The stresses of ABS

Posted by Europa

|

The stresses of ABS March 21, 2015 01:58PM |

Registered: 9 years ago Posts: 151 |

I have an Ormerod 2 which I have been very pleased with up until now.

today I have tried to print with ABS but without success, quite apart from all the usual problems people experience with bed adhesion my Ormerod 2 just does not seem to be capable of reaching the necessary settings!

After nearly an hour the bed had finally crept up to 98 degrees, the nozzle reaches the correct temperature but by this time the whole of the printer is so hot, including the power supply, Duet enclosure etc.. that it then behaves unpredictably and fails to respond to commands correctly.

It is as if the ability to print with ABS has been included just to bring it into line with other printers but in fact it is not capable of the task!

I would love to hear from other Ormerod users who have been successful.

Regards,

Brian

today I have tried to print with ABS but without success, quite apart from all the usual problems people experience with bed adhesion my Ormerod 2 just does not seem to be capable of reaching the necessary settings!

After nearly an hour the bed had finally crept up to 98 degrees, the nozzle reaches the correct temperature but by this time the whole of the printer is so hot, including the power supply, Duet enclosure etc.. that it then behaves unpredictably and fails to respond to commands correctly.

It is as if the ability to print with ABS has been included just to bring it into line with other printers but in fact it is not capable of the task!

I would love to hear from other Ormerod users who have been successful.

Regards,

Brian

|

Re: The stresses of ABS March 21, 2015 04:05PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Europa

..After nearly an hour the bed had finally crept up to 98 degrees, the nozzle reaches the correct temperature..

Hi Brian

That do not sound right (have no experience with O2 though) - a Ormerod 1 should should reach 110C in about 10 minutes if you cover the bed with some isolating material, have you measured the voltage?, I have 11.2V at duet in and 11.0V at the heatbed terminals directly

Quote

It is as if the ability to print with ABS has been included just to bring it into line with other printers but in fact it is not capable of the task!

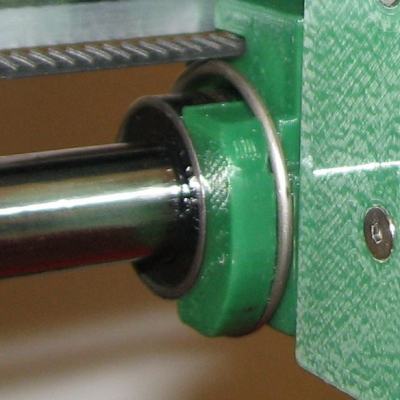

They may have oversold it a bit, but with a bit of luck you will be able to print the hotend parts and x-runner in ABS and then you should have no further problems printing, but with the first print, keep the x-axis way up high away from the heat while the bed heat up - and keep an eye on the x-runner while printing, this one is the first to go (slipping on bearing)

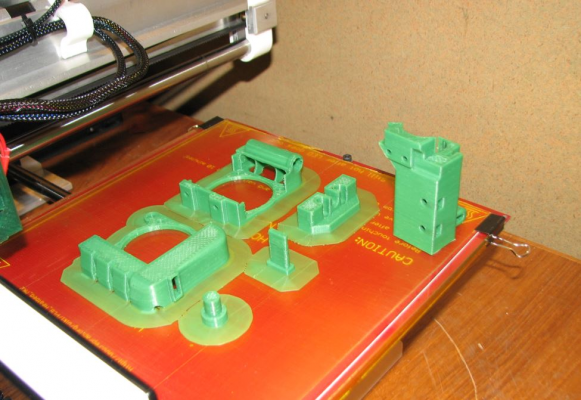

It can be done, these parts was printed with PLA parts mounted:

Quote

I would love to hear from other Ormerod users who have been successful

You just did :-) - I print a lot of ABS and my first prints was to change everything PLA on X-axis to ABS

Erik

|

Re: The stresses of ABS March 21, 2015 04:17PM |

Registered: 10 years ago Posts: 1,230 |

Quote

ormerod168

- and keep an eye on the x-runner while printing, this one is the first to go (slipping on bearing)..

Play it safe, wrap something around the x-runner to keep it from slipping the bearing

Erik

|

Re: The stresses of ABS March 21, 2015 06:10PM |

Registered: 10 years ago Posts: 14,672 |

To print successfully with ABS, you need to get the heated bed up to temperature within a reasonable time. First, check that the connections to the heated bed are tight and in good condition, and showing no signs of scorching. There have been several reports of problems with the heated bed connections on Ormerod 2, which I understand have been resolved in later kits. Next, use an insulating blanket on top of the heated bed to help it get up to temperature, and remove it just before printing. Finally, I believe the power supply on the Ormerod 2 has a voltage adjustment potentiometer, near the low voltage end of the terminal block. You can turn it up to 13V or even a little higher to increase the heating power.

The first things you should print in ABS are some new parts for the Ormerod. RepRapPro has a page on their suite discussing this.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The first things you should print in ABS are some new parts for the Ormerod. RepRapPro has a page on their suite discussing this.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The stresses of ABS March 22, 2015 06:27AM |

Registered: 9 years ago Posts: 151 |

|

Re: The stresses of ABS March 23, 2015 05:24AM |

Registered: 10 years ago Posts: 42 |

Quote

Europa

I would love to hear from other Ormerod users who have been successful.

I have been successful with this without having to play about with the voltage on an Ormerod 1.

Steps were as follows

- Make a wind break, i just made a cardboard one. This protects the heated bed from drafts.

- Make sure the insulating layer underneath the heated bed i has a good seal all the way round.

- Use ABS slurry direct onto the glass.

- As already said, use an insulator on top of the heated bed whilst heating.

- Aim for about 115 deg C for bed temp to start.

- Get hot end up to temp of about 235 deg C.

- Remove insulator from bed.

- Start Print as normal

My bed will only maintain 100 deg C during the print at best. But this was good enough to print the x carriage parts in ABS.

I did unsuccessfully try to heat an enclosure for the printer whilst using the original PLA parts but the X carriage slipped after about 5 layers each time.

Edited 1 time(s). Last edit at 03/23/2015 05:24AM by jy_oc_hx.

|

Re: The stresses of ABS March 23, 2015 09:09AM |

Registered: 10 years ago Posts: 2,472 |

I have printed exclusively in ABS for over a year, and can assure you that the Ormerod is perfectly capable of doing so. You do however need to print the X-carriage and all extruder and hotend parts in as the first prints in ABS before the PLA starts to deform under the heat. I could never get ABS to stick to kapton satisfactorily, so started by using solvent cement on plain glass, which works well. Later changed to my own mix of ABS dissolved in acetone. ABS warps far more readily than PLA, so you also have to take more robust anti-warping measures. Take a look at the threads regarding the trials and tribulations of ABS printing. Buy few litres of acetone - it has several uses with ABS.

Dave

Dave

|

Re: The stresses of ABS March 23, 2015 10:54AM |

Registered: 10 years ago Posts: 42 |

Sound advice. I will second. Although if you are in the UK you may have trouble buying it in large quantities as it is a controlled substance.Quote

dmould

Buy few litres of acetone - it has several uses with ABS.

Dave

I have found it for sale at the pound shop near where i live in 150ml bottles.(£6.67/l)

|

Re: The stresses of ABS March 23, 2015 03:31PM |

Registered: 10 years ago Posts: 2,472 |

Quote

jy_oc_hx

Sound advice. I will second. Although if you are in the UK you may have trouble buying it in large quantities as it is a controlled substance.Quote

dmould

Buy few litres of acetone - it has several uses with ABS.

Dave

I have found it for sale at the pound shop near where i live in 150ml bottles.(£6.67/l)

I had no problem buying 3 X 5 litre cans in the UK recently - arrived within 3 days from here [www.cfsnet.co.uk] Less that £2/l

Edited 1 time(s). Last edit at 03/23/2015 03:36PM by dmould.

|

Re: The stresses of ABS March 23, 2015 04:44PM |

Registered: 10 years ago Posts: 14,672 |

Buying anything but tiny bottles of acetone from retail stores in the UK is next to impossible now, but acetone can still be bought in reasonable quantities via eBay and other internet or mail order outlets. I guess the difference is that the security services can identify you as the purchaser.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The stresses of ABS March 23, 2015 05:03PM |

Registered: 9 years ago Posts: 177 |

Quote

dc42

Finally, I believe the power supply on the Ormerod 2 has a voltage adjustment potentiometer, near the low voltage end of the terminal block. You can turn it up to 13V or even a little higher to increase the heating power.

I can confirm that the O2 kit I received has this voltage adjuster on the power supply, it's a small white plastic phillips screw head next to the terminals. It doesn't have any values on it though, so I suppose you'll need to measure with a voltmeter to adjust it to a specific value. I haven't actually adjusted it, I might go back and do that later if I decide to go the ABS route, or anything that needs that kind of heat.

One thing though, I think this was discussed somewhere else, but I believe the duet is fine with quite a bit more than 12V (since I believe the huxley uses 19V with the duet?), but the hot end fan isn't, although 13V probably won't kill it on the spot....

If I were to increase the supplied voltage, should I add a resistor in series with the hot end fan to drop it down to 12V?

|

Re: The stresses of ABS March 23, 2015 05:17PM |

Registered: 10 years ago Posts: 14,672 |

If you go above 13V then I suggest putting 1 or 2 1N4001 or similar silicon diodes in series with the fan. Each diode will reduce the voltage by about 0.8V.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The stresses of ABS March 23, 2015 08:10PM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Buying anything but tiny bottles of acetone from retail stores in the UK is next to impossible now, but acetone can still be bought in reasonable quantities via eBay and other internet or mail order outlets. I guess the difference is that the security services can identify you as the purchaser.

You have made me curious, I wasn't aware that acetone was used in the production of anything nasty, now I'll have to find an untraceable IP address and go look it up! As said, ordering 15 litres from the UK online retailer cited was as easy as ordering anything else, and it arrived in 3 days so is probably the best way to go. OTOH I used a factory address for delivery, and maybe there would have been more attention paid had I used my residential address. The reason I order so much at a time is because the shipping cost is the same regardless of quantity (within reason), so the more you order the cheaper the unit cost. The last batch lasted me a year and this batch probably will as well.

Acetone is used as a brush cleaner and thinners for the most common DIY fibreglass resin (polyester), so I would have thought it could be bought over the counter in reasonable quantities from a retailer that specialises in DIY fibreglass (car body, roofing, boats etc.), but maybe not.

Dave

|

Re: The stresses of ABS March 23, 2015 10:46PM |

Registered: 9 years ago Posts: 177 |

Quote

dmould

Quote

dc42

Buying anything but tiny bottles of acetone from retail stores in the UK is next to impossible now, but acetone can still be bought in reasonable quantities via eBay and other internet or mail order outlets. I guess the difference is that the security services can identify you as the purchaser.

You have made me curious, I wasn't aware that acetone was used in the production of anything nasty

As far as I know acetone isn't a restricted substance in the United States (but if you bought a few hundred gallons you might get a call from the authorities). Although it is commonly used in chemistry labs, great for cleaning equipment and surfaces.

I can't really think of why it would be restricted. I mean, it's only mildly dangerous. Being flammable, and slightly toxic.... Plenty of other common household chemicals are just as or more dangerous (is isopropyl alcohol aka rubbing alcohol is almost exactly the same hazard, is that restricted?). I mean nail polish remover is typically pure acetone, sometimes with other additives. And gasoline is probably more dangerous.

Just seems kinda weird to me I guess... Not really sure how it could be used in a nefarious fashion.

|

Re: The stresses of ABS March 24, 2015 03:33AM |

Registered: 10 years ago Posts: 42 |

Its reportable under the heading of "supplying explosives"! Link here. It is a bit over the top.Quote

shadow651

Quote

dmould

Quote

dc42

Buying anything but tiny bottles of acetone from retail stores in the UK is next to impossible now, but acetone can still be bought in reasonable quantities via eBay and other internet or mail order outlets. I guess the difference is that the security services can identify you as the purchaser.

You have made me curious, I wasn't aware that acetone was used in the production of anything nasty

As far as I know acetone isn't a restricted substance in the United States (but if you bought a few hundred gallons you might get a call from the authorities). Although it is commonly used in chemistry labs, great for cleaning equipment and surfaces.

I can't really think of why it would be restricted. I mean, it's only mildly dangerous. Being flammable, and slightly toxic.... Plenty of other common household chemicals are just as or more dangerous (is isopropyl alcohol aka rubbing alcohol is almost exactly the same hazard, is that restricted?). I mean nail polish remover is typically pure acetone, sometimes with other additives. And gasoline is probably more dangerous.

Just seems kinda weird to me I guess... Not really sure how it could be used in a nefarious fashion.

Thanks. I'll give them a look.Quote

dmould

Quote

jy_oc_hx

Sound advice. I will second. Although if you are in the UK you may have trouble buying it in large quantities as it is a controlled substance.Quote

dmould

Buy few litres of acetone - it has several uses with ABS.

Dave

I have found it for sale at the pound shop near where i live in 150ml bottles.(£6.67/l)

I had no problem buying 3 X 5 litre cans in the UK recently - arrived within 3 days from here [www.cfsnet.co.uk] Less that £2/l

|

Re: The stresses of ABS March 24, 2015 04:39AM |

Registered: 9 years ago Posts: 151 |

You can buy acetone in the form of cellulose thinners in almost every car accessory shop here in the UK, Halfords for example sell it in 1 and 1/2 litre tins.

Amazon has it in all sizes, a 5 litre tin will cost you £16.22 with free delivery!

It is certainly not a restricted substance in the UK.

Brian

Edited 1 time(s). Last edit at 03/24/2015 04:39AM by Europa.

Amazon has it in all sizes, a 5 litre tin will cost you £16.22 with free delivery!

It is certainly not a restricted substance in the UK.

Brian

Edited 1 time(s). Last edit at 03/24/2015 04:39AM by Europa.

|

Re: The stresses of ABS March 24, 2015 05:02AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Europa

You can buy acetone in the form of cellulose thinners in almost every car accessory shop here in the UK, Halfords for example sell it in 1 and 1/2 litre tins.

Amazon has it in all sizes, a 5 litre tin will cost you £16.22 with free delivery!

It is certainly not a restricted substance in the UK.

Brian

Read the link above

Acetone as from the 2nd March this year is a reportable substance. This will cause extra admin to the retailer's and I suspect that they just won't supply it to the general public.

Also Cellulose thinner's can be a mix of various Chemical solvent's so I wouldn't rely on it being pure acetone and with these new regulations I think you will see it being based on something totally different to acetone.

Doug

|

Re: The stresses of ABS March 24, 2015 05:13AM |

Registered: 10 years ago Posts: 14,672 |

Quote

jy_oc_hx

Its reportable under the heading of "supplying explosives"! Link here. It is a bit over the top.

Sadly, it is not over the top. Explosives made from acetone and another widely-available substance were used by terrorists in 2005 to kill 52 people and injure another 700, in London.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The stresses of ABS March 24, 2015 09:28AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Sadly, it is not over the top. Explosives made from acetone and another widely-available substance were used by terrorists in 2005 to kill 52 people and injure another 700, in London.

Sure, but lots of things are used in the manufacture of explosives, including water. Restricting useful substances that have lots of innocent uses because it *could* be used to make explosives is IMO the wrong approach. That document lists acetone as a "reportable" substance rather than a "regulated" substance, which means that suppliers must report "suspicious" transactions, with no clear guidance on what constitutes "suspicious". I should think most people planning to make explosives would be able to dream up a perfectly plausible reason for wanting to buy it. It really does strike me as OTT as forbidding the sale of pencil sharpeners and can openers to people under 18 because they are "bladed instruments". A child was prevented from purchasing a small tub of ice-cream in a branch of Asda because it contained a plastic spoon. Spoon = cutlery. Cutlery = no sale to anyone under 18. If the terrorists don't kill us, the paranoia probably will.

Anyway, the law regarding the acquisition of "explosive precursors" came into force last September, and my purchase was long after that, so it does not appear to have had an effect. The law regarding the mere possession of acetone does not come into force until March 2016 - and I am not sure whether it applies to "reportable" substances as well as "regulated" substances - the cite is not at all clear. If it does apply, I wonder whether every woman in possession of nail polish remover will have to apply for a licence from the Home Office?

Dave

|

Re: The stresses of ABS March 24, 2015 11:56AM |

Registered: 10 years ago Posts: 119 |

|

Re: The stresses of ABS March 25, 2015 04:44AM |

Registered: 10 years ago Posts: 42 |

Quote

dc42

Quote

jy_oc_hx

Its reportable under the heading of "supplying explosives"! Link here. It is a bit over the top.

Sadly, it is not over the top. Explosives made from acetone and another widely-available substance were used by terrorists in 2005 to kill 52 people and injure another 700, in London.

I wasn't meaning it was safety gone mad. What i was getting at was the fact that i couldn't even buy it from places where we have an account and trackable paper trace..

|

Re: The stresses of ABS March 25, 2015 05:20AM |

Registered: 10 years ago Posts: 14,672 |

Quote

jy_oc_hx

Quote

dc42

Quote

jy_oc_hx

Its reportable under the heading of "supplying explosives"! Link here. It is a bit over the top.

Sadly, it is not over the top. Explosives made from acetone and another widely-available substance were used by terrorists in 2005 to kill 52 people and injure another 700, in London.

I wasn't meaning it was safety gone mad. What i was getting at was the fact that i couldn't even buy it from places where we have an account and trackable paper trace..

That does surprise me, especially as I can order 5 litre containers of it from various eBay UK suppliers who don't know me.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The stresses of ABS March 25, 2015 09:25AM |

Registered: 10 years ago Posts: 176 |

Fortunately I work at a factory that has a fiberglass section that buys acetone in huge drums, so obtaining 2 litres at a time is a case of going downstairs and asking nicely!

I concur with dmould and ormerod168 - printing with ABS is a bit of trial and error, but the Ormerod can do it very well with the x-axis and hot end parts all replaced with ABS alternatives. I did remove the air blowing on the part as I found it causes de-lamination sometimes.

ABS is quite a rewarding plastic to print with - I find it does a LOT better on overhangs than PLA and the things you can do with acetone vapour or wiping acetone on the part can make great looking parts.

I concur with dmould and ormerod168 - printing with ABS is a bit of trial and error, but the Ormerod can do it very well with the x-axis and hot end parts all replaced with ABS alternatives. I did remove the air blowing on the part as I found it causes de-lamination sometimes.

ABS is quite a rewarding plastic to print with - I find it does a LOT better on overhangs than PLA and the things you can do with acetone vapour or wiping acetone on the part can make great looking parts.

|

Re: The stresses of ABS March 25, 2015 09:33AM |

Registered: 10 years ago Posts: 14,672 |

Does anyone have any suggestions on how to avoid stringing with ABS? I am finding it much worse than with PLA. I currently print at 235C hot end and 110C bed temperature. I tried reducing the hot end temperature, but at 230C it wasn't any better, and at 225C the extruder drive failed to push the filament through consistently. I guess I may need to check the dreaded "Avoid crossing perimeters" in slic3r.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The stresses of ABS March 25, 2015 09:53AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: The stresses of ABS March 25, 2015 10:40AM |

Registered: 10 years ago Posts: 176 |

|

Re: The stresses of ABS March 25, 2015 01:17PM |

Registered: 10 years ago Posts: 42 |

I have some stringing issues but nothing i can't live with. I print at 235 with bed starting at 115, but this quickly drops to 100 and won't stay any higher. I've been looking at upgrading the heated bed method to a mains voltage and SSR bang bang system. But as usual it hasn't happened yet. Definately have a lot better results using ABS than PLA once the trial and error stage is over with.

|

Re: The stresses of ABS March 25, 2015 03:06PM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Does anyone have any suggestions on how to avoid stringing with ABS? I am finding it much worse than with PLA. I currently print at 235C hot end and 110C bed temperature. I tried reducing the hot end temperature, but at 230C it wasn't any better, and at 225C the extruder drive failed to push the filament through consistently. I guess I may need to check the dreaded "Avoid crossing perimeters" in slic3r.

Check your hotend temperature - I normally print at 230 (bed 110) but 225 is still plenty molten enough to push. I checked my hotend temperature with a wire K probe pushed down the Bowden tube in place of the filament so the end bottomed in the puddle of plastic in the nozzle. OTOH I have not checked for a long time and maybe later firmware reads the thermistor differently - I'll check again over the weekend. I get insignificant stringing. Retraction 4mm & 40mm/s, speed around 70mm/s. Maybe it's the filament you are using - all my filament is from 3Dfilaprint and seems to be consistent quality.

Dave

|

Re: The stresses of ABS March 25, 2015 03:13PM |

Registered: 10 years ago Posts: 14,672 |

Thanks Dave, I'll check the hot end temperature. Btw I am considering adding thermocouple support to my firmware fork - would anyone else be interested in using this?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The stresses of ABS March 25, 2015 05:09PM |

Registered: 9 years ago Posts: 177 |

Quote

dc42

Thanks Dave, I'll check the hot end temperature. Btw I am considering adding thermocouple support to my firmware fork - would anyone else be interested in using this?

I think it'd be nice to have, not sure if I'd use it myself yet. There are some exotic ABS/Polycarb or pure polycarb filaments that need extrusion temperatures higher than thermistors can handle (>260C), plus thermocouples are more accurate if you need your hot end temp to be 'exact'.

I don't know if I'd ever expect the Ormerod to work well with extreme temp exotics without an environmental chamber (which I think a few people have built); but I think the nozzle design keeps the PTFE mostly in the cooling block so it could handle those temps without a meltdown.

But the duet is a nice board and I could see other systems using it as well (I know you've upgraded your kossel delta printer), and people could always switch hot ends if they're into that kind of thing.

I take it that support would eliminate the need for an intermediate thermocouple PCB, and we'd just plug it into the duet with a new line in the config?

Sorry, only registered users may post in this forum.