Home

>

Developers

>

Topic

will this hotend work?

will this hotend work?

Posted by newbob

will this hotend work? will this hotend work? February 17, 2022 12:31PM |

Registered: 7 years ago Posts: 270 |

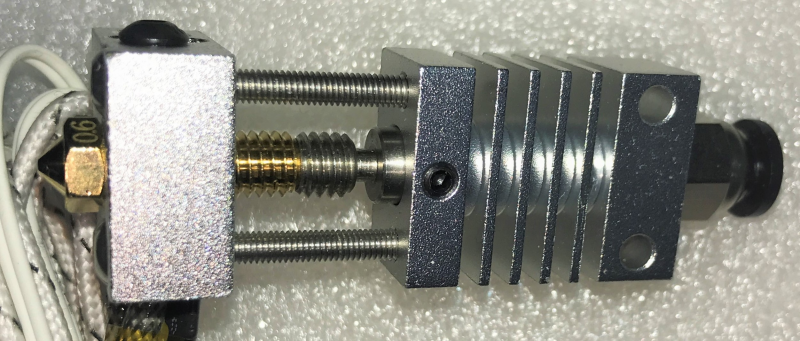

It's just a Volcano nozzle mated with a standard heatblock, throat and heatsink. Screws keep it together, I suppose I could add an M6 nut to attach nozzle and throat together. If that works than I'll try using stainless steel capillary tube for the throat. I've noticed that new hotends have much bigger melting zones but not necessarily larger heating blocks hence the idea of using standard parts with Volcano nozzle.

Edited 1 time(s). Last edit at 02/17/2022 01:08PM by newbob.

Re:  will this hotend work? will this hotend work? February 18, 2022 04:36AM |

Registered: 3 years ago Posts: 92 |

I wouldn't have thought it would mate so perfectly when "floating" like that, but it looks good.

I think it will do what you want. Thomas Sanladerer did a video on the new E3D Revo system and found that it performed similarly to Volcano despite the regular sized heater, due to the heater contact area being all brass rather than half being the steel heatbreak threads in the usual setup.

Another option is to drill one or two 1mm holes sideways through the nozzle threads and solder in copper wires to conduct heat into the melt zone. CNC Kitchen did a video on it a couple months ago and got similar performance to Volcano using a standard size nozzle.

The trouble with those solutions is that they're both patented, and not enough improvement to justify the resulting cost and being locked into a single vendor, so not likely to make a big impact on the industry overall. The Revo idea is especially sad to have cut off from further community development. In hindsight it seems obvious that if you're going to go to the trouble to make a bi-metal heatbreak, you might as well stick a nozzle onto the steel tube rather than the threaded bit that goes in the heater block and eliminate the possibility of leaks. But now we'll never see what would have come from other people iterating on it.

At least the copper wire idea is easily doable for us hackers.

I think it will do what you want. Thomas Sanladerer did a video on the new E3D Revo system and found that it performed similarly to Volcano despite the regular sized heater, due to the heater contact area being all brass rather than half being the steel heatbreak threads in the usual setup.

Another option is to drill one or two 1mm holes sideways through the nozzle threads and solder in copper wires to conduct heat into the melt zone. CNC Kitchen did a video on it a couple months ago and got similar performance to Volcano using a standard size nozzle.

The trouble with those solutions is that they're both patented, and not enough improvement to justify the resulting cost and being locked into a single vendor, so not likely to make a big impact on the industry overall. The Revo idea is especially sad to have cut off from further community development. In hindsight it seems obvious that if you're going to go to the trouble to make a bi-metal heatbreak, you might as well stick a nozzle onto the steel tube rather than the threaded bit that goes in the heater block and eliminate the possibility of leaks. But now we'll never see what would have come from other people iterating on it.

At least the copper wire idea is easily doable for us hackers.

Re:  will this hotend work? will this hotend work? February 19, 2022 02:07PM |

Registered: 7 years ago Posts: 270 |

So I actually tested it by manually feeding the filament into the hotend...

The hotend did not leak, did not clog and heat creep was very low. There was a notable temperature gradient through out the nozzle so the extruder would hardly extrude at 190degC, but it flowed, at about 15mm/s, quite easily at 210degC. Some kind of sleeve over the threaded part of the nozzle would help even out the temperature but I wonder if it's an issue big enough.

I think surface contact is more crucial in transferring heat to the plastic, something that CNC Kitchen has proved in the episodes you mentioned. Even when temperature gradient exists, plastic out of the nozzle should be of same temperature until temperature gradient shifts past the heater-block.

Overall it was not a disaster I expected it to be (I expected it to leak).

Edited 1 time(s). Last edit at 02/19/2022 02:07PM by newbob.

The hotend did not leak, did not clog and heat creep was very low. There was a notable temperature gradient through out the nozzle so the extruder would hardly extrude at 190degC, but it flowed, at about 15mm/s, quite easily at 210degC. Some kind of sleeve over the threaded part of the nozzle would help even out the temperature but I wonder if it's an issue big enough.

I think surface contact is more crucial in transferring heat to the plastic, something that CNC Kitchen has proved in the episodes you mentioned. Even when temperature gradient exists, plastic out of the nozzle should be of same temperature until temperature gradient shifts past the heater-block.

Overall it was not a disaster I expected it to be (I expected it to leak).

Edited 1 time(s). Last edit at 02/19/2022 02:07PM by newbob.

Sorry, only registered users may post in this forum.