|

Experience with magnetic joints July 11, 2015 06:01AM |

Registered: 9 years ago Posts: 6 |

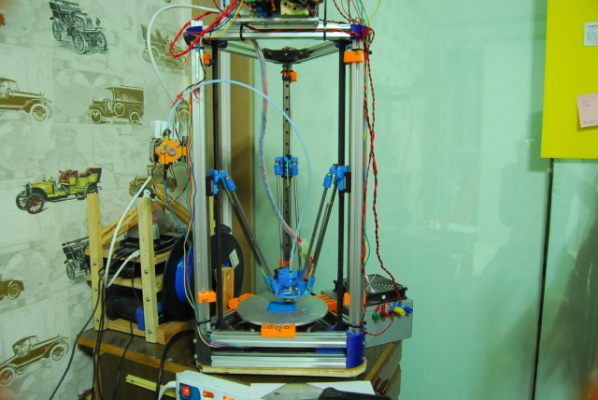

So I'm in the process of getting my delta printer (MOST delta style: [www.appropedia.org]).

Unfortunately, I seem to have quite a lot of problems with the magnetic joint system. The build uses ∅10x3mm counter sunk ring magnets (N50 strength) on the effector/carriage and steel balls on the rods.

During movements (either while printing or when running a calibration) the rods often drop out of their hinges and the effector dangles free, destroying the process of anything done.

I checked the strength of the magnets and it seems there is a big difference in magnet strength. For example, on some magnets I can pull the carriage with a single rod up and down, with other magnets the rod pulls loose immediately.

For now I try to get some dirty hacks running so i can print new carriages and an end effector with another system. As I have so many problems with my joints now I feel a bit reluctant to use the same system again.

What is your experience with magnetic joints? Was it just bad luck with weak magnets, or is the whole system inherently flawed? One thing I think I would add is hinges on both carriage and effector so I can secure them with a threat or fishing line.

Unfortunately, I seem to have quite a lot of problems with the magnetic joint system. The build uses ∅10x3mm counter sunk ring magnets (N50 strength) on the effector/carriage and steel balls on the rods.

During movements (either while printing or when running a calibration) the rods often drop out of their hinges and the effector dangles free, destroying the process of anything done.

I checked the strength of the magnets and it seems there is a big difference in magnet strength. For example, on some magnets I can pull the carriage with a single rod up and down, with other magnets the rod pulls loose immediately.

For now I try to get some dirty hacks running so i can print new carriages and an end effector with another system. As I have so many problems with my joints now I feel a bit reluctant to use the same system again.

What is your experience with magnetic joints? Was it just bad luck with weak magnets, or is the whole system inherently flawed? One thing I think I would add is hinges on both carriage and effector so I can secure them with a threat or fishing line.

|

Re: Experience with magnetic joints July 11, 2015 08:25AM |

Registered: 10 years ago Posts: 903 |

|

Re: Experience with magnetic joints July 11, 2015 03:18PM |

Registered: 8 years ago Posts: 13 |

|

Re: Experience with magnetic joints July 11, 2015 07:13PM |

Registered: 9 years ago Posts: 43 |

|

Re: Experience with magnetic joints July 12, 2015 05:00AM |

Registered: 9 years ago Posts: 6 |

Thanks for the suggestions!

Oiling the magnets didn't work for me unfortunately. For now I just doubled up the ring magnets on the carriage which seems to work enough for slower speeds.

The design of the Cherry Pi IIIs was the one that gave me the idea of using the fishing line and hinges to secure carriage and effector. I already have the rods with steel balls on each end, so I might give it a try.

But maybe a pure magnetic system should work enough if you use big enough magnets. Haydn huntley's rods use a 15mm zylindrical magnet. I have a 10mm at home and the holding force is just immense.

Oiling the magnets didn't work for me unfortunately. For now I just doubled up the ring magnets on the carriage which seems to work enough for slower speeds.

The design of the Cherry Pi IIIs was the one that gave me the idea of using the fishing line and hinges to secure carriage and effector. I already have the rods with steel balls on each end, so I might give it a try.

But maybe a pure magnetic system should work enough if you use big enough magnets. Haydn huntley's rods use a 15mm zylindrical magnet. I have a 10mm at home and the holding force is just immense.

|

Re: Experience with magnetic joints July 14, 2015 11:01AM |

Registered: 9 years ago Posts: 17 |

Matthias, if your magnets are all the same (field strength/size/etc) then they should have the same performance. It sounds like you bought a few duds. Perhaps buying a new set of magnets to replace your duds is your best solution. If you'd like to swear off magnets completely, vreihen seems to be on the right track with strings or springs.

However, I think you're touching on two much larger inherent flaws with magnets:

1. The strength of the magnetic field decreases rapidly the farther away you get from the center of the magnetic array (in both the radial and normal directions). A displacement of even a few mm's between the two parts will greatly reduce the attraction force. There's also no warning or signs a failure is about to occur, the connection will just completely fail. This is obviously undesirable (as you saw) because you will squish your prints. You could design some sort of system to prevent the failure from catastrophically destroying your prints, but at that point I'd just switch to something mechanical or chemical (strings/springs/zipties/glue) as it seems like a lot less work.

2. There's no way to "fix" or "adjust" a ring/bar magnet unlike other components. What you see is what you get. If the magnet is weak/broken/etc then there is nothing you can do to fix it.

PS-here's a cool thought I had while writing this post. Has anyone ever used an electromagnet in a reprap? An electromagnet would allow you to adjust the field strength and direction of the field. Plus the coolness factor is off the charts.

However, I think you're touching on two much larger inherent flaws with magnets:

1. The strength of the magnetic field decreases rapidly the farther away you get from the center of the magnetic array (in both the radial and normal directions). A displacement of even a few mm's between the two parts will greatly reduce the attraction force. There's also no warning or signs a failure is about to occur, the connection will just completely fail. This is obviously undesirable (as you saw) because you will squish your prints. You could design some sort of system to prevent the failure from catastrophically destroying your prints, but at that point I'd just switch to something mechanical or chemical (strings/springs/zipties/glue) as it seems like a lot less work.

2. There's no way to "fix" or "adjust" a ring/bar magnet unlike other components. What you see is what you get. If the magnet is weak/broken/etc then there is nothing you can do to fix it.

PS-here's a cool thought I had while writing this post. Has anyone ever used an electromagnet in a reprap? An electromagnet would allow you to adjust the field strength and direction of the field. Plus the coolness factor is off the charts.

|

Re: Experience with magnetic joints July 14, 2015 05:30PM |

Registered: 10 years ago Posts: 580 |

I've had a lot of experience with magnetic joints.

I had problems for a long time where the hot end would hit a curled edge on a 13" wide print and pop a joint off. This limited the width I could print reliably.

I ended up adding two springs between each set of rods: between the bearing cars and the effector.

I attached eye-bolts top and bottom and used stainless wire to connect them with the springs.

I used calipers to make sure I sprung the springs the same amount. This eliminated the problem.

Edited 1 time(s). Last edit at 07/14/2015 05:32PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I had problems for a long time where the hot end would hit a curled edge on a 13" wide print and pop a joint off. This limited the width I could print reliably.

I ended up adding two springs between each set of rods: between the bearing cars and the effector.

I attached eye-bolts top and bottom and used stainless wire to connect them with the springs.

I used calipers to make sure I sprung the springs the same amount. This eliminated the problem.

Edited 1 time(s). Last edit at 07/14/2015 05:32PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Experience with magnetic joints July 15, 2015 07:06PM |

Registered: 10 years ago Posts: 903 |

Quote

pineapple

However, I think you're touching on two much larger inherent flaws with magnets:

3) Rare earth magnets permanently lose their magnetism when exposed to heat in the range that one would encounter in a heated build chamber.

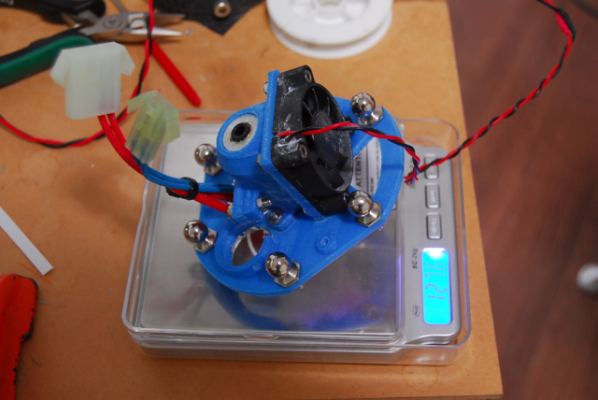

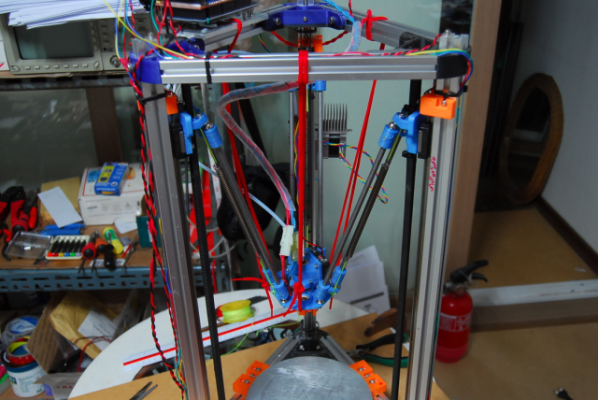

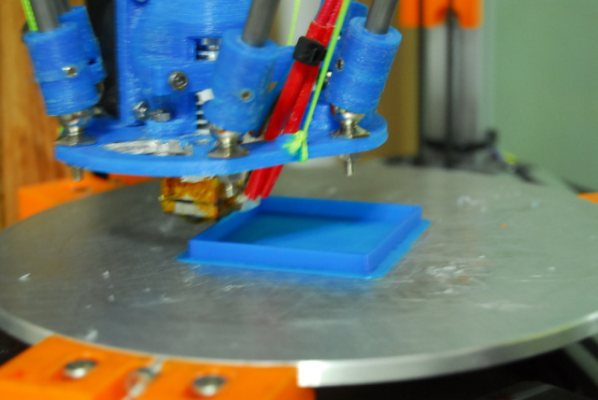

I went seriously overboard with the springs on my latest build:

I haven't actually printed with it yet, but it did go through multiple auto-calibration runs without losing a rod.....

|

Re: Experience with magnetic joints July 15, 2015 10:23PM |

Registered: 10 years ago Posts: 580 |

vreihen,

Many rare earth magnets do loose magnetism (even permanently) at higher temperatures in the range that would be used here, however there are some that do not.

Here is information on how much magnetism they loose.

Here are some magnets that have a higher resistance to heat.

I did purchase from K&J Magnetics, but have no ties to them.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Many rare earth magnets do loose magnetism (even permanently) at higher temperatures in the range that would be used here, however there are some that do not.

Here is information on how much magnetism they loose.

Here are some magnets that have a higher resistance to heat.

I did purchase from K&J Magnetics, but have no ties to them.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Experience with magnetic joints July 17, 2015 10:04AM |

Registered: 9 years ago Posts: 189 |

Hi,

I'll post the OpenSCAD files as soon as I finalize the design.

Regards,

Hughe

I'll post the OpenSCAD files as soon as I finalize the design.

Regards,

Hughe

|

Re: Experience with magnetic joints July 20, 2015 11:33AM |

Registered: 8 years ago Posts: 49 |

|

Re: Experience with magnetic joints July 23, 2015 06:16AM |

Registered: 9 years ago Posts: 6 |

So I switched to a system with fixed ball bearings and magnets on the rods. I used Geomag magnets for the rods (I got inspired from this design), which are not the strongest, but it seems to be enough. Modifying The effector and carriages was quite simple, I simply glued the balls to the ring magnets (Maybe I will print another set of parts, but for now it's ok).

I'm not sure, but it feels like having the magnets on the rods has a stronger connection, especially when exposed to shearing forces.

Edited 1 time(s). Last edit at 07/23/2015 06:17AM by MatthiasB.

I'm not sure, but it feels like having the magnets on the rods has a stronger connection, especially when exposed to shearing forces.

Edited 1 time(s). Last edit at 07/23/2015 06:17AM by MatthiasB.

|

Re: Experience with magnetic joints July 23, 2015 09:30AM |

Registered: 9 years ago Posts: 346 |

|

Re: Experience with magnetic joints July 23, 2015 01:31PM |

Registered: 9 years ago Posts: 6 |

I didn't think about that actually, but yes, they should magnetise the ball mounts. But I guess that only works well with ringmagnets, or countersunk ring magnets (Example pic). What kind of magnets do you have? ball magnets or disk magnets? Also, what is your current setup?

|

Re: Experience with magnetic joints July 23, 2015 06:24PM |

Registered: 9 years ago Posts: 346 |

I have the kossel K800 with countersunk magnets like you say. I also now have some normal round magnets that I would like to somehow implement to improve performance.

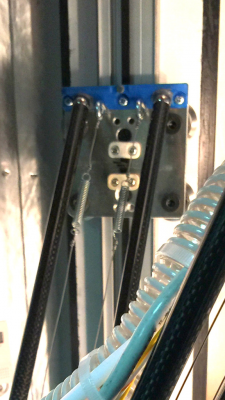

My performance is probably not enhanced by one of my countersunk being broken but there is no system in where it disconnects. Some days one side, another day another... In the picture you see one of my round magnets put on the steel ball but it does not feel like it makes much difference.

So if you have ideas fire away. I have stopped using it now because it is just too unreliable and I have a fully working other printer.

My performance is probably not enhanced by one of my countersunk being broken but there is no system in where it disconnects. Some days one side, another day another... In the picture you see one of my round magnets put on the steel ball but it does not feel like it makes much difference.

So if you have ideas fire away. I have stopped using it now because it is just too unreliable and I have a fully working other printer.

|

Re: Experience with magnetic joints July 23, 2015 11:40PM |

Registered: 9 years ago Posts: 189 |

@LarsK

The effector shape is familiar to a cheap Kossel Kit from China.

It has design flaw that creates lifting of diagonal rods when the effector moves to the edge.

I spent hours to fix it with another builder who bought the Kossel kit. Replacement of six diagonal rods, installation of springs didn't solve the problem.

The effector shape is familiar to a cheap Kossel Kit from China.

It has design flaw that creates lifting of diagonal rods when the effector moves to the edge.

I spent hours to fix it with another builder who bought the Kossel kit. Replacement of six diagonal rods, installation of springs didn't solve the problem.

|

Re: Experience with magnetic joints July 24, 2015 02:10PM |

Registered: 10 years ago Posts: 469 |

I skipped all the magnetic stuff and went to igus spherical bearings. I have to say they are of very good quality. A small spring on the rods removes all slack. Were they cheap? Hell no cost me about $50usd to get a set. But honestly they have been bullet proof so far. ~300hours.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Experience with magnetic joints July 25, 2015 09:23AM |

Registered: 9 years ago Posts: 346 |

Quote

janpenguin

@LarsK

The effector shape is familiar to a cheap Kossel Kit from China.

It has design flaw that creates lifting of diagonal rods when the effector moves to the edge.

I spent hours to fix it with another builder who bought the Kossel kit. Replacement of six diagonal rods, installation of springs didn't solve the problem.

Thank you for saving me a lot of time. It was my plan to try that next (springs). I think I will do a complete overhaul with new effector and carriages at some point. For now, I am taking it down the table and putting it in the corner to make space for my newest build.

Edited 1 time(s). Last edit at 07/25/2015 09:24AM by LarsK.

|

Re: Experience with magnetic joints July 25, 2015 09:41AM |

Registered: 10 years ago Posts: 14,672 |

Quote

LarsK

I have the kossel K800 with countersunk magnets like you say. I also now have some normal round magnets that I would like to somehow implement to improve performance.

My performance is probably not enhanced by one of my countersunk being broken but there is no system in where it disconnects. Some days one side, another day another... In the picture you see one of my round magnets put on the steel ball but it does not feel like it makes much difference.

So if you have ideas fire away. I have stopped using it now because it is just too unreliable and I have a fully working other printer.

A problem I can see with that design is that the magnetic force should ideally be acting in a direction perpendicular to the rod, or nearly so. But in that design, the magnetic force acts vertically because the sockets are mounted flat in the effector plate. So when the effector is opposite a tower, the component of the magnetic force acting along the rods to that tower will be small.

I have seen one delta printer with magnetic joints that appeared to work well. The carriages and effector had threaded steel balls mounted on them, with the mounting screws angled so as to give a good range of movement. The magnets were in the rods, just behind cups at the ends of the rods. With that design, the magnetic force is always acting in the direction of the rod. I think the rod ends were printed pieces with spherical cups, but if I were using that approach I would use machined PTFE rod ends with conical cups.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Experience with magnetic joints February 07, 2016 08:54AM |

Registered: 8 years ago Posts: 1 |

Sorry, only registered users may post in this forum.