Random jams?

Posted by ARGLaser

|

Random jams? August 04, 2013 03:46PM |

Registered: 11 years ago Posts: 5 |

Hey everyone.

I'm having random jams with my printer that I never had before. I've used this plastic lots before without problems.

What is happening is that the filament is getting stripped and won't extrude any more.

My printer is the 6 inch Prusa i3 from maker farm. I believe it uses wades extruder.

This only (so far as I can tell) happens on larger objects, and it usually strips in the second or third layer.

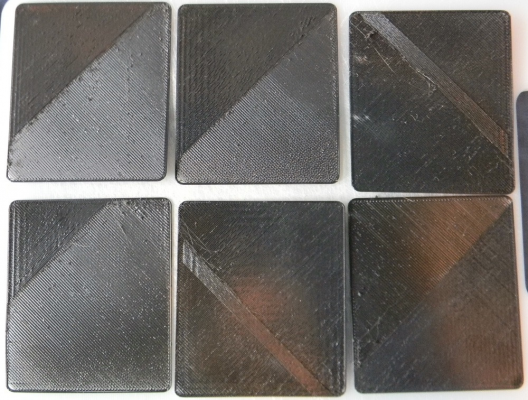

Here's a picture of 6 of the many failed prints.

So far I have tried:

Slowing all speeds to 20mm/s or less

Dropping the extrusion multiplier to .9 (worked for a moment)

Turning up the hot end to 231C

Tightening/loosening the feed bolts.

Lubing up the bearings

Feeding the plastic into the printer to remove tension

Replacing the stepper gear and the bolt gear

Any ideas what this could be? More importantly, how do I fix it?

Any help is appreciated I've spent many hours trying to fix this without avail.

I'm having random jams with my printer that I never had before. I've used this plastic lots before without problems.

What is happening is that the filament is getting stripped and won't extrude any more.

My printer is the 6 inch Prusa i3 from maker farm. I believe it uses wades extruder.

This only (so far as I can tell) happens on larger objects, and it usually strips in the second or third layer.

Here's a picture of 6 of the many failed prints.

So far I have tried:

Slowing all speeds to 20mm/s or less

Dropping the extrusion multiplier to .9 (worked for a moment)

Turning up the hot end to 231C

Tightening/loosening the feed bolts.

Lubing up the bearings

Feeding the plastic into the printer to remove tension

Replacing the stepper gear and the bolt gear

Any ideas what this could be? More importantly, how do I fix it?

Any help is appreciated I've spent many hours trying to fix this without avail.

|

Re: Random jams? August 04, 2013 05:16PM |

Registered: 11 years ago Posts: 157 |

It looks like this is reliably occurring within the first couple layers. I hypothesize that your printer works when it is still cool, but starts to fail when it warms up. I've had hard-to-troubleshoot jams occur when heat gets too far up of the extruder, and deforms the filament before it enters the top of the hotend. That deformed filament prevents any more of itself from getting pushed into the hotend.

Here's a question: after a failure, with your hotend hot and the idler disengaged, can you manually push filament into and through the hotend?

Here's a question: after a failure, with your hotend hot and the idler disengaged, can you manually push filament into and through the hotend?

|

Re: Random jams? August 04, 2013 05:52PM |

Registered: 10 years ago Posts: 47 |

I had a similar issue. I could start a print, but within the first layer or second, extrusion would stop and I could hear the hobbed bolt "ticking" as it tried to push filament through. I straightened a bit of spring wire and used it to push up into the nozzle and clear it, but it would jam again shortly after I started printing.

What I had, was a small ball of junk down in the nozzle. It was a collection of fibers and plastic that would eventually plug the nozzle. I removed it with some nylon trimmer line from above, while the nozzle was hot. Nylon wouldn't melt at that temp, and the molten PLA stuck to it like glue.

I made a simple cleaner to prevent build up of junk in the future. Video with pics of my culprit linked below.

Kevin.

[www.youtube.com]

What I had, was a small ball of junk down in the nozzle. It was a collection of fibers and plastic that would eventually plug the nozzle. I removed it with some nylon trimmer line from above, while the nozzle was hot. Nylon wouldn't melt at that temp, and the molten PLA stuck to it like glue.

I made a simple cleaner to prevent build up of junk in the future. Video with pics of my culprit linked below.

Kevin.

[www.youtube.com]

|

Re: Random jams? August 04, 2013 08:12PM |

Registered: 11 years ago Posts: 5 |

|

Re: Random jams? August 04, 2013 08:22PM |

Registered: 10 years ago Posts: 47 |

You can tear the whole thing down if you want to work that hard. I took the hot end off the extruder, set it on a dinner plate and used pronterface to set it to 170C. Once warm, I pushed some nylon trimmer line in and twisted it then pulled it out. It came out covered in PLA. I'd cut off the coated end and do it again. Eventually, the glob pictured in my bid came out with it.

Let it cool, put it back together and made the wiper to prevent stuff building up again.

Let it cool, put it back together and made the wiper to prevent stuff building up again.

|

Re: Random jams? August 05, 2013 12:10AM |

Registered: 11 years ago Posts: 5 |

|

Re: Random jams? August 05, 2013 06:37AM |

Registered: 10 years ago Posts: 47 |

|

Re: Random jams? August 05, 2013 10:07PM |

Registered: 11 years ago Posts: 5 |

|

Re: Random jams? August 07, 2013 08:30AM |

Registered: 10 years ago Posts: 194 |

|

Re: Random jams? August 07, 2013 09:30PM |

Registered: 10 years ago Posts: 47 |

Yes, that's nylon trimmer line. It doesn't soften until you get way up to 230C, so it's perfect for cleaning out PLA at around 160C

I found a 2ft. length of it laying in my lawn one day. Probably flew off a neighbors trimmer. So, I picked it up and used it to remove my clog. Lucky me. Although I think it's pretty cheap at most stores.

I found a 2ft. length of it laying in my lawn one day. Probably flew off a neighbors trimmer. So, I picked it up and used it to remove my clog. Lucky me. Although I think it's pretty cheap at most stores.

|

Re: Random jams? August 08, 2013 04:48AM |

Registered: 11 years ago Posts: 11 |

I see this all the time. I run 6 prusa mendels all day every day like work mules making parts and kits for people on ebay. There are 2 culprits.

1. you may have burnt plastic inside the heat tip of your hot end. Tiny build up and flakes can get in there, they don't melt and they don't move. The fix is to take it all apart, right down to the brass (leave the resistor in it, DON'T try to take that out) and soak the brass in acetone for 3 days (I keep a spare hot end so I can keep printing, if you don't have one buy one, you need it). Clean with a q tip and a small wire to poke into the .35mm hole. You are clean when you can see light pass through it, if no light, keep soaking and cleaning. You may need to take off the cotton to get into the melt chamber in the bottom of the brass tip. Don't worry about the resistor, it is resistant to acetone.

2. The inner PTFE liner has shrunk from being cooked, thus constricting your filament before it gets down to the melt chamber. The fix is to take a drill and use a drill bit the same size as your filament. Drill out your liner, and open it up. Do this when it is cold, they can get real messed up if you try it while it's hot. be careful not to scuff up the outside with your plyers when your holding it for drilling. Test it by placing it on your filament and sliding it up and down. It should move smoothly. If you have to push, drill it out some more.

3 is you may have out of spec filament. If it's too big it can look like problem number 2. The fix for 2 is the same fix for "too fat filament". (this might be a reason to keep a few PTFE sleeves around some for big and some for standard filament.

1. you may have burnt plastic inside the heat tip of your hot end. Tiny build up and flakes can get in there, they don't melt and they don't move. The fix is to take it all apart, right down to the brass (leave the resistor in it, DON'T try to take that out) and soak the brass in acetone for 3 days (I keep a spare hot end so I can keep printing, if you don't have one buy one, you need it). Clean with a q tip and a small wire to poke into the .35mm hole. You are clean when you can see light pass through it, if no light, keep soaking and cleaning. You may need to take off the cotton to get into the melt chamber in the bottom of the brass tip. Don't worry about the resistor, it is resistant to acetone.

2. The inner PTFE liner has shrunk from being cooked, thus constricting your filament before it gets down to the melt chamber. The fix is to take a drill and use a drill bit the same size as your filament. Drill out your liner, and open it up. Do this when it is cold, they can get real messed up if you try it while it's hot. be careful not to scuff up the outside with your plyers when your holding it for drilling. Test it by placing it on your filament and sliding it up and down. It should move smoothly. If you have to push, drill it out some more.

3 is you may have out of spec filament. If it's too big it can look like problem number 2. The fix for 2 is the same fix for "too fat filament". (this might be a reason to keep a few PTFE sleeves around some for big and some for standard filament.

|

Re: Random jams? October 30, 2013 02:15AM |

Registered: 10 years ago Posts: 8 |

Similar problem, which I imagine may be associated with the fact that I ran a print with the heat at 240 with PLA at the start of a print job. The extruder worked fine and I immediately lowered the temp in Pronterface to a standard 200 and "successfully" printed with no problems (successful only in the respect that the plastic extruded and did not burn up - the calibration cube I had intended to print shifted 20 mm in the Y direction after 20 or so layers). On my next print attempt the extruder gear only shuddered with temp at 200 C. Turned off all the motors and was easily able to squirt PLA through the nozzle by manually turning the big gear.

If I could easily push the plastic through and it melted just fine, is this still a clogged hot end issue or is it more likely I don't have enough torque at the servo?

Edited 1 time(s). Last edit at 10/30/2013 02:39AM by junkelsplitsy.

If I could easily push the plastic through and it melted just fine, is this still a clogged hot end issue or is it more likely I don't have enough torque at the servo?

Edited 1 time(s). Last edit at 10/30/2013 02:39AM by junkelsplitsy.

|

Re: Random jams? October 30, 2013 10:44AM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Random jams? November 05, 2013 06:51AM |

Registered: 10 years ago Posts: 8 |

|

Re: Random jams? November 05, 2013 07:09AM |

Registered: 10 years ago Posts: 1,433 |

Sorry, only registered users may post in this forum.