Failed first prints

Posted by ballyboy

|

Failed first prints August 27, 2014 03:41PM |

Registered: 10 years ago Posts: 23 |

Hello all,

I have my Mendel90 up and running. Unfortunately I am having some trouble with the calibration. I managed to print the android model that came with the printer but I think this may have been a bit of blind luck as I have not been able to repeat the print.

I am having a lot of trouble getting the first layer to stick to the bed. I have been adjusting the Z home point value incrementally and have it as close as I can get it to a successful print without the first layer sticking to the bed.

I have increased the bed temperature and have an infrared temp monitor giving me a temp of around 57 deg C on the top surface of the bed which is pretty much right for PLA I believe.

I have levelled the bed numerous times and think I have it as close as possible without using a dial gauge(I dont have the clamp to mount the gauge to the machine). My only other idea is that the room I am set up in is too cold but I since the bed is reaching the required temperature I'm not sure. Do you have any ideas?

Thanks

I have my Mendel90 up and running. Unfortunately I am having some trouble with the calibration. I managed to print the android model that came with the printer but I think this may have been a bit of blind luck as I have not been able to repeat the print.

I am having a lot of trouble getting the first layer to stick to the bed. I have been adjusting the Z home point value incrementally and have it as close as I can get it to a successful print without the first layer sticking to the bed.

I have increased the bed temperature and have an infrared temp monitor giving me a temp of around 57 deg C on the top surface of the bed which is pretty much right for PLA I believe.

I have levelled the bed numerous times and think I have it as close as possible without using a dial gauge(I dont have the clamp to mount the gauge to the machine). My only other idea is that the room I am set up in is too cold but I since the bed is reaching the required temperature I'm not sure. Do you have any ideas?

Thanks

|

Re: Failed first prints August 28, 2014 01:17AM |

Registered: 10 years ago Posts: 363 |

I'm not sure which PLA you are using but clean the glass with vinegar and kitchen towel till it squeaks and then slice whatever object at 80C for the bed. Set your hotend to 200C for the first layer and drop after. Doing this I can get most PLA to stick to glass. Sometime I set the bed even hotter. I leave it the same temp through the entire print. The best quality PLA likes lower temperatures than poorer quality PLA.

|

Re: Failed first prints August 28, 2014 12:05PM |

Registered: 10 years ago Posts: 439 |

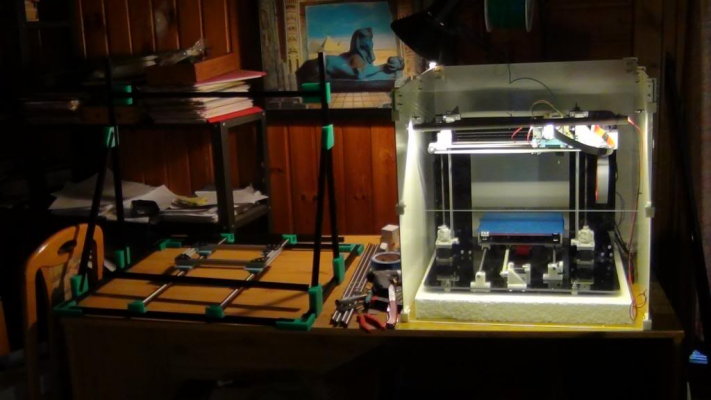

I had a lot of problems a few months after using mine when the weather became colder. I built an enclosure to stop cold draughts which resolved things. As an initial solution before creating a dibond enclosure I used cardboard. Jut the 4 sides was enough without a top.

I used blue tape over the glass to get good adhesion initially. I couldn't get plain glass to work well until after I used a dial guage to level the bed. Some glass cleaners seem to make adhesion worse. An acid wiped over the surface like vinegar or lemon juice improves it.

I used blue tape over the glass to get good adhesion initially. I couldn't get plain glass to work well until after I used a dial guage to level the bed. Some glass cleaners seem to make adhesion worse. An acid wiped over the surface like vinegar or lemon juice improves it.

|

Re: Failed first prints August 29, 2014 05:46AM |

Registered: 10 years ago Posts: 23 |

Hi,

Thanks for the replies,

Garry do you set your bed to 80C or are you looking to get that temp on the top surface? I have upped my temp to 90C for the bed giving 67C for the top surface. I'm using faberdashery green 3mm PLA provided with the kit.

Ralph your enclosure looks great, what type of blue tape are you using on your glass?

Thanks for the replies,

Garry do you set your bed to 80C or are you looking to get that temp on the top surface? I have upped my temp to 90C for the bed giving 67C for the top surface. I'm using faberdashery green 3mm PLA provided with the kit.

Ralph your enclosure looks great, what type of blue tape are you using on your glass?

|

Re: Failed first prints August 29, 2014 06:09PM |

Registered: 10 years ago Posts: 363 |

I set the bed to 80-85 in the slicer. From memory the green filament that comes with the kit stuck well with bed set to 70. Try cranking up the heat on the hotend. But print the first layer fast enough so there is sufficient plastic flow. Without the fan on the first layer heat can creep up the hotend and soften the plastic resulting in a jam. I know; I jammed mine that way.

Sorry, only registered users may post in this forum.