Threaded Z rod on twin towers

Posted by Pointy

|

Threaded Z rod on twin towers January 06, 2015 12:23PM |

Registered: 10 years ago Posts: 327 |

Hi,

I am planning on a major rebuild of my Ormerod 1 in the near future. I have already virtually modded it beyond recognition, in fact I think the only original Ormerod 1 parts left are the 2 Z bearing clamps.

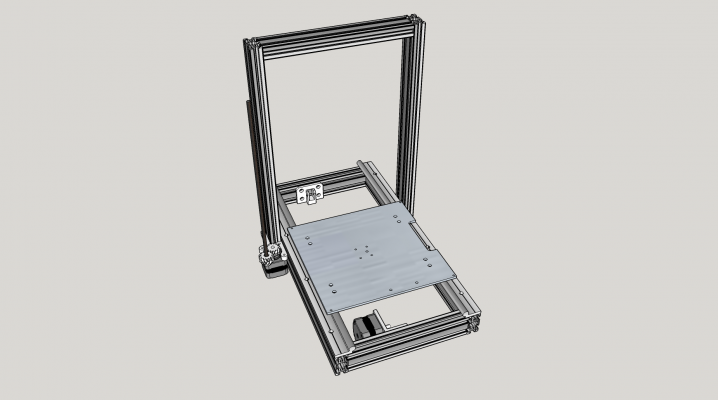

The biggest mod was Chris1965's bed frame. This improved things drastically, the Y axis is perfect, but I have never been happy with the X axis, even with the aluminium plate/rib. The next plan is to add a second vertical tower opposite the first and a connecting piece at the top, joining the two together. I might mount the extruder on this connecting piece, I haven't decided yet.. Obviously all of the X axis printed parts will need redesigning, which shouldn't be a problem. The real question is, whether I should keep the threaded Z rod & nut trap or switch to a belt drive. Would the firmware need tweaking for a belt drive system?

Anyone have any thoughts/ideas on this setup?

Regards,

Les

Pointy's Things

Pointy's Blog

I am planning on a major rebuild of my Ormerod 1 in the near future. I have already virtually modded it beyond recognition, in fact I think the only original Ormerod 1 parts left are the 2 Z bearing clamps.

The biggest mod was Chris1965's bed frame. This improved things drastically, the Y axis is perfect, but I have never been happy with the X axis, even with the aluminium plate/rib. The next plan is to add a second vertical tower opposite the first and a connecting piece at the top, joining the two together. I might mount the extruder on this connecting piece, I haven't decided yet.. Obviously all of the X axis printed parts will need redesigning, which shouldn't be a problem. The real question is, whether I should keep the threaded Z rod & nut trap or switch to a belt drive. Would the firmware need tweaking for a belt drive system?

Anyone have any thoughts/ideas on this setup?

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Threaded Z rod on twin towers January 06, 2015 01:25PM |

Registered: 10 years ago Posts: 2,472 |

I assume you will be fitting 2 Z drives, one on each tower? My choice would be to keep the screw drive method, and fit a second stepper motor & screw jack to the other tower, connected in series. A tell-tale pointer at the top of each screw jack is used to check that they start off at the same relative height when power is first applied. An alternative would be to connect the two screw jacks with a belt and have 1 stepper motor (that way they cannot get out of step once adjusted). Changing to a belt drive would introduce several challenges. One is how much gearing the stepper will need to have enough power to raise the X arm and how to arrange that gearing, another is how to prevent the X arm crashing to the bed under gravity when the stepper drive current is removed, and another is how to stop the stepper driving the nozzle into the bed if it is driven below the Z=0 height (which it inevitably will be some day).

I was thinking about doing a similar mod, but have decided that it would be easier to use the experience gained in building & using the Ormerod kit to build a different design from scratch - I'd like to try a design that has no hanging arms, does not have a Bowden extruder and has controllable filament cooling. I am however waiting to see whether the performance limitations of the Bowden extruder might be adequately overcome in software before finally deciding on a design, because mechanically the Bowden extruder is superior. I'll chose a proven design but maybe add a few modifications of my own. A larger print volume than most designs accommodate would be useful, for example, and I'd like to have the print area fully enclosed so the environment is controlled. I have yet to decide whether to use a design that has a fixed extruder and the bed moving in at least both X and Y. Such designs have the advantage of being able to accommodate large multi-headed nozzles far more easily than designs that have moving nozzles. I will preferably use the Duet board as I am happy & familiar with it. One thing to bear in mind is that if the Ormerod is the only printer you have, you will not be able to print parts that you may find you need to change after you start modifying the printer.

Dave

I was thinking about doing a similar mod, but have decided that it would be easier to use the experience gained in building & using the Ormerod kit to build a different design from scratch - I'd like to try a design that has no hanging arms, does not have a Bowden extruder and has controllable filament cooling. I am however waiting to see whether the performance limitations of the Bowden extruder might be adequately overcome in software before finally deciding on a design, because mechanically the Bowden extruder is superior. I'll chose a proven design but maybe add a few modifications of my own. A larger print volume than most designs accommodate would be useful, for example, and I'd like to have the print area fully enclosed so the environment is controlled. I have yet to decide whether to use a design that has a fixed extruder and the bed moving in at least both X and Y. Such designs have the advantage of being able to accommodate large multi-headed nozzles far more easily than designs that have moving nozzles. I will preferably use the Duet board as I am happy & familiar with it. One thing to bear in mind is that if the Ormerod is the only printer you have, you will not be able to print parts that you may find you need to change after you start modifying the printer.

Dave

|

Re: Threaded Z rod on twin towers January 06, 2015 02:04PM |

Registered: 10 years ago Posts: 14,672 |

Dave, have you considered building a delta, or a CoreXY machine?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Threaded Z rod on twin towers January 06, 2015 04:01PM |

Registered: 10 years ago Posts: 327 |

Thanks for the reply Dave,

I was hoping to just use one motor if possible. I will have to see how it pans out., it might depend on what bearings I use, I could try some V wheels running on the profile.

I thought a belt drive could introduce a lot more issues.

I thought about making it bigger but to be honest I don't print anything that big, so far the biggest thing has been the Duet enclosure. Then main thing I am after is consistent prints and I intend to use the Ormerod (hmmm might have to rename it after this) for ABS.

I am just waiting for more parts to arrive to build a Delta printer, so I can't do anything until that's up and running.( I am also waiting for a replacement Duet.)

Regards,

Les

Pointy's Things

Pointy's Blog

Quote

dmould

I assume you will be fitting 2 Z drives, one on each tower? My choice would be to keep the screw drive method, and fit a second stepper motor & screw jack to the other tower, connected in series. A tell-tale pointer at the top of each screw jack is used to check that they start off at the same relative height when power is first applied. An alternative would be to connect the two screw jacks with a belt and have 1 stepper motor (that way they cannot get out of step once adjusted).

I was hoping to just use one motor if possible. I will have to see how it pans out., it might depend on what bearings I use, I could try some V wheels running on the profile.

Quote

dmould

Changing to a belt drive would introduce several challenges. One is how much gearing the stepper will need to have enough power to raise the X arm and how to arrange that gearing, another is how to prevent the X arm crashing to the bed under gravity when the stepper drive current is removed, and another is how to stop the stepper driving the nozzle into the bed if it is driven below the Z=0 height (which it inevitably will be some day).

I thought a belt drive could introduce a lot more issues.

Quote

dmould

I was thinking about doing a similar mod, but have decided that it would be easier to use the experience gained in building & using the Ormerod kit to build a different design from scratch - I'd like to try a design that has no hanging arms, does not have a Bowden extruder and has controllable filament cooling. I am however waiting to see whether the performance limitations of the Bowden extruder might be adequately overcome in software before finally deciding on a design, because mechanically the Bowden extruder is superior. I'll chose a proven design but maybe add a few modifications of my own. A larger print volume than most designs accommodate would be useful, for example, and I'd like to have the print area fully enclosed so the environment is controlled. I have yet to decide whether to use a design that has a fixed extruder and the bed moving in at least both X and Y. Such designs have the advantage of being able to accommodate large multi-headed nozzles far more easily than designs that have moving nozzles. I will preferably use the Duet board as I am happy & familiar with it. One thing to bear in mind is that if the Ormerod is the only printer you have, you will not be able to print parts that you may find you need to change after you start modifying the printer.

I thought about making it bigger but to be honest I don't print anything that big, so far the biggest thing has been the Duet enclosure. Then main thing I am after is consistent prints and I intend to use the Ormerod (hmmm might have to rename it after this) for ABS.

Quote

dmould

IOne thing to bear in mind is that if the Ormerod is the only printer you have, you will not be able to print parts that you may find you need to change after you start modifying the printer.

I am just waiting for more parts to arrive to build a Delta printer, so I can't do anything until that's up and running.( I am also waiting for a replacement Duet.)

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Threaded Z rod on twin towers January 07, 2015 08:30AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Dave, have you considered building a delta, or a CoreXY machine?

I must admit that I like the delta from an aesthetic POV, and would probably sit watching it print for hours. However I am not convinced that I could build one well enough to get good results, I should think the tolerances are tight and setting up a bit tricky. Then there is the round and relatively small build volume and the fact that its precision varies depending on XY coordinate. I want to do most of the build myself (at home) without investing in many large and/or expensive tools. Just like my succession of quadcopters, designing and making the machine will be a hobby in its own right rather than just a means to an end, so farming out lots of the fabrication will defeat the purpose. (I probably happily spend at least an hour designing and building a quadcopter for every minute I spend flying it). On balance therefore I have ruled out building a delta as my next project - but maybe further down the line I will do so. How's yours performing?

CoreXY is elegant and appealing and does not look too mechanically challenging, so is something I am seriously considering. Does your Duet firmware support that type of drive yet? If not I shouldn't think it will be difficult to modify one of your firmware sources once I bite the bullet and go through the pain of setting up a working build environment!

I have now pretty much decided that I want a machine that has the whole build plate moving in X, Y and Z so as to have the extrusion nozzle(s) fixed to a non-moving support structure. This will allow any size & weight of extruder, hotend and filament cooling arrangement, and modifying those things (which I consider the most critical components for achieving good print quality) will be far easier than any arrangement that has a moving nozzle. That fixed extruder gantry could be made in a Meccano-like way that makes it easy to change between widely different arrangements - even swapping the extruder for a laser cutter, router, engraver, pen or some other tool or instrument. In fact the tool gantry could bolt onto the XYZ mechanism in a way that makes swapping the entire gantry easy.

Dave

|

Re: Threaded Z rod on twin towers January 07, 2015 10:17AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

I have now pretty much decided that I want a machine that has the whole build plate moving in X, Y and Z so as to have the extrusion nozzle(s) fixed to a non-moving support structure.

How about a Stewart platform then?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Threaded Z rod on twin towers January 07, 2015 10:45AM |

Registered: 9 years ago Posts: 32 |

Quote

dmould

Just like my succession of quadcopters, designing and making the machine will be a hobby in its own right rather than just a means to an end, so farming out lots of the fabrication will defeat the purpose. (I probably happily spend at least an hour designing and building a quadcopter for every minute I spend flying it).

Another multicopter builder/flyer! That's nice. Have you printed anything for the copters? One of the reasons I bought a 3d printer was to be able to print parts for my multicopter builds. Would also be fun to create entirely printed copter.

Sorry for the OT.

|

Re: Threaded Z rod on twin towers January 07, 2015 11:51AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Vizual54

Quote

dmould

Just like my succession of quadcopters, designing and making the machine will be a hobby in its own right rather than just a means to an end, so farming out lots of the fabrication will defeat the purpose. (I probably happily spend at least an hour designing and building a quadcopter for every minute I spend flying it).

Another multicopter builder/flyer! That's nice. Have you printed anything for the copters? One of the reasons I bought a 3d printer was to be able to print parts for my multicopter builds. Would also be fun to create entirely printed copter.

Sorry for the OT.

I am presently building my 9th quadcopter design, all but one has the entire frame and body plus component mounts printed except for the arms, which are aluminium extrusions (I've used round, box and U section). They are all moderately large copters (around 1.5Kg all-up) with FPV cameras/transmitters. I re-use the same motors and electronics for all, and a 5AH 4 cell Lipo gives about 15 minutes flying time on average. For my last-but-1 design I tried printed arms, but while plenty strong enough to support the copter they twisted too easily and made the copter unstable. All designed with OpenScad, which I've had fun learning.

Dave

|

Re: Threaded Z rod on twin towers January 07, 2015 12:29PM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Quote

dmould

I have now pretty much decided that I want a machine that has the whole build plate moving in X, Y and Z so as to have the extrusion nozzle(s) fixed to a non-moving support structure.

How about a Stewart platform then?

I had to look that up - good grief no! That looks just as problematic as a delta design (but just as fun to watch in action), and using 6 motors to get XYZ seems excessive. I will however keep it in mind for when I build a flight simulator (after I retire).

I think I'll play safe and start with a more conventional XY table (maybe CoreXY) that is then mounted on a platform driven up and down by 3 or 4 screw jacks, (which can also be used for bed-levelling). The jacks will obviously need to be driven together, and the easiest way to achieve that is probably to fit a timing belt around them and drive the belt from a single motor. That will allow me to design, build and test the XY table and the Z platform as separate and completely standalone parts, followed by the static tool gantry, and lastly the extruder/hotend assembly. Re-design of any part that does not perform well could then be achieved with no need to modify the other 2 parts in any way.

Dave

|

Re: Threaded Z rod on twin towers January 07, 2015 02:41PM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

I had to look that up - good grief no!

[www.youtube.com]

Looks like they mounted the print head on the Stewart platform and kept the bed fixed, instead of the other way round. Unlike a delta, the Stewart platform does not need stiff parallel rods and a lightweight extruder. So multiple extruders should be no problem with this arrangement.

OTOH, 2 of the extra 3 degrees of freedom of a bed on a Stewart platform would be good for printing overhangs.

I guess this gives me my next challenge after I finish my current work on adding Delta support to RepRapFirmware!

Edited 1 time(s). Last edit at 01/07/2015 02:42PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Threaded Z rod on twin towers January 07, 2015 04:30PM |

Registered: 10 years ago Posts: 14,672 |

btw I think Stewart platforms may be the way forward for 3D printers. What's needed is a low-cost design for a stepper-motor-driven linear actuator, cheap enough to afford 6 of them. Or possibly a design using a linear motor (I know something about these from way back) along with position-sensing feedback. The rest of the printer construction would be fairly trivial, just one or more hot ends and extruder drives to an existing design, and a solid frame.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Threaded Z rod on twin towers January 08, 2015 08:52AM |

Registered: 10 years ago Posts: 2,472 |

I cannot agree that a Stewart platform (or delta) is the best for normal FFF printing. I really cannot see any advantages whatsoever over a conventional XYZ arrangement, and there are several significant disadvantages:

1) Speed - Getting linear jacks that have both positional precision and high speed is possible but either expensive or difficult. The YouTube video DC42 links shows how slow a stepper + screw jack arrangement is. My prints average around 3 hours or so (some take more than 6 hours), and having a maximum speed of a fraction of what I can presently achieve would be a huge backward step.

2) Fabrication - For a DIY build the mechanics are more difficult to fabricate and need tighter tolerances. When the mechanics are out of adjustment or sloppy it is probably more difficult to diagnose where the problem is from the print defects. Less of an issue for a mass-produced commercial machine where the parts can be made with expensive industrial machines and bespoke punches and moulds, and assembly can be aided by having custom jigs and tools.

3) Precision - the amount the platform moves per unit move of the jacks differs over the build area. Which means that the step size and precision (amount of slop/backlash etc) of the jacks must be better than a similar precision XY table in order to accommodate the worst case.

I can see the advantages of a Stewart platform for specialist prints (printing on a non-flat surface for example, if you can get or write suitable software), and it looks great for 6-axis milling and other CAM machines, but I really don't see how it helps with FFF printing - though I'll keep an open mind if you want to try to persuade me otherwise!

Dave

1) Speed - Getting linear jacks that have both positional precision and high speed is possible but either expensive or difficult. The YouTube video DC42 links shows how slow a stepper + screw jack arrangement is. My prints average around 3 hours or so (some take more than 6 hours), and having a maximum speed of a fraction of what I can presently achieve would be a huge backward step.

2) Fabrication - For a DIY build the mechanics are more difficult to fabricate and need tighter tolerances. When the mechanics are out of adjustment or sloppy it is probably more difficult to diagnose where the problem is from the print defects. Less of an issue for a mass-produced commercial machine where the parts can be made with expensive industrial machines and bespoke punches and moulds, and assembly can be aided by having custom jigs and tools.

3) Precision - the amount the platform moves per unit move of the jacks differs over the build area. Which means that the step size and precision (amount of slop/backlash etc) of the jacks must be better than a similar precision XY table in order to accommodate the worst case.

I can see the advantages of a Stewart platform for specialist prints (printing on a non-flat surface for example, if you can get or write suitable software), and it looks great for 6-axis milling and other CAM machines, but I really don't see how it helps with FFF printing - though I'll keep an open mind if you want to try to persuade me otherwise!

Dave

|

Re: Threaded Z rod on twin towers February 08, 2015 05:04AM |

Registered: 10 years ago Posts: 327 |

I have made a start with the design of the twin towers, but I am still trying to figure out the best way to mount the X axis.

I have been using the bed design for the best part of a year now, and it works great, the only changes that I am going to make are...

For the X axis I am thinking of trying to incorporate mini v wheels, running on the profile and do away with the bearings completely. I also want to try and mount the extruder on the top cross piece along with a spool holder.

I'll try and keep this thread updated with the design progress. Any suggestions are always welcome.

Regards,

Les

Pointy's Things

Pointy's Blog

I have been using the bed design for the best part of a year now, and it works great, the only changes that I am going to make are...

- Beef up the platform from 2mm thick aluminium to 4mm.

- Bolt the frame together directly, rather than use the corner brackets.

For the X axis I am thinking of trying to incorporate mini v wheels, running on the profile and do away with the bearings completely. I also want to try and mount the extruder on the top cross piece along with a spool holder.

I'll try and keep this thread updated with the design progress. Any suggestions are always welcome.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Threaded Z rod on twin towers February 08, 2015 04:57PM |

Registered: 9 years ago Posts: 102 |

Quote

dc42

Dave, have you considered building a delta, or a CoreXY machine?

How does a delta compare concering print quality and speed to the ormerod?

I thought your firmware does support deltas by now with the 1.0 release?

I am currently in thinking about building a delta as i want to build large pieces about 60cm+ height

and i guess a moving bed is bad for such great object heights.

|

Re: Threaded Z rod on twin towers February 08, 2015 05:36PM |

Registered: 10 years ago Posts: 14,672 |

Quote

tstone

How does a delta compare concering print quality and speed to the ormerod?

The delta printer I have is a Mini Kossel, built from a kit supplied by Think3DPrint3D. I upgraded it to Duet electronics - and yes, my fork of RepRapFirmware supports deltas as of release 1.0.

Overall, I am very impressed by it. It seems very stable. With the Ormerod, I have to adjust the bed support screws to re-level the bed from time to time, especially after moving it. I also have to remember to lubricate the threaded rod occasionally. With the Mini Kossel, I don't have to do anything. Since I implemented auto calibration for deltas in the Duet firmware a few days ago, recalibration (if I ever need to do it) is trivial. The Mini Kossel also takes up much less desk space than the Ormerod, in part because of the fixed bed. It's a lot taller, but that doesn't matter to me.

I haven't done very many prints on the Mini Kossel, but the tests prints I do (Escher lizard and hollow dodecahedron) are at least as good as the Ormerod.

As for speed, the speed I use is limited by the print quality I want on both machines. I have the Duet firmware for the Mini Kossel working up to 500mm/sec for non-printing moves - and of course this is in the Z axis as well as the XY axes (unlike the Ormerod).

The main advantages of the Ormerod are the larger build area (210x200mm vs. 170mm diameter for the MK), and my Ormerod is dual nozzle. Many of my recent prints (e.g. PanelDue enclosures) won't fit on the Mini Kossel. But I am considering getting some longer extrusions and a larger heated bed to increase the build area, also perhaps an E3D Chimera dual nozzle.

I'd prefer to have a better Z probe than the one currently on the Mini Kossel, and I'm considering either a variant of my differential LED board, or a solenoid-operated mechanical probe - an idea I considered for the Ormerod, but rejected due to lack of space, given the need for the probe to be in line (in the X direction) with the nozzle.

Edited 1 time(s). Last edit at 02/08/2015 05:40PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Threaded Z rod on twin towers February 09, 2015 04:24AM |

Registered: 9 years ago Posts: 1,159 |

DAve

Have you considered the Cyclops rather than the Chimera Having just one nozzle (So no Extruder offset required) looks like it may be the preferred option to me one thermistor one heater and 2 Bowden tubes seems like a simpler and lighter solution so should get a little more speed out of it.

Just a Thought.

(This of course assumes that your Firmware supports mixing extruders and I seem to remembers seeing somewhere that it does?)

Doug

Have you considered the Cyclops rather than the Chimera Having just one nozzle (So no Extruder offset required) looks like it may be the preferred option to me one thermistor one heater and 2 Bowden tubes seems like a simpler and lighter solution so should get a little more speed out of it.

Just a Thought.

(This of course assumes that your Firmware supports mixing extruders and I seem to remembers seeing somewhere that it does?)

Doug

|

Re: Threaded Z rod on twin towers February 09, 2015 08:36AM |

Registered: 10 years ago Posts: 14,672 |

The E3D website warns that the Cyclops is still experimental. Also, I am aware that RepRapPro had problems with the filament-switching hot end they built (obviously not the same design). So I think I'll wait until this technology is a little more mature before I try it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Threaded Z rod on twin towers February 09, 2015 01:53PM |

Registered: 10 years ago Posts: 2,472 |

One downside of a mixing nozzle is that all filaments must work at the same temperature. That is no problem if all you are needing is multi-coloured prints, but is a major shortcoming if you are mixing materials (maybe using a soluble material for support, or incorporating flexible gaskets etc). It also means that you have to have a mechanism for purging the nozzle between head changes if you don't want a section of the print having mixed filaments.

Dave

Dave

Sorry, only registered users may post in this forum.