Ormerod Building Tips

Posted by KimBrown

|

Re: Ormerod Building Tips February 14, 2014 06:11AM |

Registered: 10 years ago Posts: 859 |

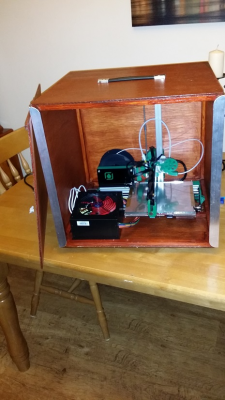

Hi Marc, yes looks good. I have to try to keep things simple and easy to carry. The printer now has a case. If I could have made it 3cm wider I could have used the printer in the case, but wouldn't get it up and down the gangway to get to work... I built my printer onboard ship, so it was INTERESTING trying to get the 3mm screws in the holes, when the holes were dancing about....LoL...

|

Re: Ormerod Building Tips February 14, 2014 08:01AM |

Registered: 10 years ago Posts: 94 |

Quote

KimBrown

Hi Marc, yes looks good. I have to try to keep things simple and easy to carry. The printer now has a case. If I could have made it 3cm wider I could have used the printer in the case, but wouldn't get it up and down the gangway to get to work... I built my printer onboard ship, so it was INTERESTING trying to get the 3mm screws in the holes, when the holes were dancing about....LoL...

Hi Kim, sounds very interesting with casing for the Ormerod I would like to do that to, do you have some pictures to share?

Kind regards Joar

|

Re: Ormerod Building Tips February 14, 2014 10:42AM |

Registered: 10 years ago Posts: 28 |

Maybe some advise: When printing on a ship, some kind of shock absorbers good be usefull. If you check the images in the documentation you will notice that RepRap uses their own shock absorbers (no idea in what kind of vehicle they are using while printing).

Would be a challange to find nice solutions. For instance using a set of springs or if you would like to balance the movements from the ship use some kind of plungers which are hydraulic connected :-)

Also be sure that the X-axis has a minimum amount of play since wobbling of the boat could influence it's position :-)

You could be the first with auto bed leveler and auto printer leveler .... ;-)

What kind of ship is it? a 1200 foot container ship, a small fisserboat, a spaceship?

So Kim, what personal item would you like to take with you during your Mars trip?

My Ormerod 3D printer Sir!

Would be a challange to find nice solutions. For instance using a set of springs or if you would like to balance the movements from the ship use some kind of plungers which are hydraulic connected :-)

Also be sure that the X-axis has a minimum amount of play since wobbling of the boat could influence it's position :-)

You could be the first with auto bed leveler and auto printer leveler .... ;-)

What kind of ship is it? a 1200 foot container ship, a small fisserboat, a spaceship?

So Kim, what personal item would you like to take with you during your Mars trip?

My Ormerod 3D printer Sir!

|

Re: Ormerod Building Tips February 14, 2014 11:27AM |

Registered: 10 years ago Posts: 859 |

Excuse the poor picture, it was done in a rush before I left home, but you'll get the idea....

Everything that is used by the printer, except Filament and Laptop lives in the box.

The printers quite safe in there, but I do need to remember to put a rubber band on the

X carriage to stop it sliding back and forth while in the car.

and with the front closed

(I needed to keep the printer safe and dry)....

Unfortunately this wasn't the only wood work I had to do while at home....

This used to be the fence till we got hit by the storms. Already I have my sisters to fix next time home.

On the Mars trip, that's easy.... A good supply of Beer and Chocolate, as well as lots of Filament for the printer.

(It'll be two weeks before I manage to get to have another pint....)

As for where I work, I work on a very large Harbour tug, bringing super tankers in to port, so if we have to go

in to the Atlantic to grab one the Printer gets moved to Bunk where it's safe, as things get very aerodynamic in

the storms we're having at the moment. Apart from that, it prints away quite happily on my desk. The only

thing that has happend is the Z axis runner bearing adjuster slackend off with the vibration we have.

But I have some 3mm Nyloc nuts here, so will fit one later.

Everything that is used by the printer, except Filament and Laptop lives in the box.

The printers quite safe in there, but I do need to remember to put a rubber band on the

X carriage to stop it sliding back and forth while in the car.

and with the front closed

(I needed to keep the printer safe and dry)....

Unfortunately this wasn't the only wood work I had to do while at home....

This used to be the fence till we got hit by the storms. Already I have my sisters to fix next time home.

On the Mars trip, that's easy.... A good supply of Beer and Chocolate, as well as lots of Filament for the printer.

(It'll be two weeks before I manage to get to have another pint....)

As for where I work, I work on a very large Harbour tug, bringing super tankers in to port, so if we have to go

in to the Atlantic to grab one the Printer gets moved to Bunk where it's safe, as things get very aerodynamic in

the storms we're having at the moment. Apart from that, it prints away quite happily on my desk. The only

thing that has happend is the Z axis runner bearing adjuster slackend off with the vibration we have.

But I have some 3mm Nyloc nuts here, so will fit one later.

|

Re: Ormerod Building Tips February 18, 2014 11:11AM |

Registered: 10 years ago Posts: 859 |

(Copied from another thread)

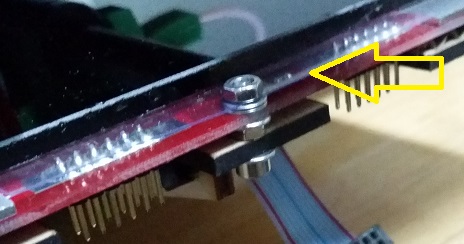

In one of the threads I mentioned covering up the HotBed soldered pins.

Shorting out these pins can Kill your Duet board, as some people have found.

I thought I'd best find a cheap fix before the Grim Reaper called here...

Here's a picture.... Clear Plastic cut from old packaging..... And it's Cheap as Chips!!!!

This is Mk 2... Bolted on.... Mk 1 was SuperGlued on, it fell off.... Mk 3 will have a folded front

edge to stop stuff getting under the cover....(But if I did a picture of Mk3 you wouldn't be able to see it

in a picture...

Hope you do this to your Ormerod before you wish you had.... It's a Duet Saver...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

In one of the threads I mentioned covering up the HotBed soldered pins.

Shorting out these pins can Kill your Duet board, as some people have found.

I thought I'd best find a cheap fix before the Grim Reaper called here...

Here's a picture.... Clear Plastic cut from old packaging..... And it's Cheap as Chips!!!!

This is Mk 2... Bolted on.... Mk 1 was SuperGlued on, it fell off.... Mk 3 will have a folded front

edge to stop stuff getting under the cover....(But if I did a picture of Mk3 you wouldn't be able to see it

in a picture...

Hope you do this to your Ormerod before you wish you had.... It's a Duet Saver...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Ormerod Building Tips February 18, 2014 11:22AM |

Registered: 10 years ago Posts: 578 |

|

Re: Ormerod Building Tips February 18, 2014 03:59PM |

Registered: 10 years ago Posts: 859 |

It's a lack of space Ray.... And clear filament..... I think the mod won't break the bank....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Ormerod Building Tips March 23, 2014 03:45AM |

Registered: 10 years ago Posts: 76 |

I having problem with Y end stop lately, the cable with pre-crimp connector came loose from time to time

So I took out the micro switch then soldered on to a strip of universal pcb solder a connector on top and

Redo the wire with 2x1 connector put it back in the same place now no loose cinnection again

So I took out the micro switch then soldered on to a strip of universal pcb solder a connector on top and

Redo the wire with 2x1 connector put it back in the same place now no loose cinnection again

|

Re: Ormerod Building Tips March 31, 2014 08:09PM |

Registered: 10 years ago Posts: 859 |

When fitting the Feeder assembley, fit it to the arm, at the notch nearest the Z-axis pilar.

The reason is, it allows the cables to move more, and also reduces the levering moment on the X-axis arm.

If you level your Bed, and then move the feeder, you will need to chack your Bed again.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

The reason is, it allows the cables to move more, and also reduces the levering moment on the X-axis arm.

If you level your Bed, and then move the feeder, you will need to chack your Bed again.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Ormerod Building Tips April 09, 2014 10:01AM |

Registered: 10 years ago Posts: 327 |

Quote

Marc van Beelen

Hi Kim,

I tried a horizontal reel holder for 1 kg filament. I used a ballbearing and it rolled very very smooth, too smooth I guess since the filmanet got jammed several times. You need some resistance to keep the filament fixed on the reel. I switched to vertical movement, no ball bearing (could install them, will test is later) but for now it works fine for me. In case you run in to problems with jamming filament you could consider a vertical stand with a foorprint which fits in the psu

Old horizontal bearing

[attachment 26856 foto1o.JPG]

[attachment 26857 foto2o.JPG]

And the new traditional vertical stand

[attachment 26858 foto1.JPG]

[attachment 26859 foto2.JPG]

Hi Marc,

Would you mind sharing the files for that vertical stand?

Regards,

Les

|

Re: Ormerod Building Tips April 15, 2014 01:27PM |

Registered: 10 years ago Posts: 859 |

A note for people using my Big Blue with twin fans....

If you place 3 small rubber 'O' rings on each of the screws the noise of the fans is greatly reduced....

On each screw it goes,,,,'O' ring,fan, 'O' ring,fan, 'O'ring.

Basicaly your rubber mounting the fans...

This should also work for single fan users...

Enjoy

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

If you place 3 small rubber 'O' rings on each of the screws the noise of the fans is greatly reduced....

On each screw it goes,,,,'O' ring,fan, 'O' ring,fan, 'O'ring.

Basicaly your rubber mounting the fans...

This should also work for single fan users...

Enjoy

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Sorry, only registered users may post in this forum.