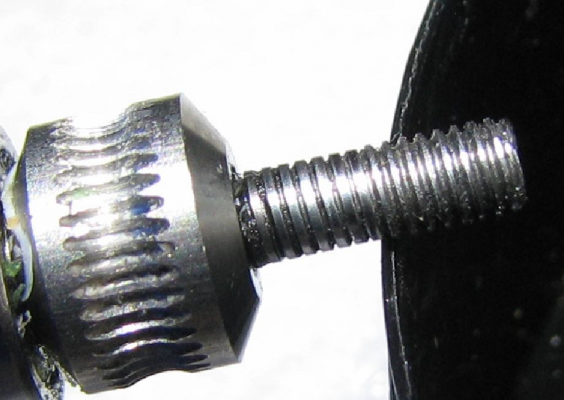

Extruder drive, worn thread

Posted by ormerod168

|

Extruder drive, worn thread May 19, 2014 03:47PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Extruder drive, worn thread May 19, 2014 03:59PM |

Registered: 10 years ago Posts: 859 |

Hint:-

I don't think you will be able to print a new one some how.....

Use an Allen screw for the replacement, as they are stronger.

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I don't think you will be able to print a new one some how.....

Use an Allen screw for the replacement, as they are stronger.

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Extruder drive, worn thread May 19, 2014 04:15PM |

Registered: 10 years ago Posts: 1,230 |

Quote

KimBrown

Use an Allen screw for the replacement, as they are stronger...

Did, but I wanted both bearing to sit on a non-threaded part of the Allen screw and to get the Hobbed insert over that part was a bit tricky :-)

I cannot see how to do this right and still keep the hobbed insert and screw at 3mm

Erik

|

Re: Extruder drive, worn thread May 19, 2014 06:52PM |

Registered: 10 years ago Posts: 378 |

Quote

KimBrown

Use an Allen screw for the replacement, as they are stronger.

How would that work? You couldn't make the big extruder gear get a decent grip on the bolt if it had a round head. I guess it would be possible to have the bolt the other way around and have two nuts (locking each other) on the side here the gear is, but it would be tricky assembling and disassembling.

A bit curious what would cause that kind of wear. That part of the bolt just sits in the bearing, doesn't it? Are there any signs of scratching or wear in the bearing? Does it rotate freely? Maybe lots and lots of pressure against the bolt (from the filament fitting "too tightly") could cause it to wear, but it sounds unlikely. Could there be similar wear under the other bearing (between the hobbed part and the gear)?

Unless there extruder bolt starts getting a lot of play in it, I wouldn't worry too much about it though.

|

Re: Extruder drive, worn thread May 19, 2014 07:29PM |

Registered: 10 years ago Posts: 1,230 |

Quote

jstck

..A bit curious what would cause that kind of wear. That part of the bolt just sits in the bearing, doesn't it?..

No, it rolls inside the bearings inner ring and that's the problem, think hula hoop - it's not wear in the sense of grit making wear, the material is moved, I think the correct word is "rolled"

Erik

|

Re: Extruder drive, worn thread May 19, 2014 10:48PM |

Registered: 9 years ago Posts: 24 |

Quote

ormerod168

... No, it rolls inside the bearings inner ring and that's the problem, ...

Ah, so the inner race of the bearing is not being prevented from turning on the bolt by a nut on the end of the bolt? I found with mine that first I needed to tighten the hobbed wheel on the bolt, and then the nyloc end nut on the bolt, both far more is probably good for them in order to stop things slipping. It looks to me like your bolt is now sufficiently worn that it might be a good idea to replace it in order help centralise the bearing on it when you do tighten the nut.

|

Re: Extruder drive, worn thread May 20, 2014 03:05AM |

Registered: 10 years ago Posts: 378 |

Quote

ormerod168

Quote

jstck

..A bit curious what would cause that kind of wear. That part of the bolt just sits in the bearing, doesn't it?..

No, it rolls inside the bearings inner ring and that's the problem, think hula hoop - it's not wear in the sense of grit making wear, the material is moved, I think the correct word is "rolled"

Erik

Even if it is "hula-hooping" (which in itself shouldn't make the wear worse, as long as the bearing turns), it would take a lot force to roll the threads flat like that. I would guess the extruder block would crack before the thread gives way.

I had my extruder bolt out and checked, and there was no sign of wear in the threads (just some dirt, looks like bearing grease and PLA dust). I wonder what could be different in your case. Could a slightly thicker filament cause lots of extra force on the bolt and bearing?

|

Re: Extruder drive, worn thread May 20, 2014 04:19AM |

Registered: 13 years ago Posts: 1,611 |

Hi Erik, looks like you left the nyloc nut a bit loose, and it's been turning on the thread of the bolt, rather than turning the inner race of the bearing. If you run a 9mm drill through the drive block (gently, so it's still sized correctly for the bearings), you can build the whole large gear and filament drive assembly as one unit and push it into the extruder block as one piece. This means you can get the tension on nyloc nut, and check the bearings are turning, before assembly, and makes it much easier to clean the teeth of the hobbed insert, as it just pulls out when the filament is removed. The filament stops the assembly 'walking' out when extruding. We've added a tiny bit of relief to the extruder body in this area on the latest version of the extruder (not released yet); it's just the filament guide that tends to print with a lump on it that stops the assembly going in anyway.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Extruder drive, worn thread May 20, 2014 02:25PM |

Registered: 10 years ago Posts: 1,230 |

Quote

droftarts

Hi Erik, looks like you left the nyloc nut a bit loose, and it's been turning on the thread of the bolt, rather than turning the inner race of the bearing.

I never thought that is was supposed to be lock up tight - as the bearing was mounted from the other side I supposed it was setting the position of the axle against the other bearing and the nuloc nut was chosen for that reason, I really do try hard to make logic mistakes :-)

Quote

... If you run a 9mm drill through the drive block (gently, so it's still sized correctly for the bearings), you can build the whole large gear and filament drive assembly as one unit and push it into the extruder block as one piece..

Brilliant! - will do, thanks

BTW, maybe you should consider making the extended (Mr.burn mod) PTFE tube in the extruder block standard? (ZeAllan pic) [forums.reprap.org]

Erik

|

Re: Extruder drive, worn thread May 20, 2014 02:33PM |

Registered: 10 years ago Posts: 1,230 |

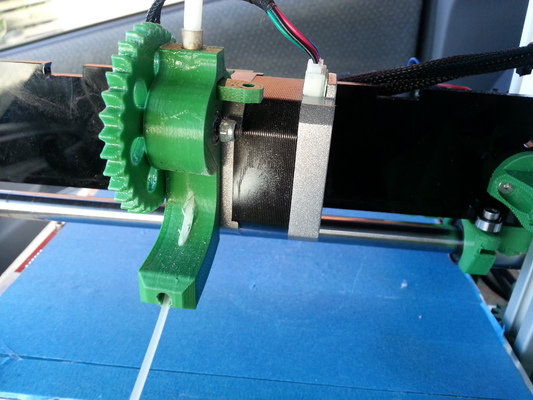

..talk about extruder - Spring-loaded extruder mod on thingiverse

[www.thingiverse.com]

Erik

Quote

..After problems with inconsistent filament diameters in my RepRapPro Ormerod I made an extruder block that includes a spring for tensioning...

[www.thingiverse.com]

Erik

|

Re: Extruder drive, worn thread May 21, 2014 07:26AM |

Registered: 13 years ago Posts: 1,611 |

|

Re: Extruder drive, worn thread May 21, 2014 08:23AM |

Registered: 10 years ago Posts: 209 |

|

Re: Extruder drive, worn thread May 22, 2014 02:47AM |

Registered: 10 years ago Posts: 176 |

Thanks for the comments - MasonStonehenge is my 'alt' on thingiverse

I've updated the design a little last night. I'd be willing to widen the hole for the PTFE liner - just need to see if there's enough space as it is, otherwise might need the thicken the extruder slightly.

I've found it's very effective for smoothing the action of a slightly inaccurate gear (10ths of a mm), it also makes cleaning the hobbed insert a LOT easier and it copes fine with differences in filament thickness.

I've updated the design a little last night. I'd be willing to widen the hole for the PTFE liner - just need to see if there's enough space as it is, otherwise might need the thicken the extruder slightly.

I've found it's very effective for smoothing the action of a slightly inaccurate gear (10ths of a mm), it also makes cleaning the hobbed insert a LOT easier and it copes fine with differences in filament thickness.

|

Re: Extruder drive, worn thread May 22, 2014 04:25AM |

Registered: 10 years ago Posts: 1,230 |

Quote

VortyZA

Thanks for the comments - MasonStonehenge is my 'alt' on thingiverse

I've updated the design a little last night. I'd be willing to widen the hole for the PTFE liner - just need to see if there's enough space as it is, otherwise might need the thicken the extruder slightly....

Great!, just what I was hoping for, thank you for your time!

Erik

|

Re: Extruder drive, worn thread May 22, 2014 04:42AM |

Registered: 10 years ago Posts: 327 |

Quote

VortyZA

Thanks for the comments - MasonStonehenge is my 'alt' on thingiverse

I've updated the design a little last night. I'd be willing to widen the hole for the PTFE liner - just need to see if there's enough space as it is, otherwise might need the thicken the extruder slightly.

I've found it's very effective for smoothing the action of a slightly inaccurate gear (10ths of a mm), it also makes cleaning the hobbed insert a LOT easier and it copes fine with differences in filament thickness.

Sorry for sounding stupid, but just how does this work?

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Extruder drive, worn thread May 22, 2014 06:51AM |

Registered: 10 years ago Posts: 176 |

Hi Les,

The original design of the extruder has been separated into two parts, one that attaches to the motor, and one for feeding the filament that attaches to a hinge at the top of the motor part.

The feeder side gets anchored at the bottom with a screw which has a mild tension on it (like the spring from a ballpoint pen). The screw is tightened so that the feeder is pressed against the motor part, with the spring allowing it a little bit of elasticity.

It acts like a lever, meaning that the mild tension in the spring equates to a very good grip on the filament.

There is a small amount of movement of the large gear towards and away from the small gear, but it's such a small amount that I haven't noticed any detrimental effects - in fact as I mentioned before it helped me with my slightly less than perfect large gear that I printed out of ABS.

Hope that's clearer?

Edited 1 time(s). Last edit at 05/22/2014 06:52AM by VortyZA.

The original design of the extruder has been separated into two parts, one that attaches to the motor, and one for feeding the filament that attaches to a hinge at the top of the motor part.

The feeder side gets anchored at the bottom with a screw which has a mild tension on it (like the spring from a ballpoint pen). The screw is tightened so that the feeder is pressed against the motor part, with the spring allowing it a little bit of elasticity.

It acts like a lever, meaning that the mild tension in the spring equates to a very good grip on the filament.

There is a small amount of movement of the large gear towards and away from the small gear, but it's such a small amount that I haven't noticed any detrimental effects - in fact as I mentioned before it helped me with my slightly less than perfect large gear that I printed out of ABS.

Hope that's clearer?

Edited 1 time(s). Last edit at 05/22/2014 06:52AM by VortyZA.

|

Re: Extruder drive, worn thread May 22, 2014 08:35AM |

Registered: 10 years ago Posts: 176 |

Quote

bobtidey

I like this idea as well and have commented in thingiverse to see if it could also incorporate the Mr Burns extended hole size for inner PTFE tube which works really well in making the filament passage smoother.

I've added another .stl with the wider tube for the PTFE insert. I'll print it tonight and see how well it works out.

Sorry, only registered users may post in this forum.