My Mendel build.

Posted by Circuits

|

My Mendel build. June 08, 2012 02:37AM |

Registered: 11 years ago Posts: 20 |

I ordered one of the RepRapPro Mendel kits back in April, and have been eagerly awaiting its arrival.

It got here Tuesday, 5/29, and I've been working most evenings on putting it together since.

Build Day 1: Spent about five hours total, and got to end of assembling the basic box frame - the two triangles and the six crossbars. Kit arrived, and I took about an hour looking over the pieces and reading through the mendel building wiki article, and assembling my tools and building supplies. I then assembled the main frame parts while sitting in front of the TV, and ended up with a complete, but not particularly square, true or plumb frame.

Build Day 2: Spent close to 5 hours after dinner tweaking the frame, and clearing and setting up a new working area. After a couple hours I had the frame parts where I thought I wanted them, and started assembling the y-axis parts. I got the frog assembled after several false starts, and disassemble/reassemble steps, mounted the y-axis smooth rods, and installed the y-axis frog to them. NOT SQUARE! It was getting late, so I'll get back to it another day.

Build Day 3: 8 hours total, took two days of not fiddling with it, then came back to it on a saturday. Tweaked the frame again, and adjusted the y-axis smooth rods, but still not getting it square to the rest of the frame, although the y-axis smooth rods are true and parallel, and the frog moves smoothly. I ignore that for the moment, and go back to finishing the y-axis assembly build. When I went to install the y-axis belt, I realized I'd mirror-imaged the motor mount washers and bearing assembly. Apart came everything again. I reamed the smooth rod holders to make adjusting them easier and more precise. I disassemble the y-axis and ream all the holes to make assembling the y-axis motor mount easier. What the heck, I disassemble the frame back to the triangles and crossbars, correct the y-axis motor mount bearing assembly and washers, and reassemble everything. STILL NOT SQUARE! GRRR! I've got the y-axis belt, y-axis motor mount and idler, y-axis smooth rods and y-axis frog assembly completed and installed, but I'm not happy with the layout yet.

Build Day 4: 4 hours total. Started assembling the x-axis. Took several tries, disassembles/reassembles to get things correctly oriented from the available pictures on the wiki. I ended up going through reaming holes to get everything to go together smoothly. The hex-head recesses on my printed parts are WAY too small, so I end up having to heat up one bolt head to melt-form the hex head recesses properly before completing that part of the assembly. Installed the x-axis motor, and smooth rods (after reaming). Did some back and forth tests and measurements, and ended up relaxing everything back to the triangle/frame assembly, then moving forward trueing up each part and axis as I go, with the y- and x-axis smooth rods and frog/assemblies installed. Things come out nice and square and true and parallel. The y-axis frog and rods align properly to the frame, and the x-axis is smooth and perpendicular to the y-axis.

Went ahead and installed the z-axis motors and smooth rods, but not happy with their fit yet - I'm getting used to this dance by now.

Build Day 5: 5 hours total - didn't work on it yesterday, so this is Tuesday 6/5. Assembled and installed the z-axis assembly and other parts, then fitted it to the z-axis smooth rods. I've managed to lose a few M3 washers and nuts, and stripped an M3x30 socket-head screw during the previous work, and having installed all the optional accessory M8 nut/washer pairs on the top cross rods, I find myself short a few parts for final assembly. I go to the hardware store for some spares, and to pick up contact cement to finish the x-axis heat shield. With the x-axis installed to the x-axis smooth rods, I go ahead and relax everything down to the triangles again. Working forward, trueing each part and axis, Y to X, I finally get the y-frog true, the x-axis traversing smoothly, but not happy with the z-axis yet. I call it an evening.

Build Day 6: 6 hours total. Ended up doing the relax and reassemble dance on the entire frame again to get the x-axis installed to both the x-axis and z-axis smooth rods, and perpendicular, and true and parallel. Come up with some assembly aids by attaching clamps to some metal bar and rod scraps to give me quick-check gap gauges for each dimension. Back to loose, then trueing up y to x to z axes, I finally get all the movable parts apparently moving smoothly, true to the frame, and mutually perpendicular, etc. I hook up the flexible z-axis motor couplings, and level the x-axis assembly on its z-axis.

I start on the heated bed assembly. Several false starts and disassemble/reassemble cycles on the heated bed get the plate, pcb and aluminum heat spreader assembled to my satisfaction. Now the problems crop up. I was looking for a color-coded 1k resistor, and didn't find one, so I presumed it was lost and went to find one from my various electronics parts bags. Got one, got the LED and 1k resistor installed. I move on and prepare the 2-conductor ribbon from the 10-coductor ribbon provided in the kit. I test what i thought was the 10k thermistor, and find out it's a 100k thermistor. I test what I thought was the 100k thermistor, and find out it's the plain-packaged grey 1k resistor I presumed was missing. Oh! there it is - hair fine wires and all.

I proceed to make the temp probe from the two-conductor ribbon and the 10k thermistor, and manage to screw it up. My lengths are uneven, and I'll never get the glass bead down in the pcb hole to touch the heat spreader. As I desolder and remove the the heatshrink to trim things up, I manage to break off one of those hair-fine leads right up at the glass bead. I go order a replacement on amazon, and call it a night.

Build Day 7: (earlier tonight). Worked about 3 hours on it. I'll be waiting a while on the thermistor, so I proceed to assemble some other stuff. I finish up the power leads for the heated bed and find that the heatshrink provided won't fit over the power wires. Off I go to radio shack for some more heatshrink (no, they don't have a glass bead 10k thermistor...). I finish the power connections, then assemble the extruder motor and idler assemblies. Done for the evenng.

Just waiting on the thermistor now to complete the heat bed assembly and install it. Then I can get down to more wiring and testing, and actually lighting this thing up.

It got here Tuesday, 5/29, and I've been working most evenings on putting it together since.

Build Day 1: Spent about five hours total, and got to end of assembling the basic box frame - the two triangles and the six crossbars. Kit arrived, and I took about an hour looking over the pieces and reading through the mendel building wiki article, and assembling my tools and building supplies. I then assembled the main frame parts while sitting in front of the TV, and ended up with a complete, but not particularly square, true or plumb frame.

Build Day 2: Spent close to 5 hours after dinner tweaking the frame, and clearing and setting up a new working area. After a couple hours I had the frame parts where I thought I wanted them, and started assembling the y-axis parts. I got the frog assembled after several false starts, and disassemble/reassemble steps, mounted the y-axis smooth rods, and installed the y-axis frog to them. NOT SQUARE! It was getting late, so I'll get back to it another day.

Build Day 3: 8 hours total, took two days of not fiddling with it, then came back to it on a saturday. Tweaked the frame again, and adjusted the y-axis smooth rods, but still not getting it square to the rest of the frame, although the y-axis smooth rods are true and parallel, and the frog moves smoothly. I ignore that for the moment, and go back to finishing the y-axis assembly build. When I went to install the y-axis belt, I realized I'd mirror-imaged the motor mount washers and bearing assembly. Apart came everything again. I reamed the smooth rod holders to make adjusting them easier and more precise. I disassemble the y-axis and ream all the holes to make assembling the y-axis motor mount easier. What the heck, I disassemble the frame back to the triangles and crossbars, correct the y-axis motor mount bearing assembly and washers, and reassemble everything. STILL NOT SQUARE! GRRR! I've got the y-axis belt, y-axis motor mount and idler, y-axis smooth rods and y-axis frog assembly completed and installed, but I'm not happy with the layout yet.

Build Day 4: 4 hours total. Started assembling the x-axis. Took several tries, disassembles/reassembles to get things correctly oriented from the available pictures on the wiki. I ended up going through reaming holes to get everything to go together smoothly. The hex-head recesses on my printed parts are WAY too small, so I end up having to heat up one bolt head to melt-form the hex head recesses properly before completing that part of the assembly. Installed the x-axis motor, and smooth rods (after reaming). Did some back and forth tests and measurements, and ended up relaxing everything back to the triangle/frame assembly, then moving forward trueing up each part and axis as I go, with the y- and x-axis smooth rods and frog/assemblies installed. Things come out nice and square and true and parallel. The y-axis frog and rods align properly to the frame, and the x-axis is smooth and perpendicular to the y-axis.

Went ahead and installed the z-axis motors and smooth rods, but not happy with their fit yet - I'm getting used to this dance by now.

Build Day 5: 5 hours total - didn't work on it yesterday, so this is Tuesday 6/5. Assembled and installed the z-axis assembly and other parts, then fitted it to the z-axis smooth rods. I've managed to lose a few M3 washers and nuts, and stripped an M3x30 socket-head screw during the previous work, and having installed all the optional accessory M8 nut/washer pairs on the top cross rods, I find myself short a few parts for final assembly. I go to the hardware store for some spares, and to pick up contact cement to finish the x-axis heat shield. With the x-axis installed to the x-axis smooth rods, I go ahead and relax everything down to the triangles again. Working forward, trueing each part and axis, Y to X, I finally get the y-frog true, the x-axis traversing smoothly, but not happy with the z-axis yet. I call it an evening.

Build Day 6: 6 hours total. Ended up doing the relax and reassemble dance on the entire frame again to get the x-axis installed to both the x-axis and z-axis smooth rods, and perpendicular, and true and parallel. Come up with some assembly aids by attaching clamps to some metal bar and rod scraps to give me quick-check gap gauges for each dimension. Back to loose, then trueing up y to x to z axes, I finally get all the movable parts apparently moving smoothly, true to the frame, and mutually perpendicular, etc. I hook up the flexible z-axis motor couplings, and level the x-axis assembly on its z-axis.

I start on the heated bed assembly. Several false starts and disassemble/reassemble cycles on the heated bed get the plate, pcb and aluminum heat spreader assembled to my satisfaction. Now the problems crop up. I was looking for a color-coded 1k resistor, and didn't find one, so I presumed it was lost and went to find one from my various electronics parts bags. Got one, got the LED and 1k resistor installed. I move on and prepare the 2-conductor ribbon from the 10-coductor ribbon provided in the kit. I test what i thought was the 10k thermistor, and find out it's a 100k thermistor. I test what I thought was the 100k thermistor, and find out it's the plain-packaged grey 1k resistor I presumed was missing. Oh! there it is - hair fine wires and all.

I proceed to make the temp probe from the two-conductor ribbon and the 10k thermistor, and manage to screw it up. My lengths are uneven, and I'll never get the glass bead down in the pcb hole to touch the heat spreader. As I desolder and remove the the heatshrink to trim things up, I manage to break off one of those hair-fine leads right up at the glass bead. I go order a replacement on amazon, and call it a night.

Build Day 7: (earlier tonight). Worked about 3 hours on it. I'll be waiting a while on the thermistor, so I proceed to assemble some other stuff. I finish up the power leads for the heated bed and find that the heatshrink provided won't fit over the power wires. Off I go to radio shack for some more heatshrink (no, they don't have a glass bead 10k thermistor...). I finish the power connections, then assemble the extruder motor and idler assemblies. Done for the evenng.

Just waiting on the thermistor now to complete the heat bed assembly and install it. Then I can get down to more wiring and testing, and actually lighting this thing up.

|

Re: My Mendel build. June 08, 2012 09:08PM |

Registered: 11 years ago Posts: 20 |

Build Day 8: about three hours so far. Well, I remembered I had an old external drive enclosure with a temp probe on it, so I went and salvaged that thermistor for my build. It's about 8.5kohm, so I'll have to wait and see if that's within acceptable adjustment range, or just eventually replace it when the 10k I ordered finally arrives.

I quickly finished up the heated bed assembly, and installed it. Then I finished testing the filament feed on the extruder drive I mostly built yesterday, and installed it. I then started assembling the hot head.

Oh, instructions! Or Oh, me! for not reading ahead. I was unable to remove the tongue that holds the filament feed tube, and ended up breaking off part of the tab trying to get that sucker out. So, I had to assemble the hot head with the feed tube still connected to the extruder drive. Awkward, but I managed. Had to jack my x-axis WAY up to get the hot head installed, but there it now sits. Still have to connect the fan, but the other connections have been made, and the 8-conductor lead coiled up on the filament feed tube, and the x-axis and stops adjusted to about 1mm above the glass.

Later this evening I may start the circuit wiring and testing, but for now, it's nice to have completed the mechanical assembly!

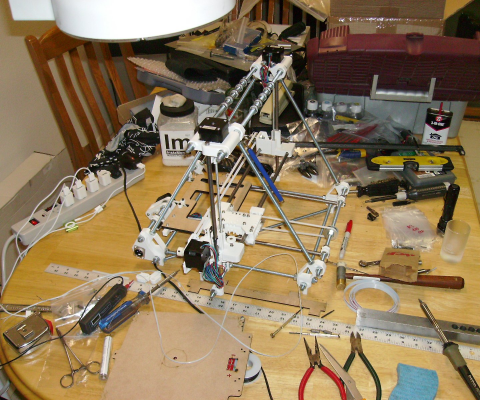

Here's a pic I took of progress to date on Build Day 7

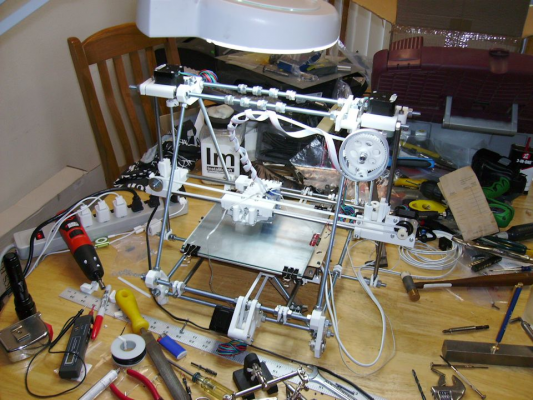

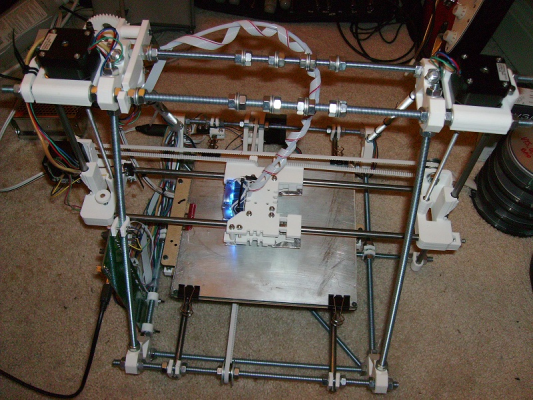

And here's how it looks this evening

I quickly finished up the heated bed assembly, and installed it. Then I finished testing the filament feed on the extruder drive I mostly built yesterday, and installed it. I then started assembling the hot head.

Oh, instructions! Or Oh, me! for not reading ahead. I was unable to remove the tongue that holds the filament feed tube, and ended up breaking off part of the tab trying to get that sucker out. So, I had to assemble the hot head with the feed tube still connected to the extruder drive. Awkward, but I managed. Had to jack my x-axis WAY up to get the hot head installed, but there it now sits. Still have to connect the fan, but the other connections have been made, and the 8-conductor lead coiled up on the filament feed tube, and the x-axis and stops adjusted to about 1mm above the glass.

Later this evening I may start the circuit wiring and testing, but for now, it's nice to have completed the mechanical assembly!

Here's a pic I took of progress to date on Build Day 7

And here's how it looks this evening

|

Re: My Mendel build. June 10, 2012 02:45AM |

Registered: 11 years ago Posts: 20 |

Build Day 9: put together the power supply. Supposed to be a 110/220 switchable, but it's not. I can see the solder pads for the switch so i make and install some 110 jumpers and cross my fingers. It lights up and tests out ok, so I proceed to the general wiring. Got the PCB installed, and about 2/3 of the wire runs laid out before calling it an evening. Still have to splice the Z motors together.

|

Re: My Mendel build. June 12, 2012 02:55AM |

Registered: 11 years ago Posts: 20 |

Build Day 10: Spliced the z-axis motors, and wired up the axis endswitches. Wiki instructions claimed there would be enough slack from cutting off the routed motor wires at the controller board, with slack, to effect the endswitch wiring, but that was not the case in my build. I scavenged some old phone wire from my electronics/parts stash to wire the x- and z-axis endswitches, and spliced some remnants from the motor wires for the y-axis endswitches. Ran out of heatshrink LONG ago in this build, so I'm well into my purchased stash of that, too.

Many distractions this week so far, so I was only able to spend an hour or so tonight on it, and about three hours last time.

Many distractions this week so far, so I was only able to spend an hour or so tonight on it, and about three hours last time.

|

Re: My Mendel build. June 13, 2012 07:18AM |

Registered: 11 years ago Posts: 15 |

|

Re: My Mendel build. June 15, 2012 12:47AM |

Registered: 11 years ago Posts: 20 |

Build Day 11: about four hours. Completed routing all the wires. Took some time to wire up the hot end fan, which I'd neglected during the hot end assembly. Began final length checking, trimming, stripping, tinning and wiring all the connectors.

Passed all the wiki wiring tests, so I plugged it up to one of my PCs (after d/ling and installing all python packages). Plugged in the USB - recognized. Ran pronterface - and communication!

Checked the trim pots one last time, then plugged in main power and threw the switch. No smoke. Fan LED is on, Fan is on.

Spent some time adjusting the trim pots to get .4V on all connections, then started issuing motor commands. X-axis works fine. Y-axis is backwards - turned off and rewired. X-axis works fine, y-axis works fine, z-axis does not work, extruder does not work.

Tested the endswitches for x and y, then turned off power and upped amperage a little to z and e motors. Still no motion. e motor is a bit hot, z motors are stone cold. I adjust the voltages for those two back down to .4V while I ponder and troubleshoot and figure out a next move.

Passed all the wiki wiring tests, so I plugged it up to one of my PCs (after d/ling and installing all python packages). Plugged in the USB - recognized. Ran pronterface - and communication!

Checked the trim pots one last time, then plugged in main power and threw the switch. No smoke. Fan LED is on, Fan is on.

Spent some time adjusting the trim pots to get .4V on all connections, then started issuing motor commands. X-axis works fine. Y-axis is backwards - turned off and rewired. X-axis works fine, y-axis works fine, z-axis does not work, extruder does not work.

Tested the endswitches for x and y, then turned off power and upped amperage a little to z and e motors. Still no motion. e motor is a bit hot, z motors are stone cold. I adjust the voltages for those two back down to .4V while I ponder and troubleshoot and figure out a next move.

|

Re: My Mendel build. June 22, 2012 04:51PM |

Registered: 11 years ago Posts: 4 |

|

Re: My Mendel build. June 25, 2012 03:11AM |

Registered: 11 years ago Posts: 20 |

With the e-stepper controller adjusted to .42V, it fires both the extruder and z-motors just fine, so it's not a current or voltage limitation, but thanks for the suggestion.

I hooked the z-motors to the e-stepper and was able to traverse them up and down multiple times from the command line, so there's no physical or electrical problems with the motors, just the z-stepper or its control lines. I'm waiting on a friend to bring over his logic analyzer so i can see what's going on between the atmega the z-stepper controller, and what it's doing on the output side in response.

Worst case at the moment is that I'll end up severing the control traces between the melzi z-stepper and atmega, and sourcing and soldering in a pololu stepper controller for that axis, presuming i don't just replace the entire board with a ramps alternative.

I hooked the z-motors to the e-stepper and was able to traverse them up and down multiple times from the command line, so there's no physical or electrical problems with the motors, just the z-stepper or its control lines. I'm waiting on a friend to bring over his logic analyzer so i can see what's going on between the atmega the z-stepper controller, and what it's doing on the output side in response.

Worst case at the moment is that I'll end up severing the control traces between the melzi z-stepper and atmega, and sourcing and soldering in a pololu stepper controller for that axis, presuming i don't just replace the entire board with a ramps alternative.

Sorry, only registered users may post in this forum.