Why is my printer struggling to bridge infill gaps with ABS?

Posted by amrbekhit

|

Why is my printer struggling to bridge infill gaps with ABS? November 20, 2014 08:11PM |

Registered: 10 years ago Posts: 20 |

Hello all,

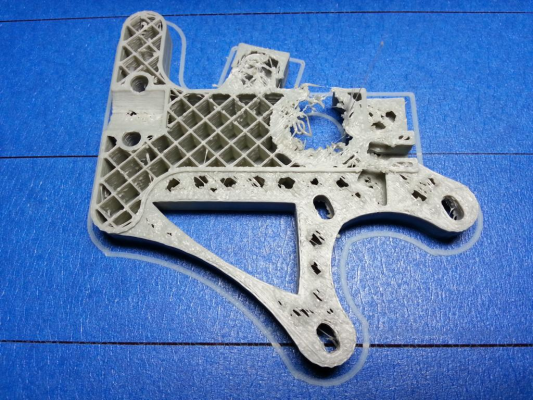

I've been printed PLA just fine with my homebuilt Prusa i3 for some time now. I've recently started to experiment with ABS and I've noticed that ABS seems to have a lot of trouble bridging over the infill (20% infill, using Cura). Here's a photo to show what I mean:

This is printed using the following settings:

Any thoughts?

I've been printed PLA just fine with my homebuilt Prusa i3 for some time now. I've recently started to experiment with ABS and I've noticed that ABS seems to have a lot of trouble bridging over the infill (20% infill, using Cura). Here's a photo to show what I mean:

This is printed using the following settings:

- Extruder: 0.5mm nozzle @ 200C (previously tried at 230C with same results)

- Heated bed: 120C (according to controller)

- Sliced using Cura: 0.2mm layer height, speed 100mm/s, Infill 20%

Any thoughts?

|

Re: Why is my printer struggling to bridge infill gaps with ABS? November 21, 2014 05:00AM |

Registered: 9 years ago Posts: 13 |

|

Re: Why is my printer struggling to bridge infill gaps with ABS? November 21, 2014 09:31AM |

Registered: 10 years ago Posts: 770 |

|

Re: Why is my printer struggling to bridge infill gaps with ABS? November 21, 2014 01:10PM |

Registered: 9 years ago Posts: 74 |

Cura does that same stuff to me, you do not have enough top/bottom thickness if you are using the defaults. I do 3x my layer height for top/bottom thickness and it has fixed this. Also your temps are WAY to low, about 30-50C to low.

Mine will sometimes do that for the first layer of the top infill with Slic3r, but once two more layers are on top of it they are solid.

Mine will sometimes do that for the first layer of the top infill with Slic3r, but once two more layers are on top of it they are solid.

|

Re: Why is my printer struggling to bridge infill gaps with ABS? November 21, 2014 01:45PM |

Registered: 10 years ago Posts: 770 |

|

Re: Why is my printer struggling to bridge infill gaps with ABS? November 21, 2014 01:46PM |

Registered: 10 years ago Posts: 20 |

Thanks for the replies everyone.

Interestingly enough, these are very similar settings to what I have been using successfully for PLA (20% infill, 3 solid layers), yet PLA doesn't have any problem with that and I get nice prints.

Is is the case that ABS is generally very poor at bridging and the distances need to be much smaller?

Interestingly enough, these are very similar settings to what I have been using successfully for PLA (20% infill, 3 solid layers), yet PLA doesn't have any problem with that and I get nice prints.

Is is the case that ABS is generally very poor at bridging and the distances need to be much smaller?

|

Re: Why is my printer struggling to bridge infill gaps with ABS? November 21, 2014 02:02PM |

Registered: 9 years ago Posts: 74 |

They have different properties, ABS needs to be kept hot(no cooling fan) but PLA can have the fan going full speed during bridging so it cools before it droops to much. I can bridge in both PLA and ABS, but PLA just comes out looking slightly better due to cooling fans, though bridging infill you should have no problems with either as it is not that far to bridge. It is possible that you are under extruding due to the cold temps you are trying to print at, maybe just upping to 240c could help or upping the temp and top thickness. I cannot use my ABS settings for PLA prints and visa versa, you gotta setup different temp profiles

Sorry, only registered users may post in this forum.