Poor Adhesion

Posted by Dreadnaught426

|

Poor Adhesion June 14, 2014 12:22PM |

Registered: 9 years ago Posts: 44 |

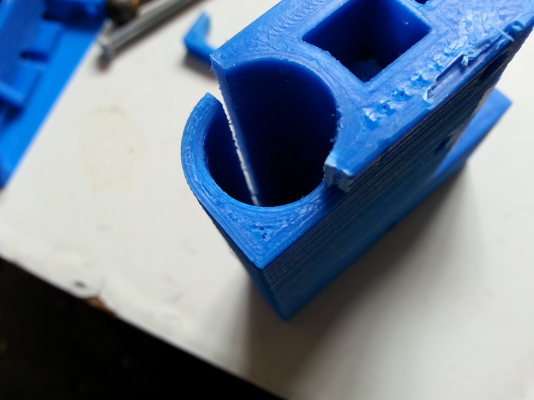

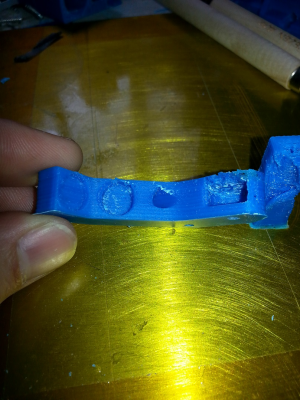

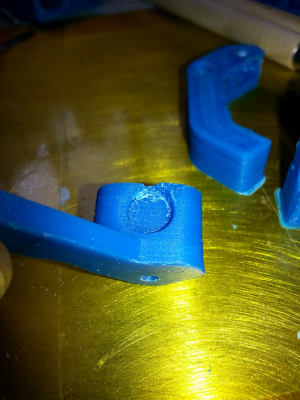

I'm trying to replace a few parts on my printer but I'm getting delamination when i put in a linear bearing. Extruding at 240 with the bed at 110. Should the hotend be hotter? And printing with ABS.

|

Re: Poor Adhesion June 14, 2014 04:39PM |

Registered: 10 years ago Posts: 153 |

|

Re: Poor Adhesion June 15, 2014 08:35AM |

Registered: 12 years ago Posts: 2,470 |

It's both. The clean separation of the broken part from the rest indicates that the layers do not adhere optimally.

The break itself is due to the hole not having the correct dimensions/shape though.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

The break itself is due to the hole not having the correct dimensions/shape though.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Poor Adhesion June 15, 2014 12:19PM |

Registered: 9 years ago Posts: 44 |

|

Re: Poor Adhesion June 15, 2014 01:13PM |

Registered: 12 years ago Posts: 2,470 |

240°C are at the lower end for ABS. Depending on the material i have to use up to 250°C.

In your case i would print a test tower with increasing temperatures and check how stable they are and how well the printed shape is. I can recommend this with every new material you get.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

In your case i would print a test tower with increasing temperatures and check how stable they are and how well the printed shape is. I can recommend this with every new material you get.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Poor Adhesion June 15, 2014 02:48PM |

Registered: 9 years ago Posts: 44 |

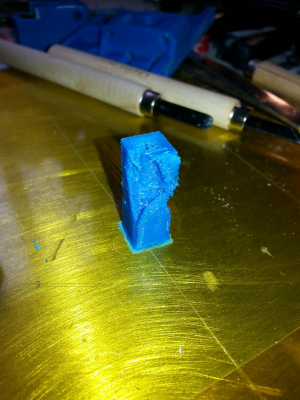

So i went to print a 10mm x 10mm x 50mm and as you can see, its all messed up.

My layer hight is .1mm, so I'm going to try .2mm and see how that goes. Maybe related, but when i try to print something with a vertical circle it has a problem up top with bridging. My nozzle is .5mm. I'm very, very, very new to this so I'm learning as i go.

My layer hight is .1mm, so I'm going to try .2mm and see how that goes. Maybe related, but when i try to print something with a vertical circle it has a problem up top with bridging. My nozzle is .5mm. I'm very, very, very new to this so I'm learning as i go.

|

Re: Poor Adhesion June 15, 2014 03:07PM |

Registered: 12 years ago Posts: 2,470 |

This looks very wrong, but i never had an issue even slightly similar, so i have no idea what happens there.

As for bridges, from nozzle development i learned that bridges become best with very thin, pointy nozzles, like the airbrush nozzles i use in the Merlin Hotend. Flatter nozzles will make it easier to create smooth surfaces by "ironing" them though. Another important thing is that the nozzle bore has to be really straight with no uneven edges, regardless ho small. When exrtuding in air the molten filament has to drop down absolutely straight for best results, any curling will make the results worse.

Cheers

Björn

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

As for bridges, from nozzle development i learned that bridges become best with very thin, pointy nozzles, like the airbrush nozzles i use in the Merlin Hotend. Flatter nozzles will make it easier to create smooth surfaces by "ironing" them though. Another important thing is that the nozzle bore has to be really straight with no uneven edges, regardless ho small. When exrtuding in air the molten filament has to drop down absolutely straight for best results, any curling will make the results worse.

Cheers

Björn

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Poor Adhesion June 15, 2014 03:48PM |

Registered: 9 years ago Posts: 44 |

Sorry, only registered users may post in this forum.