Black dust no more

Posted by ormerod168

|

Black dust no more April 28, 2014 03:46PM |

Registered: 10 years ago Posts: 1,230 |

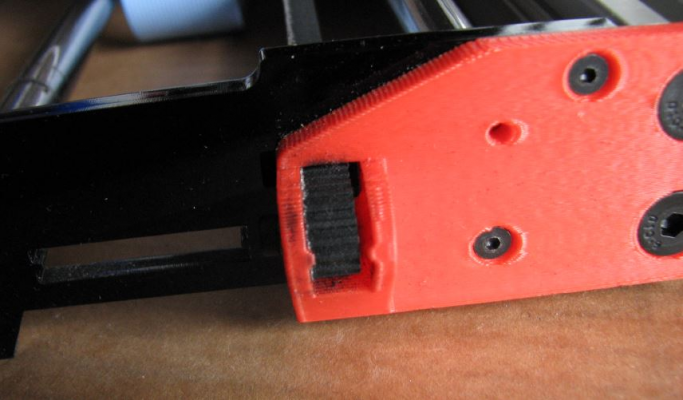

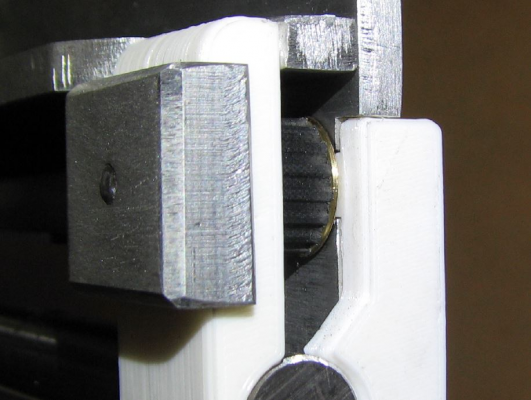

So how to put the old x-runner bearing (9mm MR93ZZ) that was leftover from the change for a 10mm 623ZZ to good use?

Brass pulley D13.3/D10.3/D9.0 x W7.8/6.5mm

Every day in every way its getting better and better

Erik

Brass pulley D13.3/D10.3/D9.0 x W7.8/6.5mm

Every day in every way its getting better and better

Erik

|

Re: Black dust no more April 28, 2014 04:10PM |

Registered: 10 years ago Posts: 780 |

|

Re: Black dust no more April 28, 2014 04:31PM |

Registered: 10 years ago Posts: 1,230 |

Quote

appjaws1

Where did you get the brass pulley from? A great idea

I made it from a piece of junk brass as I could not find any ready made pulley small enough, was thinking about buying a hollow out a spare alu belt pulley but think it will require an even smaller bearing, there is not much room there and I wanted to keep the design as original as possible

Erik

|

Re: Black dust no more April 28, 2014 04:56PM |

Registered: 10 years ago Posts: 64 |

|

Re: Black dust no more April 28, 2014 07:09PM |

Registered: 10 years ago Posts: 859 |

Well done Erik, I was going to print one tonight, but have been hesitating because I thought if it didn't run quite true, it would cause problems, but was going to use the original 10mm bearing, which was going to make the wall thickness to small. Never thought about swapping them over.

Now I'm thinking to turn one up in the lathe like you have.

It would be a great deal better.... But I want to make one for the X-axis as well I think.....

A job for tomorrow I think....

Kim..

Edited 1 time(s). Last edit at 04/28/2014 07:11PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Now I'm thinking to turn one up in the lathe like you have.

It would be a great deal better.... But I want to make one for the X-axis as well I think.....

A job for tomorrow I think....

Kim..

Edited 1 time(s). Last edit at 04/28/2014 07:11PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Black dust no more April 29, 2014 02:36AM |

Registered: 10 years ago Posts: 1,230 |

Quote

michaelljunggren

I say - where did you get that aluminum part from!? I want one!

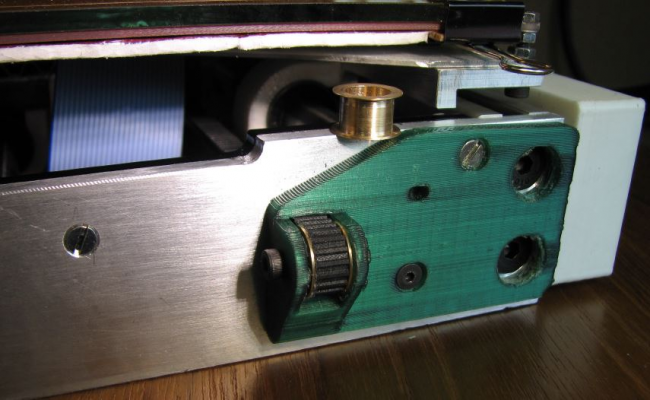

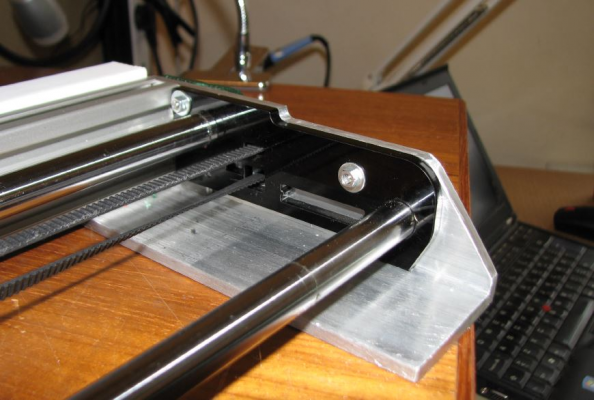

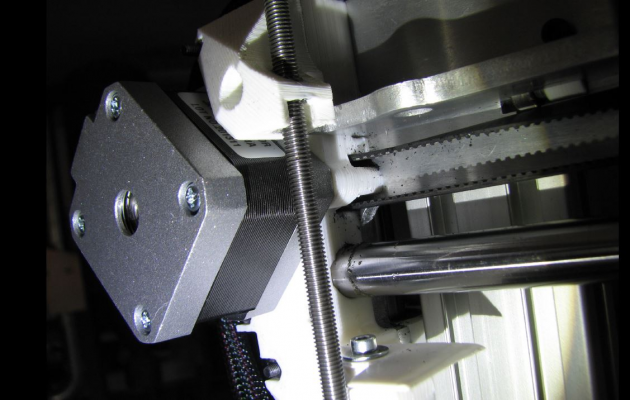

Made them from a piece of scrap aluminum, but I hope Dave will make these and and ad them to his offers, I'm working on it, hope he will crack before I run out of cherries ;-)

But there's nothing to it really, sharp angeled aluminum, 45x45mm or so, holes can be drilled instead of milled - or if one prefer squared holes, drill small holes in the corners and use a saw and file to square it out, but it really doesn't matter, a round hole for the belt and micro switch arm to go trough will be just fine - and there's no reason to make the out cut for the cable, just bolt it down to the lower aluminum, will make the free end of the cable a bit longer and more room for the belt to pass

BTW, in the acrylic part the pass through for the belt is made as two slots as not to weaken the part, this doesn't matter in aluminum, can be drilled as one

A drill press and a hack saw is all it takes, the most important thing is to fit the angled part to the extrusion, to drill and countersink the 6mm holes just right

..and yes, you could skip the countersunk holes and just slap the aluminum part under the printed part but that would destroy the strength and stability, I prefer the direct aluminum contact and just drilled a bigger hole in the printed part for the screw to go trough

..and yes they could be made of flat instead of angled aluminum, but you will then miss the lockup to the extrusion from the T-nut and bolt from underneath, this is what really give it the strength against the pull of the belt

Erik

|

Re: Black dust no more April 29, 2014 02:47AM |

Registered: 10 years ago Posts: 1,230 |

Quote

KimBrown

Well done Erik, I was going to print one tonight, but have been hesitating because I thought if it didn't run quite true, it would cause problems, but was going to use the original 10mm bearing, which was going to make the wall thickness to small.

Yes was my thoughts too, would have to design new printed part if so and I can't do that, have spend all my time fiddling with this thing instead of learning about 3d proggies, you a way ahead of me there :-)

To mount the pulley you will have to file out the support for the inner ring of the bearing and the side support for the belt but that's all, it will slip right in - and ad a 3mm nut on each side as spacers to center the bearing/pulley (drill a 3 hole trough the nut first)

Quote

... But I want to make one for the X-axis as well I think.....

Did, as you can see on the picture, but now I'm out of 9mm bearings...there's always something! ;-)

Erik

|

Re: Black dust no more April 29, 2014 04:00AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Black dust no more May 09, 2014 08:59AM |

Registered: 10 years ago Posts: 64 |

I am going to attempt to add some aluminum to the ends as you did. To do that, the y-idler and y-motor bracket needs to be fixed up a bit. You don't happen to have scad or stl sources for that? :-)Quote

ormerod168

Quote

michaelljunggren

I say - where did you get that aluminum part from!? I want one!

Made them from a piece of scrap aluminum, but I hope Dave will make these and and ad them to his offers, I'm working on it, hope he will crack before I run out of cherries ;-)

...

|

Re: Black dust no more May 09, 2014 12:53PM |

Registered: 10 years ago Posts: 1,230 |

Quote

michaelljunggren

..I am going to attempt to add some aluminum to the ends as you did. To do that, the y-idler and y-motor bracket needs to be fixed up a bit. You don't happen to have scad or stl sources for that? :-)

Attaboy! - there's nothing to it really! - I have thought of a way to make it easier for every one to make and it actually makes the setup stronger (unless you are able to drill and countersink the holes with very very close tolerances)

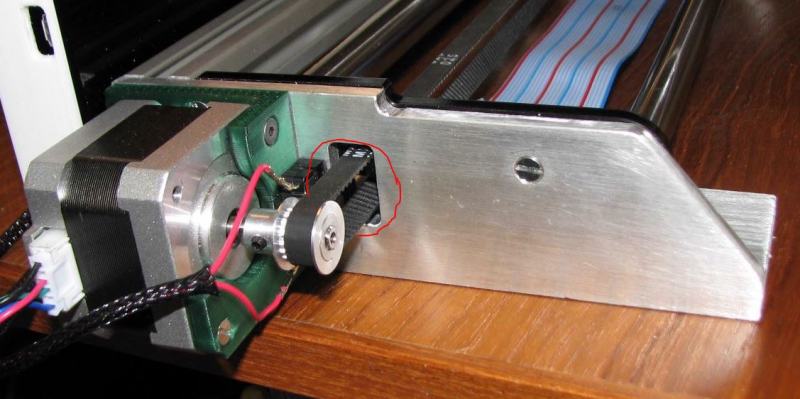

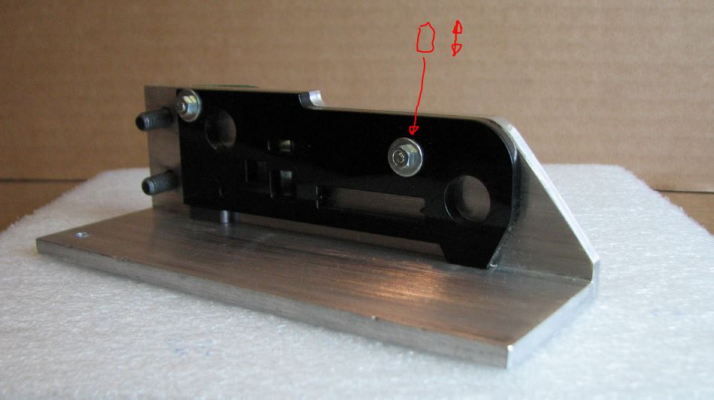

Instead of the precisely drilled 6 mm countersunk holes for the screws in the end of the y-extrusion, just drill them a bit oversize and use normal headed screws, when assembled, tighten them in sequence with the screw and T-bolt under the y-extrusion as to drag both sides of the angled part flat to the y-extrusion's end and horizontal side, mounted this way the angled part will be dragged into perfect square contact with the y-extrusion, if made this way I would recommend you drill an extra hole (red circle) near the corner and mount two screws and T-bolt in the horizontal side, then start assembly by first tighten the two screws closest to the corner

The slots for belt and micro switch could be drilled as one large round hole, it doesn't really matter, the printed/acrylic parts do not need that much support anyway

you will need to chop of at least 4mm of the acrylic parts to get them "inside" the angled aluminum, 4mm will make the acrylic part "level", so any adjustment of the parts will be up from normal, so I would recommend you take off a bit more later, but first, while they are nice and level, mark up the holes and out cuts using the acrylic pars as guide

To make nice carbon copy cuts, pin the parts together with a 12 and 3mm drill bit

and file out the hole in the acrylic part a bit as to give room for the part to swing around the inner screw while adjusting the y-rods

..but back to the printed parts, I can't draw (the shame) so just chopped the unnecessary bits of with a hacksaw and opened the countersunk holes with a drill bit, please don't tell anyone ;-)

2 x sharp angled extruded aluminum 150x45x45 (only the vertical side need to be or made to 45mm, I started out with 50x50, can't be picky at the scrapyard)

Start by making the holes for mounting the angled aluminum on the the y-extrusion, then mount and place the acrylic parts inside the angled aluminum and use these as guide to mark up the rest of the holes, at lower left you will notice a small 4mm spacer placed there as to level the part while marking the holes

you will so much enjoy this mod..

Erik

|

Re: Black dust no more May 09, 2014 01:04PM |

Registered: 10 years ago Posts: 64 |

|

Re: Black dust no more May 09, 2014 01:56PM |

Registered: 10 years ago Posts: 1,230 |

Quote

michaelljunggren

Thank you for a very instructive set of images! Unfortunately my hardware store only had 3mm thick aluminum but either that'll do, or I'll strengthen it in some other way.

You are very welcome - strength-wise 3mm will do nicely - may look a bit flimsy and out of place compared to the other nearby dimension, but that is just me

..and you can always make some thicker ones later

also notice that you could join the end parts with another aluminum plate/part for the cable to rest on and ad even more strength to the mod, it actually look a bit silly that the cables just hang down underneath the printer when you lift it up

Erik

|

Re: Black dust no more May 11, 2014 06:05AM |

Registered: 10 years ago Posts: 1,230 |

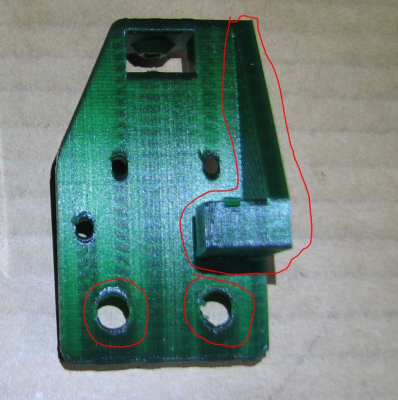

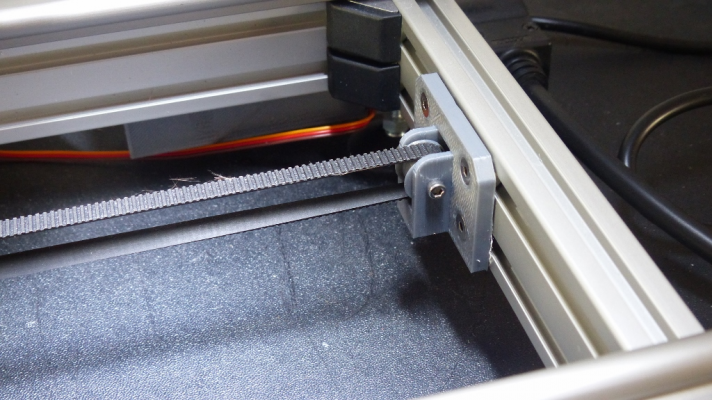

added this very on-topic post after seeing robbycar's problems with the too tight x-axis belt..

the curse:

the cure - you may want to do a wheelie on the x-axis

..but wait, there's more - should the printed part should be re-designed a bit?, belt drag at top and bottom cut-outs (disclamer: this may not mean a thing if your belt don't go pling)

Erik

the curse:

the cure - you may want to do a wheelie on the x-axis

..but wait, there's more - should the printed part should be re-designed a bit?, belt drag at top and bottom cut-outs (disclamer: this may not mean a thing if your belt don't go pling)

Erik

|

Re: Black dust no more May 14, 2014 05:30AM |

Registered: 10 years ago Posts: 76 |

Nice mod really!! I thought of enforcing the y motor mount as well.

For now i just reprint the motor mount and replace the original one.

I having problem on the motor mount lately after a long print the plastic

That mount the stepper motor to move The bed soften due to heat generated

from the moter, the causing the y belt loosen and the y motore mount bent due to the belt tension.

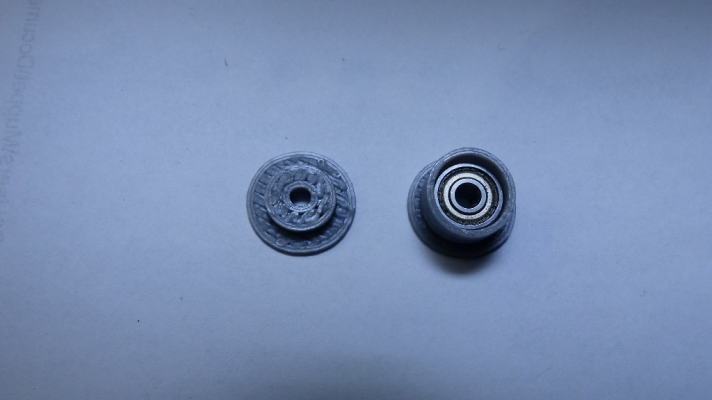

Btw. I made a belt roller but not yet replacing it in the printer yet. My version using 2 639 bearing

in the center of the hub. It's dimension is 8mm OD 3mm ID and 4 mm height. This is a

tamiya 4wd bearing but i did not buy it from rc store, they are very expensive if get it from them.

Other dimension is quite the same as you did

For now i just reprint the motor mount and replace the original one.

I having problem on the motor mount lately after a long print the plastic

That mount the stepper motor to move The bed soften due to heat generated

from the moter, the causing the y belt loosen and the y motore mount bent due to the belt tension.

Btw. I made a belt roller but not yet replacing it in the printer yet. My version using 2 639 bearing

in the center of the hub. It's dimension is 8mm OD 3mm ID and 4 mm height. This is a

tamiya 4wd bearing but i did not buy it from rc store, they are very expensive if get it from them.

Other dimension is quite the same as you did

|

Re: Black dust no more May 14, 2014 05:58AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Chaisaeng

...My version using 2 639 bearing

in the center of the hub. It's dimension is 8mm OD 3mm ID and 4 mm height. This is a

tamiya 4wd bearing but i did not buy it from rc store, they are very expensive if get it from them.

Other dimension is quite the same as you did..

Yes, that bearing is a better choice, will give you more outer mass to work with, 1.15mm instead of my flimsy 0.65mm

In the printed part you will have to file/cut the side guides for the belt away as they will not be needed anymore..and to get room for the pulley

Great work there, very solid looking pulley's! - will see if I can order same bearings from my usual supplier as RS now is banned in our firm

Erik

|

Re: Black dust no more May 14, 2014 07:06AM |

Registered: 10 years ago Posts: 64 |

|

Re: Black dust no more May 14, 2014 07:37AM |

Registered: 10 years ago Posts: 76 |

Quote

ormerod168

Quote

Chaisaeng

...My version using 2 639 bearing

in the center of the hub. It's dimension is 8mm OD 3mm ID and 4 mm height. This is a

tamiya 4wd bearing but i did not buy it from rc store, they are very expensive if get it from them.

Other dimension is quite the same as you did..

Yes, that bearing is a better choice, will give you more outer mass to work with, 1.15mm instead of my flimsy 0.65mm

In the printed part you will have to file/cut the side guides for the belt away as they will not be needed anymore..and to get room for the pulley

Great work there, very solid looking pulley's! - will see if I can order same bearings from my usual supplier as RS now is banned in our firm

Erik

You can lookup in this ebay listing. It is 639/3 2z bearing no too expensive i guess

[www.ebay.com]

Edited 1 time(s). Last edit at 05/14/2014 07:38AM by Chaisaeng.

|

Re: Black dust no more May 15, 2014 07:22AM |

Registered: 10 years ago Posts: 1,230 |

Quote

michaelljunggren

...done... I will now run a speed test. I took the opportunity to strengthen a few other things too.

Great! - looking forward to hear more, but no hurry, and some pictures would be nice, maybe you found some shortcuts or easier way to make and install the end parts - happy printing!

Erik

|

Re: Black dust no more May 15, 2014 07:25AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Chaisaeng

You can lookup in this ebay listing. It is 639/3 2z bearing no too expensive i guess

[www.ebay.com]

No problem with my usual supplier, thank you!

Erik

|

Re: Black dust no more May 17, 2014 05:40AM |

Registered: 10 years ago Posts: 327 |

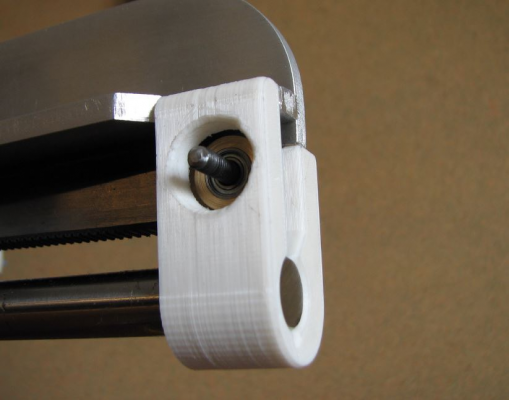

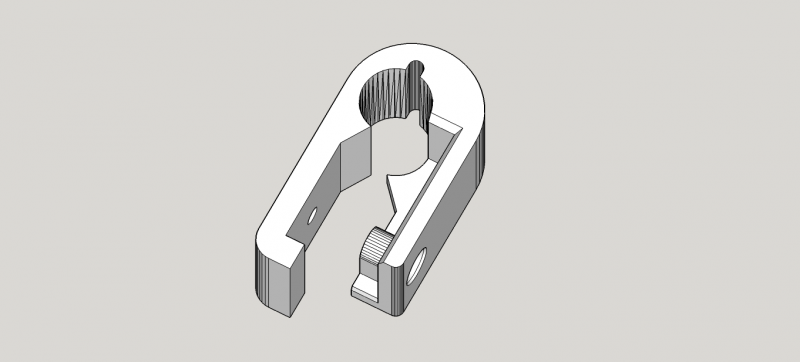

This got me thinking. (dangerous I know) I don't have access to a lathe so came up with a printed part...

Open with a 10mm bearing inside...

Closed. (I will probably glue the pieces together)...

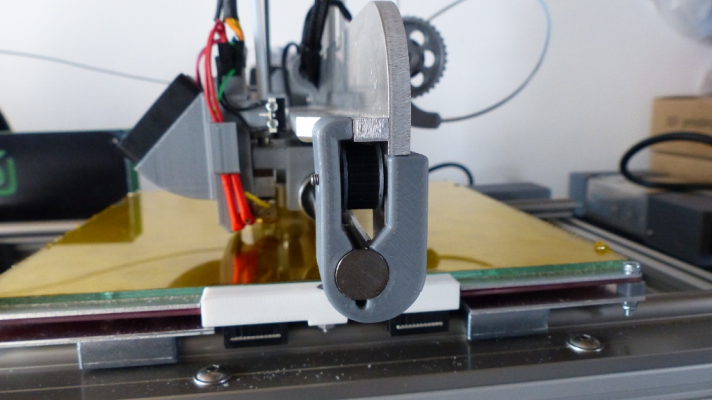

One fitted to my Y belt idler. (you can see my Y belt has started to chaff when using just the bearing)...

I have a washer either side and the screw is held in place with a nyloc nut so I can slacken of half a turn and keep it free running. I am just trying to mod the X idler to see if i can fit one there too.

Regards,

Les

Pointy's Things

Pointy's Blog

Open with a 10mm bearing inside...

Closed. (I will probably glue the pieces together)...

One fitted to my Y belt idler. (you can see my Y belt has started to chaff when using just the bearing)...

I have a washer either side and the screw is held in place with a nyloc nut so I can slacken of half a turn and keep it free running. I am just trying to mod the X idler to see if i can fit one there too.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Black dust no more May 17, 2014 05:02PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Pointy

...This got me thinking. (dangerous I know) I don't have access to a lathe so came up with a printed part...

Good thinking! - plenty of room for that with your fine build, me I had to work with the limited space of the original design so made it out of metal - and I can't 3D model, I have been playing around with OpenSCAD a bit but I don't think my brain likes it at all as it alway try to divert me to other things..

Look! - there's a squirrel at the lawn!...sigh, here we go again - who cares about a bloody tree rat anyway :-)

Erik

|

Re: Black dust no more May 18, 2014 04:38AM |

Registered: 10 years ago Posts: 327 |

Quote

ormerod168

Quote

Pointy

...This got me thinking. (dangerous I know) I don't have access to a lathe so came up with a printed part...

Good thinking! - plenty of room for that with your fine build, me I had to work with the limited space of the original design so made it out of metal - and I can't 3D model, I have been playing around with OpenSCAD a bit but I don't think my brain likes it at all as it alway try to divert me to other things..

Look! - there's a squirrel at the lawn!...sigh, here we go again - who cares about a bloody tree rat anyway :-)

Erik

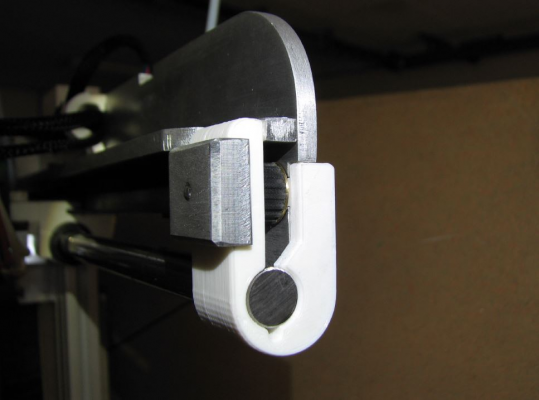

I love programming and thought OpenScad would be cool, but I just can't get into it. I personally use Sketchup for everything, I can import stl's to modify existing parts. Here's the X Idler modified in Sketchup...

And here it is printed and fitted to the Ormerod with a printed hub/pulley...

I have found Sketchup to be the easiest 3d modelling application to use, and there are so many resources and tutorials for it, that it is easy to pick up. Best of all its FREE!

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Black dust no more May 18, 2014 02:59PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Pointy

..I love programming and thought OpenScad would be cool, but I just can't get into it. I personally use Sketchup for everything, I can import stl's to modify existing parts...

My thoughts exactly, that you had to be a programmer to appreciate the text based input, and I'm not into that

Quote

..Here's the X Idler modified in Sketchup...

And here it is printed and fitted to the Ormerod with a printed hub/pulley..

Beautifull! - see, this is what you can do, this is the way it's meant to be done, I on the other hand had to open the exiting part, mill my way in to get room for the bearing - and mill another part to support the weakness I made, I might as well have made the whole bloody thing from aluminum and thats what really bother me, it do not make any sense to me to own a 3D printer and not be able to model

Quote

I have found Sketchup to be the easiest 3d modelling application to use, and there are so many resources and tutorials for it, that it is easy to pick up. Best of all its FREE!

Thanks for the hint, I'll take a look

Erik

|

Re: Black dust no more May 20, 2014 12:09PM |

Registered: 10 years ago Posts: 780 |

|

Re: Black dust no more May 20, 2014 01:33PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Black dust no more May 20, 2014 04:06PM |

Registered: 10 years ago Posts: 780 |

Pointy,

Do you have the stl's of the hub/pulley and x-idler please?

Erik,

Thank you, how do you quote?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Do you have the stl's of the hub/pulley and x-idler please?

Erik,

Thank you, how do you quote?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Black dust no more May 20, 2014 05:30PM |

Registered: 10 years ago Posts: 1,230 |

Quote

appjaws1

Pointy,

Do you have the stl's of the hub/pulley and x-idler please?

Erik,

Thank you, how do you quote?

Paul

Just press "quote" instead of "reply" and all the text in the message your are replying to will be quoted at the top, identifiable for the poster as a reply to his post - also, if you want to reply to just a part of the text, you can delete the irrelevant part and ad .....before and after....as to show that what you are replying to is out of context and your reply is to a part of the message only

Erik

|

Re: Black dust no more May 21, 2014 04:01AM |

Registered: 10 years ago Posts: 327 |

Here's the stl's for anyone that's interested. A few things to note...

To use on the X axis do the following...

Regards,

Les

Pointy's Things

Pointy's Blog

- I have a non standard bed so the Y axis part is no good for anyone else.

- The 9mm hub I haven't printed but it should be ok

- I have the aluminium X Rib/Plate but it should work for the acrylic part too.

- I have only done a couple of hours printing, so I am not sure how long these will last.

To use on the X axis do the following...

- Print the hub and fettle as necessary to run smooth on an M3 screw. Fit a bearing inside and snap on the other side,(It may be wise to glue the parts together, I have found that EMA Plastic Weld works for PLA)

- Print the new X axis idler.

- Fit a washer either side of the hub using the original screw/nut, before fitting.(It can be a little fiddly getting the washers on)

- Fit to X rib and refit belt.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Black dust no more May 21, 2014 05:41AM |

Registered: 10 years ago Posts: 780 |

Quote

ormerod168

Quote

appjaws1

Pointy,

Do you have the stl's of the hub/pulley and x-idler please?

Erik,

Thank you, how do you quote?

Paul

Just press "quote" instead of "reply" and all the text in the message your are replying to will be quoted at the top, identifiable for the poster as a reply to his post - also, if you want to reply to just a part of the text, you can delete the irrelevant part and ad .....before and after....as to show that what you are replying to is out of context and your reply is to a part of the message only

Erik

Thank you Erik

@pointy

Les,

Thank you for the stl's. I will be printing them as soon as I get back home and can operate my printer.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Sorry, only registered users may post in this forum.