print results with 0.4mm nozzle. My most favourable hotend/extruder by now.

4th is the MK8 direct drive.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

Sorry, only registered users may post in this forum.