Solving effector tilt on dual extrusion delta printers

Posted by dc42

|

Solving effector tilt on dual extrusion delta printers June 03, 2015 11:46AM |

Registered: 10 years ago Posts: 14,672 |

In using my mini differential IR sensor board, I've become aware that it isn't easy to keep the effector perfectly level as it translates in the XY plane. Any slight difference between the lengths of the diagonal rods in a pair, or the spacing between rods in a pair at the two ends, will cause the effector angle to vary with XY position. There may be other factors I haven't thought of that cause the tilt to vary.

It occurred to me that varying effector tilt will also be a big problem when using a dual-extrusion head such as the E3D chimera. I have a dual extrusion Ormerod printer, and one of the issues is to prevent the non-printing nozzle interfering with the printing nozzle. Even if they are at exactly the same height, the non-printing nozzle leaves slight marks if it passes over filament that just been printed. With varying effector tilt, there will be times when the non-printing nozzle will be slightly lower than the printing nozzle, making the situation worse.

This led me to the following idea. Suppose we deliberately tilt the effector so that the non-printing nozzle is higher than the printing nozzle? Consider the following setup. The effector carries two nozzles, one offset from the centre in the +X direction, the other offset in the -X direction. On the Z carriage slider, we use a small servo, or two solenoids, or a voice coil, or some other mechanism to rotate the carriage by a few degrees about the Y axis, thereby changing the relative heights of the two diagonal rod bearings. This will in turn cause the effector to rotate about the Y axis, raising one of the nozzles above the other.

This approach could be generalised to more than two nozzles, but depending on the arrangement of the nozzles on the effector, it may be necessary to rotate two or all three of the carriages.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

It occurred to me that varying effector tilt will also be a big problem when using a dual-extrusion head such as the E3D chimera. I have a dual extrusion Ormerod printer, and one of the issues is to prevent the non-printing nozzle interfering with the printing nozzle. Even if they are at exactly the same height, the non-printing nozzle leaves slight marks if it passes over filament that just been printed. With varying effector tilt, there will be times when the non-printing nozzle will be slightly lower than the printing nozzle, making the situation worse.

This led me to the following idea. Suppose we deliberately tilt the effector so that the non-printing nozzle is higher than the printing nozzle? Consider the following setup. The effector carries two nozzles, one offset from the centre in the +X direction, the other offset in the -X direction. On the Z carriage slider, we use a small servo, or two solenoids, or a voice coil, or some other mechanism to rotate the carriage by a few degrees about the Y axis, thereby changing the relative heights of the two diagonal rod bearings. This will in turn cause the effector to rotate about the Y axis, raising one of the nozzles above the other.

This approach could be generalised to more than two nozzles, but depending on the arrangement of the nozzles on the effector, it may be necessary to rotate two or all three of the carriages.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Solving effector tilt on dual extrusion delta printers June 03, 2015 12:07PM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

In using my mini differential IR sensor board, I've become aware that it isn't easy to keep the effector perfectly level as it translates in the XY plane. Any slight difference between the lengths of the diagonal rods in a pair, or the spacing between rods in a pair at the two ends, will cause the effector angle to vary with XY position. There may be other factors I haven't thought of that cause the tilt to vary.

It occurred to me that varying effector tilt will also be a big problem when using a dual-extrusion head such as the E3D chimera. I have a dual extrusion Ormerod printer, and one of the issues is to prevent the non-printing nozzle interfering with the printing nozzle. Even if they are at exactly the same height, the non-printing nozzle leaves slight marks if it passes over filament that just been printed. With varying effector tilt, there will be times when the non-printing nozzle will be slightly lower than the printing nozzle, making the situation worse.

This led me to the following idea. Suppose we deliberately tilt the effector so that the non-printing nozzle is higher than the printing nozzle? Consider the following setup. The effector carries two nozzles, one offset from the centre in the +X direction, the other offset in the -X direction. On the Z carriage slider, we use a small servo, or two solenoids, or a voice coil, or some other mechanism to rotate the carriage by a few degrees about the Y axis, thereby changing the relative heights of the two diagonal rod bearings. This will in turn cause the effector to rotate about the Y axis, raising one of the nozzles above the other.

This approach could be generalised to more than two nozzles, but depending on the arrangement of the nozzles on the effector, it may be necessary to rotate two or all three of the carriages.

Very interesting Idea that Dave.

Haven't a clue how it would be implemented particularly in the FW (But that's where you come in I guess) mechanically it would need for the tilting carriage's to pivot arround a center point between the rod fixingings whilst at the same time remaining pretty solid.

I suspect that if the towers lean at all (Apart from in line with their position) could also cause this effect.

Will watch this thread with great interest.

Doug

|

Re: Solving effector tilt on dual extrusion delta printers June 03, 2015 12:56PM |

Registered: 10 years ago Posts: 14,672 |

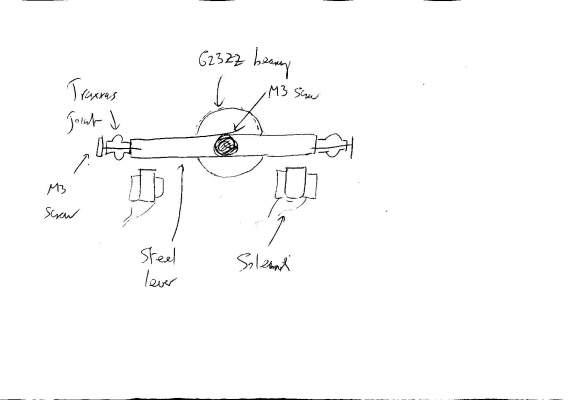

Rather than rotate the whole carriage, I think it would be better to use a horizontal lever at the top of the carriage, pivoted on a bearing at its centre, and with the diagonal rod bearings attached to the ends. There could be a solenoid under each end of the lever, so I can energise one solenoid or the other. Like this:

Edited 1 time(s). Last edit at 06/03/2015 12:56PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 06/03/2015 12:56PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Solving effector tilt on dual extrusion delta printers June 03, 2015 01:49PM |

Registered: 9 years ago Posts: 1,159 |

Dave

How would fine positioning work?

Could you use a High Quality Servo and use PWM to fine set the positioning something like a good digital servo with metal gears would have to have extremely good holding torque tho.

Like the concept tho but maybe a beam with F623 bearing's one from each side just to help hold lateral positioning?

Doug

How would fine positioning work?

Could you use a High Quality Servo and use PWM to fine set the positioning something like a good digital servo with metal gears would have to have extremely good holding torque tho.

Like the concept tho but maybe a beam with F623 bearing's one from each side just to help hold lateral positioning?

Doug

|

Re: Solving effector tilt on dual extrusion delta printers June 03, 2015 01:55PM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

Dave

How would fine positioning work?

Could you use a High Quality Servo and use PWM to fine set the positioning something like a good digital servo with metal gears would have to have extremely good holding torque tho.

Like the concept tho but maybe a beam with F623 bearing's one from each side just to help hold lateral positioning?

Doug

I don't see that fine positioning is needed for just 2 nozzles, all I need to do is be able to select 2 different tilt positions (i.e. with the beam tight against one or other solenoid) and switch between them in a reproducible manner. Small solenoids are available cheaply from China - I already have a selection of them from when I was toying with the idea of a solenoid-deployed Z probe.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Solving effector tilt on dual extrusion delta printers June 03, 2015 02:19PM |

Registered: 9 years ago Posts: 51 |

|

Re: Solving effector tilt on dual extrusion delta printers June 06, 2015 08:31PM |

Registered: 9 years ago Posts: 189 |

|

Re: Solving effector tilt on dual extrusion delta printers June 07, 2015 02:56PM |

Registered: 9 years ago Posts: 51 |

|

Re: Solving effector tilt on dual extrusion delta printers July 03, 2015 06:15AM |

Registered: 9 years ago Posts: 51 |

|

Re: Solving effector tilt on dual extrusion delta printers July 03, 2015 09:42AM |

Registered: 8 years ago Posts: 93 |

|

Re: Solving effector tilt on dual extrusion delta printers July 07, 2015 10:09AM |

Registered: 9 years ago Posts: 70 |

why not mount the effector on a small slide or linear bearing and shaft and turn a solenoid on and off that pulls the nozzle up say 1/4". i realize your adding mass to the effector but you can get some pretty small solenoids. this is one reason i like the idea of the diamond hotend. 3 filaments into one nozzle and no nozzle drag at all.

|

Re: Solving effector tilt on dual extrusion delta printers July 11, 2015 06:42AM |

Registered: 9 years ago Posts: 189 |

this guy should be contacted:

[www.youtube.com]

I think this is a good solution towards the use of dual hotends on a delta!

and seems to fix the "second-hotend-oozing" - problem at the same time

Alex

[www.youtube.com]

I think this is a good solution towards the use of dual hotends on a delta!

and seems to fix the "second-hotend-oozing" - problem at the same time

Alex

|

Re: Solving effector tilt on dual extrusion delta printers July 11, 2015 08:25AM |

Registered: 10 years ago Posts: 14,672 |

I have a dual extrusion Ormerod and have never had a problem with oozing from the inactive nozzle, using PLA filament, 10mm retraction (the slic3r default), and 150C standby temperature. So I think I ll stick to my plan, which keeps the weight of the actuator mechanism off the effector.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Solving effector tilt on dual extrusion delta printers December 15, 2015 12:54PM |

Registered: 8 years ago Posts: 319 |

Quote

dc42

I have a dual extrusion Ormerod and have never had a problem with oozing from the inactive nozzle, using PLA filament, 10mm retraction (the slic3r default), and 150C standby temperature. So I think I ll stick to my plan, which keeps the weight of the actuator mechanism off the effector.

Not to resurrect an old thread but as you know david I am obsessed with effector tilt. And during my googling process I found out that is what the spiderbot does. The dual head effector. One is tilted.

Sorry, only registered users may post in this forum.