My First Experience with ABS: I Have a Problem

Posted by Garry Bartsch

|

My First Experience with ABS: I Have a Problem June 17, 2014 08:02PM |

Registered: 10 years ago Posts: 363 |

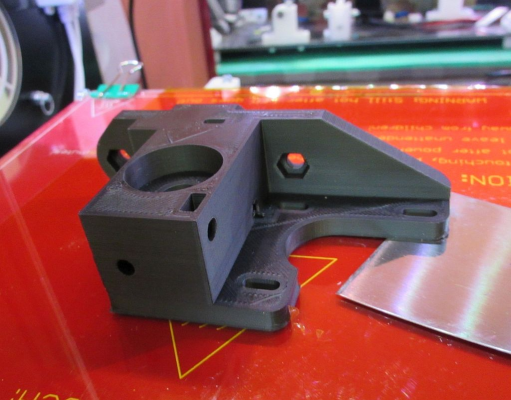

The Wade's block on my machine started cracking badly on either side of the bearing and a gap appeared above the bearing. I said to myself, "Garry, now you are going to learn how to print ABS." I had been putting off trying it for myriad reasons, not least of which was reading of all the problems people have with it. But I had no choice. To shorten the story, after a few half-hearted false starts with wrong temps (too low) and glass treatments (glue stick and Future Floor polish [which I will revisit because the result wasn't too bad]) I achieved a decent print.

I printed at 240C onto Kapton coated glass at 130C (for the whole print; I didn't alter the temps). The tape was wiped lightly with acetone soaked kitchen towel. The ABS was black from Botfeeder.ca. It's a respectable print with basically straight side except where the nozzle starts each layer. There is a bit of excess plastic there. Otherwise it's a pretty sweet part with awesome looking layer bonding. I think I over extruded slightly but that's OK for a third print.

I sliced it with Kisslicer.

Funnily, my wife with the nose of a bloodhound did not detect a bad odor from the printing plastic. Ditto for both kids. I let the print go for a while before asking them if the office smelled bad. I was dreading that they would not like me printing with ABS because of the smell but so far so good.

Anyway, I now have a nice new Wade's block. Yippee!

Oh yes, my problem. I can't get the part off the Kapton. It's stuck like crazy. I've been trying to pry it off with the same method I use successfully for PLA. Alas, no luck. After fighting I have the knife part way under one end. But I'm the crippled guy and can't exert much force. So I'll wait for help and try putting it in the freezer for a while. Who ever does help me remove it will be very careful and wear cut resistant gloves.

I think I need to find a way to make the part stick less well :-(.

I printed at 240C onto Kapton coated glass at 130C (for the whole print; I didn't alter the temps). The tape was wiped lightly with acetone soaked kitchen towel. The ABS was black from Botfeeder.ca. It's a respectable print with basically straight side except where the nozzle starts each layer. There is a bit of excess plastic there. Otherwise it's a pretty sweet part with awesome looking layer bonding. I think I over extruded slightly but that's OK for a third print.

I sliced it with Kisslicer.

Funnily, my wife with the nose of a bloodhound did not detect a bad odor from the printing plastic. Ditto for both kids. I let the print go for a while before asking them if the office smelled bad. I was dreading that they would not like me printing with ABS because of the smell but so far so good.

Anyway, I now have a nice new Wade's block. Yippee!

Oh yes, my problem. I can't get the part off the Kapton. It's stuck like crazy. I've been trying to pry it off with the same method I use successfully for PLA. Alas, no luck. After fighting I have the knife part way under one end. But I'm the crippled guy and can't exert much force. So I'll wait for help and try putting it in the freezer for a while. Who ever does help me remove it will be very careful and wear cut resistant gloves.

I think I need to find a way to make the part stick less well :-(.

|

Re: My First Experience with ABS: I Have a Problem June 18, 2014 04:37AM |

Admin Registered: 17 years ago Posts: 7,879 |

Kapton does stick too well for me. When I used Kapton I developed removable flexible beds that I could take off and bend. See [hydraraptor.blogspot.co.uk] and [hydraraptor.blogspot.co.uk].

I switched the PET tape because it is easier to remove the parts. Also Kapton's grip seems to fade over time whereas PET's doesn't.

[www.hydraraptor.blogspot.com]

I switched the PET tape because it is easier to remove the parts. Also Kapton's grip seems to fade over time whereas PET's doesn't.

[www.hydraraptor.blogspot.com]

|

Re: My First Experience with ABS: I Have a Problem June 18, 2014 05:30AM |

Admin Registered: 17 years ago Posts: 7,879 |

To remove parts stuck like that I take the glass off, hold it on its edge, put a block of wood on the top edge of the part and hit it with a hammer!

One thing to bear in mind is if you calibrate your Z axis for PLA it will be a bit low for ABS because the hot end expands more due to the higher temperature. If your first layer is low it will stick a lot harder.

[www.hydraraptor.blogspot.com]

One thing to bear in mind is if you calibrate your Z axis for PLA it will be a bit low for ABS because the hot end expands more due to the higher temperature. If your first layer is low it will stick a lot harder.

[www.hydraraptor.blogspot.com]

|

Re: My First Experience with ABS: I Have a Problem June 18, 2014 11:13AM |

Registered: 10 years ago Posts: 790 |

^First thing I noticed when printing in ABS for the first time.

Also, that flexible bed idea sounds wonderful. I might try that and go back to things that stick more than I like.

Edited 1 time(s). Last edit at 06/18/2014 11:14AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Also, that flexible bed idea sounds wonderful. I might try that and go back to things that stick more than I like.

Edited 1 time(s). Last edit at 06/18/2014 11:14AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: My First Experience with ABS: I Have a Problem June 18, 2014 01:08PM |

Registered: 10 years ago Posts: 363 |

Quote

nophead

Kapton does stick too well for me. When I used Kapton I developed removable flexible beds that I could take off and bend. See [hydraraptor.blogspot.co.uk] and [hydraraptor.blogspot.co.uk].

That was cool. The ABS stuck like crazy but you could remove the part easily.

Quote

nophead

I switched the PET tape because it is easier to remove the parts. Also Kapton's grip seems to fade over time whereas PET's doesn't.

I will try this next. Thank you!

|

Re: My First Experience with ABS: I Have a Problem June 18, 2014 01:14PM |

Registered: 10 years ago Posts: 363 |

Quote

nophead

To remove parts stuck like that I take the glass off, hold it on its edge, put a block of wood on the top edge of the part and hit it with a hammer!

Will try that. Thanks.

Quote

nophead

One thing to bear in mind is if you calibrate your Z axis for PLA it will be a bit low for ABS because the hot end expands more due to the higher temperature. If your first layer is low it will stick a lot harder.

Aha! I hadn't thought of that. I will tweak the Z offset in KISSlicer.

Sorry, only registered users may post in this forum.