Home

>

Developers

>

Topic

Screws; Acme, Hilead or Torqspline?

Posted by Iceman086

|

Screws; Acme, Hilead or Torqspline? September 02, 2011 08:59PM |

Registered: 13 years ago Posts: 70 |

Hello,

A while back I started gathering parts for my 3D printer. Due to school and a few curve balls from life I had to stop but I am now starting to move forward project again.

The plan is to create a gantry system for the printer head with a Z axis platform. I wanted to use 2 screws on the Z platform, 1 for the X axis and 1 for the Y axis. The printer itself would be a large scale printer with a printable area of around 3'-0" cubed. I know its ambitious but I am willing to give it a shot.

I know that the three different kinds of screws are the Acme, Hilead and Torqspline. What I am unsure of is which would be best for this project? What thickness they would be to support the weight of large prints on the Z axis without sheering? And, what thickness and pitch should the X and Y axis screws be to keep/improve accuracy? Can screw driven systems move as fast or faster than belt driven systems?

Here is the site that I was looking at the screw rods on: Roton

Currently I have 4 NEMA 23 stepper motors (XYZ Axis and Extruder head) that I am planning on running everything with. I know that I might need to find something a bit beefier for the Z axis but for now I am willing to see what happens with the 23. (Currently I do not know the torque of the motors but I am working on finding that out)

The plan for the Z axis is to put the motor in the base of the printer with the motor in the center. The 2 Z axis screws would be run with a sprocket at the bottom connected to the motor sprocket and driven by chain.

I will try to post a drawing of what I am considering for the Z axis as soon as I can.

Everything is still up in the air and I can change how this will work depending on cost and availability of parts.

Ideas and criticism is always welcome!

A while back I started gathering parts for my 3D printer. Due to school and a few curve balls from life I had to stop but I am now starting to move forward project again.

The plan is to create a gantry system for the printer head with a Z axis platform. I wanted to use 2 screws on the Z platform, 1 for the X axis and 1 for the Y axis. The printer itself would be a large scale printer with a printable area of around 3'-0" cubed. I know its ambitious but I am willing to give it a shot.

I know that the three different kinds of screws are the Acme, Hilead and Torqspline. What I am unsure of is which would be best for this project? What thickness they would be to support the weight of large prints on the Z axis without sheering? And, what thickness and pitch should the X and Y axis screws be to keep/improve accuracy? Can screw driven systems move as fast or faster than belt driven systems?

Here is the site that I was looking at the screw rods on: Roton

Currently I have 4 NEMA 23 stepper motors (XYZ Axis and Extruder head) that I am planning on running everything with. I know that I might need to find something a bit beefier for the Z axis but for now I am willing to see what happens with the 23. (Currently I do not know the torque of the motors but I am working on finding that out)

The plan for the Z axis is to put the motor in the base of the printer with the motor in the center. The 2 Z axis screws would be run with a sprocket at the bottom connected to the motor sprocket and driven by chain.

I will try to post a drawing of what I am considering for the Z axis as soon as I can.

Everything is still up in the air and I can change how this will work depending on cost and availability of parts.

Ideas and criticism is always welcome!

|

Re: Screws; Acme, Hilead or Torqspline? September 04, 2011 01:24AM |

Registered: 13 years ago Posts: 70 |

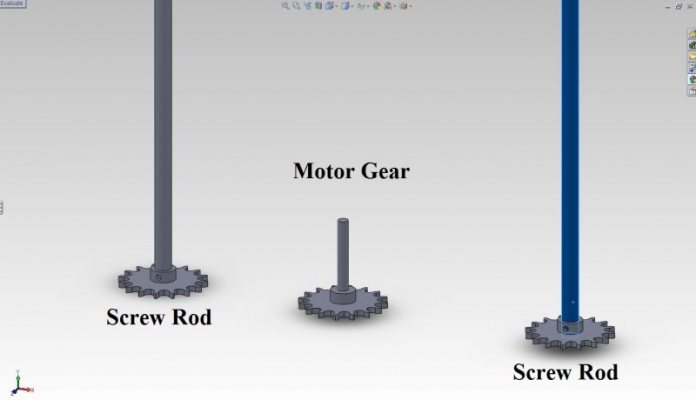

Here is the a quick model of the design that I was talking about.

The chain is not shown, but it would go around the three gears. The center gear would be larger than the outer two since it is the drive gear.

The chain is not shown, but it would go around the three gears. The center gear would be larger than the outer two since it is the drive gear.

|

Re: Screws; Acme, Hilead or Torqspline? September 08, 2011 09:05PM |

Registered: 13 years ago Posts: 70 |

The idea above has been scraped in favor of a new design that uses Acme screws to move the Z axis. 2 Screws will be used to move the Z axis up and down. Each will be run by its own high torque motor in order to evenly distribute the weight. I chose to move in this new direction to avoid the use of sprockets and chain. I really didn't want to use sprockets or chain to begin with but I was willing to do so if that type of mechanical design worked out.

I can try to have a drawing up of this new design in a day or so.

Any comments or suggestions from anyone?

I can try to have a drawing up of this new design in a day or so.

Any comments or suggestions from anyone?

|

Re: Screws; Acme, Hilead or Torqspline? September 08, 2011 11:20PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Screws; Acme, Hilead or Torqspline? September 08, 2011 11:32PM |

Registered: 13 years ago Posts: 70 |

From what I found out from the manufacturer of the screws, the Torqspline screws are used in pick and place machines. So they have alot of accuracy and good speed. The speed though is determined by the pitch that is used on the screws. So if I went with the highest pitch available in that type for a 1/2" rod, it would mean that it is the fastest rod in that class.

This was a result that I recieved while doing some of my research.

Here is a link to the page: [www.cnczone.com]

With the Z though it will be holding the weight as it moves up and down, so Acme screws would be used as speed won't be an issue there.

Edited 1 time(s). Last edit at 09/08/2011 11:36PM by Iceman086.

This was a result that I recieved while doing some of my research.

Quote

Widgitmaster

Torqspline(r) Lead Screws:

A power screw series characterized by the use of multiple start threads to produce very fast linear motion. Torqspline(r) Lead Screws have a minimum of 4 starts and a lead greater than the diameter of the screw.

Here is a link to the page: [www.cnczone.com]

With the Z though it will be holding the weight as it moves up and down, so Acme screws would be used as speed won't be an issue there.

Edited 1 time(s). Last edit at 09/08/2011 11:36PM by Iceman086.

|

Re: Screws; Acme, Hilead or Torqspline? September 09, 2011 04:41AM |

Registered: 13 years ago Posts: 228 |

|

Re: Screws; Acme, Hilead or Torqspline? September 09, 2011 08:49PM |

Registered: 13 years ago Posts: 70 |

They do ship internationally. For a 3/8" diameter rod with 0.500 pitch threads its $10.31 per foot. So about $33.85 for a meter (roughly 3.2 feet) before shipping.

Their website is really simple to find things on. Here is the link to the torqspline page though.

**EDIT**

I posted that from my phone and forgot to add in the link to the Roton page. Sorry about that! Here are 2 links to the general info page about Torqspline Screws that will give more answers to some questions about the screws and the lower link is the list of technical info on each size screw.

Torqspline Info.

Size and Tech Spec Info

Edited 1 time(s). Last edit at 09/11/2011 12:38PM by Iceman086.

Their website is really simple to find things on. Here is the link to the torqspline page though.

**EDIT**

I posted that from my phone and forgot to add in the link to the Roton page. Sorry about that! Here are 2 links to the general info page about Torqspline Screws that will give more answers to some questions about the screws and the lower link is the list of technical info on each size screw.

Torqspline Info.

Size and Tech Spec Info

Edited 1 time(s). Last edit at 09/11/2011 12:38PM by Iceman086.

|

Re: Screws; Acme, Hilead or Torqspline? September 09, 2015 09:27AM |

Registered: 8 years ago Posts: 31 |

Quote

Iceman086

They do ship internationally. For a 3/8" diameter rod with 0.500 pitch threads its $10.31 per foot. So about $33.85 for a meter (roughly 3.2 feet) before shipping.

Their website is really simple to find things on. Here is the link to the torqspline page though.

**EDIT**

I posted that from my phone and forgot to add in the link to the Roton page. Sorry about that! Here are 2 links to the general info page about Torqspline Screws that will give more answers to some questions about the screws and the lower link is the list of technical info on each size screw.

Torqspline Info.

Size and Tech Spec Info

Iceman086,

Did you ever get the torqspline screws working on your X/Y axis? I'm looking at using them on one of my builds and am finding very little about there use. If so, are you getting good speeds and precision?

Josh

|

Re: Screws; Acme, Hilead or Torqspline? September 13, 2015 07:29PM |

Registered: 9 years ago Posts: 3 |

Hi Josh,

This may be of little use to you, but the CNC mill we have at work moves relatively quickly and utilizes threaded rods for y , and z axis motion while the x axis seems to be a rack and pinion set up see: Shopbot Desktop

Im not 100% sure what type of thread they run though.

Chris

This may be of little use to you, but the CNC mill we have at work moves relatively quickly and utilizes threaded rods for y , and z axis motion while the x axis seems to be a rack and pinion set up see: Shopbot Desktop

Im not 100% sure what type of thread they run though.

Chris

Sorry, only registered users may post in this forum.