First print with ABS - printbed barely reaching 110°C

Posted by tstone

|

First print with ABS - printbed barely reaching 110°C January 12, 2015 06:45PM |

Registered: 9 years ago Posts: 102 |

I just did my first print with ABS. While the nobs of my print are slightly off by 0.1mm i would say that beeing a first print is still a success :-).

I found that 110°C would be a good starting point for the heated bed. However it took nearly an hour to heat up and during print in fell back to 100°C,

probably because the bed was moving and thus cooling off faster?

The heating LED of the board was on all the time.

The hotend remained at 230° as expected.

I moved the printer to the cellar which is about 20° room temperature right now. Thats a little colder than the 21° room temperature in the living room before but i would expect that the heating

bed should keep up with that? Any ideas?

Sidenotes:

As the printer was not to close supervision anymore, i was to chicken to install dc42 experimental new firmware.

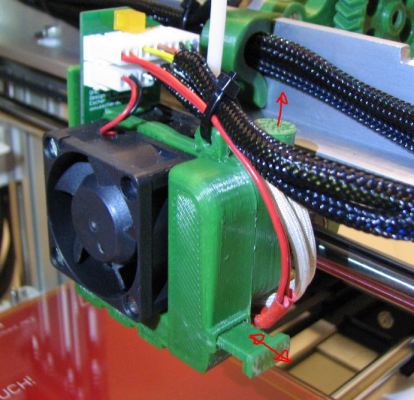

My cooling solution with the flap does not seem to cool to much even with the flap open for full venting, but its probably to early to tell.

The next step will be the mounting of dc42's LED sensor probably combined with my cooling duct...

I found that 110°C would be a good starting point for the heated bed. However it took nearly an hour to heat up and during print in fell back to 100°C,

probably because the bed was moving and thus cooling off faster?

The heating LED of the board was on all the time.

The hotend remained at 230° as expected.

I moved the printer to the cellar which is about 20° room temperature right now. Thats a little colder than the 21° room temperature in the living room before but i would expect that the heating

bed should keep up with that? Any ideas?

Sidenotes:

As the printer was not to close supervision anymore, i was to chicken to install dc42 experimental new firmware.

My cooling solution with the flap does not seem to cool to much even with the flap open for full venting, but its probably to early to tell.

The next step will be the mounting of dc42's LED sensor probably combined with my cooling duct...

|

Re: First print with ABS - printbed barely reaching 110°C January 12, 2015 07:09PM |

Registered: 10 years ago Posts: 665 |

If you have an Ormerod 1, then you're probably not getting true 12V at the heated bed connectors. That's why I decided to get rid of my original ATX PSU and replaced it with a 12V 300W LED PSU with adjustable voltage output. Now I drive my Duet at 13.5V and I've been quite happy with this configuration, I have no problems reaching 120°C within reasonable time. There is a thread somewhere on this forum describing how to increase the output voltage of the stock PSU, but I'd rather be careful with those hacks.

|

Re: First print with ABS - printbed barely reaching 110°C January 13, 2015 01:13AM |

Registered: 9 years ago Posts: 92 |

|

Re: First print with ABS - printbed barely reaching 110°C January 13, 2015 03:47AM |

Registered: 9 years ago Posts: 395 |

For abs i suggest a 3mm Carbon fibre bed plate with the hair spray and temperaturs be tweet 60 and 80.

This works vero well for me with smart abs and maybe also with regalar abs.

Just want till the plate is cold or rinse the plate in water to get the part detatched.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

This works vero well for me with smart abs and maybe also with regalar abs.

Just want till the plate is cold or rinse the plate in water to get the part detatched.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: First print with ABS - printbed barely reaching 110°C January 13, 2015 08:47AM |

Registered: 10 years ago Posts: 2,472 |

I have done the same as zombiepantslol and replaced my PSU with a 12V LED supply that has a voltage adjustment. I run at 14V and it takes about 7 minutes to heat the bed to 110 degrees. Lots of such PSUs available on ebay for around £20. e.g [www.ebay.co.uk] (Use the "select" drop down to find the 12V 30A model).

Note that you will have to get suitable mains and 12V connectors and print some sort of housing to cover the exposed terminals - there are several designs on other threads in this forum.

Dave

Edited 1 time(s). Last edit at 01/13/2015 08:48AM by dmould.

Note that you will have to get suitable mains and 12V connectors and print some sort of housing to cover the exposed terminals - there are several designs on other threads in this forum.

Dave

Edited 1 time(s). Last edit at 01/13/2015 08:48AM by dmould.

|

Re: First print with ABS - printbed barely reaching 110°C January 13, 2015 10:20AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

Note that you will have to get suitable mains and 12V connectors and print some sort of housing to cover the exposed terminals

e.g. [www.thingiverse.com]

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First print with ABS - printbed barely reaching 110°C January 13, 2015 03:12PM |

Registered: 9 years ago Posts: 102 |

|

Re: First print with ABS - printbed barely reaching 110°C January 13, 2015 04:37PM |

Registered: 10 years ago Posts: 14,672 |

You can speed up the initial heating of the heated bed by putting a heat-insulating cover on it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First print with ABS - printbed barely reaching 110°C January 14, 2015 02:38AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

You can speed up the initial heating of the heated bed by putting a heat-insulating cover on it.

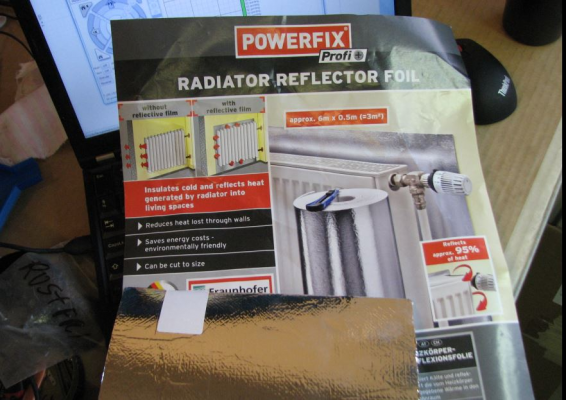

..and better isolating under the bed will also help a lot, I use this stuff, reflective side against the heatbed, sealed with Kapton tape around the corners

This is with the original Alpine ATX - 11,2V measure point here:

heat up time with the original cardboard isolator used to cover the bed:

room temperature 15C, free from draft

11:38 - 15C

11:45 - 100C

11:49 - 110C

Erik

|

Re: First print with ABS - printbed barely reaching 110°C January 14, 2015 02:48AM |

Registered: 9 years ago Posts: 92 |

|

Re: First print with ABS - printbed barely reaching 110°C January 14, 2015 03:08AM |

Registered: 9 years ago Posts: 102 |

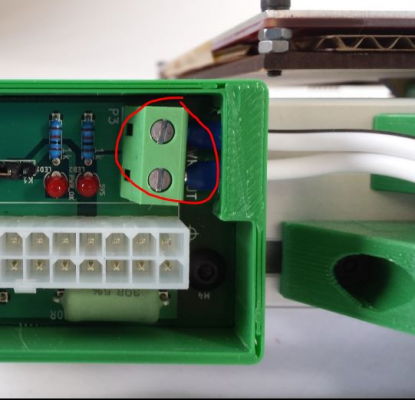

I soldered the cables directly to the screws at the bottom. But looking at Eriks nice Photos i see that he has there multi pin connectors on his bed.

I wonder if thats a better solution.

Resoldering was not the ticket: It took about half an hour to heat up to 110° and then again dropped temperature while printing to about 98° with continous heating on.

I wonder if thats a better solution.

Resoldering was not the ticket: It took about half an hour to heat up to 110° and then again dropped temperature while printing to about 98° with continous heating on.

|

Re: First print with ABS - printbed barely reaching 110°C January 14, 2015 04:11AM |

Registered: 9 years ago Posts: 92 |

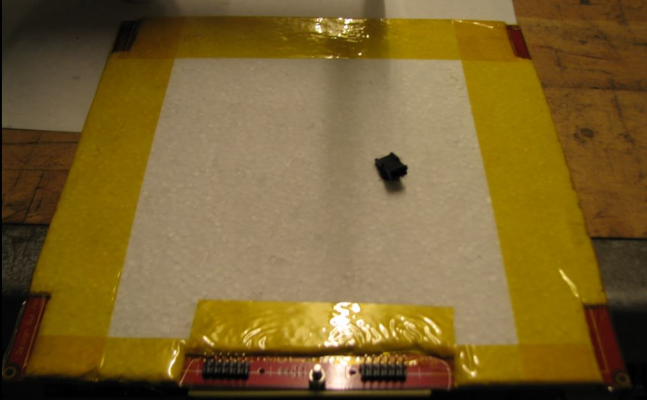

I think it is the screw connectors that are often the problem on the Ormerod 2.(several people have had their beds burn out) . I removed the screws completely and pushed the wire through from the bottom, then soldered the wires directly to the pads on top of the heat bed. Although this improved my heatbed performance, I'm still not sure if it will get to ABS temperature. I will test tonight and let you know if I have the same problem you have.

Not a great photo but you get the idea.

Edited 1 time(s). Last edit at 01/14/2015 04:17AM by jamesf.

Not a great photo but you get the idea.

Edited 1 time(s). Last edit at 01/14/2015 04:17AM by jamesf.

|

Re: First print with ABS - printbed barely reaching 110°C January 18, 2015 05:09PM |

Registered: 9 years ago Posts: 102 |

Just a short update to help people having similar problems: I upped the voltage of the power supply a little over 13.5 V and now i get above 116° C for the bed which helped to get some good prints with my venting mod (flap closed). Unfortunatly that does not fit with the ir sensor update from dc42 which i mounted yesterday. After that i could not print ABS anymore. I guess due to to much cooling. But printing PLA was pretty good. So i guess i have do redo my venting mod but this time with a servo to have automatic venting control :-)

|

Re: First print with ABS - printbed barely reaching 110°C January 18, 2015 05:47PM |

Registered: 10 years ago Posts: 14,672 |

For ABS printing, you don't want any air blowing on the print. So block off the nozzles at the bottom of the duct, and make a hole or slot in the top of the duct to let the air out. But I guess you already know that, as you did a venting mode to the duct.

Edited 2 time(s). Last edit at 01/18/2015 05:49PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 2 time(s). Last edit at 01/18/2015 05:49PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 07:35AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

For ABS printing, you don't want any air blowing on the print. So block off the nozzles at the bottom of the duct, and make a hole or slot in the top of the duct to let the air out. But I guess you already know that, as you did a venting mode to the duct.

Yes, that was a very good mod of yours for ABS that I applied about a year ago and have been using ever since. However I think that some cooling air would be beneficial when printing bridges or overhangs, so one day I really must get around to making a Duet controlled cooling system. OTOH I don't think there is any slicing software that will automatically turn cooling on for overhangs, so perhaps I may as well go for manual control along the lines "tstone" designed.

Dave

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 07:49AM |

Registered: 9 years ago Posts: 102 |

Hi Dave[id]Quote

dmould

Quote

dc42

For ABS printing, you don't want any air blowing on the print. So block off the nozzles at the bottom of the duct, and make a hole or slot in the top of the duct to let the air out. But I guess you already know that, as you did a venting mode to the duct.

Yes, that was a very good mod of yours for ABS that I applied about a year ago and have been using ever since. However I think that some cooling air would be beneficial when printing bridges or overhangs, so one day I really must get around to making a Duet controlled cooling system. OTOH I don't think there is any slicing software that will automatically turn cooling on for overhangs, so perhaps I may as well go for manual control along the lines "tstone" designed.

Dave

I have found a lightweight servo of 2g which should have enough power to drive the venting flap automatically.

One of my next planned tasks is to integrate that into a new venting duct which fits to the IR sensor of David(dc42) and

has a servo controlled venting flap.

I think that at least in the developement version of slic3r is a cooling control implemented. So the only missing stuff

is controlling the servo from the firmware according to the cooling settings from slic3r. Controlling a servo from the duet

shouldn't be to hard, if it hasn't been done already?

Concering Dave's (dmould) question in another thread about the viablity of my venting mod for ABS printing: Yes it works pretty well. I was able to do prints with my 115° hot printbed with a small brim of 5mm. I could not print with dc42

fan i mounted together with his IR mod.

I think there are weight advantages in combining one cooling fan for the hotend and the workpiece combined with a

ultra leightweight servo compared to a two fan solution.

Tim

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 08:36AM |

Registered: 10 years ago Posts: 665 |

Quote

tstone

I think there are weight advantages in combining one cooling fan for the hotend and the workpiece combined with a

ultra leightweight servo compared to a two fan solution.

Interesting idea, I was thinking of something similar (I intended to use e-magnets though), but then settled for a 4-pin PWM fan. I've been printing abs ever since I got my Ormerod and since I made the fan controllable, I haven't had a lot of problems with parts warping. Plus you can use the fan sliders and RPM readings dc42 and I provide on our Web interfaces. But if you decide to go with a servo (I guess you could use either the ATX power pin with a proper FET or perhaps even the FAN0 pin for this purpose), please post some pictures!

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 08:42AM |

Registered: 10 years ago Posts: 2,472 |

Quote

tstone

I have found a lightweight servo of 2g which should have enough power to drive the venting flap automatically.

<...>

I think that at least in the developement version of slic3r is a cooling control implemented. So the only missing stuff

is controlling the servo from the firmware according to the cooling settings from slic3r. Controlling a servo from the duet

shouldn't be to hard, if it hasn't been done already?

Tim

A solenoid would probably be easier to implement than a servo. The Duet's 12V cooling fan output is implemented in firmware but not used in the standard Ormerod. That provides a PWM output for speed control, but so long as Slicer is set up to set the fan to be either off or 100% it will act as a simple on/off output to drive a 12V solenoid directly (put a diode across the solenoid to protect against back-EMF). RS have a variety of both push and pull action 12V solenoids - weight should not be too critical.

Dave

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 11:28AM |

Registered: 10 years ago Posts: 1,230 |

Up to now I have used johneato's brilliant mod of the original heat sink duct - I do remember to change the valves between PLA and ABS prints most of times, but if not I try to catch the hotend end and do it on the fly without loosing steps - its great fun!

Did open the middle slot a bit to get more cooling to the nozzle:

johneato - Control air to the nozzles

[forums.reprap.org]

Erik

Did open the middle slot a bit to get more cooling to the nozzle:

johneato - Control air to the nozzles

[forums.reprap.org]

Erik

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 11:38AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 12:09PM |

Registered: 10 years ago Posts: 2,472 |

Quote

ormerod168

Quote

jamesf

Room temperature 15 C Erik?

I see no reason to heat up the whole house when I can regulate my temperature more efficiently and sustainable by adding hot coffee (lots of coffee!) to my internal central heating system ;-)

Erik

I don't like to have to wear the thermal insulation necessary to keep my internal CH system efficient, so prefer at least 20 degC - 25 is ideal for me.

Dave

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 01:32PM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

A solenoid would probably be easier to implement than a servo. The Duet's 12V cooling fan output is implemented in firmware but not used in the standard Ormerod. That provides a PWM output for speed control, but so long as Slicer is set up to set the fan to be either off or 100% it will act as a simple on/off output to drive a 12V solenoid directly (put a diode across the solenoid to protect against back-EMF). RS have a variety of both push and pull action 12V solenoids - weight should not be too critical.

If you do use a solenoid, don't forget to put a flyback diode in parallel with it.

My experience with sourcing solenoids when I was looking at a solenoid-activated Z probe was that they are much cheaper when sourced from China. Also, the suitable solenoid that I was able to source in the UK (from Farnell I think) did not include a spring, whereas the Chinese ones did. The spring was going to cost more than £2 to have manufactured as it was a standard design but not an off-the-shelf item,.

Edited 1 time(s). Last edit at 01/19/2015 01:35PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 03:41PM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Quote

dmould

A solenoid would probably be easier to implement than a servo. The Duet's 12V cooling fan output is implemented in firmware but not used in the standard Ormerod. That provides a PWM output for speed control, but so long as Slicer is set up to set the fan to be either off or 100% it will act as a simple on/off output to drive a 12V solenoid directly (put a diode across the solenoid to protect against back-EMF). RS have a variety of both push and pull action 12V solenoids - weight should not be too critical.

If you do use a solenoid, don't forget to put a flyback diode in parallel with it.

My experience with sourcing solenoids when I was looking at a solenoid-activated Z probe was that they are much cheaper when sourced from China. Also, the suitable solenoid that I was able to source in the UK (from Farnell I think) did not include a spring, whereas the Chinese ones did. The spring was going to cost more than £2 to have manufactured as it was a standard design but not an off-the-shelf item,.

Sourcing from China is almost always significantly cheaper than getting it locally (so long as UK customs do not decide to charge you duty) - if you are prepared to wait 3-4 weeks at least and are OK with the risk of getting something that is not fit for purpose (I've mostly had really good cheap stuff from China but on rare occasions have received some really bad quality product). UK SOGA does not cover China. I gave RS as an example because they have lots of different types of solenoid, but are also an expensive place to buy from - the average cost of a solenoid from RS is around £30 and you could probably get the same at less than half the price elsewhere. Price is not always the most important factor though.

Don't overlook the possibility of using a simple rubber band instead of a spring. Sure, it will probably need replacing every year or so, but for this type of application that's not a big deal. I appreciate that it could not be used in a high temperature location.

Dave

|

Re: First print with ABS - printbed barely reaching 110°C January 19, 2015 07:03PM |

Registered: 9 years ago Posts: 102 |

Hi ErikQuote

ormerod168

Up to now I have used johneato's brilliant mod of the original heat sink duct

Thanks for the link. It looks quite good but i want to use a larger fan, as the small one has a really annoying sound and also i can use the extra space to cool

the hotend with a seperate airstream than the venting of the workpiece. I would also like to have a flap thats easier to control with a servo.

I think i will aim for even larger cooling openings to have cooling maximised as this can be reduced with the the flap of my last revision.

I am not so fond of a selenoid and also a servo is a good reason to start firmware hacking :-)

Tim

|

Re: First print with ABS - printbed barely reaching 110°C January 20, 2015 04:50AM |

Registered: 10 years ago Posts: 1,230 |

Quote

tstone

....I would also like to have a flap thats easier to control with a servo.

Hi Tim,

Me too, its a bit risky to do it on the fly...but I've been thinking about the tube/aquarium pump cooling solution for a long time, did not want to change anything on a perfectly working printer (not being able to print - oh the horror!), but now that I have 2 printers (thanks Mario), I will allow myself to do a bit of modding an go down that road with my original ormerod nr. 168

Quote

I think i will aim for even larger cooling openings to have cooling maximised as this can be reduced with the the flap of my last revision.

Yes, those fans are made for moving air at low pressure, opening the slots will give you more air where needed instead of backwash

Erik

|

Re: First print with ABS - printbed barely reaching 110°C January 20, 2015 04:59AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: First print with ABS - printbed barely reaching 110°C January 25, 2015 06:30PM |

Registered: 9 years ago Posts: 102 |

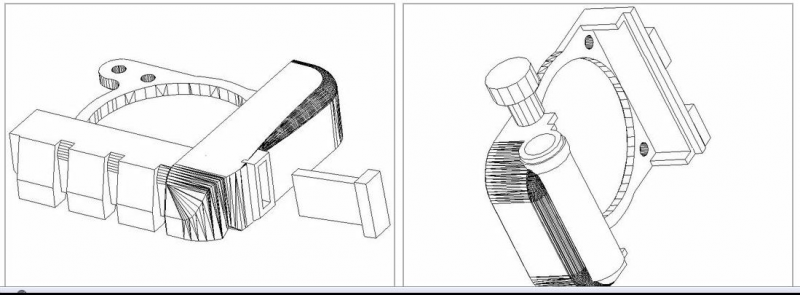

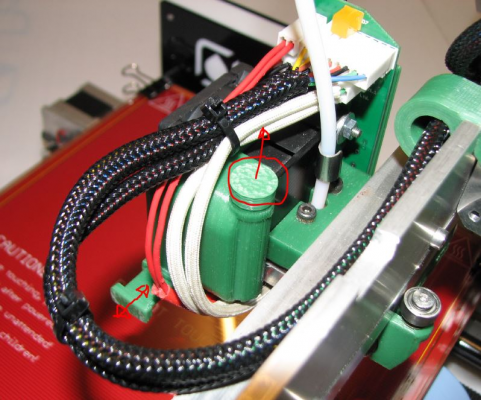

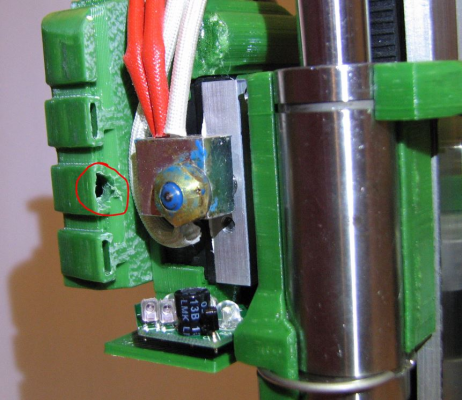

I just got around taking a picture of the servo i am planning to use to control the flap. The fan is the original ormerod 2 hotend fan.

(its not a fan, its a nuisance):

Something completly different:

I have the impression that Erik is only heating with his printing bed, so i would recommend printing ABS ;-).

(its not a fan, its a nuisance):

Something completly different:

I have the impression that Erik is only heating with his printing bed, so i would recommend printing ABS ;-).

|

Re: First print with ABS - printbed barely reaching 110°C January 26, 2015 08:00AM |

Registered: 10 years ago Posts: 2,472 |

If that servo is designed for model R/C systems, it will need 5V-6V DC power (+ to red & - to brown wire), and its position is controlled by the width of control pulses between 1mS and 2mS (to the yellow wire). The control signal is not available from the Duet, so you will need some additional electronics, and also add wiring to tap off the Duet's 5V supply. It is possible that the Duet could supply the control pulses directly (maybe to an unused GPIO pin), but that would require modification of the firmware.

Dave

Dave

|

Re: First print with ABS - printbed barely reaching 110°C January 26, 2015 10:39AM |

Registered: 9 years ago Posts: 102 |

|

Re: First print with ABS - printbed barely reaching 110°C January 26, 2015 01:26PM |

Registered: 10 years ago Posts: 2,472 |

Quote

tstone

Hi Dave

I am fully aware that this needs firmware modifications, thats where the fun starts, right :-).

Tim

Great, if you are into doing that - ISTM that an R/C servo output module might come in handy for all sorts of other things as well, so maybe keep your additions reasonably flexible :-)

Dave

Sorry, only registered users may post in this forum.