Fila Flex :-(

Posted by redblunt

|

Fila Flex :-( February 21, 2015 07:26AM |

Registered: 10 years ago Posts: 112 |

Hey guys,

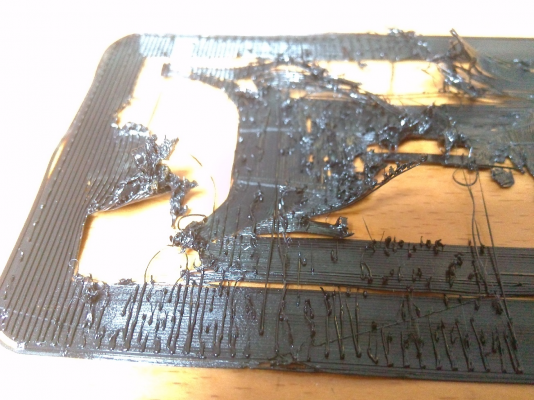

i made good experiences with Ninja Flex, now i bought a huge pack of FilaFlex

and its really anoying. I like to print a case for my cellphone but the nozzle keeps

on ripping filament out like pulling it with it so i never came passed the first layer.

im printing at 0.2 first layer and 0.3 other layers. lifting the nozzle only caused

blobs on the plate like the hot end saying: " i need to push harder against the plate"

temperature is 205°C bed 0 and i used and did not use a 120mm extra fan

any ideas?

sincierly red

Red Ormerod No. 281

Mods:

-My Bedsupport Mk2

-My upper z mount

-Davek0974s Aluminium X-Rib

-iamburnys Z Gears

-Form232-teks Cthulhu cooling ductg

-MasonStonehenges spring-loaded extruder

RepRapFirmware-0.78k-dc42,

web interface 0.99, Win7

i made good experiences with Ninja Flex, now i bought a huge pack of FilaFlex

and its really anoying. I like to print a case for my cellphone but the nozzle keeps

on ripping filament out like pulling it with it so i never came passed the first layer.

im printing at 0.2 first layer and 0.3 other layers. lifting the nozzle only caused

blobs on the plate like the hot end saying: " i need to push harder against the plate"

temperature is 205°C bed 0 and i used and did not use a 120mm extra fan

any ideas?

sincierly red

Red Ormerod No. 281

Mods:

-My Bedsupport Mk2

-My upper z mount

-Davek0974s Aluminium X-Rib

-iamburnys Z Gears

-Form232-teks Cthulhu cooling ductg

-MasonStonehenges spring-loaded extruder

RepRapFirmware-0.78k-dc42,

web interface 0.99, Win7

|

Re: Fila Flex :-( February 21, 2015 09:05AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Fila Flex :-( February 21, 2015 09:29AM |

Registered: 10 years ago Posts: 112 |

|

Re: Fila Flex :-( February 21, 2015 11:03AM |

Registered: 10 years ago Posts: 112 |

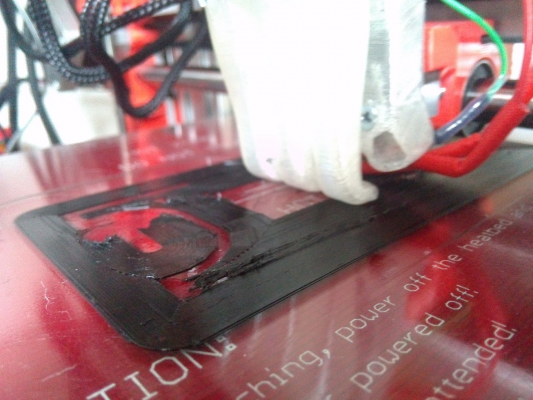

printing with the speed of 5mm/s was better still did not finish

and on the second layer it startet to "string" again

Edited 1 time(s). Last edit at 02/21/2015 11:03AM by redblunt.

and on the second layer it startet to "string" again

Edited 1 time(s). Last edit at 02/21/2015 11:03AM by redblunt.

|

Re: Fila Flex :-( February 21, 2015 04:50PM |

Registered: 9 years ago Posts: 191 |

My experience is this:

The Bowden tube design can only create so much push-force with a bendy filament. To get sufficient amount of plastic through the nozzle the speed has to be lowered. But also the nozzle temp raised to further lower the viscosity of the plastic.

My advise is to raise the temp to the filament spec. max or even higher. This will give you better adhesion to the bed by stickier plastic and greater force pressing against the bed.

Fila flex is specified to be printed at 220-230°C.

Give it a try and post you results, good luck!

The Bowden tube design can only create so much push-force with a bendy filament. To get sufficient amount of plastic through the nozzle the speed has to be lowered. But also the nozzle temp raised to further lower the viscosity of the plastic.

My advise is to raise the temp to the filament spec. max or even higher. This will give you better adhesion to the bed by stickier plastic and greater force pressing against the bed.

Fila flex is specified to be printed at 220-230°C.

Give it a try and post you results, good luck!

|

Re: Fila Flex :-( February 23, 2015 01:31PM |

Registered: 10 years ago Posts: 112 |

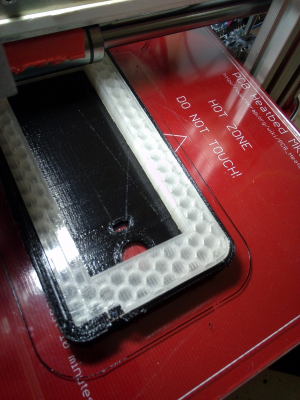

hi guys

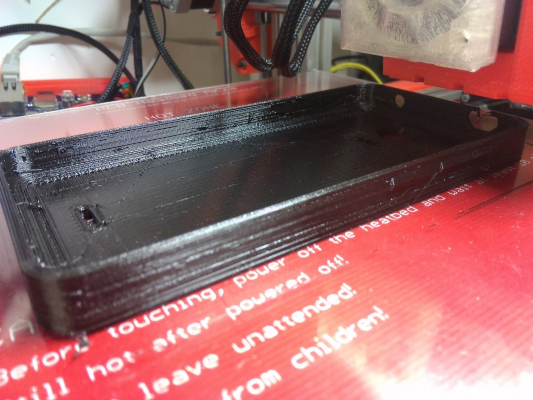

after close to 24hours of printing i can give back some report

i attached the original fanduct and set my temperature to 230°C

noticing that the hotend was loose and dangeling around it also

was off by 30° to the z and x axis. the last print worked well

till of course at the 2nd last layer the extruder clogged and i

had to do a "hot knife" finish. i will print again neyt weekend.

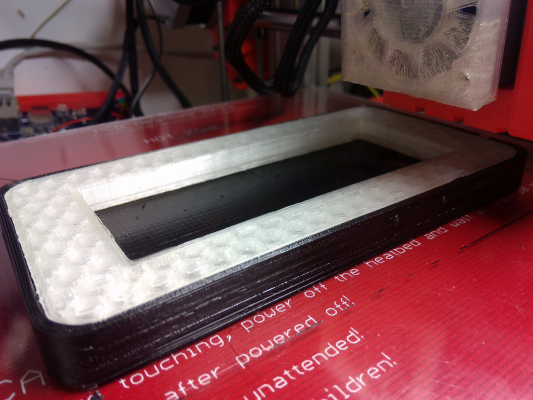

60° Overhang no problem

i used some preprinted support out of pva wich i coted 10 times

with hair spray, i also split the gcode in to 2 files so i had some time

to clean out the filament drips on it to make my support fit in.

the top solid infill was set to 85% wich made a real nice finish.

still the material is very drippy.

does anyone know if it is possible

to set a retract and lift on every travel-move(non printing)? (using slic3r)

i noticed on a move that lasts more than like a half second

the nozzle drips about 5mm filament. this produces a lot of

blops.

Edited 1 time(s). Last edit at 02/23/2015 01:32PM by redblunt.

after close to 24hours of printing i can give back some report

i attached the original fanduct and set my temperature to 230°C

noticing that the hotend was loose and dangeling around it also

was off by 30° to the z and x axis. the last print worked well

till of course at the 2nd last layer the extruder clogged and i

had to do a "hot knife" finish. i will print again neyt weekend.

60° Overhang no problem

i used some preprinted support out of pva wich i coted 10 times

with hair spray, i also split the gcode in to 2 files so i had some time

to clean out the filament drips on it to make my support fit in.

the top solid infill was set to 85% wich made a real nice finish.

still the material is very drippy.

does anyone know if it is possible

to set a retract and lift on every travel-move(non printing)? (using slic3r)

i noticed on a move that lasts more than like a half second

the nozzle drips about 5mm filament. this produces a lot of

blops.

Edited 1 time(s). Last edit at 02/23/2015 01:32PM by redblunt.

|

Re: Fila Flex :-( February 24, 2015 08:11AM |

Registered: 9 years ago Posts: 177 |

Quote

redblunt

does anyone know if it is possible

to set a retract and lift on every travel-move(non printing)? (using slic3r)

i noticed on a move that lasts more than like a half second

the nozzle drips about 5mm filament. this produces a lot of

blops.

You'll need to be in advanced mode for slic3r to show some of these settings (I think), but there is a value called 'Minimum travel after retraction' basically this is the threshold for what non-print distance triggers a retraction. I think if you set this to 0mm, all non-print moves would retract.

You might want to look at some of these other settings in the Slic3r manual under the 'fighting Ooze' section. Things like 'avoid crossing perimeters' (will cause nozzle travel to stay 'inside' the print, so most Ooze will be inside the print and not visible) and 'wipe before retract' might also help. If you're still seeing a lot of Ooze even with retractions, you might increase the retraction amount (although retracting too much can also cause problems)

[manual.slic3r.org]

All of these slic3r settings will make the print and g-code generation take longer (and typically most filaments don't need this), but if you're printing with a filament that Oozes a lot and quality of the print is your main concern, the increased print time should be worth it.

|

Re: Fila Flex :-( February 25, 2015 05:25PM |

Registered: 10 years ago Posts: 112 |

|

Re: Fila Flex :-( February 25, 2015 08:26PM |

Registered: 9 years ago Posts: 177 |

Quote

redblunt

oh i totaly missunderstood "minimum travel after..."

ty for clearing it up for me

i will change some settings and a little of my object

print and the report back

I think that the setting is poorly named, but I think the reasoning behind it is the 'minimum travel after a retraction has occurred, otherwise a retraction won't happen'

If you haven't given the slic3r manuel a read through, I'd recommend it. I've learned a lot about optimizing slic3r settings.

Please post what settings you find work the best, I'm interested to see how good you can get the print quality.

Sorry, only registered users may post in this forum.