Poor Print Quality!?!?

Posted by UNI Physics Dept.

|

Poor Print Quality!?!? January 09, 2014 03:36PM |

Registered: 10 years ago Posts: 16 |

We are using a Prusa Mendel with a .3 mm tip at 15mm/s for perimeter lays and 20mm/s for the infill.

Basically, when things work, we get kid of good prints, but typically it just messes up within the first few layers and we get trash.

I've attached pictures. I've tried lowering the speed, increasing the temperature, increasing the pressure of the extruder.

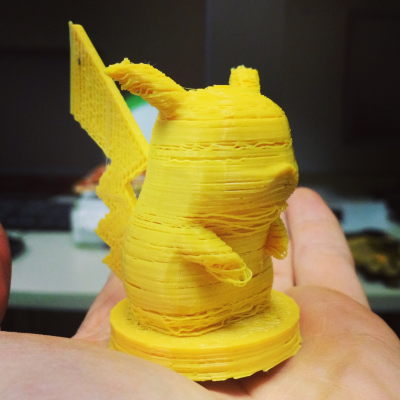

The "Good"

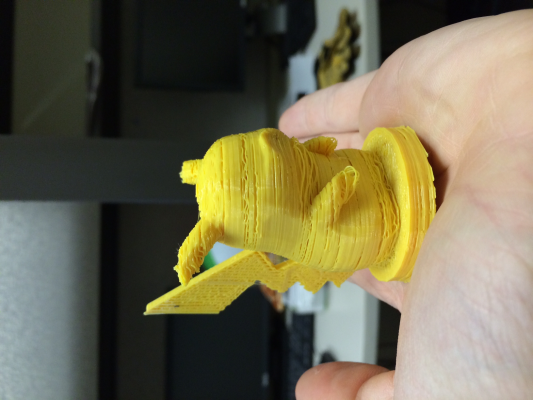

The "okay"

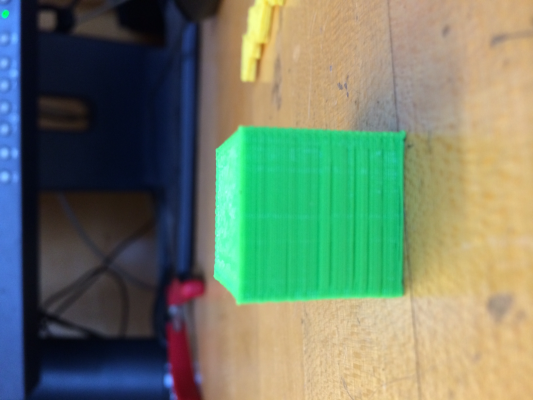

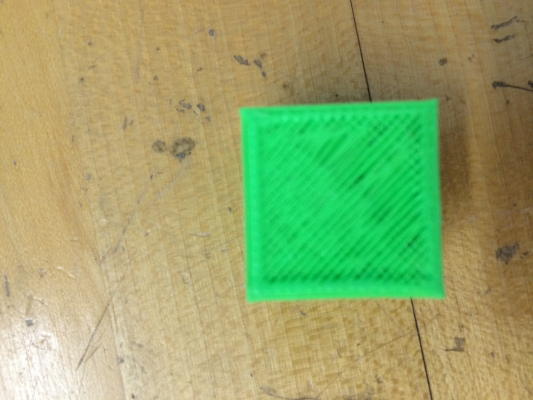

The Ugly

Basically, when things work, we get kid of good prints, but typically it just messes up within the first few layers and we get trash.

I've attached pictures. I've tried lowering the speed, increasing the temperature, increasing the pressure of the extruder.

The "Good"

The "okay"

The Ugly

|

Re: Poor Print Quality!?!? January 09, 2014 04:24PM |

Registered: 17 years ago Posts: 824 |

There are various culprits that can cause this kind of problem.

Before you begin troubleshooting, let's stop changing things that are probably not really affecting this. Set your temperature on the hot end and print bed (ABS 230°C/110°C) (PLA 170°C/70°C). If you feel you have different setting that work better on that printer, use them. The important thing is to not change things during troubleshooting, without understanding how the change affects testing.

The number one suspects for uneven flow are the hobbed bolt, if your extruder has one, and nozzle backflowing into the insulator.

If your hobbed bolt has a deep groove, it is more likely to be the cause of the problem. The ideal depth for the teeth is actually very little. There should be plenty of the bolt surface left, and the groove should definitely not be a semi-circle.

If your hot end clogs frequently, get a J-Head (a real one, not a clone). You didn;t mention much about the printer. Post some picture of it if you get a chance. Maybe something will be telling in there.

Before you begin troubleshooting, let's stop changing things that are probably not really affecting this. Set your temperature on the hot end and print bed (ABS 230°C/110°C) (PLA 170°C/70°C). If you feel you have different setting that work better on that printer, use them. The important thing is to not change things during troubleshooting, without understanding how the change affects testing.

The number one suspects for uneven flow are the hobbed bolt, if your extruder has one, and nozzle backflowing into the insulator.

If your hobbed bolt has a deep groove, it is more likely to be the cause of the problem. The ideal depth for the teeth is actually very little. There should be plenty of the bolt surface left, and the groove should definitely not be a semi-circle.

If your hot end clogs frequently, get a J-Head (a real one, not a clone). You didn;t mention much about the printer. Post some picture of it if you get a chance. Maybe something will be telling in there.

|

Re: Poor Print Quality!?!? January 09, 2014 11:22PM |

Registered: 11 years ago Posts: 560 |

|

Re: Poor Print Quality!?!? January 11, 2014 01:25PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Poor Print Quality!?!? January 11, 2014 07:31PM |

Registered: 11 years ago Posts: 560 |

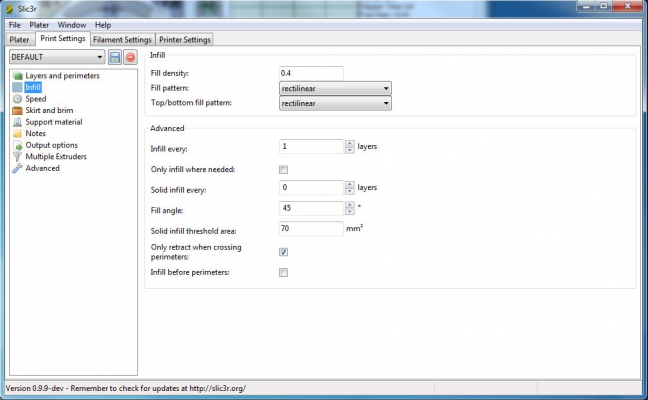

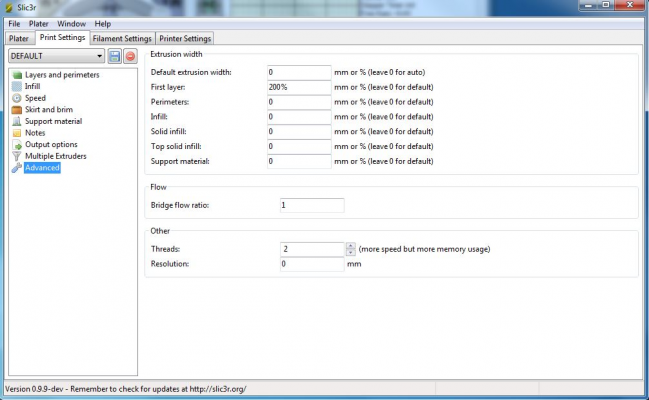

Manually setting the extrusion width has been the only way to get slic3r to work with my .25mm nozzle, and has fixed this problem for a lot of people I have helped.

It is certainly worth a 10 minute calibration cube to check. Probably a combination of that, and under-extruding. The green cube certainly looks consistent overall, you can see how the outside loops are not touching though. That's why the outside loops on Pichachu are sagged so much, because the loops are not correctly spaced.

But this is assuming slic3r is being used, and extruder steps/mm are correct.

Need more info, slicing software, slice settings, nozzle size, layer height, print speeds.

Edited 5 time(s). Last edit at 01/12/2014 12:48AM by Dirty Steve.

It is certainly worth a 10 minute calibration cube to check. Probably a combination of that, and under-extruding. The green cube certainly looks consistent overall, you can see how the outside loops are not touching though. That's why the outside loops on Pichachu are sagged so much, because the loops are not correctly spaced.

But this is assuming slic3r is being used, and extruder steps/mm are correct.

Need more info, slicing software, slice settings, nozzle size, layer height, print speeds.

Edited 5 time(s). Last edit at 01/12/2014 12:48AM by Dirty Steve.

|

Re: Poor Print Quality!?!? January 13, 2014 12:25PM |

Registered: 10 years ago Posts: 16 |

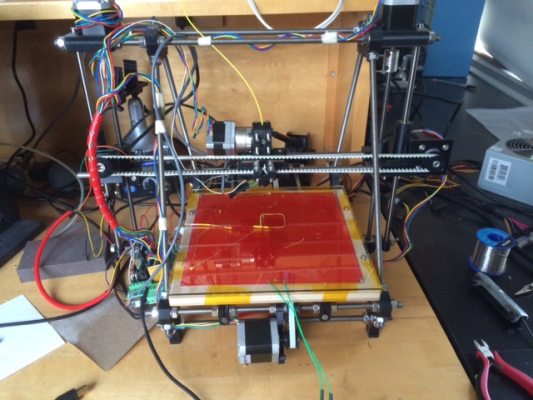

I have included pictures of the printer below.

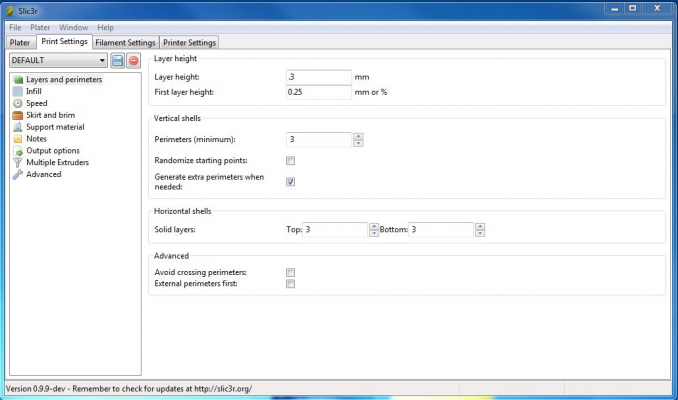

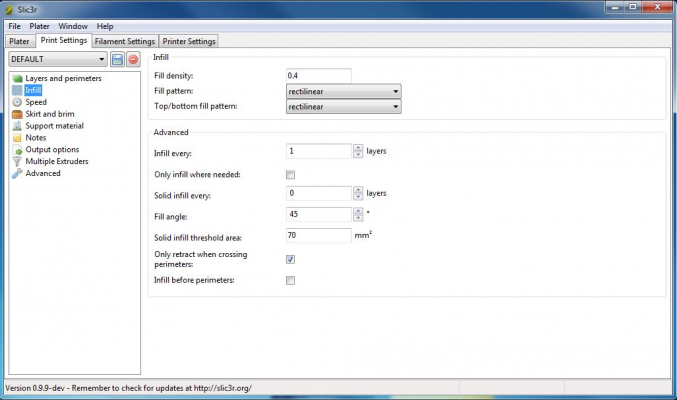

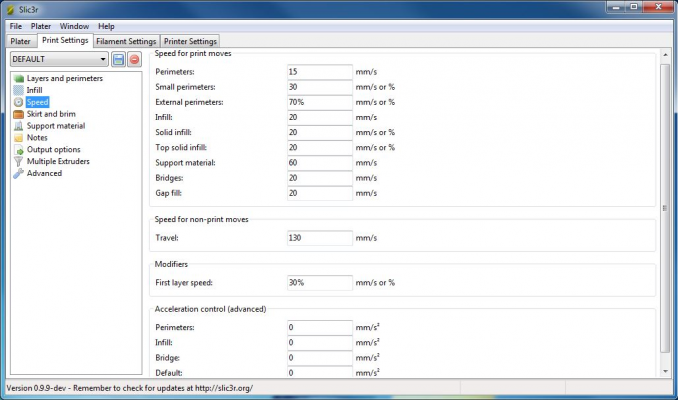

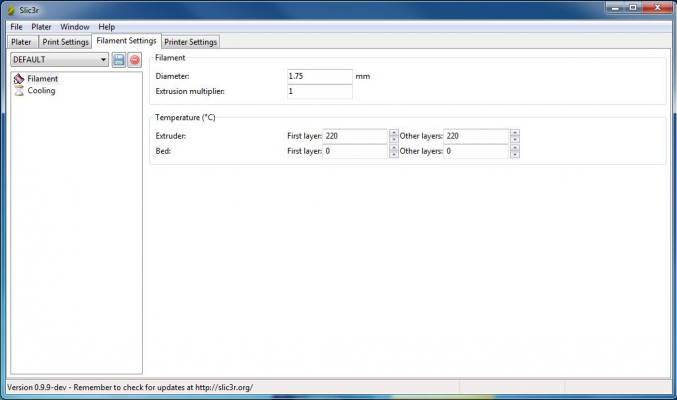

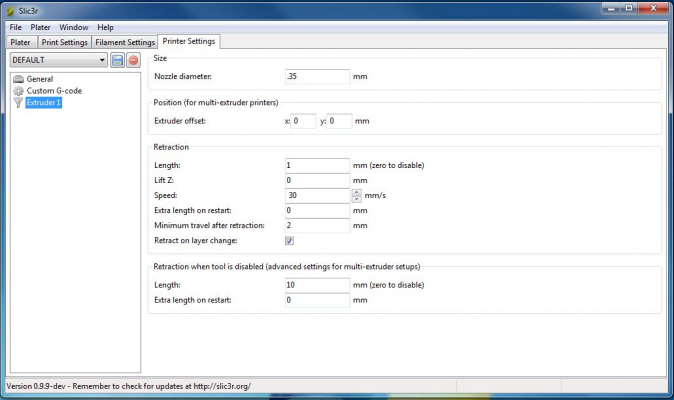

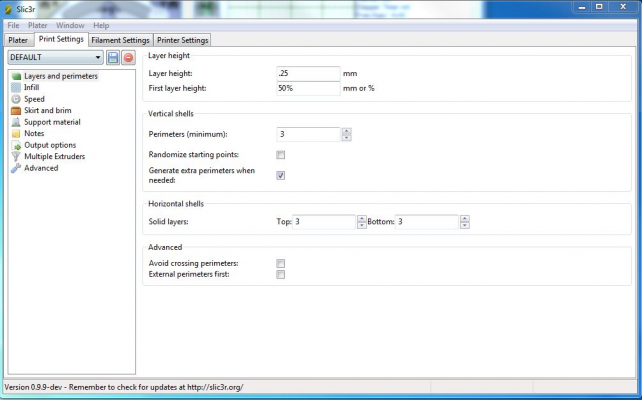

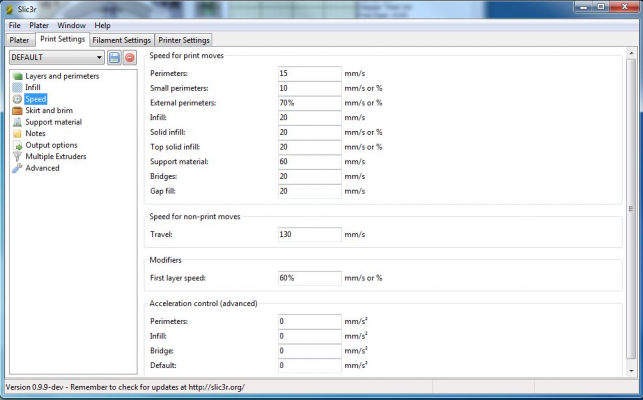

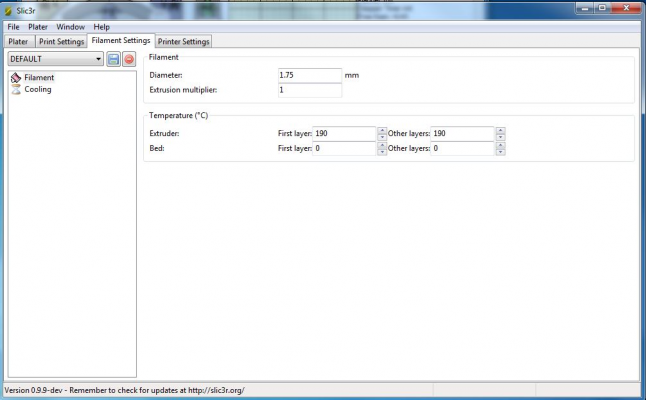

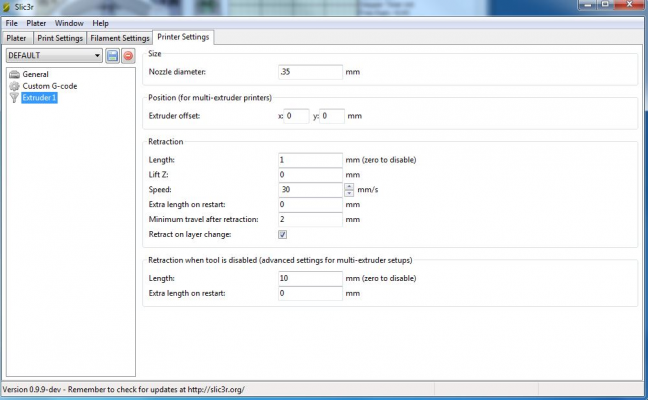

Slicing software is Slic3r, with settings shown below.

I am trying Dirty Steve's original plan now and will update when it is finished with the results.

Slicing software is Slic3r, with settings shown below.

I am trying Dirty Steve's original plan now and will update when it is finished with the results.

|

Re: Poor Print Quality!?!? January 13, 2014 01:43PM |

Registered: 11 years ago Posts: 469 |

Just my 2 cents trying to help

Comments:-

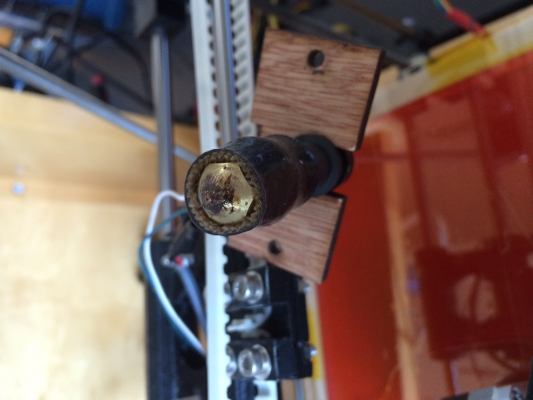

Photo1 > Get some crocodile clips for your glass print plate....Tape wont hack it.

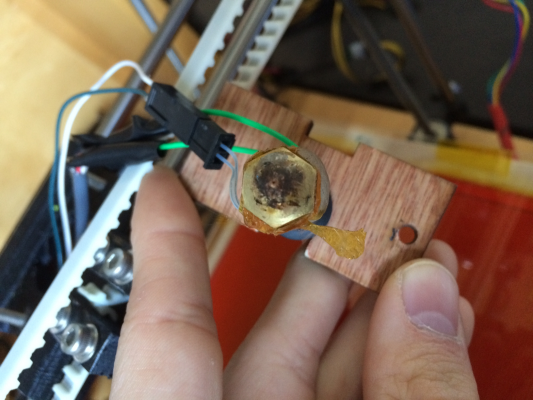

On the left Z axis stepper ...don't wrap the wires around it like that. May give all kinds of bogus / signal interference.

Make sure you set your nozzle bed height when the heated bed is on and up to temp

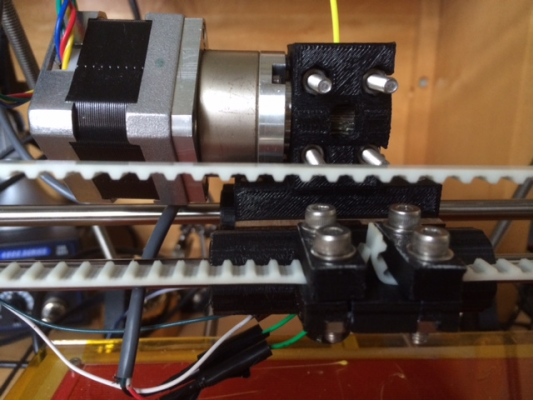

Photo 2 > X axis belt doesn't look tight and judging by the very small ends ( that would be difficult to hold and tension ) it may be too loose

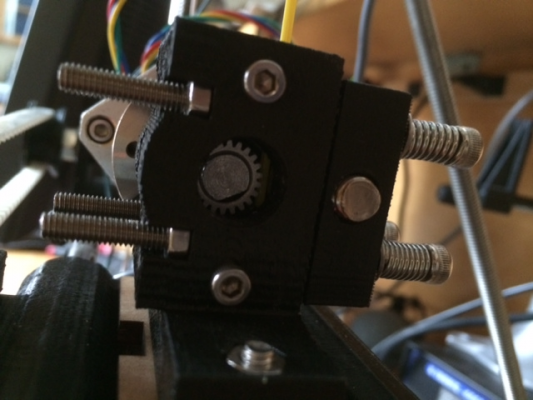

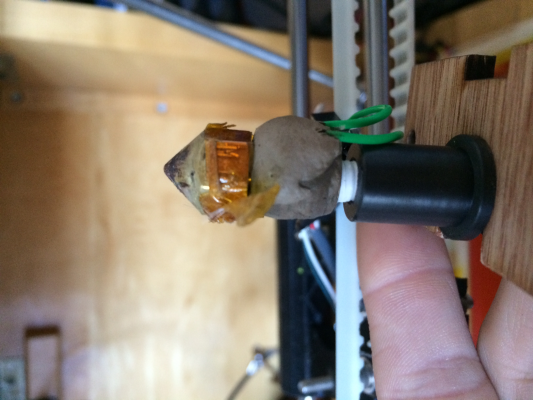

Photo 3 > Geared direct drive stepper. The teeth on the drive element don't look very sharp so may require different settings for each type colour of filament. This potential issue may be

exaggerated by a too low temp.

Make sure your e steps are calibrated calibration wiki

Slic3r1.jpg > You have layers at 0.3 but first layer at 0.25 . Normally ( i think) youd start with a thick layer to allow for any print bed to nozzle issues . So change them round

First layer speed to 80% ( that's normally the default if i remember correctly )

Slic3r3.jpeg > Set perimeters to 25 ( as a starting point) and small perimeters to 10 ( again as a starting point)

Slic3r4.jpeg > 220 is way too hot if your using PLA. 185 to 190 as a starting point

As the other have said use the 20mm cube as a test piece and stick to it till your problems are solved

The extruder is the most likely cause but your print temp and calibration don't look very good either.

Stick with it you'll get there. Most of us have been through similar at some stage and however frustrating it is just stick with it

Good luck

Phil

Edited 1 time(s). Last edit at 01/13/2014 08:50PM by bigfilsing.

Comments:-

Photo1 > Get some crocodile clips for your glass print plate....Tape wont hack it.

On the left Z axis stepper ...don't wrap the wires around it like that. May give all kinds of bogus / signal interference.

Make sure you set your nozzle bed height when the heated bed is on and up to temp

Photo 2 > X axis belt doesn't look tight and judging by the very small ends ( that would be difficult to hold and tension ) it may be too loose

Photo 3 > Geared direct drive stepper. The teeth on the drive element don't look very sharp so may require different settings for each type colour of filament. This potential issue may be

exaggerated by a too low temp.

Make sure your e steps are calibrated calibration wiki

Slic3r1.jpg > You have layers at 0.3 but first layer at 0.25 . Normally ( i think) youd start with a thick layer to allow for any print bed to nozzle issues . So change them round

First layer speed to 80% ( that's normally the default if i remember correctly )

Slic3r3.jpeg > Set perimeters to 25 ( as a starting point) and small perimeters to 10 ( again as a starting point)

Slic3r4.jpeg > 220 is way too hot if your using PLA. 185 to 190 as a starting point

As the other have said use the 20mm cube as a test piece and stick to it till your problems are solved

The extruder is the most likely cause but your print temp and calibration don't look very good either.

Stick with it you'll get there. Most of us have been through similar at some stage and however frustrating it is just stick with it

Good luck

Phil

Edited 1 time(s). Last edit at 01/13/2014 08:50PM by bigfilsing.

|

Re: Poor Print Quality!?!? January 13, 2014 07:04PM |

Registered: 11 years ago Posts: 560 |

You are also getting some of these issues from trying to do .3mm layers with a .35mm nozzle, generally you want to be no more than 80% of your nozzle size for layer heights, which would be .28mm. Drop down to .25mm or .2mm layer height. I always do 50% of layer height for first layer.

Edited 1 time(s). Last edit at 01/13/2014 07:05PM by Dirty Steve.

Edited 1 time(s). Last edit at 01/13/2014 07:05PM by Dirty Steve.

|

Re: Poor Print Quality!?!? January 13, 2014 08:03PM |

Registered: 17 years ago Posts: 824 |

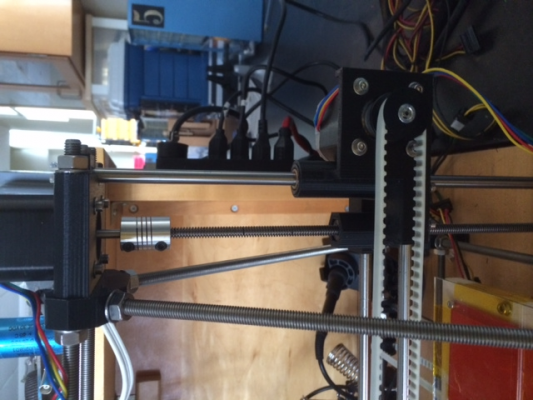

Disclaimer: This probably has nothing to do with the print problems you are showing us.

Nobody has mentioned the flex couplings. I have a Prusa Mendel with the same type of coupling. It's not a huge deal, but consider that the entire X-axis is essentially being suspended from a couple of springs. I've been putting off designing a solution for this, but now that I see it again, fresh, there is a simple printable part that will prevent the spring from stretching, but still allow flex. I'll post back when it's ready.

Nobody has mentioned the flex couplings. I have a Prusa Mendel with the same type of coupling. It's not a huge deal, but consider that the entire X-axis is essentially being suspended from a couple of springs. I've been putting off designing a solution for this, but now that I see it again, fresh, there is a simple printable part that will prevent the spring from stretching, but still allow flex. I'll post back when it's ready.

|

Re: Poor Print Quality!?!? January 13, 2014 08:39PM |

Registered: 11 years ago Posts: 560 |

I switched to solid printed Z couplers from the same type of helical aluminum couplers. I had bearings with nuts on the bottom of my lead screws to support the weight.

My main problem was Z wobble because the couplers are for 8mm threaded rod, and I'm running 5/16" rods. Instructions say to tighten the coupler more for 5/16" but that causes an offset between the center of the motor shafts and the lead screws.

I now run with just the solid couplers and the bottom ends free without bearings, this eliminated most all my Z-wobble.

My main problem was Z wobble because the couplers are for 8mm threaded rod, and I'm running 5/16" rods. Instructions say to tighten the coupler more for 5/16" but that causes an offset between the center of the motor shafts and the lead screws.

I now run with just the solid couplers and the bottom ends free without bearings, this eliminated most all my Z-wobble.

|

Re: Poor Print Quality!?!? January 14, 2014 02:17PM |

Registered: 17 years ago Posts: 824 |

I designed a flex coupling limiter last night, and put it up on Thingiverse (Boooooo!)

|

Re: Poor Print Quality!?!? January 16, 2014 12:21PM |

Registered: 10 years ago Posts: 16 |

|

Re: Poor Print Quality!?!? January 16, 2014 01:52PM |

Registered: 17 years ago Posts: 824 |

Well, you cannot follow everyone's advice at the same time. Not that anyone is giving bad advice, but in many cases, there will be conflicting advice from two or more parties that is not compatible.

Don't change anything for now. Just post the following

1. What type of hot end is on that extuder? If possible, get some pictures too.

2. Show us your current slicer settings. The same as the screenshots you provided earlier.

3. Give some details about the filament (type, verified diameter(s), vendor, color).

4. Give some details about the environment where the printer is located (near open window, air conditioned room, near a large body of water (high humidity).

5. Tell what, if anything has been done to the print bed to clean it, or cover it (tape, glue, etc)

6. Let's see you firmware settings.

If everyone else will indulge me for a while, please refrain from giving more advice until I have had a chance to look over UPD's response, and provide my input. Those of us that have been doing this for a while know that it's very easy to start chasing your tail in these matters).

If you can answer all of the above, I will have a pretty good idea of the current state of your printer, and what it needs to feel better.

Regards,

-Wildseyed-

Don't change anything for now. Just post the following

1. What type of hot end is on that extuder? If possible, get some pictures too.

2. Show us your current slicer settings. The same as the screenshots you provided earlier.

3. Give some details about the filament (type, verified diameter(s), vendor, color).

4. Give some details about the environment where the printer is located (near open window, air conditioned room, near a large body of water (high humidity).

5. Tell what, if anything has been done to the print bed to clean it, or cover it (tape, glue, etc)

6. Let's see you firmware settings.

If everyone else will indulge me for a while, please refrain from giving more advice until I have had a chance to look over UPD's response, and provide my input. Those of us that have been doing this for a while know that it's very easy to start chasing your tail in these matters).

If you can answer all of the above, I will have a pretty good idea of the current state of your printer, and what it needs to feel better.

Regards,

-Wildseyed-

|

Re: Poor Print Quality!?!? January 16, 2014 01:56PM |

Registered: 11 years ago Posts: 469 |

Mmmmh

Your glass plate has to be very clean ..use rubbing alcohol or glass cleaner ...some people swear by lemon juice.

How do you level your print bed ..cant see clearly from the photo.

You should be adjusting it so when the Z axis is homed you can just move a piece of ordinary ink jet paper between the nozzle tip and the glass plate. Do this in at least 3 ( i prefer 4) location on the print bed. Normally with the nozzle in the home position i move 30 mmm in X and 30 mm in Y direction and then do a 100 mm X 100 mm 4 point square.

This is absolutely critical. too far away and you wont get good adhesion ...too close and the nozzle cant extrude and will scuff "thru" the printed material.

A bad first layer will mess up the whole print .... as i think you have experienced

other layers ...could be your Z axis calibration . Do you have Vernier caliper ? . In pronterface move the z axis 50 mm and check its moving exactly 50 mm.

Stick with the 20 mm cube ... Print the first layer then take a close up pic and post it . Better still make a simple vid of it and share on you tube

Good luck

Edited 1 time(s). Last edit at 01/16/2014 01:56PM by bigfilsing.

Your glass plate has to be very clean ..use rubbing alcohol or glass cleaner ...some people swear by lemon juice.

How do you level your print bed ..cant see clearly from the photo.

You should be adjusting it so when the Z axis is homed you can just move a piece of ordinary ink jet paper between the nozzle tip and the glass plate. Do this in at least 3 ( i prefer 4) location on the print bed. Normally with the nozzle in the home position i move 30 mmm in X and 30 mm in Y direction and then do a 100 mm X 100 mm 4 point square.

This is absolutely critical. too far away and you wont get good adhesion ...too close and the nozzle cant extrude and will scuff "thru" the printed material.

A bad first layer will mess up the whole print .... as i think you have experienced

other layers ...could be your Z axis calibration . Do you have Vernier caliper ? . In pronterface move the z axis 50 mm and check its moving exactly 50 mm.

Stick with the 20 mm cube ... Print the first layer then take a close up pic and post it . Better still make a simple vid of it and share on you tube

Good luck

Edited 1 time(s). Last edit at 01/16/2014 01:56PM by bigfilsing.

|

Re: Poor Print Quality!?!? January 17, 2014 01:01PM |

Registered: 10 years ago Posts: 16 |

The hot end is a BigHead nozzle, according to the order sheet. Pictures below.

Slic3r settings

Filament is all PLA. Confirmed 1.75 mm diameter. We are currently using yellow, green, and purple, all supplied by ProtoParadigm.

Printer is located in the back corner of an electronics lab near two windows but both are closed and usually have shades over them. We are located in Iowa, so it has been exceptionally cold outdoors recently, but the building has remained fairly consistent and warm.

The bed is cleaned using alcohol and isopropanol because both are readily available here. Bed is composed of a glass plate covering the heated plate and covered in Kapton tape.

What firmware settings is it that you are wanting to see? I'm not exactly sure what you are looking for there..?

Also, I would just like to thank you immensely for all of you help.

Slic3r settings

Filament is all PLA. Confirmed 1.75 mm diameter. We are currently using yellow, green, and purple, all supplied by ProtoParadigm.

Printer is located in the back corner of an electronics lab near two windows but both are closed and usually have shades over them. We are located in Iowa, so it has been exceptionally cold outdoors recently, but the building has remained fairly consistent and warm.

The bed is cleaned using alcohol and isopropanol because both are readily available here. Bed is composed of a glass plate covering the heated plate and covered in Kapton tape.

What firmware settings is it that you are wanting to see? I'm not exactly sure what you are looking for there..?

Also, I would just like to thank you immensely for all of you help.

|

Re: Poor Print Quality!?!? January 17, 2014 01:18PM |

Registered: 17 years ago Posts: 824 |

|

Re: Poor Print Quality!?!? January 17, 2014 01:31PM |

Registered: 17 years ago Posts: 824 |

|

Re: Poor Print Quality!?!? January 17, 2014 05:04PM |

Registered: 17 years ago Posts: 824 |

The root of your troubles is most likely at the hot end. What you have is a V3 Makergear or more likely a clone of that. It's not what Makergear currently recommends. Since you are printing in PLA, and using 1.75mm filament, cooling the nozzle insulator and the print is NOT optional. You will need to address this issue first, even before calibration.

Everything else will need to wait for this. No way around it, unless you want to switch to 3mm ABS and a different hot end.

Edited 1 time(s). Last edit at 01/17/2014 06:26PM by jcabrer.

Everything else will need to wait for this. No way around it, unless you want to switch to 3mm ABS and a different hot end.

Edited 1 time(s). Last edit at 01/17/2014 06:26PM by jcabrer.

|

Re: Poor Print Quality!?!? January 17, 2014 10:27PM |

Registered: 11 years ago Posts: 791 |

Adding a 4mm balll bearing ball that goes between the motor shaft and the threaded shaft will eliminate a lot of movement and yet still allow the flexibility needed. I have been using that method for some time and it has overcome a lot of problems. The difference with my setup is that the motors are at the bottom, so the weight of the X assembly compresses the flex coupling and the ball takes up the movement. Maybe something to think about?Quote

jcabrer

Disclaimer: This probably has nothing to do with the print problems you are showing us.

Nobody has mentioned the flex couplings. I have a Prusa Mendel with the same type of coupling. It's not a huge deal, but consider that the entire X-axis is essentially being suspended from a couple of springs. I've been putting off designing a solution for this, but now that I see it again, fresh, there is a simple printable part that will prevent the spring from stretching, but still allow flex. I'll post back when it's ready.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Poor Print Quality!?!? January 18, 2014 01:43AM |

Registered: 11 years ago Posts: 469 |

Quote

regpye

Adding a 4mm balll bearing ball that goes between the motor shaft and the threaded shaft will eliminate a lot of movement and yet still allow the flexibility needed. I have been using that method for some time and it has overcome a lot of problems. The difference with my setup is that the motors are at the bottom, so the weight of the X assembly compresses the flex coupling and the ball takes up the movement. Maybe something to think about?Quote

jcabrer

Disclaimer: This probably has nothing to do with the print problems you are showing us.

Nobody has mentioned the flex couplings. I have a Prusa Mendel with the same type of coupling. It's not a huge deal, but consider that the entire X-axis is essentially being suspended from a couple of springs. I've been putting off designing a solution for this, but now that I see it again, fresh, there is a simple printable part that will prevent the spring from stretching, but still allow flex. I'll post back when it's ready.

The problem with mounting at the bottom ( although in general its a good idea) is that by compressing the Z axis flex coupling you effectively take out the flex which, IMO defeats the object of having them in the first place.

I have thought about washing them in thinners to clean them and filling the voids with silicone mastic. Might work but i haven't tried it (yet)

|

Re: Poor Print Quality!?!? January 20, 2014 05:19PM |

Registered: 13 years ago Posts: 118 |

That's a Makergear Mendel (not made anymore), and that's a genuine Makergear BigHead nozzle. I had no luck with a 0.35 nozzle back then and so I use a 0.5mm on my V3's. A new nozzle is $10 but I'd be happy to send you an old one (you pay shipping) I have sitting in a box. I never cared for the "big heads" myself.

Quote

jcabrer

The root of your troubles is most likely at the hot end. What you have is a V3 Makergear or more likely a clone of that. It's not what Makergear currently recommends. Since you are printing in PLA, and using 1.75mm filament, cooling the nozzle insulator and the print is NOT optional. You will need to address this issue first, even before calibration.

Everything else will need to wait for this. No way around it, unless you want to switch to 3mm ABS and a different hot end.

|

Re: Poor Print Quality!?!? January 22, 2014 01:25PM |

Registered: 10 years ago Posts: 16 |

|

Re: Poor Print Quality!?!? January 22, 2014 04:55PM |

Registered: 17 years ago Posts: 824 |

I believe that Pronterface does not include a straightforward method for viewing and changing firmware settings. It (Pronterface) relies on G-codes that can accomplish this.

Your best bet is to download a copy of Repetier Host, and use it to view your firmware settings. This will only work if your firmware supports storing values to EEPROM. Marlin and Repetire firmware support this, and probably others, but it has to be enabled.

Do you know what firmware is running on that printer right now?

Your best bet is to download a copy of Repetier Host, and use it to view your firmware settings. This will only work if your firmware supports storing values to EEPROM. Marlin and Repetire firmware support this, and probably others, but it has to be enabled.

Do you know what firmware is running on that printer right now?

|

Re: Poor Print Quality!?!? January 22, 2014 06:23PM |

Registered: 11 years ago Posts: 469 |

Just my 2 cents

You cant always read your firmware back from your controller . For example my Gen6d control board wont let me do this. The best you can hope for is that whoever configured the firmware put some info in the Marlin config. This then is part of the message you receive in pronter face when you "connect"

My suggestion would be to figure out what (controller) you have and configure it again and upload. That way you know exactly what you are dealing with. You will need to be abe to do this anyway if you want to calibrate your machine.

Good luck

You cant always read your firmware back from your controller . For example my Gen6d control board wont let me do this. The best you can hope for is that whoever configured the firmware put some info in the Marlin config. This then is part of the message you receive in pronter face when you "connect"

My suggestion would be to figure out what (controller) you have and configure it again and upload. That way you know exactly what you are dealing with. You will need to be abe to do this anyway if you want to calibrate your machine.

Good luck

|

Re: Poor Print Quality!?!? January 22, 2014 08:24PM |

Registered: 17 years ago Posts: 824 |

That's right. I already mentioned this in a PM, but it's worth mentioning here in the thread, for those who may find this in the future.

Some older firmware never supported writing settings to EEPROM, and in newer firmware, like repetier, you can disable saving to EEPROM if you need to save some memory on the ATMEGA.

I don't think the electronics has been mentioned yet, but from the pictures, it looks like a RAMPS 1.3, or 1.4. In any case, it should be able to run any current firmware without problem.

Some older firmware never supported writing settings to EEPROM, and in newer firmware, like repetier, you can disable saving to EEPROM if you need to save some memory on the ATMEGA.

I don't think the electronics has been mentioned yet, but from the pictures, it looks like a RAMPS 1.3, or 1.4. In any case, it should be able to run any current firmware without problem.

Sorry, only registered users may post in this forum.