Calibration issues

Posted by tim3716

|

Calibration issues July 16, 2015 12:01PM |

Registered: 9 years ago Posts: 40 |

So the first problem that I have is that my prints have little blobs in the lower left corner where the z axis is moved every layer. How do I fix this? I also have another problem with extrusion calibration where I set my e steps for my extruder, then I print out a .5mm thin wall test to set the extrusion multiplier in slicer. When I do this my prints turn out to be under extruded but if I increase my extrusion multiplier all the holes and the part turn out to be too small. Is there a proper way to calibrate my printer to print parts that are dimensionally correct (of course not 100% accurate)?

|

Re: Calibration issues July 17, 2015 01:27PM |

Registered: 9 years ago Posts: 40 |

|

Re: Calibration issues July 17, 2015 04:00PM |

Registered: 8 years ago Posts: 778 |

What do you mean anyone?

It is quite obvious that you need to check the calibration of your hardware.

And if you always start a layer at the same point you get these corner blobs - but that is already mentioned in the documentation to your slicer.

So check the hardware calibration, calibrate the steps and when done do a proper print test for the finetuning.

It is quite obvious that you need to check the calibration of your hardware.

And if you always start a layer at the same point you get these corner blobs - but that is already mentioned in the documentation to your slicer.

So check the hardware calibration, calibrate the steps and when done do a proper print test for the finetuning.

|

Re: Calibration issues July 17, 2015 04:36PM |

Registered: 9 years ago Posts: 40 |

|

Re: Calibration issues July 17, 2015 09:07PM |

Registered: 8 years ago Posts: 778 |

|

Re: Calibration issues July 17, 2015 09:13PM |

Registered: 9 years ago Posts: 40 |

So the solution to my problem is calibration right? Isn't setting the correct e steps for your extruder part of "calibrating"? I also do not know how to properly calibrate my printer. That is kind of the reason why I made this post in the first place. I have all my belt tight, pulleys secured, and current to my motors set. All I see left of calibration is the e steps. I am pretty sure all my hardware is fine.

|

Re: Calibration issues July 17, 2015 11:25PM |

Registered: 9 years ago Posts: 978 |

In my (not very extensive) experience, extruder calibration is more an art than a science, depending on your nozzle size (which may not be what is advertised), your filament diameter (which may vary from reel to reel and even place to place on the reel), the moisture content of the filament, and the phase of the moon.

Setting the correct E steps gives an approximation of the correct extruder calibration. I don't know that printing a .5mm thick wall is a good test of extruder calibration, but maybe someone else will confirm one way or the other.

Round holes will *always* come out too small, because they are approximated by straight lines. They may also come out too small if you're over-extruding, or if there is play in your mechanism. (There is always *some* play in your mechanism.)

People could probably give you better answers if you described your printer configuration and settings, and posted a photo of what you're unhappy about.

Frank

Edited 1 time(s). Last edit at 07/17/2015 11:26PM by frankvdh.

Setting the correct E steps gives an approximation of the correct extruder calibration. I don't know that printing a .5mm thick wall is a good test of extruder calibration, but maybe someone else will confirm one way or the other.

Round holes will *always* come out too small, because they are approximated by straight lines. They may also come out too small if you're over-extruding, or if there is play in your mechanism. (There is always *some* play in your mechanism.)

People could probably give you better answers if you described your printer configuration and settings, and posted a photo of what you're unhappy about.

Frank

Edited 1 time(s). Last edit at 07/17/2015 11:26PM by frankvdh.

|

Re: Calibration issues July 17, 2015 11:43PM |

Registered: 9 years ago Posts: 40 |

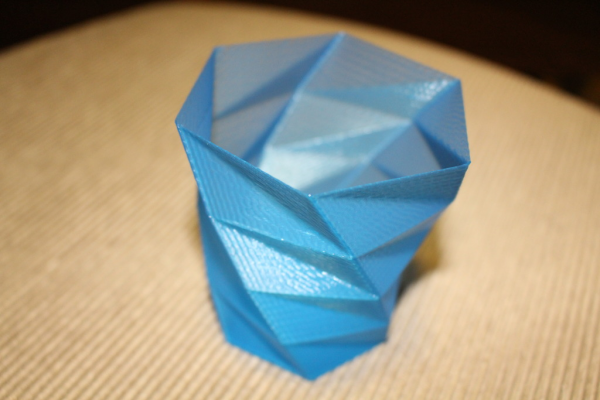

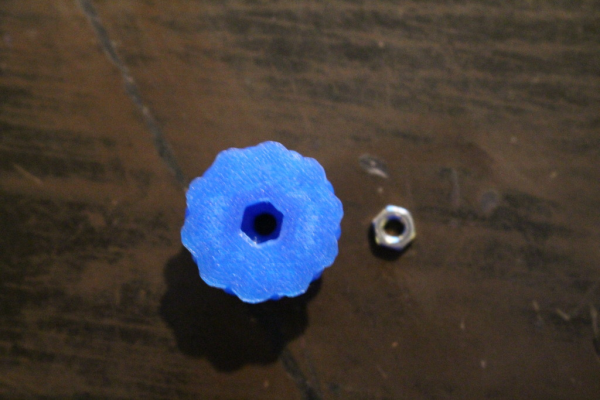

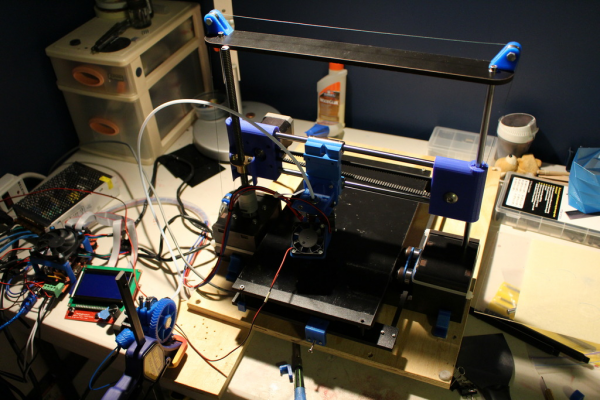

I have a QUBD Two-up and it is a cheap printer but I was able to get some pretty stunning results from it. I am using a geared extruder and a E3D lite 6 hotend. So I know that printers at the moment are not super accurate so I am aware that there is some fiddling required to get everything to fit together right. When I print parts that require hex nuts, they never fit. I am fine with filing the printed part but I see other printers that either print parts that require no extra modifications or very little modifications. I currently have to use a torch to heat the nut to seat it in parts and after I do, it is impossible to get them out again. I want to get my printer so I can press fit the nuts into place or file out the hole for a couple seconds to get everything to fit. Are my expectations too high?

|

Re: Calibration issues July 17, 2015 11:48PM |

Registered: 9 years ago Posts: 40 |

|

Re: Calibration issues July 18, 2015 03:59AM |

Registered: 9 years ago Posts: 978 |

Dunno about your expectations, but I'd be happy with either of the prints you've photographed.

If you screw a bolt into the nut before heating it, and hold the bolt with some pliers, you should be able to press the nut into the hole and pull it out again. Or you could try scaling up your print by a couple of percent to make it fit.

If you screw a bolt into the nut before heating it, and hold the bolt with some pliers, you should be able to press the nut into the hole and pull it out again. Or you could try scaling up your print by a couple of percent to make it fit.

|

Re: Calibration issues July 18, 2015 04:10AM |

Registered: 8 years ago Posts: 778 |

Those prints looks quite fine to me - did I miss something?

Ok, I will try to explain from my experience with fitting parts.

a) ABS does love to shrink quite a bit while PLA often flows too much causing bad outside perimeters.

b) "Fit" is a relative term - for example there are quite a few files on Thingyverse that have a 100% fit, e.g. a 8mm hole for a 8mm bolt is exactly 8mm in the STL file.

If the stepping for the extruder and all axis is correct the only thing left is finetuning on the slicing settings.

Many of the prints I need to fit more than to be extremly stable will be printed with the extrusion multiplicator set lower.

This way I can make sure that even corners are as close as possible to the required dimensions.

Parts I design always have some "give", so instead making the hole 8mm it will be 8.15 or even 8.2mm.

For those holes that need a perfect fit I print them with a smaller diameter and drill the hole with a matching drill bit.

If you print a 10mm test cube and it is 10mm on the outside all is good.

Best to do a thin wall print, so the walls are fixed to 1mm for example.

If your walls come out thicker than the extrusion setting need to be set lower.

If the wall thickness matches but the outside dimensions are wrong your x-y stepping is off.

My favourite tool for calibration is a digital caliper (20 bucks).

Simply by setting them in a open position to Zero and letting the axis push against it (in a fixed position of course) gives you a pretty accurate result.

You move 100mm and the caliper have to show 100mm - plus minus a tenth or so.

In many cases using a different slicer with more options also helps to get last bit of precision out of prints.

Simplify3D for example takes most of the guesswork out, where Slic3r needs a lot of finetuning to get everything to work perfectly.

Ok, I will try to explain from my experience with fitting parts.

a) ABS does love to shrink quite a bit while PLA often flows too much causing bad outside perimeters.

b) "Fit" is a relative term - for example there are quite a few files on Thingyverse that have a 100% fit, e.g. a 8mm hole for a 8mm bolt is exactly 8mm in the STL file.

If the stepping for the extruder and all axis is correct the only thing left is finetuning on the slicing settings.

Many of the prints I need to fit more than to be extremly stable will be printed with the extrusion multiplicator set lower.

This way I can make sure that even corners are as close as possible to the required dimensions.

Parts I design always have some "give", so instead making the hole 8mm it will be 8.15 or even 8.2mm.

For those holes that need a perfect fit I print them with a smaller diameter and drill the hole with a matching drill bit.

If you print a 10mm test cube and it is 10mm on the outside all is good.

Best to do a thin wall print, so the walls are fixed to 1mm for example.

If your walls come out thicker than the extrusion setting need to be set lower.

If the wall thickness matches but the outside dimensions are wrong your x-y stepping is off.

My favourite tool for calibration is a digital caliper (20 bucks).

Simply by setting them in a open position to Zero and letting the axis push against it (in a fixed position of course) gives you a pretty accurate result.

You move 100mm and the caliper have to show 100mm - plus minus a tenth or so.

In many cases using a different slicer with more options also helps to get last bit of precision out of prints.

Simplify3D for example takes most of the guesswork out, where Slic3r needs a lot of finetuning to get everything to work perfectly.

Sorry, only registered users may post in this forum.