Extruder Jamming

Posted by pyromanci

|

Extruder Jamming December 09, 2015 09:39AM |

Registered: 8 years ago Posts: 3 |

So I've seen a lot of these types of posts and I've tired a large majority of this recommendations. Alas none seem to work for me.

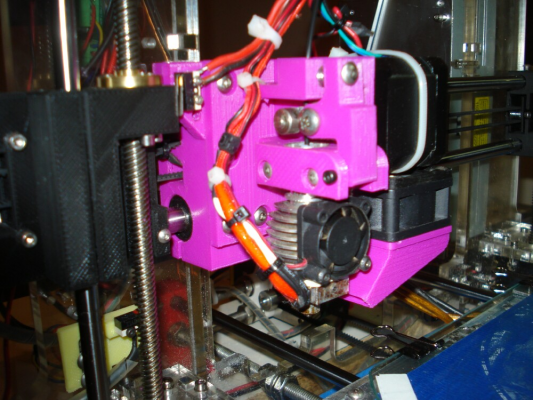

I have 0.4mm Nozzle and i'm printing 1.75mm PLA. I was able to get through a single print of the little Ultimaker robot, but both before and after I've had nothing but jam after jam in the extruder. I admit that these jams are more then likely my fault in some fashion for not understanding some aspect or another. Since i started to have PLA ooze from the top of the heater.

Below is a link to a album of pictures relating to the jam. The first picture is what the filament looked like when i cleared a early jam that forced the PTFE tube in the throat up basically creating a dam in throat. Other times the PTFE just forces it's setlf up for no reason.

[imgur.com]

I have tired:

At the moment i am stumped. Any adive would be greatly appreciated.

I have 0.4mm Nozzle and i'm printing 1.75mm PLA. I was able to get through a single print of the little Ultimaker robot, but both before and after I've had nothing but jam after jam in the extruder. I admit that these jams are more then likely my fault in some fashion for not understanding some aspect or another. Since i started to have PLA ooze from the top of the heater.

Below is a link to a album of pictures relating to the jam. The first picture is what the filament looked like when i cleared a early jam that forced the PTFE tube in the throat up basically creating a dam in throat. Other times the PTFE just forces it's setlf up for no reason.

[imgur.com]

I have tired:

- Raising and lower the temp on the extruder (185-200)

- Loosening and tightening the retaining bolts for the retention spring. To adjust the grip on the filament

- Replaced the Nozzle end

- Replaced the throat

At the moment i am stumped. Any adive would be greatly appreciated.

|

Re: Extruder Jamming December 09, 2015 11:04AM |

Registered: 8 years ago Posts: 778 |

You filament is butchered, IMHO the pressure by the extruder bearing is far too high.

If the heater cartridge is not far too long then it sticks out too far - both is bad.

There seems to be just a drilled out screw for the heatbreak with no norrow bit between hot and cold end.

The little alu cooler won't provide enough cooling, especially with a badly designed heat break.

The oozing is caused by either bad quality parts that don't fit properly or by the operator not tightening the nozzle and heat break at full temperature.

Should give you some things to address and fix

If the heater cartridge is not far too long then it sticks out too far - both is bad.

There seems to be just a drilled out screw for the heatbreak with no norrow bit between hot and cold end.

The little alu cooler won't provide enough cooling, especially with a badly designed heat break.

The oozing is caused by either bad quality parts that don't fit properly or by the operator not tightening the nozzle and heat break at full temperature.

Should give you some things to address and fix

|

Re: Extruder Jamming December 09, 2015 12:03PM |

Registered: 8 years ago Posts: 3 |

The heater cartridge I normally have centered. That just happened to my 5th rebuild of the extruder and i was starting to get sloppy yesterday working on figuring out these jams. So i was starting to get sloppy on that. Though I don't know if even that would be considered to long.

The heat break is not a drilled out screw (or at least shouldn't be). They are Kamo M6 X 30 Nozzle Throat's. Here is a link to what I had ordered. I could also be miss understanding what your referring to as a the heat break.

[www.amazon.com]

The oozing I'm hoping is just bad part fits. Cause I did crank on the nozzle with a wrench to make sure it was tight and the throat/heatbreak i did the best i could to get it tight considering there no place to get a good grip with a wrench.

For the filament butchering: in the first picture was more from the fact i didn't catch it in time and the filament started feeding bunching out the space below the bearing. Otherwise I have not seen the stress marks on it when it jams. The last time it jammed I had only tightened it as far as just having to apply a little pressure to the release before I could move it.

If it is bad part fits all around what you suggest for an alternative? I was only planning on using that style to get the unit calibrated and print a new mount for a bowden style extruder with a E3D-v6 head (which i have sitting here. Just need to print the mount for it).

Edited 2 time(s). Last edit at 12/09/2015 12:13PM by pyromanci.

The heat break is not a drilled out screw (or at least shouldn't be). They are Kamo M6 X 30 Nozzle Throat's. Here is a link to what I had ordered. I could also be miss understanding what your referring to as a the heat break.

[www.amazon.com]

The oozing I'm hoping is just bad part fits. Cause I did crank on the nozzle with a wrench to make sure it was tight and the throat/heatbreak i did the best i could to get it tight considering there no place to get a good grip with a wrench.

For the filament butchering: in the first picture was more from the fact i didn't catch it in time and the filament started feeding bunching out the space below the bearing. Otherwise I have not seen the stress marks on it when it jams. The last time it jammed I had only tightened it as far as just having to apply a little pressure to the release before I could move it.

If it is bad part fits all around what you suggest for an alternative? I was only planning on using that style to get the unit calibrated and print a new mount for a bowden style extruder with a E3D-v6 head (which i have sitting here. Just need to print the mount for it).

Edited 2 time(s). Last edit at 12/09/2015 12:13PM by pyromanci.

|

Re: Extruder Jamming December 09, 2015 10:26PM |

Registered: 8 years ago Posts: 778 |

If that heat break has the teflon tube going all the way down then it is limited to below 240°C - above the teflon will soften, schrink and start to block the filament.

To me it seems like they designed the hotend to be as easy to produce as possible

There were some issues with my E3D knockoff but not to this extend.

Your problem is that it seems the teflon liner is also producing the seal for the molten filament and that the melting chamber is quite big in diameter.

Most likely the same hotend is used for 3 and 1.75mm filament by simply changing the liner.

To avoid buying a new one:

Get a decent heatbreak without the teflon liner, something looking like this (just the first hit on Ebay, there are cheaper ones).

You see the difference in desgin?

This will give a much better seal to the nozzle and cold end.

But if your melting chamber is far too big and without the required "bottle neck" to seal the filament you might need a new block as well

As a short term fix for leaking hotends one can use a high temp plastic like Nylon.

Extrude until the goo comes out of the leaks, replace with your favourite plastic and extrude close to the extruding temp of the Nylon until it comes out clean.

Lower the temp back to normal and all should be sealed.

Obvious downside is that it is pain to clean up properly once you really want to fix it.

To me it seems like they designed the hotend to be as easy to produce as possible

There were some issues with my E3D knockoff but not to this extend.

Your problem is that it seems the teflon liner is also producing the seal for the molten filament and that the melting chamber is quite big in diameter.

Most likely the same hotend is used for 3 and 1.75mm filament by simply changing the liner.

To avoid buying a new one:

Get a decent heatbreak without the teflon liner, something looking like this (just the first hit on Ebay, there are cheaper ones).

You see the difference in desgin?

This will give a much better seal to the nozzle and cold end.

But if your melting chamber is far too big and without the required "bottle neck" to seal the filament you might need a new block as well

As a short term fix for leaking hotends one can use a high temp plastic like Nylon.

Extrude until the goo comes out of the leaks, replace with your favourite plastic and extrude close to the extruding temp of the Nylon until it comes out clean.

Lower the temp back to normal and all should be sealed.

Obvious downside is that it is pain to clean up properly once you really want to fix it.

|

Re: Extruder Jamming December 10, 2015 08:00AM |

Registered: 8 years ago Posts: 3 |

|

Re: Extruder Jamming December 10, 2015 06:12PM |

Registered: 9 years ago Posts: 705 |

I can't imagine how that can work with no cooling fin section. This is what I use and after lessening my retract to 1mm and reducing pressure on the bearing I have been jam free. To much pressure and to long retraction while printing things like support structures was eating the filament as it went back and forth. It also appears that that hotend does not have a ptfe "Collett" to keep it in place. It also appears that that hotend has a rediculous gap between the parts allowing the bulge. My Prometheus V2 eliminates those gaps. Keeping the filament cool above the hot zone is everything!

Sorry, only registered users may post in this forum.