Gaps in print, what's the cause?

Posted by bitfield

|

Gaps in print, what's the cause? December 21, 2014 03:04PM |

Registered: 9 years ago Posts: 88 |

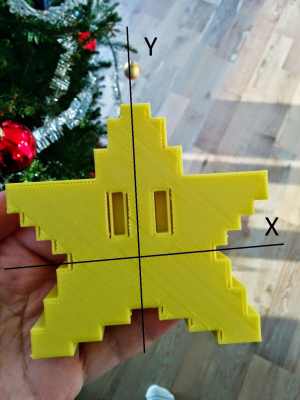

See image. Gaps around the eyes and in some edges. Not quite sure why?

Edited 1 time(s). Last edit at 12/21/2014 03:05PM by bitfield.

Edited 1 time(s). Last edit at 12/21/2014 03:05PM by bitfield.

|

Re: Gaps in print, what's the cause? December 21, 2014 04:11PM |

Registered: 10 years ago Posts: 14,672 |

Are they actually gaps? It appears to me that there is probably a small step, in the horizontal direction in your photo. If that corresponds to the Y axis, then it is a classic sign of Y belt slippage.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Gaps in print, what's the cause? December 21, 2014 11:23PM |

Registered: 10 years ago Posts: 859 |

Hi Bitfield, I have had exactly the same gap in my prints.

Check your feeder. I found that the replacement feeder I was using (the original that I'd calibrated had worn out, but the replacement used

the same parts) was only feeding in 99mm on a 100mm advancement. When I adjusted the rate to give 100mm the gaps vanished.

Bare in mind that 1mm of raw filament equates to approximately 3 to 4mm of Nozzle extrusion.

Also check the diameter of your filament. I found that some of the Reels I have the diament can be 1.7mm instead of 1.74mm.

Another thing to check is the Extrusion Multiplier.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Check your feeder. I found that the replacement feeder I was using (the original that I'd calibrated had worn out, but the replacement used

the same parts) was only feeding in 99mm on a 100mm advancement. When I adjusted the rate to give 100mm the gaps vanished.

Bare in mind that 1mm of raw filament equates to approximately 3 to 4mm of Nozzle extrusion.

Also check the diameter of your filament. I found that some of the Reels I have the diament can be 1.7mm instead of 1.74mm.

Another thing to check is the Extrusion Multiplier.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Gaps in print, what's the cause? December 22, 2014 03:32AM |

Registered: 9 years ago Posts: 88 |

The filament is supposed to be 1.75mm which is what's specified in slic3r. I have not changed anything in the feeder since I first calibrated it but I can double check the calibration of course.

As seen in the image, it looks like it's the X axis that's causing the issue right? The X belt is rather slack but I couldn't feel any slippage when I dragged it manually.

Should I try to tighten it up? I remember the X belt being a bit of a hassle.

As seen in the image, it looks like it's the X axis that's causing the issue right? The X belt is rather slack but I couldn't feel any slippage when I dragged it manually.

Should I try to tighten it up? I remember the X belt being a bit of a hassle.

|

Re: Gaps in print, what's the cause? December 22, 2014 05:40AM |

Registered: 10 years ago Posts: 14,672 |

The X motor belt is tensioned by adjusting the position of the X motor screws in their slots. The best way I found to get the belt taut was to slacken the screw furthest from the hot end (call this #1) a little, and the other screw (#2) a lot. Then pull the back of the X motor along to get the belt as taut as possible, and hold it in place while you tighten #1. Then tightening #2 will increase the belt tension further.

Edited 1 time(s). Last edit at 12/22/2014 05:40AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 12/22/2014 05:40AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Gaps in print, what's the cause? December 22, 2014 08:05AM |

Registered: 9 years ago Posts: 88 |

|

Re: Gaps in print, what's the cause? December 22, 2014 02:57PM |

Registered: 9 years ago Posts: 88 |

It started out pretty well at first but then eventually the gaps started to appear again together with a very bad squeaking sound. I had that with my first print of the star as well. Thought it was the LM12LUU bearings at first but I had a hard time localising exactly where the sound was coming from. Then I realized it was the MR93ZZ bearing on the x-carriage. It wasn't moving freely at all against the x-axis-plate. For some reason there was no washer between the carriage and the bearing. I didn't want to stop the print so I put some lubricant on the plate to help the bearing. The sound disappeared and the gaps went away as well.

Afterwards I put an M3 washer in place. The bearing doesn't spin as freely as I would expect, even with the washer, but I think it's OK now.

Afterwards I put an M3 washer in place. The bearing doesn't spin as freely as I would expect, even with the washer, but I think it's OK now.

|

Re: Gaps in print, what's the cause? December 22, 2014 04:52PM |

Registered: 10 years ago Posts: 14,672 |

Quote

bitfield

Afterwards I put an M3 washer in place. The bearing doesn't spin as freely as I would expect, even with the washer, but I think it's OK now.

Washers tend to be slightly dished, i.e. convex on one side (with blunt edges) and concave the other (with sharper edges). Make sure the convex side is next to the bearing.

Edited 1 time(s). Last edit at 12/22/2014 04:53PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Gaps in print, what's the cause? December 23, 2014 06:39AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Gaps in print, what's the cause? December 23, 2014 09:21AM |

Registered: 10 years ago Posts: 780 |

I don't believe that this is a belt tightness issue.

I think it is the settings in slic3r that you need to experiment with because it looks to me as if the extrusion is not filling right to the perimeter

check under Print Settings, Layers and Perimeters that you have Vertical shells set to 3

under infill don't check Infill before perimeters, leave blank

The other thing, is to check what your extrusion widths are set to under Advanced. I have all of mine set at 0 ( the default) except First layer which I have set at 150%

, I have a feeling that this is a firmware issue.

The only way I solved it was to increase the extrusion factor a little ( a lot more that the thin wall test indicated)

I need to get some evidence together to present to dc42 and zpl when I can definitely prove it is a firmware issue.

Hope that helps

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I think it is the settings in slic3r that you need to experiment with because it looks to me as if the extrusion is not filling right to the perimeter

check under Print Settings, Layers and Perimeters that you have Vertical shells set to 3

under infill don't check Infill before perimeters, leave blank

The other thing, is to check what your extrusion widths are set to under Advanced. I have all of mine set at 0 ( the default) except First layer which I have set at 150%

, I have a feeling that this is a firmware issue.

The only way I solved it was to increase the extrusion factor a little ( a lot more that the thin wall test indicated)

I need to get some evidence together to present to dc42 and zpl when I can definitely prove it is a firmware issue.

Hope that helps

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Gaps in print, what's the cause? December 24, 2014 12:40PM |

Registered: 10 years ago Posts: 780 |

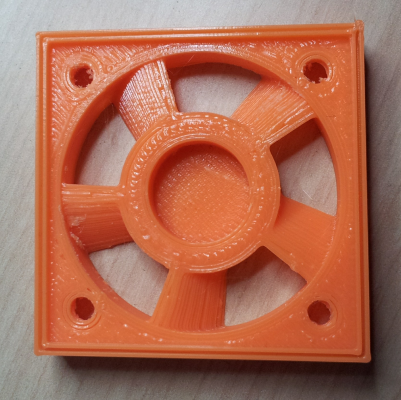

Well I haven't solved my gap problem. The outside walls are supposed top be solid.

I've run out of ideas of what to do to resolve this issue.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I've run out of ideas of what to do to resolve this issue.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Gaps in print, what's the cause? December 24, 2014 01:09PM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

Well I haven't solved my gap problem. The outside walls are supposed top be solid.

That looks to me like a classic slic3r issue I have come across before, caused by the thickness of the wall being more than twice the extrusion width but less than three times the extrusion width. So slic3r can't generate extrusion between the two perimeters. Try making the wall thicker.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Gaps in print, what's the cause? December 24, 2014 01:33PM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

That looks to me like a classic slic3r issue I have come across before, caused by the thickness of the wall being more than twice the extrusion width but less than three times the extrusion width. So slic3r can't generate extrusion between the two perimeters. Try making the wall thicker.

Yes Thank you David, I remembered that it could be to do with the wall thickness and I have increased it. I did the slicing in simplify3d so it's not just a slic3r issue.

The wall was set at 1.5 and increasing to 1.6 solved the issue.

This has nothing to do with this threads original problem which I still think is a firmware issue to do with the start or end of a printed line.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Gaps in print, what's the cause? December 25, 2014 09:24AM |

Registered: 10 years ago Posts: 2,472 |

Quote

appjaws1

Yes Thank you David, I remembered that it could be to do with the wall thickness and I have increased it. I did the slicing in simplify3d so it's not just a slic3r issue.

It does not matter which slicing software you use. It is not geometrically possible to fill a gap that is thinner than the width of the extrusion. I suppose it would be possible for the software to detect that condition and extrude less to create a thinner extrusion, but only if the gap is somewhere close to the optimum extrusion thickness.

Dave

|

Re: Gaps in print, what's the cause? December 25, 2014 10:22AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

It does not matter which slicing software you use. It is not geometrically possible to fill a gap that is thinner than the width of the extrusion. I suppose it would be possible for the software to detect that condition and extrude less to create a thinner extrusion, but only if the gap is somewhere close to the optimum extrusion thickness.

Dave

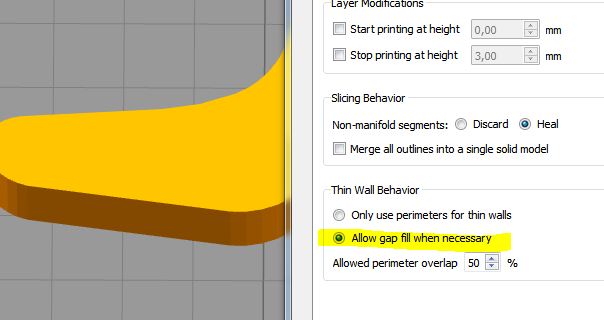

I don't quite agree - Simplify3d to gap fill better (on this model at least) than I was able to achieve with Cura and Slic3r, had to set extrusion width to 0.45 to get it just right, this is tiny stuff! - tip of leg is 1,3mm

Erik

|

Re: Gaps in print, what's the cause? December 26, 2014 08:07AM |

Registered: 10 years ago Posts: 780 |

Quote

ormerod168

I don't quite agree - Simplify3d to gap fill better (on this model at least) than I was able to achieve with Cura and Slic3r, had to set extrusion width to 0.45 to get it just right, this is tiny stuff! - tip of leg is 1,3mm

[attachment 45774 simplify3d_gap_fill.JPG]

Erik

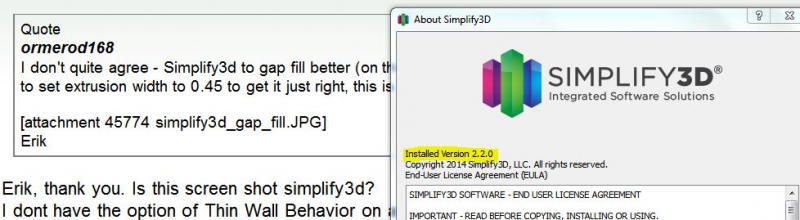

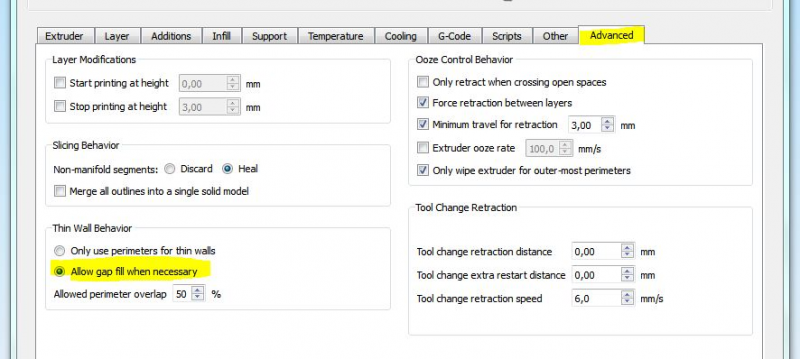

Erik, thank you. Is this screen shot simplify3d?

I dont have the option of Thin Wall Behavior on any screen. On the advanced tab, under Slicing Behavior I just have Non-manifold segments - discard - heal and a box Merge all outlines into a single solid model, this does exactly what it says and produces a solid object with no detail.

I am using simplify3d version 2.1.2 which was a recent update.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Gaps in print, what's the cause? December 26, 2014 09:20AM |

Registered: 10 years ago Posts: 1,230 |

Quote

appjaws1

Erik, thank you. Is this screen shot simplify3d?

Yes, the latest version

Quote

I dont have the option of Thin Wall Behavior on any screen. On the advanced tab, under Slicing Behavior I just have Non-manifold segments - discard - heal....

Here it is again under advanced:

its not without problems (gap fill sometime show up through outside perimeters) and you might have to fiddle with the "allow perimeter overlap %" and perimeter width - and read the simplify3d user forum about the new features:

[www.forum.simplify3d.com]

..and notice the extruder ooze rate setting is broken in the new verison, so dont tick that box, it has the habit of defaulting to 100mm/sec!

Quote

....and a box Merge all outlines into a single solid model, this does exactly what it says and produces a solid object with no detail.

Yes it sure does LOL, I could tell you a story of how I spend

BTW, this is a good trainer for gap fill (now don't tick that box!)

Scorpion Puzzle

[www.thingiverse.com]

Edit: factory file added, only use for ver.2.2.0 and as an example of settings

Erik

Edited 1 time(s). Last edit at 12/26/2014 09:31AM by ormerod168.

Sorry, only registered users may post in this forum.