really bad overhang

Posted by denshine

|

really bad overhang April 04, 2015 07:16AM |

Registered: 10 years ago Posts: 36 |

|

Re: really bad overhang April 04, 2015 09:22AM |

Registered: 10 years ago Posts: 62 |

|

Re: really bad overhang April 04, 2015 10:20AM |

Registered: 10 years ago Posts: 36 |

im using 0.1 layerhight and a 0.2 nozzle.

at the moment im using kim browns Big Blue cooler but i get the same resaults using the orignal hotend cooler.

i havent used support on thes models cuz its not that much of an overhang, i really would like to manage to print "normal overhang" without support.

at the moment im using kim browns Big Blue cooler but i get the same resaults using the orignal hotend cooler.

i havent used support on thes models cuz its not that much of an overhang, i really would like to manage to print "normal overhang" without support.

|

Re: really bad overhang April 04, 2015 10:49AM |

Registered: 10 years ago Posts: 62 |

Ok, well a 45 degree overhang with your setup isn't putting much material under the overhanging. For something that doesn't have to be pretty, I would use a bigger nozzle. If you use a .3 nozzle with the same layer height, you will probably fare much better.

You could also try and point an extra fan at that area whe it gets to it.

You're also putting a lot of time into that print, adding a support under that bit won't cost you much extra.

Maybe someone else can offer some more advice.

You could also try and point an extra fan at that area whe it gets to it.

You're also putting a lot of time into that print, adding a support under that bit won't cost you much extra.

Maybe someone else can offer some more advice.

|

Re: really bad overhang April 04, 2015 04:52PM |

Registered: 9 years ago Posts: 191 |

IMHO

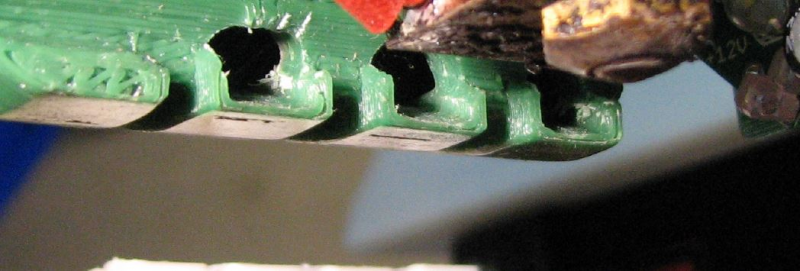

At 45 degrees half the layer is without support, when printing straight ahead. When it comes to corners it is even more that rests on thin air. That's why the corners looks so bad.

So the solution is wider nozzle, lower layer height or support. Lower layer height is nor an reasonable option.

Another way is to overextrude to print wider and use higher layer height. But I am not compleatly sure that would give much better results. In latest version of Slic3r this can be simulated an visually inspected.

I would go for a .5 nozzle and layer height .2. But that's me...

/Tomas

At 45 degrees half the layer is without support, when printing straight ahead. When it comes to corners it is even more that rests on thin air. That's why the corners looks so bad.

So the solution is wider nozzle, lower layer height or support. Lower layer height is nor an reasonable option.

Another way is to overextrude to print wider and use higher layer height. But I am not compleatly sure that would give much better results. In latest version of Slic3r this can be simulated an visually inspected.

I would go for a .5 nozzle and layer height .2. But that's me...

/Tomas

|

Re: really bad overhang April 05, 2015 03:02PM |

Registered: 10 years ago Posts: 1,230 |

Quote

denshine

im using 0.1 layerhight and a 0.2 nozzle.

at the moment im using kim browns Big Blue cooler but i get the same resaults using the orignal hotend cooler.

i havent used support on thes models cuz its not that much of an overhang, i really would like to manage to print "normal overhang" without support.

I have no experience other than with the stock 0.5 nozzle and its hard to see if the mess is from perimeters sagging or curl-ups but either way I would say you need more cooling - no I don't think support would help, not with curl-ups anyway

Greater layer width might help, ditto printing outer perimeters first, also gravity can be of help against curl-ups if you can get the temperature just right, the cure for curl-ups _can_ be higher temperature plus more cooling

I also find ABS slightly more forgiving that PLA when it comes to overhangs

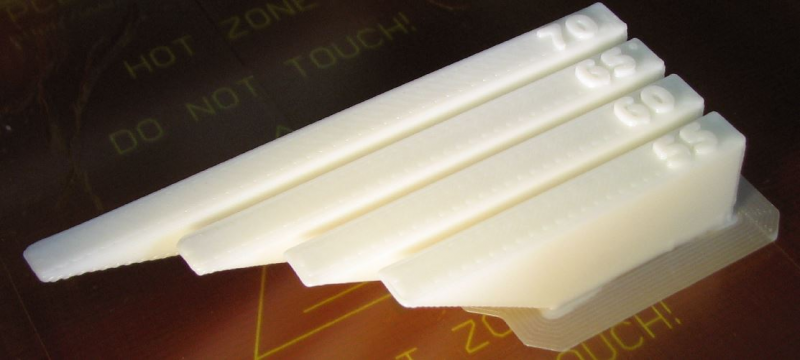

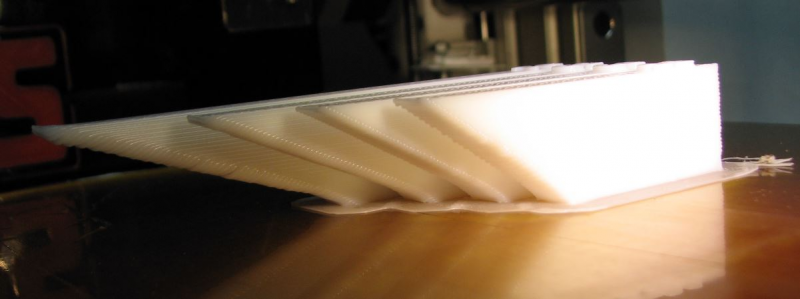

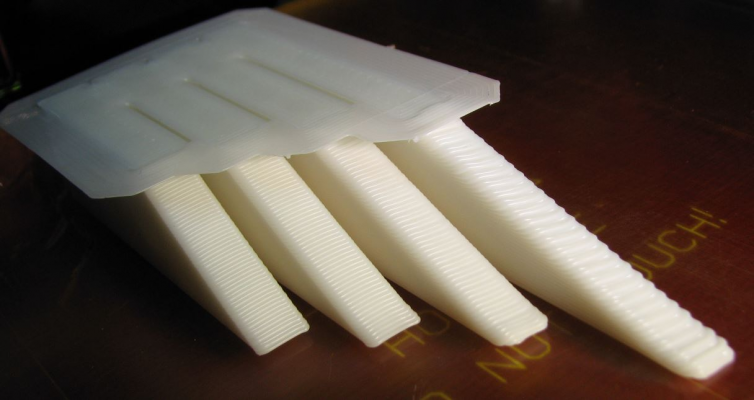

I have attached a cut version of the Massive Overhang Test from Thingiverse you can grind you teeth on, did cut of the easy part and sliced of part of the bottom for faster printing

The original here:

[www.thingiverse.com]

Here picture of same test piece printed in PLA and ABS, I use Johneato's control air to the nozzle mod, have opened up the air slots for max airflow (also used for ABS if printing overhangs)

PLA 205/57, nozzle 0.5, extrusion width 0.75, 30mm/sec

ABS 235/210, nozzle 0.5, extrusion width 0.75, 30mm/sec

Good luck and hang in there, ditto your perimeters :-)

Erik

|

Re: really bad overhang April 06, 2015 07:12AM |

Registered: 10 years ago Posts: 36 |

|

Re: really bad overhang April 07, 2015 08:10AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: really bad overhang April 07, 2015 04:01PM |

Registered: 10 years ago Posts: 1,230 |

Quote

denshine

..il try a bigger nozzel and see where that leeds me.

I think that's a better start, to get everything right first with the standard trim and then eventually scale down to a smaller nozzle later

I have learned a lot from this group (thank you!), also from watching the nozzle do its thing, getting in eye level with the nozzle, sitting on a chair with a mug of coffee, experimenting with temperature and cooling, see what effect it has on the print and try to figure out what makes it tick

The problem with overhang and curl-ups - I picture the hot filament as a string of rubber band, if you stretch it it will try to go back to normal (and curl up), if you compress it, it should have no reason to do so, therefore It makes sense to me to raise the extrusion width at least with overhangs (not while bridging, there you may want the stretch ), also a broader extrusion will leave a lesser part of the total perimeter hanging in free air - and as few perimeters as possible, when the perimeters cool and shrink, more perimeters will ad to the problem, to print outer perimeter first also make sense to me in the rubber band theory, every perimeter will ad to shrinking force if printed from inside

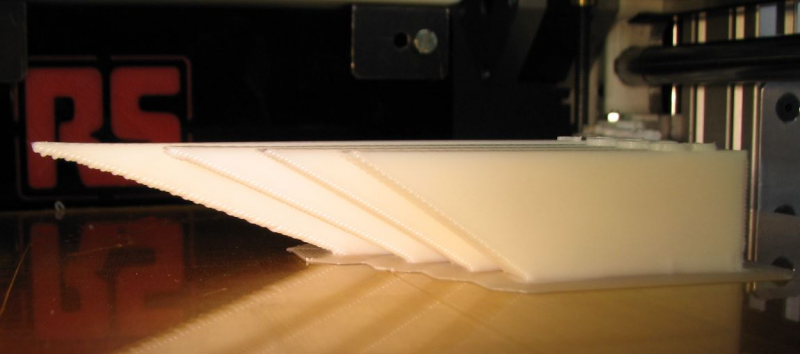

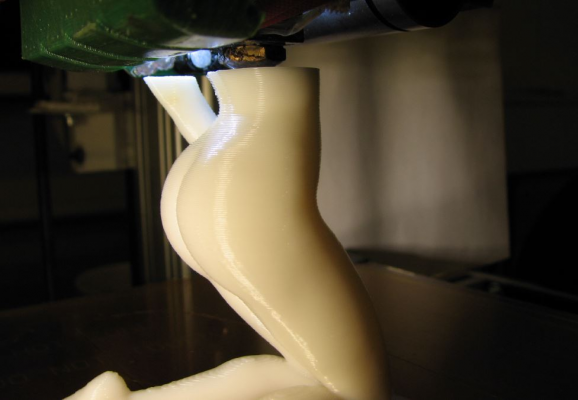

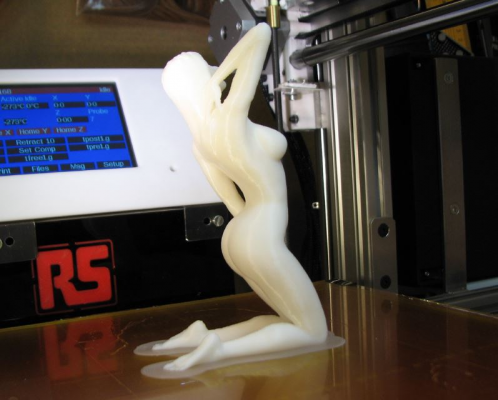

..BTW, testing for overhang don't have to be boring, here's another test, max 45 degrees overhang I think (it's a dirty job but someone has to do it ehem..)

The artist pulled it from thingiverse some time ago but you can get it here (he

[www.makershop.co]

..also notice this one - it's a beauty!

[www.makershop.co]

ABS, 235/110, nozzle 0.5, layer hight 0.25, extrusion width 0.75, outer perimeter first, lots of cooling

Erik

Sorry, only registered users may post in this forum.