Kossel Mini bed leveling problem

Posted by tomasf

|

Kossel Mini bed leveling problem December 14, 2015 04:22PM |

Registered: 8 years ago Posts: 59 |

Hi,

I'm using a T3P3 Kossel Mini R3 (Duet 0.8.5, RepRapFirmware 1.09m+1-dc42) with an IR probe for autocalibration. Yet, I never seem to get a proper bed level. On the side of the bed facing the Z tower, filament is laid out further from the surface. I can adjust the Z offset manually, of course, but then the level is too close on the opposite side. It doesn't matter much for smaller prints, but it gets really problematic for prints with a larger footprint.

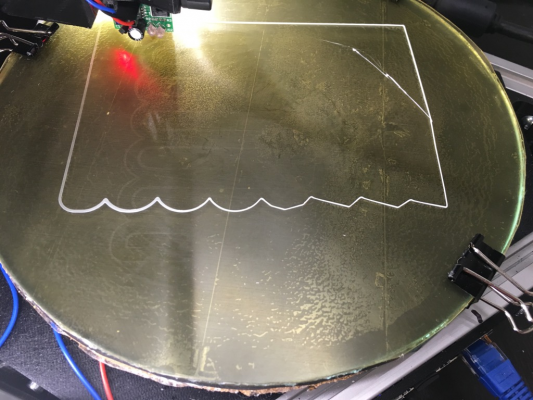

Here's a typical example. To the left, the line is squished against the bed. The wavy lines on the bottom get worse towards the right side where the filament loses grip:

What could I be doing wrong? Is there something that needs to be adjusted hardware-wise? Any ideas? Thanks!

Here's a log where I do three G32s and print the M665 and M666 afterwards (in reverse chronological order), in case that's useful info:

I'm using a T3P3 Kossel Mini R3 (Duet 0.8.5, RepRapFirmware 1.09m+1-dc42) with an IR probe for autocalibration. Yet, I never seem to get a proper bed level. On the side of the bed facing the Z tower, filament is laid out further from the surface. I can adjust the Z offset manually, of course, but then the level is too close on the opposite side. It doesn't matter much for smaller prints, but it gets really problematic for prints with a larger footprint.

Here's a typical example. To the left, the line is squished against the bed. The wavy lines on the bottom get worse towards the right side where the filament loses grip:

What could I be doing wrong? Is there something that needs to be adjusted hardware-wise? Any ideas? Thanks!

Here's a log where I do three G32s and print the M665 and M666 afterwards (in reverse chronological order), in case that's useful info:

22:10:45 CET M666 Endstop adjustments X1.28 Y0.45 Z-1.73 22:10:43 CET M665 Diagonal 215.00, delta radius 105.11, homed height 241.53, bed radius 85.0, X 0.49°, Y 1.19°, Z 0.00° 22:10:35 CET G32 Calibrated 6 factors using 10 points, deviation before 0.163 after 0.113 22:09:48 CET M666 Endstop adjustments X1.41 Y0.12 Z-1.53 22:09:47 CET M665 Diagonal 215.00, delta radius 105.12, homed height 241.59, bed radius 85.0, X -0.56°, Y 0.48°, Z 0.00° 22:09:42 CET G32 Calibrated 6 factors using 10 points, deviation before 0.172 after 0.135 22:08:53 CET M666 Endstop adjustments X1.18 Y0.44 Z-1.61 22:08:52 CET M665 Diagonal 215.00, delta radius 105.01, homed height 241.57, bed radius 85.0, X 0.32°, Y 1.14°, Z 0.00° 22:08:34 CET G32 Calibrated 6 factors using 10 points, deviation before 0.350 after 0.088

|

Re: Kossel Mini bed leveling problem December 14, 2015 06:05PM |

Registered: 10 years ago Posts: 14,672 |

I think you have two problems:

1. Inconsistent homing and/or Z probe trigger height.

2. Effector tilt as the effector translates in the XY plane, causing the Z probe trigger height to vary with XY position.

To check (1), first check for obvious sources of inconsistency, such as loose grub screws, loose belts, and play in the Traxxas joints. Then set up a Check Bed macro file. This should contain the same gcodes as bed.g but change S6 in the final G30 command to S-1. When you run it, it will probe the bed and report the height errors without changing anything. Run it a few times and see how repeatable it is. Then remove the G28 command(s) from it so that it never homes the printer between runs, and run it a few more times. If removing the G28 command(s) improved the reproducibility of the height errors, then the homing switches are not triggering at consistent heights; reducing the final homing speed in homedelta.g may help. If it makes no difference, the Z probe is giving inconsistent results; reducing the probing speed (F parameter in the M558 command) may help.

To check (2), measure the probe trigger height at a few probe points. To do this, lower the nozzle so that it just grips a piece of paper, send G92 Z0, raise the nozzle 5mm, remove the paper, and send G30 S-1. The probe will stop at the trigger height, which you can read off the web interface or use M114 to retrieve. If the trigger height changes significantly between probe points, you can confirm how much it is due to tilt, by dropping the nozzle to the bed surface again and using feeler gauges to measure the height of the bottom edge of the IR sensor board above the bed.

Do you have the black paper under the glass? What is the patterning I can see, under the glass I think, especially in the 4 o'clock to 6'oclock sector?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Inconsistent homing and/or Z probe trigger height.

2. Effector tilt as the effector translates in the XY plane, causing the Z probe trigger height to vary with XY position.

To check (1), first check for obvious sources of inconsistency, such as loose grub screws, loose belts, and play in the Traxxas joints. Then set up a Check Bed macro file. This should contain the same gcodes as bed.g but change S6 in the final G30 command to S-1. When you run it, it will probe the bed and report the height errors without changing anything. Run it a few times and see how repeatable it is. Then remove the G28 command(s) from it so that it never homes the printer between runs, and run it a few more times. If removing the G28 command(s) improved the reproducibility of the height errors, then the homing switches are not triggering at consistent heights; reducing the final homing speed in homedelta.g may help. If it makes no difference, the Z probe is giving inconsistent results; reducing the probing speed (F parameter in the M558 command) may help.

To check (2), measure the probe trigger height at a few probe points. To do this, lower the nozzle so that it just grips a piece of paper, send G92 Z0, raise the nozzle 5mm, remove the paper, and send G30 S-1. The probe will stop at the trigger height, which you can read off the web interface or use M114 to retrieve. If the trigger height changes significantly between probe points, you can confirm how much it is due to tilt, by dropping the nozzle to the bed surface again and using feeler gauges to measure the height of the bottom edge of the IR sensor board above the bed.

Do you have the black paper under the glass? What is the patterning I can see, under the glass I think, especially in the 4 o'clock to 6'oclock sector?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 17, 2015 05:31AM |

Registered: 9 years ago Posts: 13 |

I'm sorry for intruding, but I have been experiencing exactly the problems tomasf describes (lately, or rather they showed up lately because I had to print larger pieces ...), having a similar setup with the IR probe, but 0.6.x duet and having scotch blue directly on a glass bed. I'm using plain microswitches (without levers) as endstops.

I followed your instructions, dc42, using M558 P1 X0 Y0 Z0 H8:

Test with F2000 homing speed and G28 between probing:

Bed probe heights: 3.283 3.008 3.193 3.449 3.493 3.321 3.171 3.141 3.467 3.250, mean 3.277, deviation from mean 0.150

Bed probe heights: 3.283 3.008 3.183 3.399 3.423 3.281 3.161 3.121 3.437 3.210, mean 3.250, deviation from mean 0.134

Bed probe heights: 3.263 3.028 3.133 3.259 3.233 3.151 3.151 3.081 3.247 3.150, mean 3.169, deviation from mean 0.076

Bed probe heights: 3.273 3.018 3.173 3.359 3.393 3.241 3.151 3.111 3.377 3.210, mean 3.230, deviation from mean 0.117

Bed probe heights: 3.283 3.018 3.193 3.409 3.433 3.281 3.161 3.131 3.437 3.230, mean 3.257, deviation from mean 0.132

Continuing probing without a G28 gives a MUCH better repeatability:

Bed probe heights: 3.283 3.008 3.193 3.409 3.433 3.271 3.161 3.121 3.447 3.230, mean 3.255, deviation from mean 0.136

Bed probe heights: 3.283 3.008 3.183 3.409 3.433 3.271 3.161 3.121 3.447 3.230, mean 3.254, deviation from mean 0.137

Bed probe heights: 3.283 3.008 3.183 3.409 3.433 3.271 3.161 3.131 3.447 3.230, mean 3.255, deviation from mean 0.136

Bed probe heights: 3.283 3.008 3.183 3.409 3.443 3.281 3.161 3.121 3.447 3.230, mean 3.256, deviation from mean 0.138

Bed probe heights: 3.283 3.018 3.193 3.409 3.443 3.281 3.161 3.131 3.447 3.230, mean 3.259, deviation from mean 0.135

So I took the advice of reducing homing speed to check if this helps making the consistency of the homing switches better,

probing with G28 again. The results with a reduced homing speed of F500 seem rather disastrous:

Bed probe heights: 3.283 2.998 3.183 3.429 3.483 3.301 3.161 3.121 3.477 3.240, mean 3.267, deviation from mean 0.152

Bed probe heights: 3.273 3.008 3.183 3.409 3.433 3.281 3.161 3.131 3.447 3.230, mean 3.255, deviation from mean 0.136

Bed probe heights: 3.243 3.008 3.133 3.259 3.233 3.141 3.121 3.071 3.257 3.140, mean 3.160, deviation from mean 0.081

Bed probe heights: 3.283 3.018 3.203 3.429 3.463 3.291 3.171 3.141 3.467 3.240, mean 3.270, deviation from mean 0.140

Bed probe heights: 3.283 3.008 3.193 3.439 3.473 3.301 3.161 3.141 3.477 3.250, mean 3.272, deviation from mean 0.147

Bed probe heights: 3.243 3.008 3.143 3.259 3.233 3.141 3.121 3.081 3.257 3.140, mean 3.162, deviation from mean 0.080

Reducing homing speed to a nerve-racking low F150 makes this better, but there still are annoying and not acceptable runaways:

Bed probe heights: 3.373 3.078 3.193 3.439 3.513 3.381 3.241 3.151 3.507 3.280, mean 3.315, deviation from mean 0.143

Bed probe heights: 3.363 3.068 3.193 3.439 3.513 3.371 3.241 3.151 3.507 3.270, mean 3.311, deviation from mean 0.144

Bed probe heights: 3.373 3.068 3.193 3.429 3.493 3.361 3.231 3.141 3.507 3.270, mean 3.306, deviation from mean 0.142

Bed probe heights: 3.363 3.058 3.153 3.339 3.403 3.291 3.221 3.111 3.407 3.230, mean 3.257, deviation from mean 0.117

Bed probe heights: 3.353 3.058 3.173 3.429 3.493 3.371 3.221 3.131 3.497 3.260, mean 3.298, deviation from mean 0.146

Bed probe heights: 3.353 3.048 3.163 3.389 3.453 3.331 3.211 3.121 3.457 3.240, mean 3.276, deviation from mean 0.134

Bed probe heights: 3.353 3.048 3.163 3.389 3.453 3.321 3.211 3.121 3.447 3.240, mean 3.274, deviation from mean 0.133

So I guess my endstops are a problem. Still, I printed another test object with these settings which again had the same

problems tomasf describes, with the filament being laid too high to the Y tower.

I'm wondering what to do now -- should I try to go for some really nifty endstop solution? Would hall effect sensors like [www.ebay.de] make sense?

Thank you very much!

Jost

I followed your instructions, dc42, using M558 P1 X0 Y0 Z0 H8:

Test with F2000 homing speed and G28 between probing:

Bed probe heights: 3.283 3.008 3.193 3.449 3.493 3.321 3.171 3.141 3.467 3.250, mean 3.277, deviation from mean 0.150

Bed probe heights: 3.283 3.008 3.183 3.399 3.423 3.281 3.161 3.121 3.437 3.210, mean 3.250, deviation from mean 0.134

Bed probe heights: 3.263 3.028 3.133 3.259 3.233 3.151 3.151 3.081 3.247 3.150, mean 3.169, deviation from mean 0.076

Bed probe heights: 3.273 3.018 3.173 3.359 3.393 3.241 3.151 3.111 3.377 3.210, mean 3.230, deviation from mean 0.117

Bed probe heights: 3.283 3.018 3.193 3.409 3.433 3.281 3.161 3.131 3.437 3.230, mean 3.257, deviation from mean 0.132

Continuing probing without a G28 gives a MUCH better repeatability:

Bed probe heights: 3.283 3.008 3.193 3.409 3.433 3.271 3.161 3.121 3.447 3.230, mean 3.255, deviation from mean 0.136

Bed probe heights: 3.283 3.008 3.183 3.409 3.433 3.271 3.161 3.121 3.447 3.230, mean 3.254, deviation from mean 0.137

Bed probe heights: 3.283 3.008 3.183 3.409 3.433 3.271 3.161 3.131 3.447 3.230, mean 3.255, deviation from mean 0.136

Bed probe heights: 3.283 3.008 3.183 3.409 3.443 3.281 3.161 3.121 3.447 3.230, mean 3.256, deviation from mean 0.138

Bed probe heights: 3.283 3.018 3.193 3.409 3.443 3.281 3.161 3.131 3.447 3.230, mean 3.259, deviation from mean 0.135

So I took the advice of reducing homing speed to check if this helps making the consistency of the homing switches better,

probing with G28 again. The results with a reduced homing speed of F500 seem rather disastrous:

Bed probe heights: 3.283 2.998 3.183 3.429 3.483 3.301 3.161 3.121 3.477 3.240, mean 3.267, deviation from mean 0.152

Bed probe heights: 3.273 3.008 3.183 3.409 3.433 3.281 3.161 3.131 3.447 3.230, mean 3.255, deviation from mean 0.136

Bed probe heights: 3.243 3.008 3.133 3.259 3.233 3.141 3.121 3.071 3.257 3.140, mean 3.160, deviation from mean 0.081

Bed probe heights: 3.283 3.018 3.203 3.429 3.463 3.291 3.171 3.141 3.467 3.240, mean 3.270, deviation from mean 0.140

Bed probe heights: 3.283 3.008 3.193 3.439 3.473 3.301 3.161 3.141 3.477 3.250, mean 3.272, deviation from mean 0.147

Bed probe heights: 3.243 3.008 3.143 3.259 3.233 3.141 3.121 3.081 3.257 3.140, mean 3.162, deviation from mean 0.080

Reducing homing speed to a nerve-racking low F150 makes this better, but there still are annoying and not acceptable runaways:

Bed probe heights: 3.373 3.078 3.193 3.439 3.513 3.381 3.241 3.151 3.507 3.280, mean 3.315, deviation from mean 0.143

Bed probe heights: 3.363 3.068 3.193 3.439 3.513 3.371 3.241 3.151 3.507 3.270, mean 3.311, deviation from mean 0.144

Bed probe heights: 3.373 3.068 3.193 3.429 3.493 3.361 3.231 3.141 3.507 3.270, mean 3.306, deviation from mean 0.142

Bed probe heights: 3.363 3.058 3.153 3.339 3.403 3.291 3.221 3.111 3.407 3.230, mean 3.257, deviation from mean 0.117

Bed probe heights: 3.353 3.058 3.173 3.429 3.493 3.371 3.221 3.131 3.497 3.260, mean 3.298, deviation from mean 0.146

Bed probe heights: 3.353 3.048 3.163 3.389 3.453 3.331 3.211 3.121 3.457 3.240, mean 3.276, deviation from mean 0.134

Bed probe heights: 3.353 3.048 3.163 3.389 3.453 3.321 3.211 3.121 3.447 3.240, mean 3.274, deviation from mean 0.133

So I guess my endstops are a problem. Still, I printed another test object with these settings which again had the same

problems tomasf describes, with the filament being laid too high to the Y tower.

I'm wondering what to do now -- should I try to go for some really nifty endstop solution? Would hall effect sensors like [www.ebay.de] make sense?

Thank you very much!

Jost

|

Re: Kossel Mini bed leveling problem December 17, 2015 10:26AM |

Registered: 10 years ago Posts: 14,672 |

Hi Jost,

It looks like one of your homing switches is working well (the one for the tower near the first probe point), another is a bit worse (3rd probe point), and one is very poor (5th probe point).

I think you may have adjusted the wrong line in homedelta.g. The first G1 S1 command does the course homing. I have the speed on that one set to 2500. The second G1 S2 line is the one that you need to adjust because it does the final homing. I have the speed set to 250 on that one.

If the problem can't be fixed by slowing down the final homing speed (second G1 S1 command), then one option is to always run auto calibration before printing, and take care not to home between auto calibrating and starting the print (e.g. don't include any G28 commands in your slicer start gcode). Then the homing switch errors will get calibrated out.

Can you post a photo showing the position and mounting of one your homing switches, and how it is triggered by the carriage?

Hall sensors may be more consistent than switches, but switches ought to be good enough.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

It looks like one of your homing switches is working well (the one for the tower near the first probe point), another is a bit worse (3rd probe point), and one is very poor (5th probe point).

I think you may have adjusted the wrong line in homedelta.g. The first G1 S1 command does the course homing. I have the speed on that one set to 2500. The second G1 S2 line is the one that you need to adjust because it does the final homing. I have the speed set to 250 on that one.

If the problem can't be fixed by slowing down the final homing speed (second G1 S1 command), then one option is to always run auto calibration before printing, and take care not to home between auto calibrating and starting the print (e.g. don't include any G28 commands in your slicer start gcode). Then the homing switch errors will get calibrated out.

Can you post a photo showing the position and mounting of one your homing switches, and how it is triggered by the carriage?

Hall sensors may be more consistent than switches, but switches ought to be good enough.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 17, 2015 04:21PM |

Registered: 9 years ago Posts: 13 |

Thank you for that analysis  I still have some different endstops lying around so I'll just replace them and then try again. But having a closer look at the state of my endstops I noticed that the mounts seem to have taken some damage in the past, there obviously is some week point where layers started separating; this might be the reason for some inaccuracy. I attach a photo (I only now notice how dusty my setup is ...). I just printed new endstop mounts and will replace them tomorrow while replacing the microswitches.

I still have some different endstops lying around so I'll just replace them and then try again. But having a closer look at the state of my endstops I noticed that the mounts seem to have taken some damage in the past, there obviously is some week point where layers started separating; this might be the reason for some inaccuracy. I attach a photo (I only now notice how dusty my setup is ...). I just printed new endstop mounts and will replace them tomorrow while replacing the microswitches.

I had the speeds in all G1 S2 lines set to a lower value -- it's good to know that I can keep high speed for the first run!

My autocalibration only homes before probing the points, I use a modified bed.g from your distribution, with only some probe points modified so that layer cooling fan duct etc. don't collide with anything, here it is:

Is this okay?

I still have some different endstops lying around so I'll just replace them and then try again. But having a closer look at the state of my endstops I noticed that the mounts seem to have taken some damage in the past, there obviously is some week point where layers started separating; this might be the reason for some inaccuracy. I attach a photo (I only now notice how dusty my setup is ...). I just printed new endstop mounts and will replace them tomorrow while replacing the microswitches.

I still have some different endstops lying around so I'll just replace them and then try again. But having a closer look at the state of my endstops I noticed that the mounts seem to have taken some damage in the past, there obviously is some week point where layers started separating; this might be the reason for some inaccuracy. I attach a photo (I only now notice how dusty my setup is ...). I just printed new endstop mounts and will replace them tomorrow while replacing the microswitches. I had the speeds in all G1 S2 lines set to a lower value -- it's good to know that I can keep high speed for the first run!

My autocalibration only homes before probing the points, I use a modified bed.g from your distribution, with only some probe points modified so that layer cooling fan duct etc. don't collide with anything, here it is:

; Auto calibration routine for delta printers ; Before running this, you should have set up your zprobe Z offset to suit your build, in the G31 command in config.g. M561 ; clear any bed transform, otherwise homing may be at the wrong height G31 X0 Y0 ; don't want any probe offset for this G28 ; home the printer ;*** Remove the following line if your Z probe does not need to be deployed ;M98 Pdeployprobe.g ; deploy the mechanical Z probe ; The first time the mechanical probe is used after deployment, it gives slightly different results. ; So do an extra dummy probe here. The value stored gets overwritten later. You can remove this if you use an IR probe. ;G30 P0 X0 Y0 Z-99999 ; Probe the bed and do 6- or 7-factor auto calibration G30 P0 X-66 Y-30 Z-99999 ; X tower G30 P1 X0 Y-66 Z-99999 ; between X and Y towers G30 P2 X66 Y-30 Z-99999 ; Y tower G30 P3 X46 Y42 Z-99999 ; between Y and Z towers G30 P4 X6 Y62 Z-99999 ; Z tower G30 P5 X-56 Y28 Z-99999 ; between Z and X towers G30 P6 X-36.8 Y-21.25 Z-99999 ; half way to X tower G30 P7 X36.8 Y-21.25 Z-99999 ; half way to Y tower G30 P8 X0 Y42.5 Z-99999 ; half way to Z tower G30 P9 X0 Y0 Z-99999 S6 ; centre, and auto-calibrate 6 factors ;*** Remove the following line if your Z probe does not need to be retracted ;M98 Pretractprobe.g ; retract the mechanical Z probe G1 X0 Y0 Z150 F15000 ; get the head out of the way of the bed

Is this okay?

|

Re: Kossel Mini bed leveling problem December 17, 2015 05:20PM |

Registered: 10 years ago Posts: 14,672 |

Your bed.g file looks ok. Do the switches have levers? You may need to rotate the endstop switch about the mounting screw slightly to make sure that the carriage triggers the switch before it jams up against a corner of the switch body.

My large delta uses the endstop switches that came with my t3p3 mini kossel R1 kit.

Edited 1 time(s). Last edit at 12/17/2015 05:21PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

My large delta uses the endstop switches that came with my t3p3 mini kossel R1 kit.

Edited 1 time(s). Last edit at 12/17/2015 05:21PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 18, 2015 05:08PM |

Registered: 9 years ago Posts: 13 |

No, no levers. The vendor of my original kit (builda3dprinter.eu) told in the instructions to snap them off, I have no idea if that was a good idea (the kit is in most respects not as well thought through as the one by t3p3 where I would definitely buy next time ...).

I now replaced the endstops and the endstop mounts. On several runs with a homing speed of F250 I had a repeatability of <=0.05mm, which is better than my above results but definitely far from perfect. When repeating without a G28 inbetween, I get <=0.02.

So the endstops are still a problem, but if they are supposed to be calibrated out (I do your calibration routine before every print without homing afterwards), then I suppose there's only effector tilt left as an explanation, or not? I repeated my testprints and they still show the problem tomasf described, in my case a too high print head towards the Y tower.

If I'm going this way: how can I compensate for this tilt in software? I remember you said somewhere in your blog that this is possible, but I don't understand how to do this.

Thank you very much for your help!

Jost

I now replaced the endstops and the endstop mounts. On several runs with a homing speed of F250 I had a repeatability of <=0.05mm, which is better than my above results but definitely far from perfect. When repeating without a G28 inbetween, I get <=0.02.

So the endstops are still a problem, but if they are supposed to be calibrated out (I do your calibration routine before every print without homing afterwards), then I suppose there's only effector tilt left as an explanation, or not? I repeated my testprints and they still show the problem tomasf described, in my case a too high print head towards the Y tower.

If I'm going this way: how can I compensate for this tilt in software? I remember you said somewhere in your blog that this is possible, but I don't understand how to do this.

Thank you very much for your help!

Jost

|

Re: Kossel Mini bed leveling problem December 18, 2015 06:22PM |

Registered: 10 years ago Posts: 14,672 |

Yes you can compensate in software.

First, measure the Z probe trigger height at every probe point. I usually lower the nozzle until it grips a piece of paper, send G92 Z0, raise the nozzle 5mm, remove the paper, then run G30 S-1, then read off the height form the web interface. If you have feeler gauges, you can also measure the height of the bottom edge of the sensor above the bed.

Next, set the G31 Z parameter in config.g to the trigger height at the centre of the bed.

Finally, in the bed.g file, on each G30 command add a correction of the form H# where # is the trigger height at that point minus the trigger height at bed centre.

If you have serious effector tilt then you really ought to try to fix it. Here are some common causes of effector tilt and partial remedies:

1. The two diagonal rods in a parallel pair do not have quite the same length. If they have Traxxas ends, you can test how close they are by putting all 6 over a pair of long M3 screws. If they have noticeably different lengths, pair the two shortest and also the two longest.

2. The bearing spacing at the carriage is not quite the same as it is at the effector. Use washers or shims under the bearings to equalise them.

3. The bearing lines on the carriages are not parallel to the bearing lines on the effector (both should have the 3 bearing lines at 120 degrees to each other). Check that the carriages are running parallel to the towers. If you are using wheeled carriages, check that all 3 wheels are spaced the correct amount from the backs of the carriages.

4. Play in the joints, coupled with the sideways force exerted by the Bowden tube, which changes direction with XY position. Use springs or elastic to tie the rods together and take up the play, and support the weight of the Bowden tube if necessary from the top frame using elastic.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

First, measure the Z probe trigger height at every probe point. I usually lower the nozzle until it grips a piece of paper, send G92 Z0, raise the nozzle 5mm, remove the paper, then run G30 S-1, then read off the height form the web interface. If you have feeler gauges, you can also measure the height of the bottom edge of the sensor above the bed.

Next, set the G31 Z parameter in config.g to the trigger height at the centre of the bed.

Finally, in the bed.g file, on each G30 command add a correction of the form H# where # is the trigger height at that point minus the trigger height at bed centre.

If you have serious effector tilt then you really ought to try to fix it. Here are some common causes of effector tilt and partial remedies:

1. The two diagonal rods in a parallel pair do not have quite the same length. If they have Traxxas ends, you can test how close they are by putting all 6 over a pair of long M3 screws. If they have noticeably different lengths, pair the two shortest and also the two longest.

2. The bearing spacing at the carriage is not quite the same as it is at the effector. Use washers or shims under the bearings to equalise them.

3. The bearing lines on the carriages are not parallel to the bearing lines on the effector (both should have the 3 bearing lines at 120 degrees to each other). Check that the carriages are running parallel to the towers. If you are using wheeled carriages, check that all 3 wheels are spaced the correct amount from the backs of the carriages.

4. Play in the joints, coupled with the sideways force exerted by the Bowden tube, which changes direction with XY position. Use springs or elastic to tie the rods together and take up the play, and support the weight of the Bowden tube if necessary from the top frame using elastic.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 19, 2015 06:15AM |

Registered: 9 years ago Posts: 13 |

Nr. 4 (mostly) was it for me, thank you!

I first noticed that indeed the bearing spacing at the carriages was approx. 0.4mm less than the bearing spacing on the effector (strange, because all parts came from the same vendor). However, as this was the same over all three rod pairs, I suppose this can't be the problem.

Although I could not find any play while trying every single screw and joint, I decided to put rubber bands between the rods and hold the bowden tube with a sling so that it enters the effector as vertically as possible. This made a huge difference. I still have some slight differences, but the situation is MUCH better now. I will continue going for the other aspects to see if there is still room for improvement, but large pieces should not pose a problem anymore

Thank you very much, dc42!

I first noticed that indeed the bearing spacing at the carriages was approx. 0.4mm less than the bearing spacing on the effector (strange, because all parts came from the same vendor). However, as this was the same over all three rod pairs, I suppose this can't be the problem.

Although I could not find any play while trying every single screw and joint, I decided to put rubber bands between the rods and hold the bowden tube with a sling so that it enters the effector as vertically as possible. This made a huge difference. I still have some slight differences, but the situation is MUCH better now. I will continue going for the other aspects to see if there is still room for improvement, but large pieces should not pose a problem anymore

Thank you very much, dc42!

|

Re: Kossel Mini bed leveling problem December 19, 2015 07:03AM |

Registered: 10 years ago Posts: 14,672 |

Quote

jschenck

I first noticed that indeed the bearing spacing at the carriages was approx. 0.4mm less than the bearing spacing on the effector (strange, because all parts came from the same vendor). However, as this was the same over all three rod pairs, I suppose this can't be the problem.

That will cause the effector to tilt, which will in turn cause variation in Z probe trigger height and XY scaling errors. So I suggest you fix it. Some M3 washers are about 0.4mm thick. You can also buy packs of M3 shims of various thickesses on ebay.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 19, 2015 12:47PM |

Registered: 9 years ago Posts: 13 |

|

Re: Kossel Mini bed leveling problem December 19, 2015 02:18PM |

Registered: 8 years ago Posts: 59 |

Hi. OP here again.

Thanks for your helpful tips, David! I've done a lot of testing, and it took me a while to reply because I wasn't sure what to make of the results. Before, I was convinced the bed surface wasn't the problem, because I had the same bed level problems a while before I even started using PEI. But after doing some pretty conclusive tests, I have to admit I was wrong, as it definitely seems my PEI surfaces are at fault.

Printing on blue tape (on top of glass), my test prints look fine. The level isn't perfect, but not far from it, and compared to the PEI results, it's night and day.

I have two PEI plates, both attached to glass plates with 3M adhesive tape (the adhesive is the pattern you see in the picture), and both behave the same way. I then tried sanding one with a rough sandpaper to make it more opaque, but that had the opposite effect; the IR probe did not detect the surface properly at all and the nozzle buried itself into the bed. Sanding it further with finer grit sand paper helped somewhat, but it still smashes the nozzle into the bed sometimes, so it's still worse than the non-sanded surface. And yes, there's a black sheet of paper between the glass and aluminium.

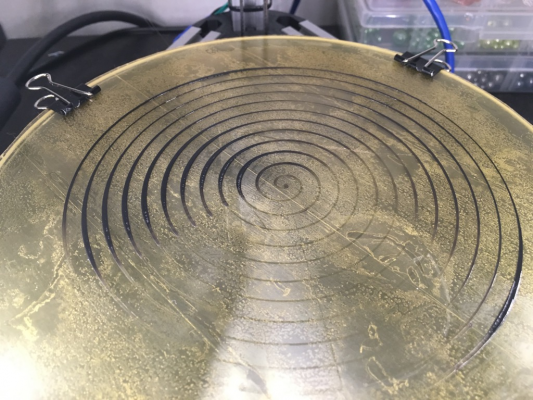

Here's a good example, printing a test spiral on PEI (non-sanded) and blue tape.

PEI:

Blue tape:

I had such high hopes for PEI. Prints stick so well and detach so easily when done, and there's almost no need for much maintenance. But I guess I need to go back to something else

Edited 2 time(s). Last edit at 12/19/2015 03:13PM by tomasf.

Thanks for your helpful tips, David! I've done a lot of testing, and it took me a while to reply because I wasn't sure what to make of the results. Before, I was convinced the bed surface wasn't the problem, because I had the same bed level problems a while before I even started using PEI. But after doing some pretty conclusive tests, I have to admit I was wrong, as it definitely seems my PEI surfaces are at fault.

Printing on blue tape (on top of glass), my test prints look fine. The level isn't perfect, but not far from it, and compared to the PEI results, it's night and day.

I have two PEI plates, both attached to glass plates with 3M adhesive tape (the adhesive is the pattern you see in the picture), and both behave the same way. I then tried sanding one with a rough sandpaper to make it more opaque, but that had the opposite effect; the IR probe did not detect the surface properly at all and the nozzle buried itself into the bed. Sanding it further with finer grit sand paper helped somewhat, but it still smashes the nozzle into the bed sometimes, so it's still worse than the non-sanded surface. And yes, there's a black sheet of paper between the glass and aluminium.

Here's a good example, printing a test spiral on PEI (non-sanded) and blue tape.

PEI:

Blue tape:

I had such high hopes for PEI. Prints stick so well and detach so easily when done, and there's almost no need for much maintenance. But I guess I need to go back to something else

Edited 2 time(s). Last edit at 12/19/2015 03:13PM by tomasf.

|

Re: Kossel Mini bed leveling problem December 19, 2015 06:31PM |

Registered: 10 years ago Posts: 14,672 |

I use PEI now and it works beautifully. The problem is that it is transparent to IR, and the adhesive sheet you use to attach it to the glass or aluminium bed reflects IR very unevenly. So the trick is to paint the underside of the sheet matt black. See [miscsolutions.wordpress.com]. I added a note about this to the IR probe fitting instructions a few days ago.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 20, 2015 09:15AM |

Registered: 8 years ago Posts: 59 |

|

Re: Kossel Mini bed leveling problem December 20, 2015 10:15AM |

Registered: 10 years ago Posts: 14,672 |

Quote

tomasf

Ooh. That makes sense. Shoot, I wish I had read that before. Oh well, I'm off to get some heat-resistant paint and hope there's enough adhesive tape left on the roll so I don't have to order another one from half-way across the planet.

Thanks again!

btw I have only tested this with thin PEI sheet so far. I have been sent some offcuts of thick PEI sheet, so I am going to paint those and test them too.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 22, 2015 09:01PM |

Registered: 9 years ago Posts: 83 |

I wanted to piggy back off this post because its topic is related to mine.

So I have this very same setup (Hardware and software) everything works but when i start a print im not sure if i have the wrong starting gcode in my slicer or whaT but my printer head smashes into the bed every time. My IR sensor works and it runs through the entire probing fine it seems like its not saving the autocal adjustments? or should i be running autocal using slicer in the starting gcode?

Im not very familiar with how to set these starting g codes so this could very well be my problem.... but after calibration i should just be including the things like heaters on and autocal?

So I have this very same setup (Hardware and software) everything works but when i start a print im not sure if i have the wrong starting gcode in my slicer or whaT but my printer head smashes into the bed every time. My IR sensor works and it runs through the entire probing fine it seems like its not saving the autocal adjustments? or should i be running autocal using slicer in the starting gcode?

Im not very familiar with how to set these starting g codes so this could very well be my problem.... but after calibration i should just be including the things like heaters on and autocal?

|

Re: Kossel Mini bed leveling problem December 23, 2015 05:00AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Ace67aod

I wanted to piggy back off this post because its topic is related to mine.

So I have this very same setup (Hardware and software) everything works but when i start a print im not sure if i have the wrong starting gcode in my slicer or whaT but my printer head smashes into the bed every time. My IR sensor works and it runs through the entire probing fine it seems like its not saving the autocal adjustments? or should i be running autocal using slicer in the starting gcode?

Im not very familiar with how to set these starting g codes so this could very well be my problem.... but after calibration i should just be including the things like heaters on and autocal?

To save the results of auto calibration between power cycles, send M665 without parameters, and M666 without parameters, to read off the results of auto calibration. Then edit those values into the M665 and M666 commands in config.g. See section "Updating config.g" at [reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 23, 2015 07:42PM |

Registered: 9 years ago Posts: 83 |

|

Re: Kossel Mini bed leveling problem December 24, 2015 03:02AM |

Registered: 10 years ago Posts: 14,672 |

1. Have you set the trigger height of your Z probe correctly, using the Z parameter of the G31 command in config.g?

2. Is the Z=0 height correct immediately after running G32, and only goes wrong if you home the printer again? If so then you probably haven't updated the H parameter in the M665 command to the value found by auto calibration.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

2. Is the Z=0 height correct immediately after running G32, and only goes wrong if you home the printer again? If so then you probably haven't updated the H parameter in the M665 command to the value found by auto calibration.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 25, 2015 11:23PM |

Registered: 9 years ago Posts: 83 |

So if i manually subtract 5 mm from the .Config M665 command it will snag my paper at .17 when i check zero after changing and homeing. After i run the auto calibration it resets my home height back to the height that will crash the head into the bed again...

I have set my z trigger height, when i set this to the value i got following the set zero instructions G92 Z0 (with the paper snagged) then probing with G28 S-1 command, this results in a lower value for my ztrigger but then it throws off the probing which ultimatly results in one or two good probe points then drags through to the next and drives the head into the bed....

Any ideas what could be going on?

I have set my z trigger height, when i set this to the value i got following the set zero instructions G92 Z0 (with the paper snagged) then probing with G28 S-1 command, this results in a lower value for my ztrigger but then it throws off the probing which ultimatly results in one or two good probe points then drags through to the next and drives the head into the bed....

Any ideas what could be going on?

|

Re: Kossel Mini bed leveling problem December 26, 2015 02:33AM |

Registered: 10 years ago Posts: 14,672 |

If the probe drags through the bed when probing then your printer is a long way out of calibration. Until it is better calibrated, you should make probing start from a greater height such as 10mm. Do this by adding parameter H10 to the M558 command in config.g.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 26, 2015 07:31PM |

Registered: 9 years ago Posts: 83 |

My auto leveling keeps setting the H parameter to 229 mm which snags my paper at 5.0mm and not zero i have gotten everything else working as far as the probe points and such, i think my true H should be 224 mm because when i set it to this in the config file the paper will snag at .1. So could this mean my steppers are off or something because they think my bed is lower than it really is? auto compensate always returns 229mm which will result in my nozzle crashing into my bed if i try to print even if i update this value to my config file

I tried adding the H parameter but keeping my current settings keeps the auto compensate running properly(if it is even properly?)

Appreciate the help DC!

I tried adding the H parameter but keeping my current settings keeps the auto compensate running properly(if it is even properly?)

Appreciate the help DC!

|

Re: Kossel Mini bed leveling problem December 27, 2015 02:05AM |

Registered: 10 years ago Posts: 14,672 |

Place the nozzle about 5mm above the centre of the bed, then send G30 with no parameters to probe the bed at that point. After it stops, what does the web interface or M114 report as the Z height, and what is the actual nozzle height above the bed? If they are not the same then you need to adjust the G31 Z parameter, which should be aet to the trigger height of the Z probe.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Mini bed leveling problem December 28, 2015 11:06PM |

Registered: 9 years ago Posts: 83 |

Sorry, only registered users may post in this forum.