Problem printing thin wall objects.

Posted by gmh39

|

Problem printing thin wall objects. January 25, 2014 09:53AM |

Registered: 10 years ago Posts: 553 |

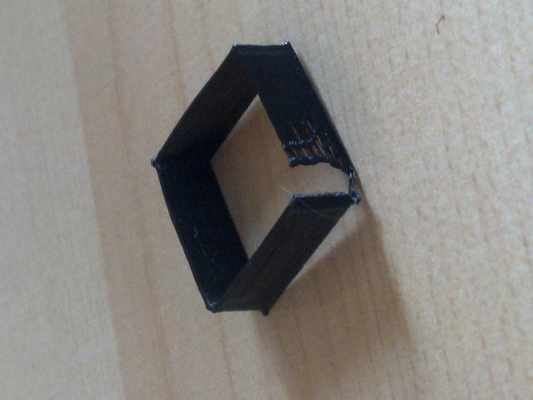

So a I am trying to calibrate my Printrbot and I am at the point of calibrating the scale (make sure everything comes out the correct dimensions). I am using the 0.4 thin wall cube (http://www.thingiverse.com/thing:52946). But every time I print it out I get weird none filling on one of the walls. Also, when I measure the other 3 walls, they are all different thicknesses (they get incrementally larger as you go around). I have tried a number of things:

-turn off retract

-played withe extrusion multiplier

-tried vase option

-checked/unchecked "retract at layer change"

-randomize start points

-number of perimeters

I have also noticed that the point which the none filling starts, is also the point that the printer starts the layer. I does this for all thin walled objects I try, it works fine for infilled objects.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

-turn off retract

-played withe extrusion multiplier

-tried vase option

-checked/unchecked "retract at layer change"

-randomize start points

-number of perimeters

I have also noticed that the point which the none filling starts, is also the point that the printer starts the layer. I does this for all thin walled objects I try, it works fine for infilled objects.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Problem printing thin wall objects. January 25, 2014 11:51AM |

Registered: 10 years ago Posts: 128 |

|

Re: Problem printing thin wall objects. January 25, 2014 01:57PM |

Registered: 10 years ago Posts: 553 |

I figured it out. I that to turn on the "Extra Length on Restart" setting for the retraction. Now it is print out great and I am back to calibrating.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Problem printing thin wall objects. January 26, 2014 09:08AM |

Registered: 11 years ago Posts: 6 |

Your problem is not about the gcode or the calibration, instead the hardware of your extruder. Be precise, your extruder is not quite extruding. The reason could be too much friction along the tubing, nozzle blockage, or having a poorly designed extruder.

In case of too much friction along the tubing, it can be improved by using PTFE tube all the way to the tip of the nozzle or adding an extruder fan to cool the tube right before the hot end. More than likely, you need both.

In case of nozzle blockage, there is nothing you can do besides finding a more relibable filament vendor. By the way, there is a very popular rumor saying that the filament is being degraded by moisture and therefore the blockage. Some even said that baking the filament in oven can help. NO NO NO, it's just not the case. Nozzle blockage is another way of saying your filament had been contaminated during its production.

In case of poorly designed extruders... A typical faulty extruder design would be http://www.thingiverse.com/thing:87236, which unrealistically assuming printed parts has steel strength. A better design with printed parts would be http://www.thingiverse.com/thing:127873. Take a while to compare, it's obvious.

Playing with "Extra Length on Restart" would help a tiny bit. Unfortunately, it doesn't work in general, i.e. you will still have a lot of random "weird none filling" when you print something with more complicated geometry.

Edited 27 time(s). Last edit at 01/26/2014 12:56PM by whitemousegary.

In case of too much friction along the tubing, it can be improved by using PTFE tube all the way to the tip of the nozzle or adding an extruder fan to cool the tube right before the hot end. More than likely, you need both.

In case of nozzle blockage, there is nothing you can do besides finding a more relibable filament vendor. By the way, there is a very popular rumor saying that the filament is being degraded by moisture and therefore the blockage. Some even said that baking the filament in oven can help. NO NO NO, it's just not the case. Nozzle blockage is another way of saying your filament had been contaminated during its production.

In case of poorly designed extruders... A typical faulty extruder design would be http://www.thingiverse.com/thing:87236, which unrealistically assuming printed parts has steel strength. A better design with printed parts would be http://www.thingiverse.com/thing:127873. Take a while to compare, it's obvious.

Playing with "Extra Length on Restart" would help a tiny bit. Unfortunately, it doesn't work in general, i.e. you will still have a lot of random "weird none filling" when you print something with more complicated geometry.

Edited 27 time(s). Last edit at 01/26/2014 12:56PM by whitemousegary.

|

Re: Problem printing thin wall objects. January 31, 2014 01:06PM |

Registered: 10 years ago Posts: 553 |

Quote

whitemousegary

Your problem is not about the gcode or the calibration, instead the hardware of your extruder. Be precise, your extruder is not quite extruding. The reason could be too much friction along the tubing, nozzle blockage, or having a poorly designed extruder.

In case of too much friction along the tubing, it can be improved by using PTFE tube all the way to the tip of the nozzle or adding an extruder fan to cool the tube right before the hot end. More than likely, you need both.

In case of nozzle blockage, there is nothing you can do besides finding a more relibable filament vendor. By the way, there is a very popular rumor saying that the filament is being degraded by moisture and therefore the blockage. Some even said that baking the filament in oven can help. NO NO NO, it's just not the case. Nozzle blockage is another way of saying your filament had been contaminated during its production.

In case of poorly designed extruders... A typical faulty extruder design would be http://www.thingiverse.com/thing:87236, which unrealistically assuming printed parts has steel strength. A better design with printed parts would be http://www.thingiverse.com/thing:127873. Take a while to compare, it's obvious.

Playing with "Extra Length on Restart" would help a tiny bit. Unfortunately, it doesn't work in general, i.e. you will still have a lot of random "weird none filling" when you print something with more complicated geometry.

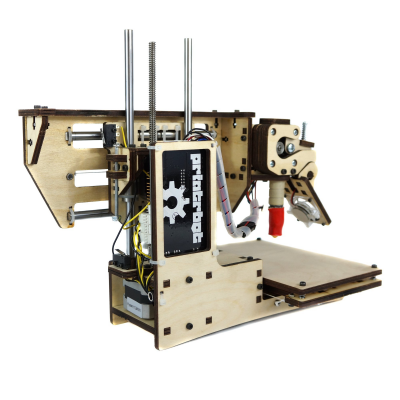

Im using a Printrbot Jr. It's got a fan that blows on the hotend and print, PTFE from the hobbed bolt down through the hotend, and it's laser cut from wood. I think I am good on all points besides the nozzle blockage.

I was able to get it working without the "Extra Length on Restart" but I cant remember what I did.

Now I just gotta get this conductive filament to extrude consistently...

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Problem printing thin wall objects. February 02, 2014 01:17AM |

Registered: 11 years ago Posts: 6 |

Quote

gmh39

... Im using a Printrbot Jr. It's got a fan that blows on the hotend and print, ...

A fan for printing is different from a fan to cool the tube. If the picture above is what you have, you don't have a fan to cool the tube.

Quote

gmh39

I was able to get it working without the "Extra Length on Restart" but I cant remember what I did.

Now I just gotta get this conductive filament to extrude consistently...

"conductive filament"... is that the one black in color? If it is so, give it up. I have tried it numerious times, and it just doesn't work.

By the way, transparent filaments are better in quality in general. If transparent, quite a lot kinds of contamination would become visable to naked eyes, which deters the filament vendors from being stupid or cheating. Start with transparent filaments first. It helps a lot for identifing problems.

Edited 5 time(s). Last edit at 02/02/2014 01:33AM by whitemousegary.

|

Re: Problem printing thin wall objects. February 02, 2014 04:48AM |

Admin Registered: 11 years ago Posts: 3,096 |

It's not always true about the clear filaments, I had a white variant of PLA from repraper that would print great, but it was very brittle and layer adhesion wasn't super. After that I uses black PLA from repraper and the parts were incredibly strong, even so strong that I hadn't counted on that with the supports I had built into some models I designed

Currently using 'natural PLA' from repraper (but bought at www.filamentenmeer.nl because he is a reselling vendor in the Netherlands with Repraper filament, since thats where I live), also looks great, it looks 'icy' when it's on the reel but becomes quite clear when printed. Has good adhesion on the print bed, good layer adhesion, but still the black filament was the strongest and had best layer adhesion

It is generally true that the darker filaments are more contaminated because cheaper producers can 'get away' with doing so because it's practically invisible in darker filaments. But it doesn't always hold up and filament reviews are not always worth anything because some people print with badly calibrated printers and they call a filament 'bad' because their retraction settings and printing temperature isn't optimally configured.

Technically speaking a review can be backed up with facts, but when the human factor comes in, most of the reviews are unreliable, and the same goes for the production of filaments, done by humans. In the end it's just a matter of trusting a certain person about what they tell you.

Currently using 'natural PLA' from repraper (but bought at www.filamentenmeer.nl because he is a reselling vendor in the Netherlands with Repraper filament, since thats where I live), also looks great, it looks 'icy' when it's on the reel but becomes quite clear when printed. Has good adhesion on the print bed, good layer adhesion, but still the black filament was the strongest and had best layer adhesion

It is generally true that the darker filaments are more contaminated because cheaper producers can 'get away' with doing so because it's practically invisible in darker filaments. But it doesn't always hold up and filament reviews are not always worth anything because some people print with badly calibrated printers and they call a filament 'bad' because their retraction settings and printing temperature isn't optimally configured.

Technically speaking a review can be backed up with facts, but when the human factor comes in, most of the reviews are unreliable, and the same goes for the production of filaments, done by humans. In the end it's just a matter of trusting a certain person about what they tell you.

|

Re: Problem printing thin wall objects. February 02, 2014 01:18PM |

Registered: 10 years ago Posts: 553 |

Quote

whitemousegary

Quote

gmh39

... Im using a Printrbot Jr. It's got a fan that blows on the hotend and print, ...

A fan for printing is different from a fan to cool the tube. If the picture above is what you have, you don't have a fan to cool the tube.

Quote

gmh39

I was able to get it working without the "Extra Length on Restart" but I cant remember what I did.

Now I just gotta get this conductive filament to extrude consistently...

"conductive filament"... is that the one black in color? If it is so, give it up. I have tried it numerious times, and it just doesn't work.

By the way, transparent filaments are better in quality in general. If transparent, quite a lot kinds of contamination would become visable to naked eyes, which deters the filament vendors from being stupid or cheating. Start with transparent filaments first. It helps a lot for identifing problems.

That looks like a modified Printrbot Simple, but the fan is still in the same spot. I guess I dont then. It seemed to me that the fan was blowing air over both the tube and the nozzle. Im using an E3D now, but with the Jr's fan (dont have the connectors to wire up the E3D fan). Since the E3D is shorter than the Ubis, it is definitely blowing on both the heatsink and the nozzle.

As for the conductive filament, I have pretty much given up trying to use it in my printer. I still want to use it for my project cause it actually does conduct to a useful degree, but I think I am going to try to cast it or something.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Problem printing thin wall objects. February 02, 2014 04:40PM |

Registered: 10 years ago Posts: 553 |

Also, would switching slicers help at all? I'm currently using Slic3r but I have been considering switching to Cura it Kisslicer.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Problem printing thin wall objects. February 02, 2014 05:17PM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: Problem printing thin wall objects. February 02, 2014 07:43PM |

Registered: 11 years ago Posts: 6 |

|

Re: Problem printing thin wall objects. February 05, 2014 09:27AM |

Registered: 10 years ago Posts: 553 |

So I gave Cura a try. Im officially switching over. Runs much better for me and gives better prints. I've still got some tuning to do, but it was able to print a mold right out of the gate that repetier couldn't.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

Sorry, only registered users may post in this forum.