changing filament question

Posted by Amsterdamman

|

changing filament question September 01, 2014 03:51PM |

Registered: 9 years ago Posts: 146 |

Hi Guys,

A simple question I cant find the answer to.

Whats best way to change a filament?

I'd like to change to a different color and save the rest of the roll.

Worried if it is hot it will pull materiel into the tube if I reverse the extruder.

Cold it doesn't have the power to snap the old filament.

About to make my version of a filament holder rack.

Thanks for the help guys!

I hope to be able to give some of it back to the next wave of new reppers!

A simple question I cant find the answer to.

Whats best way to change a filament?

I'd like to change to a different color and save the rest of the roll.

Worried if it is hot it will pull materiel into the tube if I reverse the extruder.

Cold it doesn't have the power to snap the old filament.

About to make my version of a filament holder rack.

Thanks for the help guys!

I hope to be able to give some of it back to the next wave of new reppers!

|

Re: changing filament question September 01, 2014 04:20PM |

Registered: 10 years ago Posts: 14,672 |

To remove the old filament, I just heat the nozzle to about 120C and then retract the filament.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: changing filament question September 01, 2014 04:35PM |

Registered: 9 years ago Posts: 146 |

|

Re: changing filament question September 01, 2014 06:42PM |

Registered: 10 years ago Posts: 859 |

@ Amsterdamman

Hello, I use Pronterface (The USB interface) and to change filament I heat the nozzle to the regular temperature (215') that I use, then set the Extrusion Distance to 500mm (the PTFE tube is actualy about 350mm) and set the Extrusion Speed at 10000 mm/min, then press Reverse. (It's very quick)

For feeding in the filament I alter the distance to 350mm keeping the same speed, press extrude, this then takes the filament nearly to the nozzle, I then reduce the speed to 100mm/min and do two Extrusion presses, this then gets the filament to the nozzle, and allows enough to go throu the nozzle for the nozzle to prime.

After that it's ready to go. If I'm not going to be printing for a while, I retract 3mm at a high speed, to reduce the dribble from the nozzle.

When I'm printing something and the last of the filament is running out..... I get the next spool of filament mounted on the spooler, and as the last of the filament starts to go into the feeder, a gently push the new filament in after it. You then have to maintain the gentle pressure untill the new filament reaches the Hubbed Nut.

This way you don't end up with either incomplete prints, of short lengths of unused filament.... You can even change the colour while printing doing it that way.

3D printing is abit like riding a bike..... When you've never ridden one before it feels impossible..... A week later you don't realise it, but you start to do thing automaticaly, and it's easy....

If you ever experiance a blocked nozzle then heat to about 116' (a low almost molten temperature) and retract the filament... Again I prefer to use a High speed.

When the filament comes out of the machine I snap off the last 4cm of filament, then put the filament back in to the machine. If it still is blocked then I repeat the process a couple of times. Normaly that clears it.....

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Hello, I use Pronterface (The USB interface) and to change filament I heat the nozzle to the regular temperature (215') that I use, then set the Extrusion Distance to 500mm (the PTFE tube is actualy about 350mm) and set the Extrusion Speed at 10000 mm/min, then press Reverse. (It's very quick)

For feeding in the filament I alter the distance to 350mm keeping the same speed, press extrude, this then takes the filament nearly to the nozzle, I then reduce the speed to 100mm/min and do two Extrusion presses, this then gets the filament to the nozzle, and allows enough to go throu the nozzle for the nozzle to prime.

After that it's ready to go. If I'm not going to be printing for a while, I retract 3mm at a high speed, to reduce the dribble from the nozzle.

When I'm printing something and the last of the filament is running out..... I get the next spool of filament mounted on the spooler, and as the last of the filament starts to go into the feeder, a gently push the new filament in after it. You then have to maintain the gentle pressure untill the new filament reaches the Hubbed Nut.

This way you don't end up with either incomplete prints, of short lengths of unused filament.... You can even change the colour while printing doing it that way.

3D printing is abit like riding a bike..... When you've never ridden one before it feels impossible..... A week later you don't realise it, but you start to do thing automaticaly, and it's easy....

If you ever experiance a blocked nozzle then heat to about 116' (a low almost molten temperature) and retract the filament... Again I prefer to use a High speed.

When the filament comes out of the machine I snap off the last 4cm of filament, then put the filament back in to the machine. If it still is blocked then I repeat the process a couple of times. Normaly that clears it.....

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: changing filament question September 01, 2014 11:03PM |

Registered: 9 years ago Posts: 146 |

Thanks Kim!

I tried the faster extrusion speed, that definitely has uses.

Some of the stretched old filament end broke off in the top of the extruder and blocked the new line.

I removed the Bowden tube and could see the blockage, tweezers cleared it and a short piece of new filament went cleanly through.

We are reloaded and ready to start printing my filament rack

So far its gone very well. I use kapton tape and its been working pretty good.

Using KISSlicer as I prefer the interface and like the way it does debugging models.

Running via Pronterface as well. Designing on Sketchup.

Will be trying my first support piece next.

Do you have a link for your Big Blue 360? The one in your sig didn't work, but I found one of your pages about it.

That looks very interesting and with a great bridge ability!

Thanks for your advice and help!

Kimon

I tried the faster extrusion speed, that definitely has uses.

Some of the stretched old filament end broke off in the top of the extruder and blocked the new line.

I removed the Bowden tube and could see the blockage, tweezers cleared it and a short piece of new filament went cleanly through.

We are reloaded and ready to start printing my filament rack

So far its gone very well. I use kapton tape and its been working pretty good.

Using KISSlicer as I prefer the interface and like the way it does debugging models.

Running via Pronterface as well. Designing on Sketchup.

Will be trying my first support piece next.

Do you have a link for your Big Blue 360? The one in your sig didn't work, but I found one of your pages about it.

That looks very interesting and with a great bridge ability!

Thanks for your advice and help!

Kimon

|

Re: changing filament question September 01, 2014 11:53PM |

Registered: 10 years ago Posts: 859 |

[SNAP!]

Hello Kimon, I had removed the Big blue because a guy was copying my other designs and claiming it was his own work, and I didn't want his hands on Big blue.

The new link is:-

[www.thingiverse.com]

Regards,

Kimon........ (But I just use Kim)

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Hello Kimon, I had removed the Big blue because a guy was copying my other designs and claiming it was his own work, and I didn't want his hands on Big blue.

The new link is:-

[www.thingiverse.com]

Regards,

Kimon........ (But I just use Kim)

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Anonymous User

Re: changing filament question September 02, 2014 02:37AM |

Quote

Amsterdamman

Hi Guys,

A simple question I cant find the answer to.

Whats best way to change a filament?

I'd like to change to a different color and save the rest of the roll.

Worried if it is hot it will pull materiel into the tube if I reverse the extruder.

Cold it doesn't have the power to snap the old filament.

About to make my version of a filament holder rack.

Thanks for the help guys!

I hope to be able to give some of it back to the next wave of new reppers!

have you gone to this page already Changing Filaments?

Edited 1 time(s). Last edit at 09/02/2014 02:38AM by FrancisDaniel.

|

Re: changing filament question September 02, 2014 04:23AM |

Registered: 13 years ago Posts: 1,611 |

Or see the 'Nozzle blockage (also for changing filament)' section here: [reprappro.com]

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: changing filament question September 03, 2014 08:30AM |

Registered: 10 years ago Posts: 2,472 |

I turn the extruder gear by hand (with motors off) to remove and insert filament, and find it faster.

1) Set nozzle heat to 200 deg or so while lightly trying to turn extruder gear (in direction to pull filament out)

2) As soon as the plastic gets soft enough the gear will turn and the filament extracts - and because the plastic has only just become molten it does not leave much of a string in the tube

3) Turn off heater and continue to extract filament by hand

4) Put in new filament and turn gear by hand until the filament stops in the (now cool) nozzle

5) Set nozzle to working temperature and keep pressure on gear till the plastic starts extruding

6) Turn off heater but continue extruding by hand till there is no trace of the previous colour

Turning the gear by hand will alert you if the filament is sticking in the tube or elsewhere.

Dave

(#106)

1) Set nozzle heat to 200 deg or so while lightly trying to turn extruder gear (in direction to pull filament out)

2) As soon as the plastic gets soft enough the gear will turn and the filament extracts - and because the plastic has only just become molten it does not leave much of a string in the tube

3) Turn off heater and continue to extract filament by hand

4) Put in new filament and turn gear by hand until the filament stops in the (now cool) nozzle

5) Set nozzle to working temperature and keep pressure on gear till the plastic starts extruding

6) Turn off heater but continue extruding by hand till there is no trace of the previous colour

Turning the gear by hand will alert you if the filament is sticking in the tube or elsewhere.

Dave

(#106)

|

Re: changing filament question September 06, 2014 08:13AM |

Registered: 9 years ago Posts: 146 |

My Update: pretty sure it was the hot end and fast withdraw suggested by KimBrown that clogged the Bowden tube.

It worked with the RS blue filament but now I'm using 3dprima.com filament and maybe that was the issue,

the second time it left a major clogged tube and I had to disassemble the entire hot end to clear it.

Once running it seemed the nozzle went in 0.5mm too high... So I'm getting ready to redisassemble the hot end,

Decided to try to practice a few filament changes since I have to open the hot end anyway, and... the cooling fan wont run!

So, from my experience do NOT use KimBrown's fast remove the hot filament unless your using RS filament.

My plan was to try dmoulds slow hand turned method once I figure out why the fan is dead...

If it wasn't for one more thing,

I'd be working on a solution...

Kimon

It worked with the RS blue filament but now I'm using 3dprima.com filament and maybe that was the issue,

the second time it left a major clogged tube and I had to disassemble the entire hot end to clear it.

Once running it seemed the nozzle went in 0.5mm too high... So I'm getting ready to redisassemble the hot end,

Decided to try to practice a few filament changes since I have to open the hot end anyway, and... the cooling fan wont run!

So, from my experience do NOT use KimBrown's fast remove the hot filament unless your using RS filament.

My plan was to try dmoulds slow hand turned method once I figure out why the fan is dead...

If it wasn't for one more thing,

I'd be working on a solution...

Kimon

|

Re: changing filament question September 06, 2014 10:19AM |

Registered: 9 years ago Posts: 146 |

Found the loose fan wire in the harness, then the heater gave a fault. Reset everything and pushed connectors again and it worked.

Removed and replaced filament using hand method above @dmoulds. KimBrown's method is easier if it works for your filament,

but the clog I got was a major headache and I am now going to disassemble the nozzle and reset the height...

One more filament removal first.

Just added my modular tube design to thingiverse.com/thing:453879

Will be the basis of my large free standing filament holder...

sketchup files included.

Thanks everyone for the input and help!

I would be stuck without you guys!

Kimon ~ The Amsterdamman

Removed and replaced filament using hand method above @dmoulds. KimBrown's method is easier if it works for your filament,

but the clog I got was a major headache and I am now going to disassemble the nozzle and reset the height...

One more filament removal first.

Just added my modular tube design to thingiverse.com/thing:453879

Will be the basis of my large free standing filament holder...

sketchup files included.

Thanks everyone for the input and help!

I would be stuck without you guys!

Kimon ~ The Amsterdamman

|

Re: changing filament question September 06, 2014 10:27AM |

Registered: 10 years ago Posts: 14,672 |

After heating the nozzle to 120C, I retract the filament slowly for the first 10mm, then quickly. It's worked every time for me so far.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: changing filament question September 07, 2014 08:45AM |

Registered: 9 years ago Posts: 146 |

We are finally printing again! Took lots of effort to rehome the Z axis until I got a tight bed stick again.

I'm still using Kapton tape even though I don't see many people reporting using it.

When I get the setup right it sticks very tight indeed.

I've started using a wooden dowel and a rubber mallet to knock the pieces off the bed with a quick sharp tap.

Seems the easiest way to remove finished parts..

After three tests and a extra removal I've had great experiences with rolling the extruder by hand with motors off.

Either from a cold nozzle which lets you feel the moment the filament softens when you have some tension on the extruder wheel.

Or as the nozzle cools under approx. 100c you can also reverse the extruder wheel by hand (motors off).

The end comes out very clean and so far has given me no issues.

Cut the new fresh end at a angle with a wire snipper and it loads very easy as well.

Where do most reppers get their filament?

I'm liking the 3Dprima(com) spool so far.

I'm still using Kapton tape even though I don't see many people reporting using it.

When I get the setup right it sticks very tight indeed.

I've started using a wooden dowel and a rubber mallet to knock the pieces off the bed with a quick sharp tap.

Seems the easiest way to remove finished parts..

After three tests and a extra removal I've had great experiences with rolling the extruder by hand with motors off.

Either from a cold nozzle which lets you feel the moment the filament softens when you have some tension on the extruder wheel.

Or as the nozzle cools under approx. 100c you can also reverse the extruder wheel by hand (motors off).

The end comes out very clean and so far has given me no issues.

Cut the new fresh end at a angle with a wire snipper and it loads very easy as well.

Where do most reppers get their filament?

I'm liking the 3Dprima(com) spool so far.

|

Re: changing filament question September 08, 2014 03:43AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Amsterdamman

My Update: pretty sure it was the hot end and fast withdraw suggested by KimBrown that clogged the Bowden tube.

It worked with the RS blue filament but now I'm using 3dprima.com filament and maybe that was the issue,

the second time it left a major clogged tube and I had to disassemble the entire hot end to clear it.

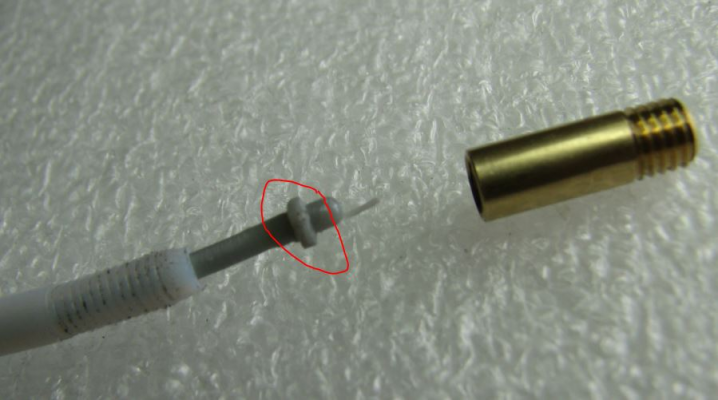

Fast filament withdrawal, my experience:

Erik

|

Re: changing filament question September 08, 2014 10:56AM |

Registered: 10 years ago Posts: 176 |

|

Re: changing filament question September 08, 2014 05:34PM |

Registered: 10 years ago Posts: 378 |

Sorry, only registered users may post in this forum.