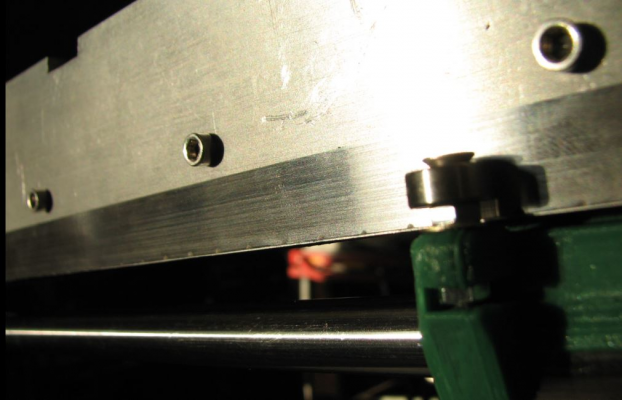

Bearing runners wear.

Posted by coen4d

|

Bearing runners wear. March 11, 2015 07:28PM |

Registered: 9 years ago Posts: 6 |

|

Re: Bearing runners wear. March 12, 2015 02:38AM |

Registered: 10 years ago Posts: 776 |

Nothing here, done a fair bit of printing. I did supply some steel shim tape with my aluminium arms but it's not needed and the bearing does no harm. I don't think there is enough stress to break the surface of the alumnium.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Bearing runners wear. March 12, 2015 04:07AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Davek0974

.. I don't think there is enough stress to break the surface of the alumnium.

I agree - if the bearing run square to the plate, I see some wear from the edge of the bearing on the original acrylic rib, but only on the middle of the rib where the force of the bowden cable was greatest

But if one should worry about wear there is always the hacksaw mod, no need to grind down the flats as I did, just grind of the teeth and glue it to the axis with loctite if alu, superglue if acrylic

Erik

|

Re: Bearing runners wear. March 12, 2015 10:39AM |

Registered: 9 years ago Posts: 6 |

|

Re: Bearing runners wear. March 12, 2015 12:25PM |

Registered: 13 years ago Posts: 1,611 |

|

Re: Bearing runners wear. March 12, 2015 12:42PM |

Registered: 9 years ago Posts: 6 |

|

Re: Bearing runners wear. March 12, 2015 02:04PM |

Registered: 10 years ago Posts: 1,230 |

Quote

coen4d

...I don't suppose there is a similar mod for the extruded tower, or would a saw blade work there to?

As Ian said, no problem with the z-axis, the anodized surface of the aluminium extrusion is very hard - I see no wear after a year+ printing - and if there were it would be very easy to rotate the extrusion 180 degrees and double the lifetime

Erik

|

Re: Bearing runners wear. March 12, 2015 02:15PM |

Registered: 9 years ago Posts: 6 |

|

Re: Bearing runners wear. March 13, 2015 05:51AM |

Registered: 13 years ago Posts: 1,611 |

Basically, aluminium rusts. But aluminium 'rust' is aluminium oxide, which is harder than aluminium, and seals and protects the underlying aluminium. Anodizing aluminium is, effectively, speeding up this process. See [en.wikipedia.org]

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Bearing runners wear. March 13, 2015 11:46AM |

Registered: 9 years ago Posts: 6 |

I did know that the anodized layer is harder than the aluminium, I did not know that this layer can be harder than stainless steel (at least if my understanding is correct : [aluminumsurface.blogspot.nl].

I also did not know that the normal forming "rust" layer is essentially the same.

Thanks for teaching me.

I also did not know that the normal forming "rust" layer is essentially the same.

Thanks for teaching me.

|

Re: Bearing runners wear. March 13, 2015 02:18PM |

Registered: 10 years ago Posts: 2,472 |

Quote

coen4d

I did know that the anodized layer is harder than the aluminium, I did not know that this layer can be harder than stainless steel (at least if my understanding is correct : [aluminumsurface.blogspot.nl].

I also did not know that the normal forming "rust" layer is essentially the same.

Thanks for teaching me.

Yes, the coating is very hard, but also very thin so will wear off with constant rubbing. Going from memory, the anodized coating is different to the aluminium oxide coat that forms naturally in air in that the oxide crystals are closed so the surface does not have "pores". IIUC it is the final operation of the anodizing process wherein the aluminium is placed into boiling water that expands and closes the oxide coating. Also of note is that aluminium oxide is not electrically conductive, so if you need to make electrical contact with an anodised part the anodised coat must be broken or scratched off at the point of contact (a serrated lock washer will do the trick).

Most metal fasteners (including stainless) will form a battery if in contact with wet aluminium, which will lead to galvanic corrosion, turning the aluminium into soft white flakes or powder. This can often be seen on aluminium frame windows around steel screws that are exposed to the weather. Salt water speeds up the process, and you have to be very careful what fasteners to use on aluminium aboard ships (e.g. yachts with aluminium masts), and if clamping aluminium against a different metal you should put electrical insulating material in between.

Liquid mercury does not play well with aluminium - it forms an amalgam in the form of a fragile crystalline "growth," and then the mercury is ejected from the growth and "infects" the next bit of aluminium, so a small drop of mercury can destroy a large aluminium structure over time (see [www.youtube.com]). That's why goods containing liquid mercury are not permitted to be taken by passengers onto an aircraft - a small spillage could result in an entire 747 having to be scrapped!

Dave

Sorry, only registered users may post in this forum.