Why does the filament get stuck in the nozzle?

Posted by Sardi

|

Why does the filament get stuck in the nozzle? April 28, 2014 05:50AM |

Registered: 10 years ago Posts: 466 |

So, that is my latest problem. Everything is working (lets say) fine, extruder is filling the filament, the Z probe is working ok, and just when I thought things are going the right way - the head gets clogged for reasons absolutely unknown to me!

It shoots out a tiny bit of filament (I guess what was in the nozzle) and its like it stops melting the PLA. I tried with different temperatures from 185 to 235 - no result.

There shouldnt be any dirt or filth anywhere (like in the bowden tube) because Ive cleaned it clear.

The filament seems to be going out on its own (I dont know why - gravity maybe?) but the extruder is, altough funcitioning perfectly, of no use to me atm.

There is no way for me to make the filament squirt through the nozzle.

So the hot end is melting the PLA but it doesnt want to come out via extruder but by itself?? wtf??

Looking forward to solutions, and if nothing helps im returning the ormerod cause this is a problem machine, not a printing machine.

Edited 1 time(s). Last edit at 04/28/2014 06:02AM by Sardi.

It shoots out a tiny bit of filament (I guess what was in the nozzle) and its like it stops melting the PLA. I tried with different temperatures from 185 to 235 - no result.

There shouldnt be any dirt or filth anywhere (like in the bowden tube) because Ive cleaned it clear.

The filament seems to be going out on its own (I dont know why - gravity maybe?) but the extruder is, altough funcitioning perfectly, of no use to me atm.

There is no way for me to make the filament squirt through the nozzle.

So the hot end is melting the PLA but it doesnt want to come out via extruder but by itself?? wtf??

Looking forward to solutions, and if nothing helps im returning the ormerod cause this is a problem machine, not a printing machine.

Edited 1 time(s). Last edit at 04/28/2014 06:02AM by Sardi.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 06:11AM |

Registered: 10 years ago Posts: 665 |

I had a similar problem a few days ago, and this can have different causes:

- Did you apply too much force when turning in the Bowden PTFE tube? In that case, the end of the bowden tube might be somewhat deformed, letting only some filament go into the nozzle.

- Is some of your PLA filament burnt inside the nozzle? This happened to me once, and I had to replace the little PTFE tube inside the nozzle and clean it properly to get it going again.

- Did you apply too much force when turning in the Bowden PTFE tube? In that case, the end of the bowden tube might be somewhat deformed, letting only some filament go into the nozzle.

- Is some of your PLA filament burnt inside the nozzle? This happened to me once, and I had to replace the little PTFE tube inside the nozzle and clean it properly to get it going again.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 06:26AM |

Registered: 10 years ago Posts: 22 |

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 06:32AM |

Registered: 10 years ago Posts: 466 |

Hi zombie.

The filament doesnt appear to be burnt, and both ends of the Bowden tube are well clear for the filament to pass through easily since I broadend it a bit with 2mm drill and it was cleaned from and dirt inside.

Now to think of it, maybe I didnt explain the problem to be fully understandable - the nozzle is not clogged since the filament does come out - but ONLY at its own pace - it does not allow the force of the extruder to squirt the filament out.

When it comes to that that I can not feed any more filament to the nozzle, I wait a minute, see that some of the filament got through the nozzle by itself, and then there is space for a couple of mm of filament in the nozzle. But thats it, I am in no control over the filament once it gets to the nozzle.

The filament doesnt appear to be burnt, and both ends of the Bowden tube are well clear for the filament to pass through easily since I broadend it a bit with 2mm drill and it was cleaned from and dirt inside.

Now to think of it, maybe I didnt explain the problem to be fully understandable - the nozzle is not clogged since the filament does come out - but ONLY at its own pace - it does not allow the force of the extruder to squirt the filament out.

When it comes to that that I can not feed any more filament to the nozzle, I wait a minute, see that some of the filament got through the nozzle by itself, and then there is space for a couple of mm of filament in the nozzle. But thats it, I am in no control over the filament once it gets to the nozzle.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 06:35AM |

Registered: 10 years ago Posts: 466 |

Hi Pete, I have done that a couple of times though but without help :/

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 06:51AM |

Registered: 10 years ago Posts: 176 |

Had a problem during the week with that - could not even manually push the filament through or even pull it out again.

Turns out that there was a slight gap between the Bowden tube and the brass cap, and filament had melted it's way into the gap, then solidified. This could probably happen between the PTFE tube and the hot end too?

Have you tried manually extruding the filament to make sure that the extruder's hobbed gear isn't slipping on the filament? Have had that problem with inconsistent filament too.

Turns out that there was a slight gap between the Bowden tube and the brass cap, and filament had melted it's way into the gap, then solidified. This could probably happen between the PTFE tube and the hot end too?

Have you tried manually extruding the filament to make sure that the extruder's hobbed gear isn't slipping on the filament? Have had that problem with inconsistent filament too.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 07:06AM |

Registered: 10 years ago Posts: 466 |

Quote

VortyZA

Had a problem during the week with that - could not even manually push the filament through or even pull it out again.

Turns out that there was a slight gap between the Bowden tube and the brass cap, and filament had melted it's way into the gap, then solidified. This could probably happen between the PTFE tube and the hot end too?

Have you tried manually extruding the filament to make sure that the extruder's hobbed gear isn't slipping on the filament? Have had that problem with inconsistent filament too.

Hi VortyZA.

I will dismantle the tube and re-check if there is anything I have missed.

Had a problem with the hobbed gear, but its working fine now. Took a bit of adjustment but the complete extruder assembly is working without faults.

The problem is somewhere arround the nozzle.

@Peterdl

Have tried to clean the nozzle a couple of times, each time with no change.

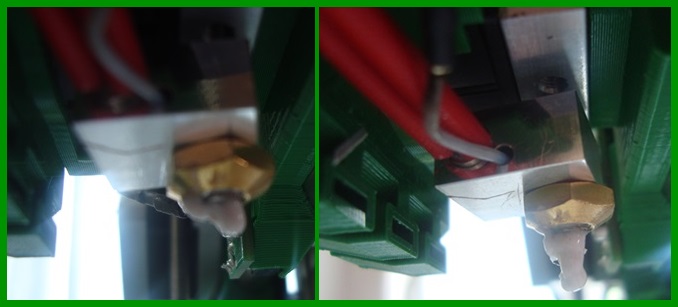

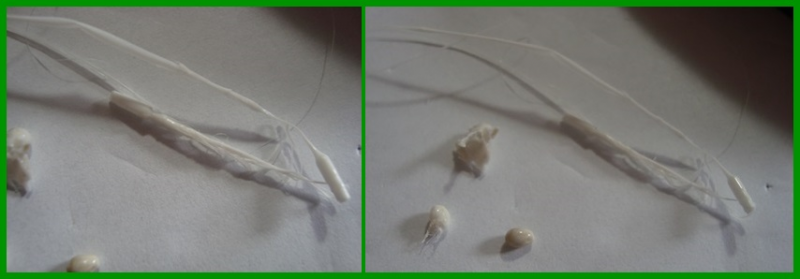

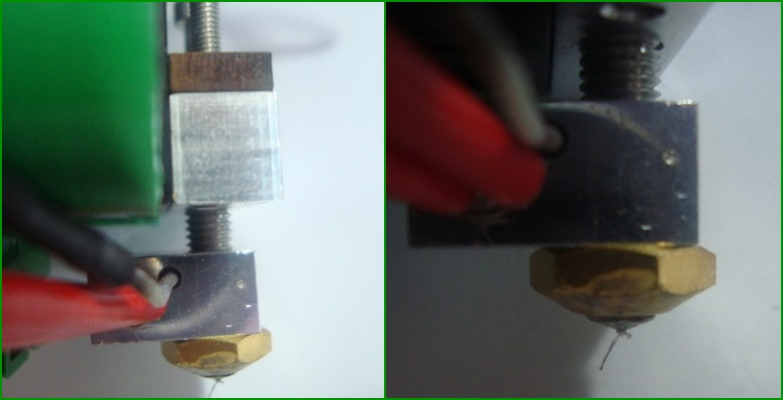

The balls on the left is what keeps dripping from the nozzle at a very slow rate, the strings on the right is what comes out of the tube when I clean the nozzle.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 07:14AM |

Registered: 10 years ago Posts: 466 |

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 07:20AM |

Registered: 10 years ago Posts: 14,672 |

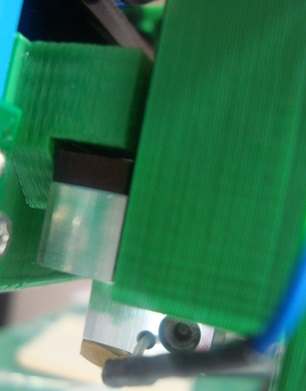

Is the fan working, is air blowing through the heatsink and out of the exits at the bottom of the heatsink duct, and is the heatsink in good thermal contact with the aluminium block? I'm wondering whether the aluminium cooling block (the one at the top of the nozzle) is getting too hot, which means that the filament will melt too far up the nozzle. Also wondering whether the small diameter PTFE tubing is missing or too short.

Edited 1 time(s). Last edit at 04/28/2014 07:21AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/28/2014 07:21AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 07:38AM |

Registered: 10 years ago Posts: 466 |

Yes, fan always working, air blowing through the heatsink to the other side.Quote

dc42

Is the fan working, is air blowing through the heatsink and out of the exits at the bottom of the heatsink duct

Yes, no space between the aluminium block and the heatsink.Quote

dc42

is the heatsink in good thermal contact with the aluminium block?

Just tested it with my finger, the top of the block is cold as ice, the bottom is hot.Quote

dc42

I'm wondering whether the aluminium cooling block (the one at the top of the nozzle) is getting too hot, which means that the filament will melt too far up the nozzle.

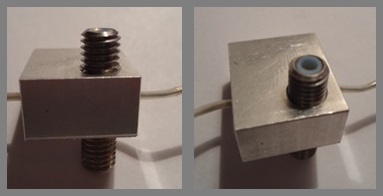

This is how the the small diameter PTFE tube looks like in the nozzle. Is it too short?Quote

dc42

Also wondering whether the small diameter PTFE tubing is missing or too short.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 08:00AM |

Registered: 10 years ago Posts: 176 |

The shape on the end of what you cleaned out of the nozzle looks as if it's backing up in the pipe - like a blockage somewhere at the end?

Another thought occurs - have you been successfully printing yet?

Reason I ask is that I found that Slic3r had the incorrect settings for the extruder and would try to do absolute extruder positioning instead of relative, so the extruder would push the material out, then pull it back again, so it wasn't actually printing anything.

It had a similar looking cylindrical mess at the end of the filament when I cleaned it out.

Another thought occurs - have you been successfully printing yet?

Reason I ask is that I found that Slic3r had the incorrect settings for the extruder and would try to do absolute extruder positioning instead of relative, so the extruder would push the material out, then pull it back again, so it wasn't actually printing anything.

It had a similar looking cylindrical mess at the end of the filament when I cleaned it out.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 08:08AM |

Registered: 10 years ago Posts: 466 |

No mate, didnt print a bloody thing yet. I am still trying to print out Ormaxis.g via Pronterface.

You are close on the solution, the problem is somewhere between the Bowden tube an the nozzle. I keep thinking if I put the right tube inside the nozzle since in my opinion the filament gets there, somehow gets stuck, while the tip of it gets melted and just drips on the bed.

We got 2 tubes with the kit - the thicker one (and less "see through") is the Bowden tube, and the other one is so called "smaller diameter tube" right?

EDIT:

Tried pushing it through by hand, removed the bowden tube and just pushed by hand at195C with no excessive force - same thing. The filament gets stuck somewhere somehow.

Also I have cleaned the nozzle minimum of 7 times.

Edited 4 time(s). Last edit at 04/28/2014 08:41AM by Sardi.

You are close on the solution, the problem is somewhere between the Bowden tube an the nozzle. I keep thinking if I put the right tube inside the nozzle since in my opinion the filament gets there, somehow gets stuck, while the tip of it gets melted and just drips on the bed.

We got 2 tubes with the kit - the thicker one (and less "see through") is the Bowden tube, and the other one is so called "smaller diameter tube" right?

EDIT:

Tried pushing it through by hand, removed the bowden tube and just pushed by hand at195C with no excessive force - same thing. The filament gets stuck somewhere somehow.

Also I have cleaned the nozzle minimum of 7 times.

Edited 4 time(s). Last edit at 04/28/2014 08:41AM by Sardi.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 09:12AM |

Registered: 10 years ago Posts: 176 |

I found that printing at 205C with PLA worked best - it's possible that it's not liquifying enough to go through the 0.5mm hole?

I'd suggest disconnecting the Bowden tube from the extruder (the small clip can just be removed), set the temperature then push the filament by hand until you find it's coming out.

If it doesn't extract at any temperature it's possible that there is a physical jam that needs to be removed - I've seen people suggest removing the hot end and using a cigarette lighter on the tip, push filament through the tip.

The thicker white tube is the Bowden tube, yes

Edited 1 time(s). Last edit at 04/28/2014 09:18AM by VortyZA.

I'd suggest disconnecting the Bowden tube from the extruder (the small clip can just be removed), set the temperature then push the filament by hand until you find it's coming out.

If it doesn't extract at any temperature it's possible that there is a physical jam that needs to be removed - I've seen people suggest removing the hot end and using a cigarette lighter on the tip, push filament through the tip.

The thicker white tube is the Bowden tube, yes

Edited 1 time(s). Last edit at 04/28/2014 09:18AM by VortyZA.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 09:18AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Sardi

No mate, didnt print a bloody thing yet. I am still trying to print out Ormaxis.g via Pronterface.

You are close on the solution, the problem is somewhere between the Bowden tube an the nozzle. I keep thinking if I put the right tube inside the nozzle since in my opinion the filament gets there, somehow gets stuck, while the tip of it gets melted and just drips on the bed.

We got 2 tubes with the kit - the thicker one (and less "see through") is the Bowden tube, and the other one is so called "smaller diameter tube" right?

EDIT:

Tried pushing it through by hand, removed the bowden tube and just pushed by hand at195C with no excessive force - same thing. The filament gets stuck somewhere somehow.

Also I have cleaned the nozzle minimum of 7 times.

Just to eliminate a possible cause, use a vernier or digital calliper to check that your filament is close to 1.75mm diameter along a large length, or as a quick check slide your spare tube over a long length to ensure it doesn't bind anywhere. If it is the RS supplied reel, I doubt that is the issue.

It sounds like something is not assembled correctly at the hotend. Is there a good gap between the hot block and the cold block? While touching the hot block will give you a nasty burn, you should be able to hold a finger on the cold block above without discomfort (don't try it unless you are willing to accept the risk of a burn - use a thermometer instead). You have said that you correctly drilled out the inside of the tube - but are you certain you drilled up far enough? Perhaps you used the wrong PTFE tube - I don't recall what the other one looked like (I never used it). The filament should extrude smoothly and easily with very moderate hand pressure. If nothing is obvious, take off the nozzle and see whether filament can then be fed through very easily (cold). If so, replace the nozzle and re-assemble without the Bowden tube (everything except the tube) and after heating it up, feed some filament by hand vertically down into the nozzle to see if it flows freely in that situation.

If none of the above identifies the problem, post an overall photo of your extruder-to-hotend and as many close-ups from various angles of your hotend as is reasonable.

Dave

(#106)

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 09:24AM |

Registered: 10 years ago Posts: 859 |

It sounds to me you might have got a bit of PTFE in the nozzle after cleaning the tube out, and missed abit.

That would cause that to happen.

You could heat the nozzle with filament in it, reduce the temp to 170', and retract it. With luck the debri will stick to the filament and come out with it.

After running over a bolt on my bed I think I got a burr on my nozzle, and that also did similar things. I replaced the nozzle in the end and that solved it.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

That would cause that to happen.

You could heat the nozzle with filament in it, reduce the temp to 170', and retract it. With luck the debri will stick to the filament and come out with it.

After running over a bolt on my bed I think I got a burr on my nozzle, and that also did similar things. I replaced the nozzle in the end and that solved it.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 10:24AM |

Registered: 10 years ago Posts: 378 |

Not sure if it is of any help, but I've had the same thing happen a couple times, with a "plug" of PLA blocking the nozzle. It was always due to insufficient cooling (such as running the heater without the fan), but I can see how the same thing would happen if the teflon liner isn't quite in the right place. Is the liner uneven or damaged at the bottom end? Is it seated properly inside the nozzle? It should go all the way to the bottom.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 10:26AM |

Registered: 10 years ago Posts: 466 |

@dmould @kimbrown

unfortunately as I have dismantled the hot end a couple of times today, something had to go wrong. I suddenly noticed that the tube that was in the nozzle this morning - just isnt there any more! Somewhere inbetween all of the assembling and dissasembling it jumped out, dissapeared, teleported itself, melted... I dont know any more, all I know is that it isnt there any more and that the nozzle is full of filament that I cant completly clean to put another pice of the tube inside.

So, any ideas where I could buy a nozzle?

But just to answer to dmould:

The filament goes throught the tube with no problems at all in both directions.

2 tubes were in the kit. One was a bit thicker and I suppose that is the Bowden tube. Other was not so thick, it was light and you could almost see through it, in the manual that one was (i suppose) called "smaller diameter tube".

Cant do this any more, the nozzle is completly dirty from the filament because I (not knowing absolutely how) somehow lost the tube that was in the nozzle and have filled it with filament later on.

@jstck

Edited 2 time(s). Last edit at 04/28/2014 10:33AM by Sardi.

unfortunately as I have dismantled the hot end a couple of times today, something had to go wrong. I suddenly noticed that the tube that was in the nozzle this morning - just isnt there any more! Somewhere inbetween all of the assembling and dissasembling it jumped out, dissapeared, teleported itself, melted... I dont know any more, all I know is that it isnt there any more and that the nozzle is full of filament that I cant completly clean to put another pice of the tube inside.

So, any ideas where I could buy a nozzle?

But just to answer to dmould:

It is.Quote

dmould

Just to eliminate a possible cause, use a vernier or digital calliper to check that your filament is close to 1.75mm diameter along a large length, or as a quick check slide your spare tube over a long length to ensure it doesn't bind anywhere. If it is the RS supplied reel, I doubt that is the issue.

Yes there is a gap.Quote

dmould

It sounds like something is not assembled correctly at the hotend. Is there a good gap between the hot block and the cold block?

The cold block is cold, maybe not stone cold, a bit warmish, but def not hot as the hot end.[/quote]Quote

dmould

While touching the hot block will give you a nasty burn, you should be able to hold a finger on the cold block above without discomfort (don't try it unless you are willing to accept the risk of a burn - use a thermometer instead).

Yes, the PTFE tube was drilled far enough and cleaned several times, even with pressurized air can.Quote

dmould

You have said that you correctly drilled out the inside of the tube - but are you certain you drilled up far enough? Perhaps you used the wrong PTFE tube - I don't recall what the other one looked like (I never used it). The filament should extrude smoothly and easily with very moderate hand pressure.

The filament goes throught the tube with no problems at all in both directions.

2 tubes were in the kit. One was a bit thicker and I suppose that is the Bowden tube. Other was not so thick, it was light and you could almost see through it, in the manual that one was (i suppose) called "smaller diameter tube".

Quote

dmould

If nothing is obvious, take off the nozzle and see whether filament can then be fed through very easily (cold). If so, replace the nozzle and re-assemble without the Bowden tube (everything except the tube) and after heating it up, feed some filament by hand vertically down into the nozzle to see if it flows freely in that situation.

Cant do this any more, the nozzle is completly dirty from the filament because I (not knowing absolutely how) somehow lost the tube that was in the nozzle and have filled it with filament later on.

@jstck

Edited 2 time(s). Last edit at 04/28/2014 10:33AM by Sardi.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 11:14AM |

Registered: 10 years ago Posts: 466 |

UPDATE!

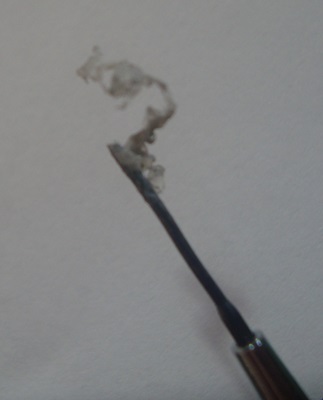

This

was at the very tip of my nozzle! After 3 hrs, and continuous heating and cooling of the head (also using canned air), I finally managed to clean the nozzle all the way through so I can see through it.

Everything happens for a reason I guess, I wuldnt clean the nozzle this thorough if the tube that was inside didnt vanish, and the retraction of the filament couldnt grab all the dirt inside the nozzle.

I think thats it for today.

Tomorrow Ill be reassembling the hot end and will try to print!

This

was at the very tip of my nozzle! After 3 hrs, and continuous heating and cooling of the head (also using canned air), I finally managed to clean the nozzle all the way through so I can see through it.

Everything happens for a reason I guess, I wuldnt clean the nozzle this thorough if the tube that was inside didnt vanish, and the retraction of the filament couldnt grab all the dirt inside the nozzle.

I think thats it for today.

Tomorrow Ill be reassembling the hot end and will try to print!

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 11:23AM |

Registered: 10 years ago Posts: 2,472 |

Two things to try to rescue your nozzle. First is to buy some PLA solvent (tetrahydrofuran - Amazon or Ebay) and soak the nozzle in that till all the plastic is gone - the chemical has fumes that you should not breathe to any significant extent, but swirled around in a sealed jar it should be quite safe. The other is easier - hold the nozzle in a pair of pliers and heat strongly in a gas flame to burn out all the plastic. With a bit of luck you will then be able to wash or blow out the residue until it is sufficiently clean to use. The hole can be "pricked" with strands of wire or a primus stove pricker, but it is not advisable to try re-drilling it. If you are planning to throw away your nozzle and get a new one you have little to lose by giving it a try.

Dave

(#106)

Dave

(#106)

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 12:07PM |

Registered: 10 years ago Posts: 466 |

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 12:34PM |

Registered: 13 years ago Posts: 1,611 |

Oops, a bit late on the scene...

It looks like ptfe swarfe (which doesn't melt until around 350C!) from drilling out the Bowden tube got stuck in the nozzle. Usually blowing through/putting filament through the Bowden tube before assembly gets rid of this, though I note you say you did this. Unlucky, I guess!

If you lose/run out of the ptfe nozzle liner, you can cut a piece off the end of the long filament guide tube, with is 3mm OD x 2mm ID tube. It isn't as accurately sized on the outside as the small piece that is supplied with the nozzle (it's cheaper stuff), but should work the same way.

Ian

RepRapPro tech support

It looks like ptfe swarfe (which doesn't melt until around 350C!) from drilling out the Bowden tube got stuck in the nozzle. Usually blowing through/putting filament through the Bowden tube before assembly gets rid of this, though I note you say you did this. Unlucky, I guess!

If you lose/run out of the ptfe nozzle liner, you can cut a piece off the end of the long filament guide tube, with is 3mm OD x 2mm ID tube. It isn't as accurately sized on the outside as the small piece that is supplied with the nozzle (it's cheaper stuff), but should work the same way.

Ian

RepRapPro tech support

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 12:53PM |

Registered: 10 years ago Posts: 466 |

The only thing that comes to mind is that I didnt do such a good cleanup of the tube the very first time, some of the debris from the bowden tube might have gotten to the nozzle. Thats the only explanation I could come up with since (and only now I see it) the nozzle hole was only about half way free for the filament to pass throught. The rest was clogged by debris.

Too bad I didnt notice that before, but as the nozzle hole is only 0.5 it wasnt easy too.

Too bad I didnt notice that before, but as the nozzle hole is only 0.5 it wasnt easy too.

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 01:12PM |

Registered: 13 years ago Posts: 1,611 |

It is possible to get such a nozzle blockage out without dismantling the nozzle, I managed it the other day. I disconnected the Bowden tube from the extruder, with some spare filament in the end of the Bowden tube. I heated the nozzle to 200C, pushed a little, poke up the nozzle with a bit of wire, set temperature to 90C, then as soon as the temperature hits 90C on the graph, gently pull the filament out of the Bowden tube. With luck it clears down to the nozzle - though I did have to repeat the process 5 times!

Hope that helps.

Ian

RepRapPro tech support

Hope that helps.

Ian

RepRapPro tech support

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 01:44PM |

Registered: 10 years ago Posts: 859 |

Maybe that bit of swarf is the remains of the missing tube.... did you use a drill to try and clean it. That PTFE is real soft stuff.

At least you found the critter...

Hopefully it'll work for you now....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

At least you found the critter...

Hopefully it'll work for you now....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Why does the filament get stuck in the nozzle? April 28, 2014 05:45PM |

Registered: 10 years ago Posts: 466 |

Quote

droftarts

It is possible to get such a nozzle blockage out without dismantling the nozzle, I managed it the other day. I disconnected the Bowden tube from the extruder, with some spare filament in the end of the Bowden tube. I heated the nozzle to 200C, pushed a little, poke up the nozzle with a bit of wire, set temperature to 90C, then as soon as the temperature hits 90C on the graph, gently pull the filament out of the Bowden tube. With luck it clears down to the nozzle - though I did have to repeat the process 5 times!

I did something similar, just without the wire, for 7 times. Heating to 200, droping to 100, pulling the filament.. sometimes by hand, sometimes by extruder, sometimes without the bowden tube, but with no effect.

As I think, this piece of dirt was all the way down to the nozzle, and I got it out by rapidly cooling the nozzle with canned air, so the plastic somehow just got separated from the rest.

Quote

KimBrown

Maybe that bit of swarf is the remains of the missing tube.... did you use a drill to try and clean it. That PTFE is real soft stuff.

At least you found the critter...

Hopefully it'll work for you now....

I hope so too. I did not use a drill to clean it, altough the drill got most of it out while widening the tube. Later I used filament and pressurized canned air to clear the tube of any leftovers.

Tomorrow I am starting clean with the hot end, everything is clean and ready to be put together again, and I hope this time I will make my first print.

|

Re: Why does the filament get stuck in the nozzle? May 13, 2014 08:49AM |

Registered: 10 years ago Posts: 176 |

Reviving the thread a little - would be interested to find out how you got on Sardi?

Due to the high cost of the PLA filament in South Africa I sourced some cheap ABS filament.

Occasionally a print would fail and the printer would start air-printing. I thought it might be the variable diameter of the filament - it could vary from 1.5 to 1.9mm, so I altered the extruder to be spring loaded so that it could cope.

I still had failures however - turned out that there was small little bits of carbon or something inside the filament - rare enough that I'd have a couple of successful prints, then a failure. It's amazing how such a small little bit of 'sand' could block up the whole works, but then I guess a 0.5mm nozzle doesn't take much to block!

Each time it would be a full dismantle, clean, soak overnight in acetone, wire through the tip to get the nozzle totally clean, and along the way I broke a wire to the heater!

I still have like 4Kgs of the rubbish (sigh), but I'm hesitant to use it unless I find a good way to make the head cleaning easier! I suppose buying cheap means paying in other ways..

Edited 2 time(s). Last edit at 05/13/2014 10:12AM by VortyZA.

Due to the high cost of the PLA filament in South Africa I sourced some cheap ABS filament.

Occasionally a print would fail and the printer would start air-printing. I thought it might be the variable diameter of the filament - it could vary from 1.5 to 1.9mm, so I altered the extruder to be spring loaded so that it could cope.

I still had failures however - turned out that there was small little bits of carbon or something inside the filament - rare enough that I'd have a couple of successful prints, then a failure. It's amazing how such a small little bit of 'sand' could block up the whole works, but then I guess a 0.5mm nozzle doesn't take much to block!

Each time it would be a full dismantle, clean, soak overnight in acetone, wire through the tip to get the nozzle totally clean, and along the way I broke a wire to the heater!

I still have like 4Kgs of the rubbish (sigh), but I'm hesitant to use it unless I find a good way to make the head cleaning easier! I suppose buying cheap means paying in other ways..

Edited 2 time(s). Last edit at 05/13/2014 10:12AM by VortyZA.

Sorry, only registered users may post in this forum.