x motor bracket - what are the additional shells for?

Posted by Stemer114

|

x motor bracket - what are the additional shells for? June 14, 2013 06:50PM |

Registered: 11 years ago Posts: 22 |

Hello,

having built myself a wolfstrap based repstrap I am now in the process of preparing to rebuild my working but clumsy printer to become a much nicer and better Mendel90. So far, I have downloaded, configured and compiled the mendel90 files (sturdy) from latest github and printed almost all of them - except the x motor bracket. Now I have a couple of questions I am stuck at and after having searched the mendel build manual, the scad source files and this forum to no avail (using the all dates option) I'd need to ask the forum at last:

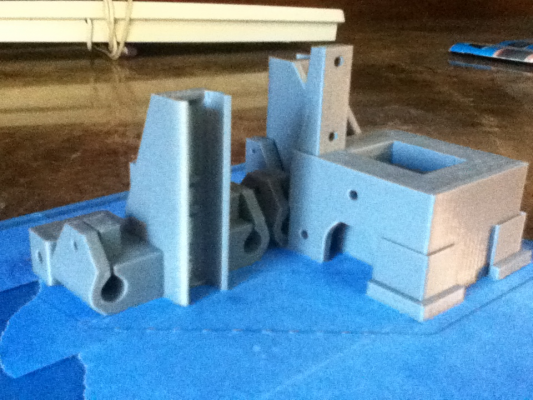

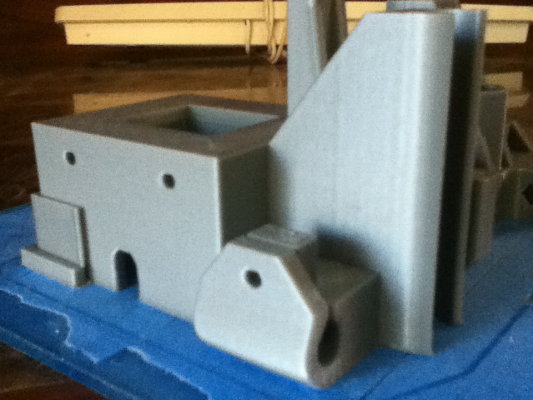

What are the additional shells (see attached png, marked red) for in the x-motor-bracket, because these shells do not seem to be connected to the main body of the bracket? Do they just come off after printing?

Additionally, am I correct in assuming that the central column (marked green in the attached png) is a built-in support structure?

Regards,

steffen

having built myself a wolfstrap based repstrap I am now in the process of preparing to rebuild my working but clumsy printer to become a much nicer and better Mendel90. So far, I have downloaded, configured and compiled the mendel90 files (sturdy) from latest github and printed almost all of them - except the x motor bracket. Now I have a couple of questions I am stuck at and after having searched the mendel build manual, the scad source files and this forum to no avail (using the all dates option) I'd need to ask the forum at last:

What are the additional shells (see attached png, marked red) for in the x-motor-bracket, because these shells do not seem to be connected to the main body of the bracket? Do they just come off after printing?

Additionally, am I correct in assuming that the central column (marked green in the attached png) is a built-in support structure?

Regards,

steffen

|

Re: x motor bracket - what are the additional shells for? June 14, 2013 07:24PM |

Admin Registered: 17 years ago Posts: 7,879 |

The shells are to help stop the corners warping, see: [hydraraptor.blogspot.co.uk]

Yes the central column is support material and is broken off after printing.

[www.hydraraptor.blogspot.com]

Yes the central column is support material and is broken off after printing.

[www.hydraraptor.blogspot.com]

|

Re: x motor bracket - what are the additional shells for? June 15, 2013 08:59AM |

Registered: 11 years ago Posts: 22 |

Hello nophead, thank you very much for the explanation. That makes it clear.

What is more, thank you very much for making your mendel90 files available via github. (Having come via the diy/repstrap route buying the complete kit was not an option here)

It is really amazing what amount of work must have been put in there. Whatever the detail I look at in the components, I cannot help but being really impressed. Just the other day I took one of the printed y bearing mounts with me to the office and we were all marveling at the little "tunnel" for the cable tie that has been integrated, so the linear bearing can be fixated. Details like that..

Edited 1 time(s). Last edit at 06/15/2013 09:00AM by Stemer114.

What is more, thank you very much for making your mendel90 files available via github. (Having come via the diy/repstrap route buying the complete kit was not an option here)

It is really amazing what amount of work must have been put in there. Whatever the detail I look at in the components, I cannot help but being really impressed. Just the other day I took one of the printed y bearing mounts with me to the office and we were all marveling at the little "tunnel" for the cable tie that has been integrated, so the linear bearing can be fixated. Details like that..

Edited 1 time(s). Last edit at 06/15/2013 09:00AM by Stemer114.

|

Re: x motor bracket - what are the additional shells for? June 16, 2013 05:35AM |

Registered: 15 years ago Posts: 81 |

I've just printed two sets of mendel90 parts and of all the parts, that x-motor-bracket was by far the most difficult to print - and in the end there was still quite a lot of warping of the end "protected" by the shells. It will need a bit of dremelling and drilling a new motor mounting hole in the correct place in order to get a usable part. The other part that gave me a lot of bother was the x-carriage -- the protruberances for the belt attachment kept wanting to lift off. (It is winter here, so maybe printing in summer or in a warmed chamber might help, but there are probably also design improvements that would make that x motor bracket easier to print). The rest of the parts have been relatively straight forward, and you can appreciate the thought that has gone into the whole set.

Make sure you spend some time tuning your current printer using the cal.stl so that you get the nut traps all fitting nicely before embarking on printing the rest of the parts.

Cheers,

Len.

Make sure you spend some time tuning your current printer using the cal.stl so that you get the nut traps all fitting nicely before embarking on printing the rest of the parts.

Cheers,

Len.

|

Re: x motor bracket - what are the additional shells for? June 21, 2013 06:06PM |

Registered: 11 years ago Posts: 22 |

Well, I had to wait until Friday till I could start the 6+ hours printjob for the x motor bracket (only running at 20mm/s..). But it worked out quite well. Both the bridging and the corner shells gave good results. After all, I am printing on a wooden repstrap with a drill-and-file hotend..

|

Re: x motor bracket - what are the additional shells for? June 22, 2013 01:06PM |

Registered: 11 years ago Posts: 250 |

LOL yea, these can be pretty long prints... I printed both together, and it was 10 hours!!

(I was also going slow on a second round as I lost steps into it at the 4 hour mark! Doh!)

Ecstatic with the results!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

(I was also going slow on a second round as I lost steps into it at the 4 hour mark! Doh!)

Ecstatic with the results!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Sorry, only registered users may post in this forum.