Fixing a Print Flaw - Y Axis Idler

Posted by madscifi

|

Fixing a Print Flaw - Y Axis Idler March 11, 2011 12:16AM |

Registered: 14 years ago Posts: 196 |

I've encountered an interesting flaw in test prints made with my recently completed Mendel.

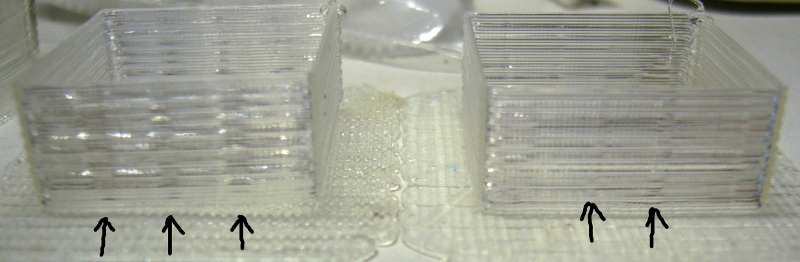

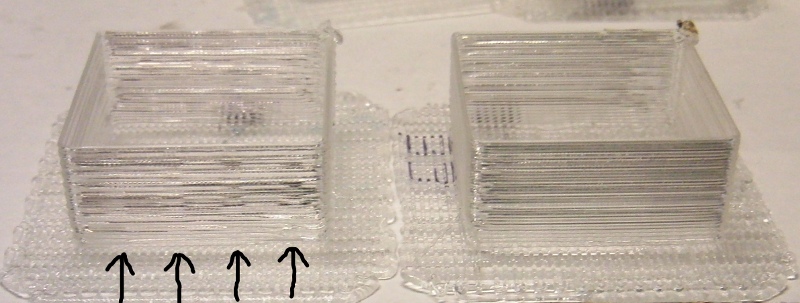

The flaw is the rather wide vertical bands on the front and back faces of the test print on the left (the test print on the right is the result after a partial fix outlined below was implemented). These bands appear at the same locations on the front and back sides of the test print (from the perspective of the image above), but not on the left and right sides of the test print. The are rather minor, but they are significant enough to be felt as well as seen. I believe they are caused by the teeth on the y-axis belt riding up and down as the belt passes over the upper-most y-axis idler bearings.

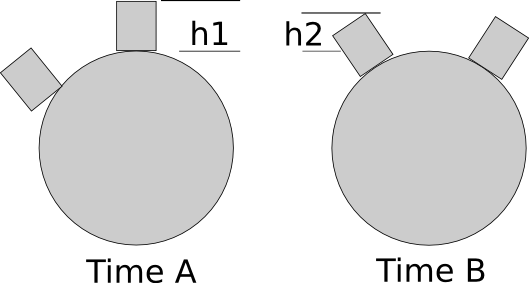

The circles in the above image represent a y-axis idler bearing and the rectangles represent the teeth on the belt. Note that the vertical distance from the top of the bearing to the top of the teeth changes as the belt moves over the bearing. This diagram is not to scale, but the effect in quite visable in reality.

There are two obvious approaches to fixing this problem. The first approach: redo the y-axis belt path so that the teeth never touch a bearing, just like the x-axis belt path. This is probably the best overall solution as it requires no new vitamins, but I'm not interested in doing major surgery on the machine just yet. The other approach is to use pulleys with teeth in place of the two existing upper-most y-axis idlers.

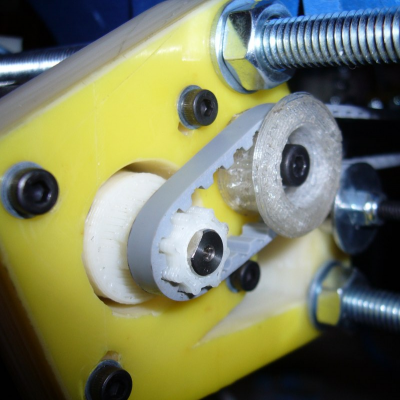

The pulley above was created from thing 1362 (by Erik de Bruijn) using the following settings:

The printed pulley was placed over the existing y-axis pulley on just one side of the machine.

The right-most test print in the first image above shows the result of running the GCODE that was used to print the left-most test print. The majority of the banding has been fixed and I believe what remains can be attributed to the fact that I only put a pulley on one of the y-axis idler bearings.

This was done simply as a quick test in order to verify that the vertical bands in the print were, in fact, caused by the teeth riding up and down on the bearings. There are two problems with the pulley above that need to be addressed. First, the belt height is now a bit higher than it was before, so a cosine error has been introduced along the y-axis and the pulley is now large enough that the portion of the belt that passes below the pulley does not quite clear it entirely. Second, the pulley pushes the belt out in the x-axis direction a bit, causing the belt to be out-of-line vertically, creating even more cosine error and increasing wear on the belt. The first problem can be resolved by ordering a couple of smaller bearings and making pulleys with an outside diameter that matches that of the original bearing but an inside diameter that matches that of the smaller bearings. With a little bit of rework of the pulley I believe the x-axis issue can also be resolved.

I'll post a complete scad file for the new pulleys once I get some smaller bearings and have had a chance to test them.

Edited 1 time(s). Last edit at 03/11/2011 12:19AM by madscifi.

The flaw is the rather wide vertical bands on the front and back faces of the test print on the left (the test print on the right is the result after a partial fix outlined below was implemented). These bands appear at the same locations on the front and back sides of the test print (from the perspective of the image above), but not on the left and right sides of the test print. The are rather minor, but they are significant enough to be felt as well as seen. I believe they are caused by the teeth on the y-axis belt riding up and down as the belt passes over the upper-most y-axis idler bearings.

The circles in the above image represent a y-axis idler bearing and the rectangles represent the teeth on the belt. Note that the vertical distance from the top of the bearing to the top of the teeth changes as the belt moves over the bearing. This diagram is not to scale, but the effect in quite visable in reality.

There are two obvious approaches to fixing this problem. The first approach: redo the y-axis belt path so that the teeth never touch a bearing, just like the x-axis belt path. This is probably the best overall solution as it requires no new vitamins, but I'm not interested in doing major surgery on the machine just yet. The other approach is to use pulleys with teeth in place of the two existing upper-most y-axis idlers.

The pulley above was created from thing 1362 (by Erik de Bruijn) using the following settings:

shaftDiameter = 13; hubDiameter = 22; hubHeight = 0; flanges = 1; hubSetScewDiameter = 3; numSetScrews = 3; numTeeth = 12; toothType = 3; // Belt properties: pitch = 5; beltWidth = 5.3; beltThickness = 0.65; notchDepth = 1.8; toothWidth = 1.4;

The printed pulley was placed over the existing y-axis pulley on just one side of the machine.

The right-most test print in the first image above shows the result of running the GCODE that was used to print the left-most test print. The majority of the banding has been fixed and I believe what remains can be attributed to the fact that I only put a pulley on one of the y-axis idler bearings.

This was done simply as a quick test in order to verify that the vertical bands in the print were, in fact, caused by the teeth riding up and down on the bearings. There are two problems with the pulley above that need to be addressed. First, the belt height is now a bit higher than it was before, so a cosine error has been introduced along the y-axis and the pulley is now large enough that the portion of the belt that passes below the pulley does not quite clear it entirely. Second, the pulley pushes the belt out in the x-axis direction a bit, causing the belt to be out-of-line vertically, creating even more cosine error and increasing wear on the belt. The first problem can be resolved by ordering a couple of smaller bearings and making pulleys with an outside diameter that matches that of the original bearing but an inside diameter that matches that of the smaller bearings. With a little bit of rework of the pulley I believe the x-axis issue can also be resolved.

I'll post a complete scad file for the new pulleys once I get some smaller bearings and have had a chance to test them.

Edited 1 time(s). Last edit at 03/11/2011 12:19AM by madscifi.

|

Re: Fixing a Print Flaw - Y Axis Idler March 12, 2011 08:00PM |

Registered: 13 years ago Posts: 482 |

That indeed is an interesting observation madscifi.

If I am not mistaken, the updated x-axis now has the teeth of the belt facing inward? I guess that will also cause similar errors in the x-axis, although possibly less pronounced due to 4 bearings as opposed to 2 of the Y axis.

I think that would mean the X-Axis should be redesigned back to having the teeth facing outwards... with the necessary move of the motor to drive the belt, but to avoid the sharp bends of the original X-axis belt.

Looking forward to your confirmation once you have finished your investigations madscifi.

If I am not mistaken, the updated x-axis now has the teeth of the belt facing inward? I guess that will also cause similar errors in the x-axis, although possibly less pronounced due to 4 bearings as opposed to 2 of the Y axis.

I think that would mean the X-Axis should be redesigned back to having the teeth facing outwards... with the necessary move of the motor to drive the belt, but to avoid the sharp bends of the original X-axis belt.

Looking forward to your confirmation once you have finished your investigations madscifi.

|

Re: Fixing a Print Flaw - Y Axis Idler March 13, 2011 05:29AM |

Admin Registered: 17 years ago Posts: 7,879 |

If you have the teeth facing outwards you need much bigger pulleys and idlers or the belt will snap due to being bent back on itself.

Odd that I don't see this effect on my Y-axis. There are no noticeable ripples in the sides of my objects.

Edited 1 time(s). Last edit at 03/13/2011 07:49AM by nophead.

[www.hydraraptor.blogspot.com]

Odd that I don't see this effect on my Y-axis. There are no noticeable ripples in the sides of my objects.

Edited 1 time(s). Last edit at 03/13/2011 07:49AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Fixing a Print Flaw - Y Axis Idler March 13, 2011 08:34AM |

Registered: 13 years ago Posts: 1,780 |

I think that madscifi does make a good point. But even though I can't say that my filaments are perfectly lined up, they they're much better than his bad example and they look just as good or better than his good example. I also don't see a difference between the X and Y direction. I've been thinking that the irregularities that I see in the single walled test may be due to the hacked stepper control in the Gen 3 extruder controller which I'm soon converting to a Pololu.

|

Re: Fixing a Print Flaw - Y Axis Idler March 13, 2011 10:28AM |

Registered: 13 years ago Posts: 486 |

I have seen that effect on my Y. I think it depends on belt tension. If you get the tension just right, the stiffness in the belt at the radius of the idler means it comes off the idler smoothly. With the belt too tight, the belt nods up and down as the teeth roll over the idler causing the madscifi flaw. Too loose and you probably get it too with a bit of backlash to boot.

|

Re: Fixing a Print Flaw - Y Axis Idler March 13, 2011 04:48PM |

Registered: 14 years ago Posts: 196 |

Based on everyone's comments I've decided that I need to find some sort of crash course on idlers. I found this.

Assuming that I understand the terminology (and there is little reason to believe that I do), a bearing with the teeth touching the bearing is an inside flat idler. The recommended minimum diameter for a flat inside idler is that which is equivalent to a 40 groove pulley, or about 63.5mm (See table 21 on page two of the linked reference). Even the recommended diameter for a pulley is 14 grooves, or about 22.3mm. Essentially, it is not possible to meet the recommended minimums without redoing the belt path as there simply is not enough room.

I'm now left with more questions than when I started. Is the recommended diameter simply a matter of belt longevity or does accuracy figure into the recommendation? Does the fact that the y-belt makes a minimal bend over the bearing affect the minimum diameter recommendation? Does the linked reference even apply to the belts on the Mendel? I'm really out of my depth here.

Nophead, Brnrd - Have you tried printing in clear PLA? I think the effect is much easier to see in clear plastic than it is in opaque plastic. On the other hand, almost no one else is seeing the problem so maybe it is simply a matter of the belt tension on my machine as Greg suggests.

Greg - I'm glad someone else has seen the effect. I was beginning to think I was, well, enough said ;-). I'll try different tensions with a bearing as the idler and see if I can eliminate the effect that way. Thanks for the suggestion.

Edited 1 time(s). Last edit at 03/13/2011 06:26PM by madscifi.

Assuming that I understand the terminology (and there is little reason to believe that I do), a bearing with the teeth touching the bearing is an inside flat idler. The recommended minimum diameter for a flat inside idler is that which is equivalent to a 40 groove pulley, or about 63.5mm (See table 21 on page two of the linked reference). Even the recommended diameter for a pulley is 14 grooves, or about 22.3mm. Essentially, it is not possible to meet the recommended minimums without redoing the belt path as there simply is not enough room.

I'm now left with more questions than when I started. Is the recommended diameter simply a matter of belt longevity or does accuracy figure into the recommendation? Does the fact that the y-belt makes a minimal bend over the bearing affect the minimum diameter recommendation? Does the linked reference even apply to the belts on the Mendel? I'm really out of my depth here.

Nophead, Brnrd - Have you tried printing in clear PLA? I think the effect is much easier to see in clear plastic than it is in opaque plastic. On the other hand, almost no one else is seeing the problem so maybe it is simply a matter of the belt tension on my machine as Greg suggests.

Greg - I'm glad someone else has seen the effect. I was beginning to think I was, well, enough said ;-). I'll try different tensions with a bearing as the idler and see if I can eliminate the effect that way. Thanks for the suggestion.

Edited 1 time(s). Last edit at 03/13/2011 06:26PM by madscifi.

|

Re: Fixing a Print Flaw - Y Axis Idler March 13, 2011 07:49PM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes I have printed PLA on my Mendel and I didn't notice effects like that.

Yes Mendel violates the spec for the belts. The X-axis used to bend the belt both ways and it would snap in about 100 hours. With the revised X-axis and the original Y- axis it seems to get away with it. Mine has been running 24/7 for nearly a year and the Y-belt is the original. This is because the pulleys are only a little smaller than the minimum and the Y-axis only bends slightly the wrong way. Since I upgraded the X-axis to the new design that is still on the same belt. Before that I got through three or four.

Edited 1 time(s). Last edit at 03/13/2011 08:42PM by nophead.

[www.hydraraptor.blogspot.com]

Yes Mendel violates the spec for the belts. The X-axis used to bend the belt both ways and it would snap in about 100 hours. With the revised X-axis and the original Y- axis it seems to get away with it. Mine has been running 24/7 for nearly a year and the Y-belt is the original. This is because the pulleys are only a little smaller than the minimum and the Y-axis only bends slightly the wrong way. Since I upgraded the X-axis to the new design that is still on the same belt. Before that I got through three or four.

Edited 1 time(s). Last edit at 03/13/2011 08:42PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Fixing a Print Flaw - Y Axis Idler March 13, 2011 09:35PM |

Registered: 13 years ago Posts: 1,780 |

Yes. I went through 5 lbs of clear PLA before switching to white PLA and now black ABS. I think you can see this imperfection on any color but the clear ones might show more since you can see through the filament to the other side. As I wrote, you make a good point and i already made a note to myself to try putting the same gears on the idlers in the Y and also on the X when I switch to the alternate motor bracket.

|

Re: Fixing a Print Flaw - Y Axis Idler March 14, 2011 02:05AM |

Registered: 14 years ago Posts: 196 |

I've put the bearing back and run a couple of tests.

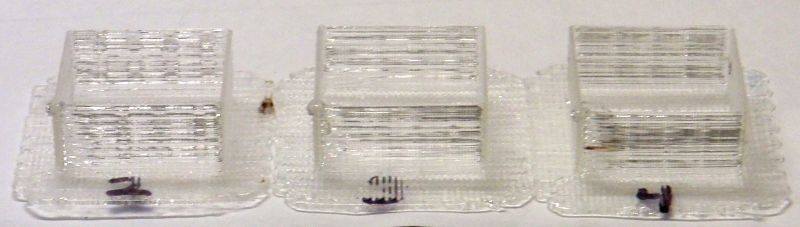

Printed using the same GCODE as before. The leftmost print has the least tension on the belt and the rightmost print has the most tension on the belt. The print using the least tension shows the problem strongly. I think the rightmost shows a bit more banding in person than the middle print, so there does seem to be an window where the banding effect is minimized. I do not seem to have hit the magic minimum, however.

I need to see if I can eliminate the problem by tweaking the tension some more. But I need to find a good way to quantify it first as I'm not going to get anywhere if I keep trying to adjust it by hand. Has anyone attempted to quantify the belt tension? Maybe hang a known weight on the belt and measure the amount the belt sinks? Even better would be a small scale attached to the loose end of the belt, pull until the scale reads X, then tighten the belt clamp down? Any other ideas?

Also, is there a wiki page for known problems and solutions. I did some searching and browsing and really could not find such a page. Sebastien (just checking to see if you are awake ;-), I'd actually be willing to start working on such a page if you wouldn't mind deciding on a good title or pointing me at the appropriate page.

I assume a pulley of the same diameter would still be better than a bearing, based on the recommend relative sizes of the flat verses pulley in the technical documentation.

It looks to me that a 2mm belt would be a better match for the Mendel. The downside appears to be that the pulleys would not really be printable on a Mendel, but the commercial pulleys seem to be reasonably priced. That would be especially true if the belt path was adjusted a bit so that only two pulleys on each axis are used, which looks to be possible, at least on the y-axis. I have not seen the redesigned x-axis, so I don't know about that at the moment.

Printed using the same GCODE as before. The leftmost print has the least tension on the belt and the rightmost print has the most tension on the belt. The print using the least tension shows the problem strongly. I think the rightmost shows a bit more banding in person than the middle print, so there does seem to be an window where the banding effect is minimized. I do not seem to have hit the magic minimum, however.

I need to see if I can eliminate the problem by tweaking the tension some more. But I need to find a good way to quantify it first as I'm not going to get anywhere if I keep trying to adjust it by hand. Has anyone attempted to quantify the belt tension? Maybe hang a known weight on the belt and measure the amount the belt sinks? Even better would be a small scale attached to the loose end of the belt, pull until the scale reads X, then tighten the belt clamp down? Any other ideas?

Also, is there a wiki page for known problems and solutions. I did some searching and browsing and really could not find such a page. Sebastien (just checking to see if you are awake ;-), I'd actually be willing to start working on such a page if you wouldn't mind deciding on a good title or pointing me at the appropriate page.

I assume a pulley of the same diameter would still be better than a bearing, based on the recommend relative sizes of the flat verses pulley in the technical documentation.

It looks to me that a 2mm belt would be a better match for the Mendel. The downside appears to be that the pulleys would not really be printable on a Mendel, but the commercial pulleys seem to be reasonably priced. That would be especially true if the belt path was adjusted a bit so that only two pulleys on each axis are used, which looks to be possible, at least on the y-axis. I have not seen the redesigned x-axis, so I don't know about that at the moment.

|

Re: Fixing a Print Flaw - Y Axis Idler March 14, 2011 06:49AM |

Admin Registered: 17 years ago Posts: 7,879 |

I am struggling to understand this as I don't have the problem and I haven't fine tuned my belt tension. I just make as tight as I can when pulling it with one hand and tightening the clamp with the other.

I think it must be down to the type of belt as yours looks totally different to mine, picture [1.bp.blogspot.com]. Is it a proper timing belt with wires in it?

[www.hydraraptor.blogspot.com]

I think it must be down to the type of belt as yours looks totally different to mine, picture [1.bp.blogspot.com]. Is it a proper timing belt with wires in it?

[www.hydraraptor.blogspot.com]

|

Re: Fixing a Print Flaw - Y Axis Idler March 14, 2011 07:12AM |

Admin Registered: 17 years ago Posts: 7,879 |

If you do the maths for the error caused by the difference between an arc and a chord length 2.5mm on a circle 13mm diameter it is very small, 0.03mm. Also the middle of the chord is only about 0.1mm less than the radius. It is hard to imaging how that would produce the effect you have.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Fixing a Print Flaw - Y Axis Idler March 14, 2011 05:13PM |

Registered: 13 years ago Posts: 486 |

Belt stiffness plays a significant role here too. With a stiff belt, you need more tension and when you dont have enough tension, the belt doesnt come off the idler at a tangent, but instead arcs up a little bit. The amount it arcs up varies depending on the tooth phase on the idler, so if you watch the belt as the axis moves in one direction, it nods up and down. Perhaps nophead's belts are more flexible meaning he is far less likely to see these effects.

|

Re: Fixing a Print Flaw - Y Axis Idler March 14, 2011 10:57PM |

Registered: 14 years ago Posts: 196 |

Greg, Nophead - I think you both may be on to something.

I put an .0005 (inch) indicator on the backside of the belt just past the bearing and I see a .030 inch (0.76mm) change as I turn the stepper manually. The belt had been held as tightly as I could with one hand and the clamp tightened down with the other. Since the indicator was not exactly parallel to the belt the actual change was even greater.

The belt was purchased from one of the suppliers of reprap components here in the states. On the surface it meets the requirements - T5, steel support wires - maybe it is just too stiff for use on the Mendel. Can someone recommend a specific belt from anyone that will ship to the states for a reasonable price?

Also, would anyone be interested in testing the belt after I get a new one? It would be a good way to verify that it is the belt that is causing the problem. I'll pay for shipping and I won't need it back. PM me is interested.

I suppose that it is possible that the bearing is bad, although that seems unlikely. A quick test with the indicator on the underside of the bearing should rule it out.

Edited 2 time(s). Last edit at 03/15/2011 02:27AM by madscifi.

I put an .0005 (inch) indicator on the backside of the belt just past the bearing and I see a .030 inch (0.76mm) change as I turn the stepper manually. The belt had been held as tightly as I could with one hand and the clamp tightened down with the other. Since the indicator was not exactly parallel to the belt the actual change was even greater.

The belt was purchased from one of the suppliers of reprap components here in the states. On the surface it meets the requirements - T5, steel support wires - maybe it is just too stiff for use on the Mendel. Can someone recommend a specific belt from anyone that will ship to the states for a reasonable price?

Also, would anyone be interested in testing the belt after I get a new one? It would be a good way to verify that it is the belt that is causing the problem. I'll pay for shipping and I won't need it back. PM me is interested.

I suppose that it is possible that the bearing is bad, although that seems unlikely. A quick test with the indicator on the underside of the bearing should rule it out.

Edited 2 time(s). Last edit at 03/15/2011 02:27AM by madscifi.

|

Re: Fixing a Print Flaw - Y Axis Idler March 15, 2011 11:06AM |

Registered: 13 years ago Posts: 601 |

i received at least 3 bad bearings. Ebay :-(

so don't rule it out so quickly

I'm also wondering if the banding changes frequency if you change the print speed. perhaps it's resonance in the belt and stepper at certain speeds.

Another thought; could it also be caused by the shape of the filament as it exits the nozzle? Nophead did a blog post a while back about how his filament was curling when extruded into air because it had an elliptical profile instead of a circular one. if you have a similar problem, it might be causing some oscillation when the filament exits. if you can, try swiveling the hot end about 90 degrees and see if it shows up on the X axis.

I do think a toothed sleeve for the 624 bearing would be a good idea, regardless of what your ultimate findings turn out to be, so i hope you post the file to the wiki when you finalize the design.

so don't rule it out so quickly

I'm also wondering if the banding changes frequency if you change the print speed. perhaps it's resonance in the belt and stepper at certain speeds.

Another thought; could it also be caused by the shape of the filament as it exits the nozzle? Nophead did a blog post a while back about how his filament was curling when extruded into air because it had an elliptical profile instead of a circular one. if you have a similar problem, it might be causing some oscillation when the filament exits. if you can, try swiveling the hot end about 90 degrees and see if it shows up on the X axis.

I do think a toothed sleeve for the 624 bearing would be a good idea, regardless of what your ultimate findings turn out to be, so i hope you post the file to the wiki when you finalize the design.

|

Re: Fixing a Print Flaw - Y Axis Idler March 15, 2011 06:11PM |

Registered: 13 years ago Posts: 486 |

|

Re: Fixing a Print Flaw - Y Axis Idler March 15, 2011 06:35PM |

Registered: 14 years ago Posts: 1,092 |

Greg: Nice.

BTW: Could it be that this 'riding' of teeth on a bearing surface is happening at both ends of the axis, at the same time?

eg: When the tooth on the bearing raises the belt to it's maximum height on one end, the other end is doing the same thing.

I can see this causing the belt to wobble up/down, and also to change the tension on it slightly.

A way to fix this may be to simply move the bearings closer together (ie: up to 2.5mm, half the pitch of the belt) or further apart, and see if the effect is lessened.

Either you could file out the bearing bolt holes (probably easier), or you could adjust the position of the bottom vertices slightly (nearer or apart).

Note: Adjusting the vertices means you're changing the area of the triangles on the side of your bot, and to keep it square, you need to adjust at least 4 of the corner vertices.

BTW: Could it be that this 'riding' of teeth on a bearing surface is happening at both ends of the axis, at the same time?

eg: When the tooth on the bearing raises the belt to it's maximum height on one end, the other end is doing the same thing.

I can see this causing the belt to wobble up/down, and also to change the tension on it slightly.

A way to fix this may be to simply move the bearings closer together (ie: up to 2.5mm, half the pitch of the belt) or further apart, and see if the effect is lessened.

Either you could file out the bearing bolt holes (probably easier), or you could adjust the position of the bottom vertices slightly (nearer or apart).

Note: Adjusting the vertices means you're changing the area of the triangles on the side of your bot, and to keep it square, you need to adjust at least 4 of the corner vertices.

|

Re: Fixing a Print Flaw - Y Axis Idler March 15, 2011 10:36PM |

Registered: 14 years ago Posts: 196 |

Buback - I have since put an indicator on the bearing and verified that it is not the cause of the problem. But you were right to recommend not dismissing the idea out of hand.

I'll give printing at a different speed a try, but I don't think that resonance is the issue. The large vertical motion occurs even when turning very slowly by hand. Resonances may increase the effect, but I believe the base problem is the vertical motion.

Changing the tension on the Y-belt dramatically changes the effect. If it was a shape of the filament issue I'm pretty sure that would not be the case. I definitely had the belt too loose to begin with.

I agree that a toothed idler would be better, but one really needs to put it on a smaller bearing so that the belt comes off it at the same height (without redesigning the y-motor support piece). However, a 13mm toothed pulley is still smaller than the minimum recommended size for a 5mm belt.

Greg - you've been holding out on us ;-) That looks very nice, by the way.

Depending on the results I get with a different 5mm belt I may give a 2mm belt and toothed idler a try. A 13 mm diameter 2mm pulley is at the bottom end of the recommended range for a 2mm belt. I'm convinced that redesigning the belt path so that no idlers on the motor mount side are used, and a single toothed pulley on the opposite side is really the best way to address the problem.

I just discovered that someone has already produced a redesigned Y axis that appears to address most of these issues: See here. That, I think, gets me out of having to attempt to do it.

Edited 1 time(s). Last edit at 03/15/2011 10:39PM by madscifi.

I'll give printing at a different speed a try, but I don't think that resonance is the issue. The large vertical motion occurs even when turning very slowly by hand. Resonances may increase the effect, but I believe the base problem is the vertical motion.

Changing the tension on the Y-belt dramatically changes the effect. If it was a shape of the filament issue I'm pretty sure that would not be the case. I definitely had the belt too loose to begin with.

I agree that a toothed idler would be better, but one really needs to put it on a smaller bearing so that the belt comes off it at the same height (without redesigning the y-motor support piece). However, a 13mm toothed pulley is still smaller than the minimum recommended size for a 5mm belt.

Greg - you've been holding out on us ;-) That looks very nice, by the way.

Depending on the results I get with a different 5mm belt I may give a 2mm belt and toothed idler a try. A 13 mm diameter 2mm pulley is at the bottom end of the recommended range for a 2mm belt. I'm convinced that redesigning the belt path so that no idlers on the motor mount side are used, and a single toothed pulley on the opposite side is really the best way to address the problem.

I just discovered that someone has already produced a redesigned Y axis that appears to address most of these issues: See here. That, I think, gets me out of having to attempt to do it.

Edited 1 time(s). Last edit at 03/15/2011 10:39PM by madscifi.

|

Re: Fixing a Print Flaw - Y Axis Idler March 18, 2011 01:31AM |

Registered: 14 years ago Posts: 196 |

|

Re: Fixing a Print Flaw - Y Axis Idler March 18, 2011 02:07AM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Fixing a Print Flaw - Y Axis Idler March 18, 2011 02:40AM |

Registered: 14 years ago Posts: 196 |

|

Re: Fixing a Print Flaw - Y Axis Idler March 20, 2011 08:39PM |

Registered: 14 years ago Posts: 196 |

I tried a 2 mm (*1) belt with a commercial pulley - this completely eliminated the vertical banding on the walls parallel to the y-axis.

The print on the left is the best I was able to obtain with a 5 mm belt using bearings for all of the idlers. In reality the banding is pretty subtle and I'm not certain that it would be visible in opaque plastic. The print on the right was done with a 2 mm belt and a commercial 15 groove pulley on the stepper (also with bearings for all of the idlers).

It appears that lots of people simply do not have this problem. However, if you do, the first thing to do is to try tightening the y-axis belt. You might also try a less flexible belt - i tried a more flexible belt and it made the problem a bit worse. A 2 mm belt and a commercial pulley appears to be one way to completely eliminate the problem.

The y-axis idler bearings are still smaller than the recommended idler pulley diameter for a 2 mm belt. However, they are significantly closer to the recommended size for a 2 mm belt than they are for a 5 mm belt.

I think that a redesigned Y-axis belt path, such as the one eckertech designed, might solve the problem and allow reprapable pulleys to be used. However, I have not tested that approach as would would involve significant disassembly of my reprap, something I don't want to do at the moment.

(*1) In reality I replaced the 5 mm belt with a 1/4 inch wide MXL (0.08 inch, 2.032 mm) belt. An extra washer was added to each idler bearing assembly to allow space for the wider belt. The teacup firmware was modified to account for the belt and pulley changes.

The print on the left is the best I was able to obtain with a 5 mm belt using bearings for all of the idlers. In reality the banding is pretty subtle and I'm not certain that it would be visible in opaque plastic. The print on the right was done with a 2 mm belt and a commercial 15 groove pulley on the stepper (also with bearings for all of the idlers).

It appears that lots of people simply do not have this problem. However, if you do, the first thing to do is to try tightening the y-axis belt. You might also try a less flexible belt - i tried a more flexible belt and it made the problem a bit worse. A 2 mm belt and a commercial pulley appears to be one way to completely eliminate the problem.

The y-axis idler bearings are still smaller than the recommended idler pulley diameter for a 2 mm belt. However, they are significantly closer to the recommended size for a 2 mm belt than they are for a 5 mm belt.

I think that a redesigned Y-axis belt path, such as the one eckertech designed, might solve the problem and allow reprapable pulleys to be used. However, I have not tested that approach as would would involve significant disassembly of my reprap, something I don't want to do at the moment.

(*1) In reality I replaced the 5 mm belt with a 1/4 inch wide MXL (0.08 inch, 2.032 mm) belt. An extra washer was added to each idler bearing assembly to allow space for the wider belt. The teacup firmware was modified to account for the belt and pulley changes.

|

Re: Fixing a Print Flaw - Y Axis Idler March 23, 2011 07:36PM |

Registered: 13 years ago Posts: 39 |

I regret not being more active on this thread. There's a photo of the banding I'm getting with opaque PLA on my webpage. Is there a thingiverse number for Greg's toothed bearing?

Woodsmoke

r:-7

[ resistentialist report ]

Woodsmoke

r:-7

[ resistentialist report ]

|

Re: Fixing a Print Flaw - Y Axis Idler March 26, 2011 05:15PM |

Registered: 14 years ago Posts: 196 |

I'm don't know if the design Greg printed is up on Thingiverse or not. However, you can make a reasonable toothed bearing cover using Thing 1362 (with the appropriate settings changed in the scad file). To get something much closer to Greg's design than what I printed above set flanges=0 in the scad file.

|

Re: Fixing a Print Flaw - Y Axis Idler March 29, 2011 07:23PM |

Registered: 13 years ago Posts: 39 |

|

Re: Fixing a Print Flaw - Y Axis Idler September 05, 2012 01:18PM |

Registered: 12 years ago Posts: 122 |

I'm resurrecting this old topic because it was the most relevant thing I could find and it helped me to understand a new problem I experienced yesterday. I just swapped out my old printed X and Y belt pulleys on my Mendel90 for new aluminium ones and expected to see an improvement in print quality. What I saw was quite a serious ripple on the Y axis which hadn't been there before.

I discovered that my problem was caused by the Y axis belt being too tight.

When I fitted the new pulleys they were larger than the old ones which I knew meant that I would have to recalibrate my steps/mm setting. On the X axis there is a belt tensioner which allowed easy adjustment of belt length for the new pulley. On the Y axis, this was more difficult because the belt locks cannot be loosened without removing the print bed. I foolishly tried to take the lazy option and simply loosened the Y-idler, fitted the belt over the new pulley and then screwed the idler down again. It worked perfectly except that the belt was very, very tight - about middle C tight!

I think that the resulting transmission of tooth vibrations (or possibly the microstepping errors discovered by nophead which I still haven't fixed yet) down the excessively tight belt were the cause of the dramatic rippling. Anyway, I have now loosened the Y belt by one notch so that I can now use the proper idler tensioning adjustment method and the ripples have gone away.

richgain

I discovered that my problem was caused by the Y axis belt being too tight.

When I fitted the new pulleys they were larger than the old ones which I knew meant that I would have to recalibrate my steps/mm setting. On the X axis there is a belt tensioner which allowed easy adjustment of belt length for the new pulley. On the Y axis, this was more difficult because the belt locks cannot be loosened without removing the print bed. I foolishly tried to take the lazy option and simply loosened the Y-idler, fitted the belt over the new pulley and then screwed the idler down again. It worked perfectly except that the belt was very, very tight - about middle C tight!

I think that the resulting transmission of tooth vibrations (or possibly the microstepping errors discovered by nophead which I still haven't fixed yet) down the excessively tight belt were the cause of the dramatic rippling. Anyway, I have now loosened the Y belt by one notch so that I can now use the proper idler tensioning adjustment method and the ripples have gone away.

richgain

Sorry, only registered users may post in this forum.