Power supply modifications

Posted by Squags

|

Power supply modifications April 29, 2014 10:38AM |

Registered: 10 years ago Posts: 48 |

Does anyone have any bright ideas about modifying the power supply in the following ways:

timer switch, so it'll turn machine off either after a preset time (do-able with cheap socket timer), or when G-code is finished

smoke alarm - getting a bit worried after this: [forums.reprap.org]

Cheers, Squags

timer switch, so it'll turn machine off either after a preset time (do-able with cheap socket timer), or when G-code is finished

smoke alarm - getting a bit worried after this: [forums.reprap.org]

Cheers, Squags

|

Re: Power supply modifications April 29, 2014 10:44AM |

Registered: 10 years ago Posts: 14,672 |

See this thread [forums.reprap.org]. This lets you turn off the 12V power, although the 5V power will still be on.

Edited 1 time(s). Last edit at 04/29/2014 10:44AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/29/2014 10:44AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Power supply modifications April 29, 2014 10:52AM |

Registered: 10 years ago Posts: 48 |

|

Re: Power supply modifications April 29, 2014 11:12AM |

Registered: 10 years ago Posts: 327 |

I got one of these and hooked up a thermistor to an ATtiny45 to control it. I was hoping to use it in conjunction with the new 30a PSU I bought.

Regards,

Les

Pointy's Things

Pointy's Blog

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications April 29, 2014 11:30AM |

Registered: 10 years ago Posts: 76 |

I get rid of that ATX power supply almost a month now. So leaving a 5V to power the duet board will not be an option.

I am building a timer which will turn off the printer when the print is finished by monitoring the Z-Axis movement

If the print finished the Z axis will not move and the timer will start ticking for 5 minutes. If there is any movement

On the Z axis before 5 minutes time out the timer will reset to 0 then start counting down again for another 5 minutes.

If the count down reach 0 the relay will switch off the main power turn off the printer. I hope i will have it by end of next week.

This is a very simple circuit with a latch type relay. 2 button for engage the timer and reset. A cheap optical end stop from ebay

to generate an interrupt signal to a small mcu (pic12f629) if ther is a movement on the z axis.

I design a one side pcb with all through hole component which can easily manufacture by any one at home.

I will share it to this forum after my testing all the circuits, it's small firmware and pcb design include the printed part

for mounting the optical end stop on the top of z column.

I am building a timer which will turn off the printer when the print is finished by monitoring the Z-Axis movement

If the print finished the Z axis will not move and the timer will start ticking for 5 minutes. If there is any movement

On the Z axis before 5 minutes time out the timer will reset to 0 then start counting down again for another 5 minutes.

If the count down reach 0 the relay will switch off the main power turn off the printer. I hope i will have it by end of next week.

This is a very simple circuit with a latch type relay. 2 button for engage the timer and reset. A cheap optical end stop from ebay

to generate an interrupt signal to a small mcu (pic12f629) if ther is a movement on the z axis.

I design a one side pcb with all through hole component which can easily manufacture by any one at home.

I will share it to this forum after my testing all the circuits, it's small firmware and pcb design include the printed part

for mounting the optical end stop on the top of z column.

|

Re: Power supply modifications April 29, 2014 01:36PM |

Registered: 10 years ago Posts: 2,472 |

Quote

Chaisaeng

I get rid of that ATX power supply almost a month now. So leaving a 5V to power the duet board will not be an option.

I am building a timer which will turn off the printer when the print is finished by monitoring the Z-Axis movement

If the print finished the Z axis will not move and the timer will start ticking for 5 minutes. If there is any movement

On the Z axis before 5 minutes time out the timer will reset to 0 then start counting down again for another 5 minutes.

That will work if you have to have bed compensation set up, but if you have a solid & levelled bed (e.g. aluminium frame) and thus no compensation, 5 minutes may not be sufficient. Some of my large prints have had layer times of 30 minutes or more when doing a solid infill of a large area, during which time there is no Z movement. Probably better to use X, Y or (probably best) extruder movements to reset your timer (which could then be set to time out after a very short time, because no active print should have more than a few seconds without any extrusion).

Dave

(#106)

|

Re: Power supply modifications April 30, 2014 01:08AM |

Registered: 10 years ago Posts: 76 |

Quote

dmould

Quote

Chaisaeng

I get rid of that ATX power supply almost a month now. So leaving a 5V to power the duet board will not be an option.

I am building a timer which will turn off the printer when the print is finished by monitoring the Z-Axis movement

If the print finished the Z axis will not move and the timer will start ticking for 5 minutes. If there is any movement

On the Z axis before 5 minutes time out the timer will reset to 0 then start counting down again for another 5 minutes.

That will work if you have to have bed compensation set up, but if you have a solid & levelled bed (e.g. aluminium frame) and thus no compensation, 5 minutes may not be sufficient. Some of my large prints have had layer times of 30 minutes or more when doing a solid infill of a large area, during which time there is no Z movement. Probably better to use X, Y or (probably best) extruder movements to reset your timer (which could then be set to time out after a very short time, because no active print should have more than a few seconds without any extrusion).

Dave

(#106)

Thanks for the advice, i do not think of the print that would took a long time to print a layer.

Btw. All the major part is still working I guess but i must rethink the sensor part. I having a few broken

optical mouse lying around in my house may be I can use it's optical sensor to sense the filament

movements.

|

Re: Power supply modifications April 30, 2014 03:09AM |

Registered: 10 years ago Posts: 327 |

As there are built in Gcode commands for the ATX switching in newer firmware, can't you just monitor the pin for ATX control signal? M80 will pull the control low at the start of the print, and M81 at the end should make it go high. (Guessing here as I haven't tested, but I am sure dc can confirm) I was thinking of using this method. for my PSU control.

Regards,

Les

Pointy's Things

Pointy's Blog

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications April 30, 2014 04:23AM |

Registered: 10 years ago Posts: 378 |

|

Re: Power supply modifications April 30, 2014 05:55AM |

Registered: 10 years ago Posts: 327 |

This is a little off topic, but I bought a mini blade fuse holder, to fit in-line on the 12v. I didn't notice in the description, it had 16awg wire on it. The seller is advertising it as 30a, but all tables I find say that 16awg is only good for about 20a.(16awg looks painfully thin too)

I messaged him and he is still adamant that 16awg is suitable...

I don't want to risk it so I have ordered another with 12awg, but I was just curious if he is correct.

Regards,

Les

Pointy's Things

Pointy's Blog

I messaged him and he is still adamant that 16awg is suitable...

Quote

On 12 Volt circuit, Max current (Amps) depend on wire length and AWG.

15cm cable, Max current is 30A.

I don't want to risk it so I have ordered another with 12awg, but I was just curious if he is correct.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications April 30, 2014 09:41AM |

Registered: 10 years ago Posts: 378 |

|

Re: Power supply modifications April 30, 2014 10:36AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Pointy

This is a little off topic, but I bought a mini blade fuse holder, to fit in-line on the 12v. I didn't notice in the description, it had 16awg wire on it. The seller is advertising it as 30a, but all tables I find say that 16awg is only good for about 20a.(16awg looks painfully thin too)

I messaged him and he is still adamant that 16awg is suitable...

Quote

On 12 Volt circuit, Max current (Amps) depend on wire length and AWG.

15cm cable, Max current is 30A.

I don't want to risk it so I have ordered another with 12awg, but I was just curious if he is correct.

Regards,

Les

Fuses are a fairly complex subject! The basic rating of a fuse is the current that it can take indefinitely without blowing, not the current at which it will blow. At constant higher currents the fuse is not guaranteed to last forever - but neither is it guaranteed to blow within a short space of time. It may operate for days at significantly more than its rated current. The rating depends not only on the thickness of the fuse material but also on the material it is made from, the way it is held (mounted) - and also the environment - e.g. vibrations can make some types of fuse fail prematurely. A fuse holder/cartridge that acts as a heat sink will tend to increase the rating of the fuse wire it is holding compared with a holder that does not sink much heat (e.g. blade vs tube). Bear in mind that a fuse carrying close to its rated current will get pretty hot (that's why the "live" pin on a fused mains plug that has been supplying high current (e.g. a kettle) can burn your fingers while the neutral pin is still cool), and a fuse will also have a voltage drop across it that can be significant at low voltages. So the answer to your question may well be that *both* sizes of wire can be used to make a 30A fuse, depending on what the wire is made from, the way the wire is mounted and the other specifications of the fuse.

As you will know, a fuse blows when the power it is dissipating due to its resistance at that current is sufficient to cause its temperature to rise above the melting point of the material it is made from. The temperature of any given fuse is proportional to the power (watts) it is absorbing. It therefore makes sense to make a fuse from a material with a relatively low melting point, because it can then be run cooler at its rated current and so will be absorbing (wasting) less power during normal operation. Lead is better in that respect than copper - but will need to be significantly thicker for the same rating due to its higher resistance and therefore could end up taking more power because there is a greater surface area to dissipate the heat (and take longer to blow because there is a greater mass to heat). Fuse wire mounted in air should also not oxidise much at the temperature it reaches at its rated current, otherwise it will degrade in a fairly short time and fail by {i}burning[/i] out rather than melting. So the rating of a fuse could be significantly below the current at which it melts in order to ensure it can take its rated current indefinitely without degrading - but exactly the same fuse wire will have a far higher rating if mounted in a sealed cartridge containing an inert gas. Both however will blow (melt) at the same over-current, so the latter provides better protection from an overload (as opposed to a short).

A fuse mounted on a board that is potted or submerged in oil will not perform to anything like its specifications (and neither do resistors or other components comply with their normal power ratings).

Dave

(#106)

|

Re: Power supply modifications April 30, 2014 11:02AM |

Registered: 10 years ago Posts: 327 |

Thanks Dave for the very detailed explanation.

I was actually concerned about the wire connecting the fuse holder not being able to take the current. This is the fuse holder in question.

I have the 30a PSU from Ebay and although it does allegedly have short circuit/Over load/ Over voltage/ Over temp protection, I just wanted to add my own fuse for a bit more piece of mind.

Regards,

Les

Pointy's Things

Pointy's Blog

I was actually concerned about the wire connecting the fuse holder not being able to take the current. This is the fuse holder in question.

I have the 30a PSU from Ebay and although it does allegedly have short circuit/Over load/ Over voltage/ Over temp protection, I just wanted to add my own fuse for a bit more piece of mind.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications April 30, 2014 11:17AM |

Registered: 10 years ago Posts: 14,672 |

As a general guide, the wire supplied by RRP for connecting the ATX power board to the Duet is barely thick enough to carry the current (IMO it should be a bit thicker, it gets warm and there is a significant voltage drop across it with both heaters on). I wouldn't use anything thinner than that.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Power supply modifications April 30, 2014 01:56PM |

Registered: 10 years ago Posts: 76 |

I just finished the build of the timer. This is coming up before dc put the atx control in his firmware.

There is a 3 pin connector to connect to power a sensor with active low pin in the middle.

The duet board is quite expensive so I do not want to put any more wire on to it if i not sure

Smoking the duet board is quite scary. I intended to use it not only for the ormerod but for my desktop cnc as well

BTW. I can just connect the atx control signal from duet to the connector mention and reprogram the PIC to just toggle

the relay after detecting the kill power signal from duet it is very easy. The relay is a latch type with 2 coils energize one coil

briefly will toggle the relay contact from NO to NC in reverse toggle another coil will put the contact back to NO from NC.

This is quite convenient and do not require power to the relay coil the whole time.

There is a 3 pin connector to connect to power a sensor with active low pin in the middle.

The duet board is quite expensive so I do not want to put any more wire on to it if i not sure

Smoking the duet board is quite scary. I intended to use it not only for the ormerod but for my desktop cnc as well

BTW. I can just connect the atx control signal from duet to the connector mention and reprogram the PIC to just toggle

the relay after detecting the kill power signal from duet it is very easy. The relay is a latch type with 2 coils energize one coil

briefly will toggle the relay contact from NO to NC in reverse toggle another coil will put the contact back to NO from NC.

This is quite convenient and do not require power to the relay coil the whole time.

|

Re: Power supply modifications April 30, 2014 03:46PM |

Registered: 10 years ago Posts: 2,472 |

Quote

Pointy

Thanks Dave for the very detailed explanation.

I was actually concerned about the wire connecting the fuse holder not being able to take the current. This is the fuse holder in question.

I have the 30a PSU from Ebay and although it does allegedly have short circuit/Over load/ Over voltage/ Over temp protection, I just wanted to add my own fuse for a bit more piece of mind.

Regards,

Les

Yes, I realised after I posted that I had mis-read your post. Ah well. The most appropriate wire thickness for carrying a particular current depends on the length of wire - until the wire gets so thin that there is risk of it over-heating. Consider that 1m of thinner wire will have the same voltage drop as 2m of a wire twice the cross-sectional area. So even though the main connecting wire might need to be quite thick, it does no harm to have a few cm of much thinner wire in between. The resistance per meter of copper wire is tabled for all wire gauges, so you can easily work out how much voltage drop and/or power loss will be caused by any given length of wire. If I've done the sums correctly, 16AWG copper will have a voltage drop of about 0.8 volts per meter at 30A - or a loss of around 22 watts per meter (assuming two conductors - i.e. the electrical circuit of 1m of wire is 2m). Which apart from the undesirability of more than 6% voltage drop would probably cause the wire to overheat if it is coiled up on a reel. So I think it is too thin to use for the main connecting wire, but a short straight length between fuse and connector should be OK. A very long (10cm) tail of 16AWG on each fuse terminal for example would have a combined voltage drop of under 0.1V and dissipate about 2W at 30A which shouldn't be a problem in free air. It's worth mentioning that the fuse holder should have a current rating at least twice as much as the rating of the fuse it is carrying, else the power loss due to the resistance of the fuse + holder is likely to cause them to over-heat.

It is however usually entirely sufficient and more desirable to protect against overload with a fuse in the input (mains) side of the PSU, which draws far less current and so can use a fuse that absorbs less power in normal use. A PSU cannot make energy, so any overload in the output must be reflected by a similar overload in the input - and a fuse there also protects against an overload within the PSU circuit itself, which an output fuse will not. High-current fuses can cause a lot of trouble, presenting a greater fire risk than they protect against, especially when mounted in small enclosed spaces, and should not be used unless really necessary. In a vehicle powered only with 12V they are necessary because there is no other place to put them. A correctly rated fuse on the mains input or even just the mains plug will blow PDQ if there is a short on the output - just ensure that you actually fit an appropriate fuse and not a "standard" 13A mains fuse as so many people do, which will be of little protection. For a 30A supply the correct mains fuse rating will be around 2A.

Dave

(#106)

|

Re: Power supply modifications April 30, 2014 03:57PM |

Registered: 10 years ago Posts: 327 |

Thanks again for the detailed reply Dave.

I have fitted a switched, fused C14 inlet to the PSU, I did have a 5a fuse in it but I will replace it with a 2a one.

Regards,

Les

PS. Apologies to Squags for hijacking the thread.

Pointy's Things

Pointy's Blog

I have fitted a switched, fused C14 inlet to the PSU, I did have a 5a fuse in it but I will replace it with a 2a one.

Regards,

Les

PS. Apologies to Squags for hijacking the thread.

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications April 30, 2014 05:00PM |

Registered: 10 years ago Posts: 14,672 |

I use a 12V 300W PSU with this [github.com] printed cover for the connections:

The mains inlet socket (sourced from Maplin) includes the fuse.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The mains inlet socket (sourced from Maplin) includes the fuse.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Power supply modifications May 01, 2014 09:11AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

The mains inlet socket (sourced from Maplin) includes the fuse.

But what value of fuse was supplied? They are usually supplied with a fuse of the same rating as the inlet, which is not going to protect against overloads on a device that should only draw a fraction of that current. The fuse should be chosen to match the device that is being powered, not to match the rating of the socket!

A 30A 12V PSU that is around 75% efficient will draw around 2A on the mains under full load, and so knowing that I am normally not running it close to full load, that's the size fuse I have put in my mains inlet (or the closest I had, which I think was a 2.5A slow-blow). A 5 amp mains fuse will not blow until you are drawing over 100A on the 12V side, but smoke & flames will usually start appearing long before you reach that point. In fact a 5A fuse may not even blow with a full short on the 12V side, and a PSU fed via a 13A fuse will almost certainly burn up in order to protect the fuse! If you find that in practice the fuse blows every few hours/days/weeks under normal loads, increase it by 25% or so, though it is always best to measure the mains current under full load conditions and base your choice of fuse on that. You may also need to use a "slow-blow" fuse so that the inrush current does not frequently pop the fuse as you switch on, though many modern PSUs have circuits that prevent high inrush currents (for that very reason).

A fuse in the plug top provides the same degree of protection if you fit one of the correct rating - but it is not a good idea to rely on that because sooner or later you will probably use the supply with a different mains lead that has a higher rating of fuse in its plug. Besides which it can be a nuisance because there is no way to tell externally that the plug is fitted with a 2A fuse, so if you "borrow" the lead to feed your kettle or microwave oven, the fuse will instantly blow.

All that the 13A fuse usually fitted in plugs will do is protect your main house fuses against a dead short, and stop the plug and wall-socket from overheating if you plug too many loads into it (and it doesn't even do a good job of that in many cases) - the majority of appliances will have set fire to the house long before an overload in them reaches anywhere near 13A, and so you might as well have used a nail. Few people pay as much attention to the value of fuse they are fitting as they ought to.

Dave

(#106)

|

Re: Power supply modifications May 01, 2014 10:13AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

Quote

dc42

The mains inlet socket (sourced from Maplin) includes the fuse.

But what value of fuse was supplied? They are usually supplied with a fuse of the same rating as the inlet, which is not going to protect against overloads on a device that should only draw a fraction of that current. The fuse should be chosen to match the device that is being powered, not to match the rating of the socket!

I replaced the fuse supplied, with a 2A slow one AFAIR.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Power supply modifications May 04, 2014 08:57AM |

Registered: 10 years ago Posts: 327 |

How much current does the Duet require on 5v?

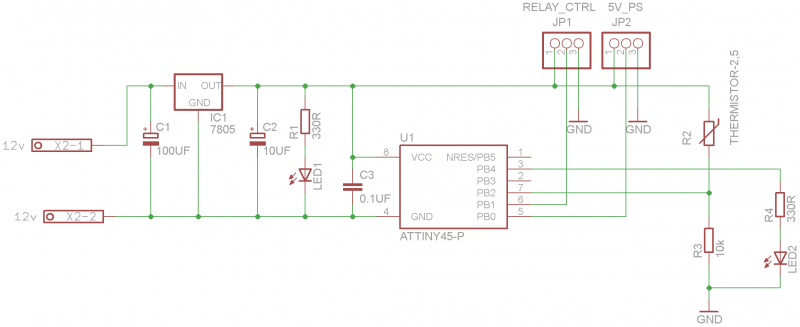

This is the circuit I have come up with for my 12v control...

I am assuming when you use the 5V_PS connector you are feeding the 5v for the Duet. I was then planning to monitor the control signal and switch the relay on or off. I have also added a simple thermistor so I could monitor the temperature of the 12v wire and shut things down if something is amiss.

I am very much a novice at electronics, even though I have been playing for 20 over years, so any feedback from you experts is very much appreciated.

Regards,

Les

Pointy's Things

Pointy's Blog

This is the circuit I have come up with for my 12v control...

I am assuming when you use the 5V_PS connector you are feeding the 5v for the Duet. I was then planning to monitor the control signal and switch the relay on or off. I have also added a simple thermistor so I could monitor the temperature of the 12v wire and shut things down if something is amiss.

I am very much a novice at electronics, even though I have been playing for 20 over years, so any feedback from you experts is very much appreciated.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications May 05, 2014 03:12AM |

Registered: 10 years ago Posts: 327 |

I spent a bit of time on the software side and I think I have got that part sorted. I have a 2 minute timer on normal shutdown request and have made it immediate for an over temperature situation., requiring a power cycle to reset.

I just need to convert the thermistor values into temperature., and decide was is a sensible value to shut down.

As far as the 5v goes, I am guessing that 1amp will be plenty, as USB power is normally a maximum of 500ma and the Duet can be powered from USB.

Regards,

Les

Pointy's Things

Pointy's Blog

I just need to convert the thermistor values into temperature., and decide was is a sensible value to shut down.

As far as the 5v goes, I am guessing that 1amp will be plenty, as USB power is normally a maximum of 500ma and the Duet can be powered from USB.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications May 05, 2014 06:12AM |

Registered: 10 years ago Posts: 76 |

|

Re: Power supply modifications May 05, 2014 07:45AM |

Registered: 10 years ago Posts: 327 |

Quote

Chaisaeng

I hope the firmware can generate charge pump signal

I asked about that here. DC said it wasn't necessary as the chip/firmware has a built in watchdog.

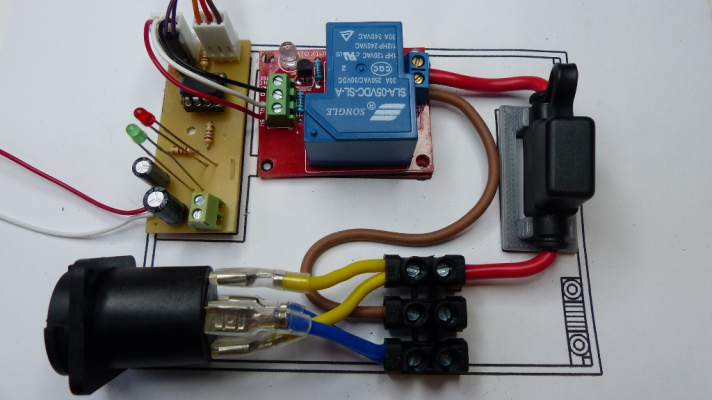

For my PSU control, this is what I have come up with so far...

12v comes in through the 4 pin 20a connector, through the fuse to the relay board and will exit out bottom left. The board is controlled by an ATTiny45, the top right 3 pin molex connector will connect to the PS_ON on the Duet. There is also a thermistor which I intended to wrap around the 12v output to stop this happening.

Note. The red/white wires are temporarily connected to my bench supply in place of a 7805, as I don't have any in stock. Once the 7805 is fiited the board will take 12v via the green connector on the bootom right.

Suggestions welcome.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications May 05, 2014 11:31AM |

Registered: 10 years ago Posts: 76 |

Quote

Pointy

Quote

Chaisaeng

I hope the firmware can generate charge pump signal

I asked about that here. DC said it wasn't necessary as the chip/firmware has a built in watchdog.

For my PSU control, this is what I have come up with so far...

[attachment 32212 psucontrol.jpg]

12v comes in through the 4 pin 20a connector, through the fuse to the relay board and will exit out bottom left. The board is controlled by an ATTiny45, the top right 3 pin molex connector will connect to the PS_ON on the Duet. There is also a thermistor which I intended to wrap around the 12v output to stop this happening.

Note. The red/white wires are temporarily connected to my bench supply in place of a 7805, as I don't have any in stock. Once the 7805 is fiited the board will take 12v via the green connector on the bootom right.

Suggestions welcome.

Regards,

Les

Wow! Look pretty! My wish is when i trun on the printer it powered by 12V only and did not need to externally supply 5 V to duet.

My first thought is using a latch relay which will make contact when power up. Or using some circuit to provide self latching somehow.

After the signal triggered to power off the the relay cut the mains then everything brownout.

|

Re: Power supply modifications May 08, 2014 12:14PM |

Registered: 10 years ago Posts: 327 |

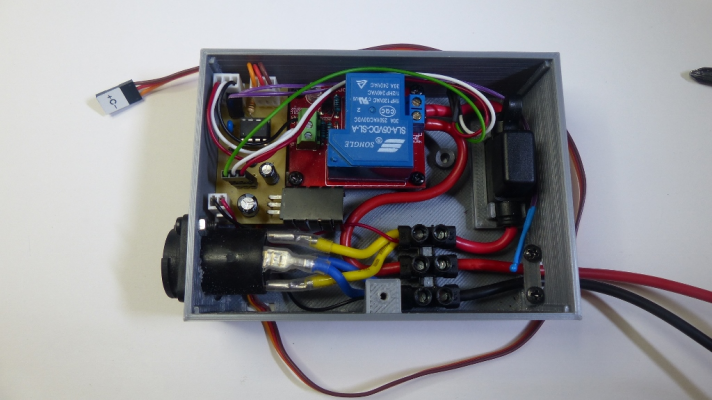

Finally got the PSU control PCB finished and assembled.

There is a 3mm status LED on top which signals the following conditions...

In addition to the above, the first 3 scenarios could be orange if the temperature is high.

I just need to calibrate the thermistor and decide sensible values for high temperature and over temperature and then get brave enough to connect it to the Ormerod.

Regards,

Les

Pointy's Things

Pointy's Blog

There is a 3mm status LED on top which signals the following conditions...

- Slow Flash Green - Standby

- Solid Green 12v Active

- Fast Flash Green - In 2 minute cool down period

- Red - Over temperature (12v switched off and won't restart until a power cycle)

In addition to the above, the first 3 scenarios could be orange if the temperature is high.

I just need to calibrate the thermistor and decide sensible values for high temperature and over temperature and then get brave enough to connect it to the Ormerod.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications May 09, 2014 04:42AM |

Registered: 10 years ago Posts: 327 |

I managed to figure out how to get the serial debug working on my ATTiny45 with my Uno, so I have been able to calibrate the analogue readings of the thermistor by using some hot water and my digital temperature probe. I am just taking single readings at 100ms intervals for now, it may be better to take more and average them, but I don't think I need pinpoint accuracy. I was thinking of 50 degrees for high temperature and 70 for over temperature. The 7805 heatsink reaches about 50 degrees under load (180ma with led, ATTiny and relay on), so the temperature in the box will build up over time. It may be a bit of trial and error to get it right.

I am hoping to get this fitted later and test it out.

Regards,

Les

Pointy's Things

Pointy's Blog

I am hoping to get this fitted later and test it out.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications May 13, 2014 11:04AM |

Registered: 10 years ago Posts: 327 |

I finally got around to fitting this today, and although it works I have found a problem with my design.

The 7805 is getting too hot when I put the lid on, so I need a plan B. I have some LM2575 switching regulators and wonder whether they will be better thermally at dropping the 7v. It will mean a PCB redesign and some extra components, but I should be able to fit them inside. Of course the other option is to fit a bigger heatsink to the 7805 or fit a fan. Time to do some more testing I guess.

Regards,

Les

Pointy's Things

Pointy's Blog

The 7805 is getting too hot when I put the lid on, so I need a plan B. I have some LM2575 switching regulators and wonder whether they will be better thermally at dropping the 7v. It will mean a PCB redesign and some extra components, but I should be able to fit them inside. Of course the other option is to fit a bigger heatsink to the 7805 or fit a fan. Time to do some more testing I guess.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Power supply modifications May 13, 2014 11:13AM |

Registered: 10 years ago Posts: 76 |

Is this cause by powering 5 V to the duet from your control circuit.

I just want to do the same setting as yours but I already have the relay part assembled.

Still dit not put together the circuits to it yet. My design having 78L05 and it never have the overheat problem

because it only pulse the outout pins to toggle relay then go to sleep. Is it need to power the duet then

I may have to take out the 78l05 out and using some switching mode regulator instead.

I just want to do the same setting as yours but I already have the relay part assembled.

Still dit not put together the circuits to it yet. My design having 78L05 and it never have the overheat problem

because it only pulse the outout pins to toggle relay then go to sleep. Is it need to power the duet then

I may have to take out the 78l05 out and using some switching mode regulator instead.

|

Re: Power supply modifications May 13, 2014 11:28AM |

Registered: 10 years ago Posts: 327 |

Quote

Chaisaeng

Is this cause by powering 5 V to the duet from your control circuit.

I just want to do the same setting as yours but I already have the relay part assembled.

Still dit not put together the circuits to it yet. My design having 78L05 and it never have the overheat problem

because it only pulse the outout pins to toggle relay then go to sleep. Is it need to power the duet then

I may have to take out the 78l05 out and using some switching mode regulator instead.

Yes, it is powering the Duet as well as the relay and ATTiny45. The last 2 only draw 180ma, but I haven't checked what the Duet is drawing yet.

Regards,

Les

Pointy's Things

Pointy's Blog

Sorry, only registered users may post in this forum.