Adding Multi extruder support - howto

Posted by colsenfoto

|

Re: Adding Multi extruder support - howto July 16, 2014 07:33AM |

Registered: 10 years ago Posts: 14,672 |

Here is my recipe for getting 2-head prints to work:

1. Hardware and wiring as already described. If using my hot end board, it's safest to put a wire link across R22 to turn the fan permanently on. Otherwise you risk softening plastic if you heat up head 2 but not head 1 (although the heat from the heatsink will eventually get through to the #1 heater block and thermistor, at which point the board will turn the fan on). I'm going to do a mod to the board to allow it to monitor 2 thermistors.

2. Firmware 0.78c-dc42 and web interface 0.97. I will release an update to the firmware and web interface sometime to get the filament calculations right for multiple extruders.

3. tpre1.g, tpost1.g and tfree1.g files in /sys on the SD card as attached here. The files for head 2 are similar.

4. In slic3r printer settings, select 2 extruders. Set up the nozzle offset for each one (I used -7mm X offset for extruder 1 and 7mm X offset for extruder 2). Leave the other settings alone, in particular the setting that retracts the not-in-use extruder by 10mm (which is why I don't do any retraction/extension in the tfree/tpost files).

5. Create 2 non-overlapping STL models, combine them in slic3r using File->Combine multi-material STL files. Load the resulting file on to the slic3r platter, view it to check, then export gcode.

6. Run my sed script (see earlier post) on the result.

7. Home axes etc. and print!

Edited 1 time(s). Last edit at 07/16/2014 07:41AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Hardware and wiring as already described. If using my hot end board, it's safest to put a wire link across R22 to turn the fan permanently on. Otherwise you risk softening plastic if you heat up head 2 but not head 1 (although the heat from the heatsink will eventually get through to the #1 heater block and thermistor, at which point the board will turn the fan on). I'm going to do a mod to the board to allow it to monitor 2 thermistors.

2. Firmware 0.78c-dc42 and web interface 0.97. I will release an update to the firmware and web interface sometime to get the filament calculations right for multiple extruders.

3. tpre1.g, tpost1.g and tfree1.g files in /sys on the SD card as attached here. The files for head 2 are similar.

4. In slic3r printer settings, select 2 extruders. Set up the nozzle offset for each one (I used -7mm X offset for extruder 1 and 7mm X offset for extruder 2). Leave the other settings alone, in particular the setting that retracts the not-in-use extruder by 10mm (which is why I don't do any retraction/extension in the tfree/tpost files).

5. Create 2 non-overlapping STL models, combine them in slic3r using File->Combine multi-material STL files. Load the resulting file on to the slic3r platter, view it to check, then export gcode.

6. Run my sed script (see earlier post) on the result.

7. Home axes etc. and print!

Edited 1 time(s). Last edit at 07/16/2014 07:41AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 16, 2014 09:58AM |

Registered: 10 years ago Posts: 14,672 |

The traffic cone is a good print because it shows up any inaccuracy in the nozzle offsets:

In this case, it appears that there is a slight Y offset between the nozzles. I'll correct this in slic3r. The model comprises the orange rings and white rings files from [www.thingiverse.com].

Changing tools takes a long time, because the new nozzle has to heat up to operating temperature and the old one has to cool down to standby temperature. It occurred to me that there is probably no need to wait for the old nozzle to cool right down to standby temperature before starting to print with the new one. So I am going to add an optional parameter to the M116 command to specify which tool(s) you want to wait for.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

In this case, it appears that there is a slight Y offset between the nozzles. I'll correct this in slic3r. The model comprises the orange rings and white rings files from [www.thingiverse.com].

Changing tools takes a long time, because the new nozzle has to heat up to operating temperature and the old one has to cool down to standby temperature. It occurred to me that there is probably no need to wait for the old nozzle to cool right down to standby temperature before starting to print with the new one. So I am going to add an optional parameter to the M116 command to specify which tool(s) you want to wait for.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 16, 2014 11:42AM |

Registered: 10 years ago Posts: 780 |

Dave,

Could you let me know the parts numbers, descriptions and suppliers of the connectors you supplied with your boards, I just realised that I will need some to complete my 2-nozzle hot end.

Thanks

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Could you let me know the parts numbers, descriptions and suppliers of the connectors you supplied with your boards, I just realised that I will need some to complete my 2-nozzle hot end.

Thanks

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Adding Multi extruder support - howto July 16, 2014 01:11PM |

Registered: 10 years ago Posts: 14,672 |

Hi Paul,

You don't need these connectors unless you use one of my prototype hot end boards or a piece of Veroboard as a mounting point for the connectors. You can use the RRP 6-pin hot end connector instead, which is supplied with the Ormerod hot end loom and the hot end kit.

If you want to buy one of my (unpopulated) prototype boards for this purpose, I have all the connectors in stock and I can give you a good price for the board + connectors because I buy the connectors in bulk. Alternatively, if you want to use Veroboard or similar, the Molex connectors are the same as for my original IR + ultrasonic board, and you can find the part numbers at [github.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

You don't need these connectors unless you use one of my prototype hot end boards or a piece of Veroboard as a mounting point for the connectors. You can use the RRP 6-pin hot end connector instead, which is supplied with the Ormerod hot end loom and the hot end kit.

If you want to buy one of my (unpopulated) prototype boards for this purpose, I have all the connectors in stock and I can give you a good price for the board + connectors because I buy the connectors in bulk. Alternatively, if you want to use Veroboard or similar, the Molex connectors are the same as for my original IR + ultrasonic board, and you can find the part numbers at [github.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 17, 2014 07:02AM |

Registered: 10 years ago Posts: 14,672 |

I've released new firmware and web interface files to improve multi-tool support, see [forums.reprap.org]. In the tpost#.g files, I now us an M116 command that only waits for the new tool to reach operating temperature. This has greatly speeded up tool changes, because it no longer waits for the old tool to finish cooling down to standby temperature.

I am getting some interference between the nozzles. In my traffic cone prints, one side of the middle purple band had a rough near-vertical protrusion on it. While watching the print, I could see that the white nozzle was riding over the purple piece being printed and smearing some filament out. I checked the nozzle heights, and found that the white nozzle was a little lower than the purple one. So I adjusted the head level to get them at equal heights, and did another print.

The near-vertical rough protrusion on the purple band is still there, although less bad than before (it's on the right hand side in this image). However, I now have near-vertical indentations on the white bands as well, which were not there in previous prints.

So it seems that I am unable to prevent the nozzle on standby interfering with the print from the other one. Does anyone have any suggestions how I might cure this?

PS - on reflection, when one nozzle is printing a circle, the other nozzle will also describe a circle that intersects the one being printed at two points. So I might expect to see both an indentation and a rough protrusion in both colour bands. But I don't. I suppose that when the non-printing nozzle passes over the second intersection, the printing nozzle hasn't printed that point yet. A sufficiently clever slicing program could adjust the start and end points of each circle printed so as to print the areas of those intersections after the other nozzle has passed them - that is, start by printing those parts that cause the other nozzle to pass over other parts of the print, and then print the rest. It wouldn't always be possible to do this, and it would become impossible when printing with the middle nozzle of a 3 inline nozzle system.

Edited 1 time(s). Last edit at 07/17/2014 07:32AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I am getting some interference between the nozzles. In my traffic cone prints, one side of the middle purple band had a rough near-vertical protrusion on it. While watching the print, I could see that the white nozzle was riding over the purple piece being printed and smearing some filament out. I checked the nozzle heights, and found that the white nozzle was a little lower than the purple one. So I adjusted the head level to get them at equal heights, and did another print.

The near-vertical rough protrusion on the purple band is still there, although less bad than before (it's on the right hand side in this image). However, I now have near-vertical indentations on the white bands as well, which were not there in previous prints.

So it seems that I am unable to prevent the nozzle on standby interfering with the print from the other one. Does anyone have any suggestions how I might cure this?

PS - on reflection, when one nozzle is printing a circle, the other nozzle will also describe a circle that intersects the one being printed at two points. So I might expect to see both an indentation and a rough protrusion in both colour bands. But I don't. I suppose that when the non-printing nozzle passes over the second intersection, the printing nozzle hasn't printed that point yet. A sufficiently clever slicing program could adjust the start and end points of each circle printed so as to print the areas of those intersections after the other nozzle has passed them - that is, start by printing those parts that cause the other nozzle to pass over other parts of the print, and then print the rest. It wouldn't always be possible to do this, and it would become impossible when printing with the middle nozzle of a 3 inline nozzle system.

Edited 1 time(s). Last edit at 07/17/2014 07:32AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 17, 2014 07:50AM |

Registered: 10 years ago Posts: 2,472 |

Something that might be interesting is to try using soluble support filament (e.g. [creative3d.co.uk] or [www.shop.3dfilaprint.com]). This is what I see as being the most useful reason to have dual extruders - and in that case the XY offsets do not need to be extremely accurate. You can then print objects that require buried support in places where it would be virtually impossible to cut it away - plus you hopefully won't get marks on the print from where the support was removed. Slic3r can be set to automatically print its added support structure using the other extruder, so no need to modify or merge STL files. It's also an easy way to make a test G file that uses an intricate mix from both filaments on almost every layer.

[added]

Even without using soluble filament, it would be useful to have support in a different colour so you can see exactly what needs to be removed. Also if the support nozzle is slightly higher than the print nozzle, it should overcome the issue of having marks on the print (the marks will only be on the support material which don't matter).

Dave

(#106)

Edited 1 time(s). Last edit at 07/17/2014 07:59AM by dmould.

[added]

Even without using soluble filament, it would be useful to have support in a different colour so you can see exactly what needs to be removed. Also if the support nozzle is slightly higher than the print nozzle, it should overcome the issue of having marks on the print (the marks will only be on the support material which don't matter).

Dave

(#106)

Edited 1 time(s). Last edit at 07/17/2014 07:59AM by dmould.

|

Re: Adding Multi extruder support - howto July 17, 2014 08:42AM |

Registered: 10 years ago Posts: 780 |

Well I am well on my way to 2 nozzle printing.

I have just finished assembling the hot-end. It was a bit fiddly because you can't follow the on-line instructions for the ormerod hot end because you can't rotate the heater blocks. So to fit, you have to fit the nozzle onto the block and screw it down so that you can screw the nozzle into the aluminium cooling block whilst keeping the heater block still, making sure you have enough nozzle remaining to fit the brass nut correctly.

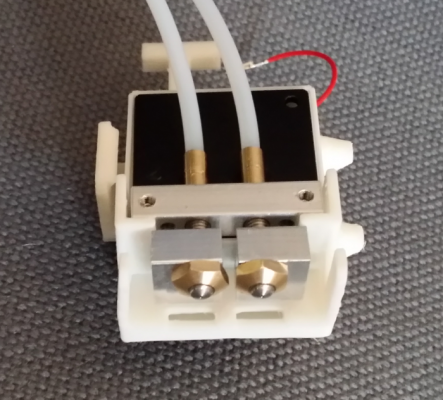

The picture shows the new aluminium cooling block made by DaveK - Thank you, with my one piece, 2 vents hot end

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I have just finished assembling the hot-end. It was a bit fiddly because you can't follow the on-line instructions for the ormerod hot end because you can't rotate the heater blocks. So to fit, you have to fit the nozzle onto the block and screw it down so that you can screw the nozzle into the aluminium cooling block whilst keeping the heater block still, making sure you have enough nozzle remaining to fit the brass nut correctly.

The picture shows the new aluminium cooling block made by DaveK - Thank you, with my one piece, 2 vents hot end

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Adding Multi extruder support - howto July 17, 2014 09:09AM |

Registered: 10 years ago Posts: 14,672 |

Hi Paul, it looks like you have added wings to the duct part. I suggest you paint the outside of the one on the right in the picture black. Otherwise, when you fit the differential LED hot end board, the wing is likely to reflect light from the IR emitters into the phototransistor.

My original prototype had a ceramic disc capacitor between the emitters and the phototransistor, to block the direct light path. However, there was a light path from the emitters to the PCB under the capacitor, where it was reflected into the phototransistor and upset the readings. That's why I changed to using a large cylindrical capacitor there instead.

Edited 1 time(s). Last edit at 07/17/2014 10:05AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

My original prototype had a ceramic disc capacitor between the emitters and the phototransistor, to block the direct light path. However, there was a light path from the emitters to the PCB under the capacitor, where it was reflected into the phototransistor and upset the readings. That's why I changed to using a large cylindrical capacitor there instead.

Edited 1 time(s). Last edit at 07/17/2014 10:05AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 17, 2014 09:27AM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

H Paul, it looks like you have added wings to the duct part. I suggest you paint the outside of the one on the right in the picture black. Otherwise, when you fit the differential LED hot end board, the wing is likely to reflect light from the IR emitters into the phototransistor.

.

Thank you David, I wonder if that is part of my problem with the levelling because my single nozzle hot end also has wings but in blue plastic.

I'll remove them and see if that makes a difference.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Adding Multi extruder support - howto July 17, 2014 01:02PM |

Registered: 10 years ago Posts: 14,672 |

I've been trying to print the perfect traffic cone, experimenting with settings and watching what is happening to try to get rid of the 2-nozzle artefacts.

The problem is similar to printing a tall, thin pillar, where one layer does not have time to solidify before the next layer is printed on top of it, so the print head pulls and pushes the pillar sideways while printing. The fix for that is to print a second pillar as well, to increase the time between layers.

I can see the one nozzle printing an outer perimeter, then shortly afterwards the second nozzle passes over it, dragging the still-molten plastic with it.

I have tried the following solutions:

1. Reduce printing speed. I reduced the printing speed when it was about to start the first white ring.

2. Adjusting the standby nozzle temperature. Lower temperature causes more dragging, higher temperature causes less dragging.

3. Reducing print temperature so that the print solidifies more in the same amount of time. I thought about this quite late, so I didn't experiment with it much.

Here is the result. The new print is on the left, the old one on the right.

The rough protrusion on the purple band has gone, and the indentation on the white bands is greatly reduced and absent in places. However, I had to reduce speed to 20% of normal to get it this good.

Two further solutions I propose, but haven't tried yet:

4. Increase nozzle spacing, which will in most cases increase the time between the two nozzles passing over the same point. See [forums.reprap.org].

5. Improve cooling of the print by using a better heatsink duct or fan/heatsink duct design.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The problem is similar to printing a tall, thin pillar, where one layer does not have time to solidify before the next layer is printed on top of it, so the print head pulls and pushes the pillar sideways while printing. The fix for that is to print a second pillar as well, to increase the time between layers.

I can see the one nozzle printing an outer perimeter, then shortly afterwards the second nozzle passes over it, dragging the still-molten plastic with it.

I have tried the following solutions:

1. Reduce printing speed. I reduced the printing speed when it was about to start the first white ring.

2. Adjusting the standby nozzle temperature. Lower temperature causes more dragging, higher temperature causes less dragging.

3. Reducing print temperature so that the print solidifies more in the same amount of time. I thought about this quite late, so I didn't experiment with it much.

Here is the result. The new print is on the left, the old one on the right.

The rough protrusion on the purple band has gone, and the indentation on the white bands is greatly reduced and absent in places. However, I had to reduce speed to 20% of normal to get it this good.

Two further solutions I propose, but haven't tried yet:

4. Increase nozzle spacing, which will in most cases increase the time between the two nozzles passing over the same point. See [forums.reprap.org].

5. Improve cooling of the print by using a better heatsink duct or fan/heatsink duct design.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 17, 2014 01:18PM |

Registered: 9 years ago Posts: 138 |

Quote

appjaws1

Well I am well on my way to 2 nozzle printing.

I have just finished assembling the hot-end. It was a bit fiddly because you can't follow the on-line instructions for the ormerod hot end because you can't rotate the heater blocks. So to fit, you have to fit the nozzle onto the block and screw it down so that you can screw the nozzle into the aluminium cooling block whilst keeping the heater block still, making sure you have enough nozzle remaining to fit the brass nut correctly.

The picture shows the new aluminium cooling block made by DaveK - Thank you, with my one piece, 2 vents hot end

[attachment 36744 2-nozzle-hot-end.png]

Hi,

can you please share your heat sink fan duct modification?

|

Re: Adding Multi extruder support - howto July 17, 2014 03:17PM |

Registered: 10 years ago Posts: 101 |

Hi dc42,

I tried printing with my three-nozzle setup yesterday, but never got off the first layer. One of the nozzles was constantly ripping the print off the bed. Going from 2 to 3 nozzles only makes the problems you described even worse

This guy has some very interesting posts down the blog about rebuilding a Stratasys hot-end - lots of pictures: [feedly.com]

They can retract the support-filament nozzle a little bit. I guess it's in order to avoid the problems, you (and me also) ran into.

I have made a my own 2-nozzle aluminium-bar based on your description, so now I just need to find and print your fan-duct and modified hot-end-mount. Fitting three nozzles under iamburney's fan-duct was a pain in a certain part of the body

By the way, I have a lot of noise on my temperature measurements via the extension-board also. I hope to get the time to do some oscilloscope-noise-hunting some day.

:-) Carsten

I tried printing with my three-nozzle setup yesterday, but never got off the first layer. One of the nozzles was constantly ripping the print off the bed. Going from 2 to 3 nozzles only makes the problems you described even worse

This guy has some very interesting posts down the blog about rebuilding a Stratasys hot-end - lots of pictures: [feedly.com]

They can retract the support-filament nozzle a little bit. I guess it's in order to avoid the problems, you (and me also) ran into.

I have made a my own 2-nozzle aluminium-bar based on your description, so now I just need to find and print your fan-duct and modified hot-end-mount. Fitting three nozzles under iamburney's fan-duct was a pain in a certain part of the body

By the way, I have a lot of noise on my temperature measurements via the extension-board also. I hope to get the time to do some oscilloscope-noise-hunting some day.

:-) Carsten

|

Re: Adding Multi extruder support - howto July 17, 2014 04:38PM |

Registered: 10 years ago Posts: 780 |

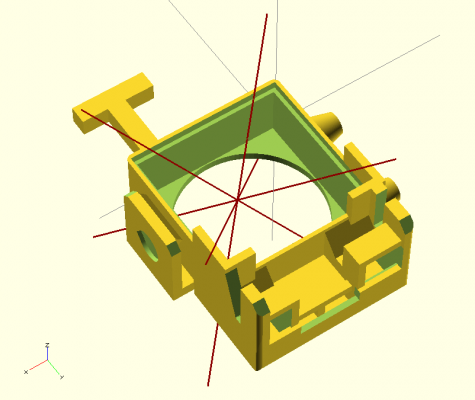

Do you mean the 1 nozzle or the 2 nozzle.

I am redesigning the 2 nozzle so will post details when I have tested it, the 1 nozzle scad file attached.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I am redesigning the 2 nozzle so will post details when I have tested it, the 1 nozzle scad file attached.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Adding Multi extruder support - howto July 17, 2014 05:03PM |

Registered: 10 years ago Posts: 859 |

Nice work Dave.... Love the cone..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Adding Multi extruder support - howto July 17, 2014 06:04PM |

Registered: 10 years ago Posts: 14,672 |

Quote

colsenfoto

Hi dc42,

I tried printing with my three-nozzle setup yesterday, but never got off the first layer. One of the nozzles was constantly ripping the print off the bed. Going from 2 to 3 nozzles only makes the problems you described even worse

This guy has some very interesting posts down the blog about rebuilding a Stratasys hot-end - lots of pictures: [feedly.com]

They can retract the support-filament nozzle a little bit. I guess it's in order to avoid the problems, you (and me also) ran into.

I have made a my own 2-nozzle aluminium-bar based on your description, so now I just need to find and print your fan-duct and modified hot-end-mount. Fitting three nozzles under iamburney's fan-duct was a pain in a certain part of the body

By the way, I have a lot of noise on my temperature measurements via the extension-board also. I hope to get the time to do some oscilloscope-noise-hunting some day.

:-) Carsten

Hi Carsten,

Sorry to hear about your multi-nozzle printing problems. Did you get all 3 of your nozzles at the same height, as measured by gripping a piece of paper between the nozzles and the bed, or by rolling a drill shank between the nozzles and the bed?

Did you also set the non-printing nozzles to a reasonable standby temperature? I am using 150C at present, but I may increase it to 160C. Lower temperatures cause the non-printing nozzle to drag the print more.

I revised my thoughts on the best design for a 2-nozzle hot end conversion earlier today - see the other thread. I'm now suggesting 22mm nozzle separation, with the heater blocks turned the other way round.

I haven't looked at the temperature measurement noise with a scope yet, but the grounding seems a likely cause. Unless I can find a way to separate signal and power grounds on the X4, I'll probably move the thermistor connector and the associated resistor and capacitor to the Duet board.

You can find my designs for printed parts within 2 subdirectories of [github.com].

Edited 1 time(s). Last edit at 07/17/2014 06:05PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 18, 2014 05:25AM |

Registered: 10 years ago Posts: 14,672 |

In case anyone is interested, I've given DaveK amended designs for single and dual nozzle heatsink blocks, using the wider nozzle spacing to reduce interference between the nozzles. See [forums.reprap.org] for the design. I've also updated the nozzle mount design at [github.com] to use the increased nozzle spacing and to include a third central Bowden cutout. The idea is that I can use the same nozzle mount for both my single nozzle print head (after I have installed the new heatsink block in it) and dual nozzle head.

Edited 2 time(s). Last edit at 07/18/2014 05:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 2 time(s). Last edit at 07/18/2014 05:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 21, 2014 04:54PM |

Registered: 10 years ago Posts: 14,672 |

Here are a couple of points for anyone using the dual-nozzle design to bear in mind:

1. You will have to leave at least one of the brass Bowden ends not quite screwed all the way in so as to leave room for nozzle height adjustment. This means the nozzles are slightly higher and there is a greater risk of the fan duct touching the print if the head sags at all. So I suggest sanding the bottom of the fan duct down a little.

2. Be very careful to make sure that the 12V negative connections to both the Duet and the X4 are solid. If one of them ceases to make a good connection, either the Duet or the X4 will draw the heater and motor current through the signal ground connection in the ribbon cable. This could wreck not only the ribbon cable but also the Duet or the X4.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. You will have to leave at least one of the brass Bowden ends not quite screwed all the way in so as to leave room for nozzle height adjustment. This means the nozzles are slightly higher and there is a greater risk of the fan duct touching the print if the head sags at all. So I suggest sanding the bottom of the fan duct down a little.

2. Be very careful to make sure that the 12V negative connections to both the Duet and the X4 are solid. If one of them ceases to make a good connection, either the Duet or the X4 will draw the heater and motor current through the signal ground connection in the ribbon cable. This could wreck not only the ribbon cable but also the Duet or the X4.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 22, 2014 06:20AM |

Registered: 10 years ago Posts: 780 |

I've just finished installing the boards into my new printed enclosure and was just about to put all the connections back when I realised that I didn't mark the connection for the blue and white sensor cables.

I need to connect the white wire to the pin marked AD14 and the blue wire to AD12 on the X4 board, so I have connected a ribbon cable to the X4 board and intend to use the other end for this and any future connections. The only problem is I forgot to mark the ribbon cable and don't really want to dismantle the enclosure again.

So is there a Duet X4 schematic anywhere so I can work out the correct connection?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I need to connect the white wire to the pin marked AD14 and the blue wire to AD12 on the X4 board, so I have connected a ribbon cable to the X4 board and intend to use the other end for this and any future connections. The only problem is I forgot to mark the ribbon cable and don't really want to dismantle the enclosure again.

So is there a Duet X4 schematic anywhere so I can work out the correct connection?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Adding Multi extruder support - howto July 22, 2014 06:29AM |

Registered: 10 years ago Posts: 14,672 |

[github.com]

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 22, 2014 07:37AM |

Registered: 10 years ago Posts: 780 |

|

Re: Adding Multi extruder support - howto July 22, 2014 08:47AM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

Thank you David,

Wish me luck when I switch on.

Paul

Good luck, Paul! Don't forget to make sure that the +12v and GND in connections are secure on both boards before you turn it on. Before you apply 12V, check that you can read sensible values from all 3 thermistors using just USB power.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 22, 2014 12:25PM |

Registered: 9 years ago Posts: 138 |

Quote

appjaws1

I've just finished installing the boards into my new printed enclosure and was just about to put all the connections back when I realised that I didn't mark the connection for the blue and white sensor cables.

I need to connect the white wire to the pin marked AD14 and the blue wire to AD12 on the X4 board, so I have connected a ribbon cable to the X4 board and intend to use the other end for this and any future connections. The only problem is I forgot to mark the ribbon cable and don't really want to dismantle the enclosure again.

So is there a Duet X4 schematic anywhere so I can work out the correct connection?

Paul

Hi Paul, Hi David,

my parts for the dual extruder cames slowly per mail to me..... and soon i will start the dual extrution adventure.

So if i think right, for example i have to bend the AD12 pin on the x4 board to connect it to the prbe wires and not to the ribbon cable????

|

Re: Adding Multi extruder support - howto July 22, 2014 01:41PM |

Registered: 9 years ago Posts: 138 |

Quote

appjaws1

Well I am well on my way to 2 nozzle printing.

I have just finished assembling the hot-end. It was a bit fiddly because you can't follow the on-line instructions for the ormerod hot end because you can't rotate the heater blocks. So to fit, you have to fit the nozzle onto the block and screw it down so that you can screw the nozzle into the aluminium cooling block whilst keeping the heater block still, making sure you have enough nozzle remaining to fit the brass nut correctly.

The picture shows the new aluminium cooling block made by DaveK - Thank you, with my one piece, 2 vents hot end

[attachment 36744 2-nozzle-hot-end.png]

Hi Appjaws1,

i also get this 2 - noozle heatsink block. Do you have a moddified scad file or a SCL file for this?

|

Re: Adding Multi extruder support - howto July 22, 2014 02:32PM |

Registered: 10 years ago Posts: 780 |

Well I have installed both boards, 2 extruders and 2 hot ends.

When cold I have applied Temp correction:- M305 P2 H30 M305 P1 H41 and M305 P0 H38. But head 2 temperature is very erratic ranging from 25.3 to 28.3, Head 1 ranges from 26.5 to 27

I believe the web interface should display the position of all extruders it finds, but my page is only displaying one, the original.

I have added to config, the following;-

M563 P1 D0 H1 ; Define tool 1

G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures

M563 P2 D0 H2 ; Define tool 2

G10 P2 S0 R0 ; Set tool 1 operating and standby temperatures

I have also copied the t files so I have a version for 1 and 2 e.g. tfree1.g, tfree2.g.

The 1 versions are from dc42's site.

I have powered the ormerod on and all looks good except I have no controls for the second extruder.

What else do I need to do?

Thanks for any help

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

When cold I have applied Temp correction:- M305 P2 H30 M305 P1 H41 and M305 P0 H38. But head 2 temperature is very erratic ranging from 25.3 to 28.3, Head 1 ranges from 26.5 to 27

I believe the web interface should display the position of all extruders it finds, but my page is only displaying one, the original.

I have added to config, the following;-

M563 P1 D0 H1 ; Define tool 1

G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures

M563 P2 D0 H2 ; Define tool 2

G10 P2 S0 R0 ; Set tool 1 operating and standby temperatures

I have also copied the t files so I have a version for 1 and 2 e.g. tfree1.g, tfree2.g.

The 1 versions are from dc42's site.

I have powered the ormerod on and all looks good except I have no controls for the second extruder.

What else do I need to do?

Thanks for any help

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Adding Multi extruder support - howto July 22, 2014 04:48PM |

Registered: 10 years ago Posts: 780 |

Quote

muggi

Quote

appjaws1

i also get this 2 - noozle heatsink block. Do you have a moddified scad file or a SCL file for this?

Attached is my amended hot-end 2 vents and my 2 nozzle mount.

Hope that helps

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Adding Multi extruder support - howto July 22, 2014 06:10PM |

Registered: 10 years ago Posts: 14,672 |

Paul, you appear to have defined both tools to use the same extruder i.e. D0. Change tool 2 to use D1. Also check you are using web interface 0.98 and firmware 0.78e-dc42. The erratic temperature reading for heater 2 is normal unfortunately, see my earlier post.

Edited 2 time(s). Last edit at 07/22/2014 06:12PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 2 time(s). Last edit at 07/22/2014 06:12PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 22, 2014 11:30PM |

Registered: 9 years ago Posts: 138 |

Quote

dc42

I considered mounting the X4 next to the Duet like that, but I didn't like the idea of having such a tall enclosure, or cables going to the top of it. So I've taken bobtidey's enclosure design here [forums.reprap.org] and adapted it to accommodate the Duet and X4 boards back-to-back.

I will attach the cables to the X4 first, using the screw terminals to keep the profile low, then fit the X4 to the enclosure component side down. Then I will fit the Duet on top of it in the usual way.

Normally, connecting the Z probe wires would be a problem with this arrangement, because one or two of them would be connected to the expansion connector on the X4, so a low-profile mounting would be needed or the X4 stood off further from the base of the enclosure. However, I already epoxied an extra 3-way header to the bottom of my Duet board for the Z probe to reduce noise pickup from the switching regulator, so that won't be a problem for me.

Hi david,

so you have connect the probe wires from the backside of the x4 pcb? can you post a picture?

Edited 1 time(s). Last edit at 07/23/2014 12:12AM by muggi.

|

Re: Adding Multi extruder support - howto July 23, 2014 02:31AM |

Registered: 10 years ago Posts: 14,672 |

No, I already had an extra connector on the bottom edge of the Duet for connecting the probe. One option for connecting the probe to the expansion connector on the X4 is to use a ribbon cable connector as I believe Paul has done.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 23, 2014 03:10AM |

Registered: 10 years ago Posts: 119 |

I think David already posted a picture of the extra connector and wires in another thread in the forum, I think it was when he discussed the problem of noise and the thermistors for duel extruders.

That might answer your request muggi, if I have time I'll look for it and post the reference, David might remember it quicker though .

.

Lloyd

That might answer your request muggi, if I have time I'll look for it and post the reference, David might remember it quicker though

.

.Lloyd

|

Re: Adding Multi extruder support - howto July 23, 2014 04:55AM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

Paul, you appear to have defined both tools to use the same extruder i.e. D0. Change tool 2 to use D1. Also check you are using web interface 0.98 and firmware 0.78e-dc42. The erratic temperature reading for heater 2 is normal unfortunately, see my earlier post.

I have changed the extruder to D1 (I wondered what the D parameter was for) and confirm I am using web interface 0.98 and firmware 0.78e-dc42.

On the web interface, under Head position-Extruders, 2 extruders are showing( 1,0)

On the control page only 1 extruder control is displayed so I can only move the original extruder.

On the print Status page under print control I have sliders for speed, Extr1 and Extr2.

So I still have something not quite correct

One thing I have noticed is that if I click on either of the Head boxes under Heater temps, the bed moves to the right, away from the microswitch.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Sorry, only registered users may post in this forum.