Slic3r profile for Ormerod 2 results in rubbish prints

Posted by bartdietrich

|

Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 08:22AM |

Registered: 9 years ago Posts: 106 |

Hi all,

I'm new to this so apologies if the resolution of this problem is obvious.

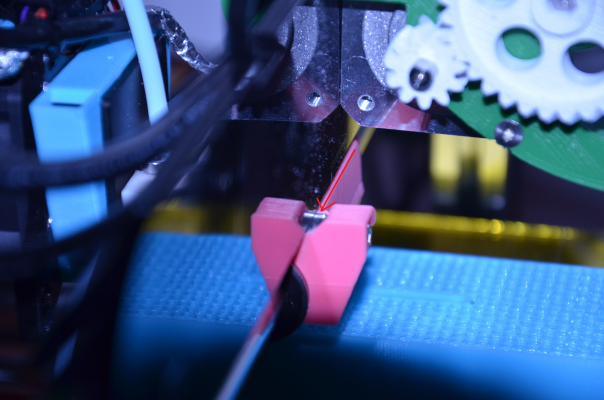

My Ormerod 2 prints the G code that came with the firmware (e.g. the whistle or coathook) well enough, only the occasional small blob or wisp of melted PLA. So I thought I'd give a few STL files a go. I use Slic3r to create the G code from the STL files. Downloaded and installed the Ormerod profile for Slic3r as per instructions on RepRap website. The problem is that, after a few layers, the nozzle starts riding over and bumping into material it has already printed. After a sufficient number of layers this gets so bad that the nozzle either detaches the print from the bed and drags it around or gets stuck in parts of the print and makes the x,y motors skip. Not to mention overhangs, which curl up like mad, but one thing at a time I guess (attempted to print the Massive Overhangs Test Light)

Given that the G code files that came with the printer print OK, but ones that I create using Slic3r don't, I figured the problem must be with Slic3r settings, maybe over-extrusion. I've set filament diameter to 1.71 mm (about right, average value measured over a length of it) and went as low as 0.85 for the extrusion multiplier. My steps/mm for the extruder motor is spot-on. I've tried different bed temperatures (75/70 to 60/55 first/next) and nozzle temperature (215/210 to 185/180 first/next). The axes and infrared probe are calibrated. I've played around with various other parameters (print speeds, extrudate widths, layers heights etc) but nothing seems to stop what looks like over-extrusion and the resulting crashing of the nozzle into the print.

Does anyone have any ideas? Is the Slic3r profile for Ormerod on github the same as for the Ormerod 2? What slicing software was used to generate the G code that came with the firmware (the coathook etc)? If by any chance it was Slic3r, can I have a copy of those settings files? Any other suggestions?

Thanks,

Bart

I'm new to this so apologies if the resolution of this problem is obvious.

My Ormerod 2 prints the G code that came with the firmware (e.g. the whistle or coathook) well enough, only the occasional small blob or wisp of melted PLA. So I thought I'd give a few STL files a go. I use Slic3r to create the G code from the STL files. Downloaded and installed the Ormerod profile for Slic3r as per instructions on RepRap website. The problem is that, after a few layers, the nozzle starts riding over and bumping into material it has already printed. After a sufficient number of layers this gets so bad that the nozzle either detaches the print from the bed and drags it around or gets stuck in parts of the print and makes the x,y motors skip. Not to mention overhangs, which curl up like mad, but one thing at a time I guess (attempted to print the Massive Overhangs Test Light)

Given that the G code files that came with the printer print OK, but ones that I create using Slic3r don't, I figured the problem must be with Slic3r settings, maybe over-extrusion. I've set filament diameter to 1.71 mm (about right, average value measured over a length of it) and went as low as 0.85 for the extrusion multiplier. My steps/mm for the extruder motor is spot-on. I've tried different bed temperatures (75/70 to 60/55 first/next) and nozzle temperature (215/210 to 185/180 first/next). The axes and infrared probe are calibrated. I've played around with various other parameters (print speeds, extrudate widths, layers heights etc) but nothing seems to stop what looks like over-extrusion and the resulting crashing of the nozzle into the print.

Does anyone have any ideas? Is the Slic3r profile for Ormerod on github the same as for the Ormerod 2? What slicing software was used to generate the G code that came with the firmware (the coathook etc)? If by any chance it was Slic3r, can I have a copy of those settings files? Any other suggestions?

Thanks,

Bart

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 08:36AM |

Registered: 10 years ago Posts: 2,472 |

Make sure you have not set Slic3r to output absolute extruder lengths (i.e. the "use relative E distance" box is unticked in the printer settings) but have the printer set for relative moves. If Slicer is set to absolute extruder moves you should have a "M82" command in the start G code, otherwise there should be an "M83" command.

Dave

Dave

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 01:31PM |

Registered: 9 years ago Posts: 106 |

Hi Dave,

Thanks for your reply, but this is not the problem. I double-checked: the "use relative E distances" tick box is ticked and start code contains M83. The generated G code uses consistently small numbers for the E parameter (for the first couple of pages I flicked through). I changed to absolute E moves just to see: I unchecked the box and changed the M83 to M82 in the start code. The generated G code now uses gradually increasing numbers for the E parameter. But when printing, the result is the same: after 2-3 layers, the nozzle starts riding on top of the previous layers (mostly on the infill it would seem).

Any other ideas?

Thanks,

Bart

Thanks for your reply, but this is not the problem. I double-checked: the "use relative E distances" tick box is ticked and start code contains M83. The generated G code uses consistently small numbers for the E parameter (for the first couple of pages I flicked through). I changed to absolute E moves just to see: I unchecked the box and changed the M83 to M82 in the start code. The generated G code now uses gradually increasing numbers for the E parameter. But when printing, the result is the same: after 2-3 layers, the nozzle starts riding on top of the previous layers (mostly on the infill it would seem).

Any other ideas?

Thanks,

Bart

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 01:45PM |

Registered: 10 years ago Posts: 14,672 |

Sounds to me like either over-extrusion, or the Z axis not moving as far up as it should when it is given commands to move up a short distance - a problem that I had once. Try putting then nozzle just above/touching the bed, then send G91 to select relative mode. Then do G1 Z0.24 F6000 to simulate the gcode moving the nozzle up a layer, and repeat this several times. After about 20 times, measure how high the nozzle is above the bed, and see if it is at the expected height.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 02:29PM |

Registered: 9 years ago Posts: 106 |

Hi dc42,

Ok, I'll try that in a bit (trying another print at the moment). If that's the problem though, why would the G codes that came with the printer (coathook etc) print ok?

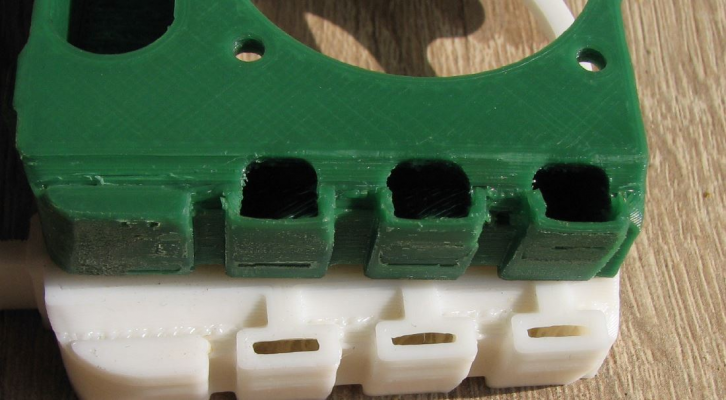

I printed a little box with lid (see photo, I know, not exactly earth-shattering but you've got to start somewhere) and it fits together quite nicely and the dimensions are nearly exactly as I specified in OpenSCAD (2-4 tenths of a mm too low for length and width, but spot-on for height and wall thickness (1 mm)). The top and bottom don't exactly look water-tight though (in fact, I can see tiny gaps when looking through it at a light source) between the deposited tracks. This suggests that I'm under-extruding (my extrusion multiplier is set to 0.85) rather than over-extruding. I just printed the box again, this time with 0.95 extrusion multiplier: length and width are now spot-on but the wall thickness is 15% over (I've read about walls tending to bulge a bit?) There are no issues with the nozzle crashing into the print though.

On a technical note: can STL files contain hardware-specific instructions? That is, something which, when converted to G code, could override printer parameters (that were specified while slicing) on the fly? If so, that could explain why I'm having problems with Massive_Overhang_Test_Light (got this off the internet, don't know where it's been and what's in it)...

Thanks,

Bart

Edited 1 time(s). Last edit at 04/27/2015 02:31PM by bartdietrich.

Ok, I'll try that in a bit (trying another print at the moment). If that's the problem though, why would the G codes that came with the printer (coathook etc) print ok?

I printed a little box with lid (see photo, I know, not exactly earth-shattering but you've got to start somewhere) and it fits together quite nicely and the dimensions are nearly exactly as I specified in OpenSCAD (2-4 tenths of a mm too low for length and width, but spot-on for height and wall thickness (1 mm)). The top and bottom don't exactly look water-tight though (in fact, I can see tiny gaps when looking through it at a light source) between the deposited tracks. This suggests that I'm under-extruding (my extrusion multiplier is set to 0.85) rather than over-extruding. I just printed the box again, this time with 0.95 extrusion multiplier: length and width are now spot-on but the wall thickness is 15% over (I've read about walls tending to bulge a bit?) There are no issues with the nozzle crashing into the print though.

On a technical note: can STL files contain hardware-specific instructions? That is, something which, when converted to G code, could override printer parameters (that were specified while slicing) on the fly? If so, that could explain why I'm having problems with Massive_Overhang_Test_Light (got this off the internet, don't know where it's been and what's in it)...

Thanks,

Bart

Edited 1 time(s). Last edit at 04/27/2015 02:31PM by bartdietrich.

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 03:00PM |

Registered: 9 years ago Posts: 638 |

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 03:14PM |

Registered: 9 years ago Posts: 106 |

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 04:33PM |

Registered: 9 years ago Posts: 106 |

Hi again,

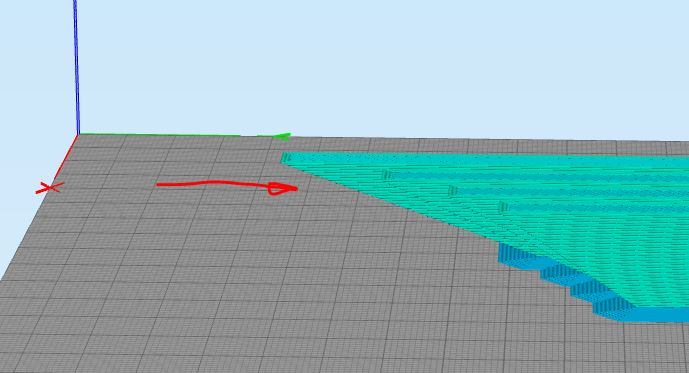

So I've been closely observing what the printer is doing. With the Massive Overhang Test the problem starts at the first layer. When the printer is printing the bottom layer infill it's doing those very closely spaced zigzag moves. When laying down an adjacent line, it digs through part of the previous line, pushing its boundary to the side and up a bit. This effect is cumulative and the problem is exacerbated on subsequent layers.

The perimeters appear to be laid down cleanly. Nor does this happen when I print my box and lid: the lines in the bottom layer seem to be spaced further apart.

Maybe it's time to have a play with max resolution, extrusion width or infill parameters. Any suggestions still welcome of course.

So I've been closely observing what the printer is doing. With the Massive Overhang Test the problem starts at the first layer. When the printer is printing the bottom layer infill it's doing those very closely spaced zigzag moves. When laying down an adjacent line, it digs through part of the previous line, pushing its boundary to the side and up a bit. This effect is cumulative and the problem is exacerbated on subsequent layers.

The perimeters appear to be laid down cleanly. Nor does this happen when I print my box and lid: the lines in the bottom layer seem to be spaced further apart.

Maybe it's time to have a play with max resolution, extrusion width or infill parameters. Any suggestions still welcome of course.

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 27, 2015 04:49PM |

Registered: 9 years ago Posts: 106 |

Speaking of max resolution, is it possible that the massive overhang test has a resolution far higher than the printer can do or is necessary but because I didn't limit this parameter in Slic3r (it's set to 0), the printer is trying to lay down a thread through a hawse pipe so-to-say, which results in unintentional over-extrusion? (can't check this right now, printer woes drove me to the pub)

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 28, 2015 09:05AM |

Registered: 10 years ago Posts: 2,472 |

The first layer will not give you a good indication of extrusion accuracy. If the nozzle is slightly too close to the bed (zero height set too low) it will give the symptom of over-extruding, and if it is a fraction too far it will look as if it is under-extruding. If you set your Z zero height (home position) slightly higher, you will not see the extrusions being squashed together as you describe (but if it is too high the plastic won't stick to the bed). In fact that is possibly your problem - if the first layer is too far out (nozzle too low) it can have a knock-on effect for subsequent layers. The low nozzle causes the first layer extrusions to bunch up and create bumps, and the bumps cause the extrusion to break occasionally on the second layer, which creates worse bumps of broken threads, making the 3rd layer even worse. I deliberately set my Z zero height to be slightly too low as that helps with bed adhesion, but not so low that the resulting over-extrusion cannot be absorbed into the following few layers without causing problems.

As for the supplied G code working OK - you need to look at the G-code to see what parameters are different. Usually the parameters are displayed in comment fields at the start and end of the G-code (which you open in a text editor). If the supplied G-code files do not have parameters in comments you can still determine the move speeds and temperatures from the code.

Many printing issues can be resolved by simply printing more slowly. This is easy to do using DC42 or Zombie's firmware & web interface as you can adjust the print speed on the fly. There are many times that I have noticed a broken extrusion or curl-up that I know will get worse and worse, but I have saved the print by slowing down to 30% or so for the following few layers.

Overhangs always curl up to some extent, and getting a good overhang print requires adjusting several factors. I suggest however that you first get your non-overhanging prints to come out satisfactorily before looking at improving the overhangs, otherwise you are juggling too many variables at once.

Dave

As for the supplied G code working OK - you need to look at the G-code to see what parameters are different. Usually the parameters are displayed in comment fields at the start and end of the G-code (which you open in a text editor). If the supplied G-code files do not have parameters in comments you can still determine the move speeds and temperatures from the code.

Many printing issues can be resolved by simply printing more slowly. This is easy to do using DC42 or Zombie's firmware & web interface as you can adjust the print speed on the fly. There are many times that I have noticed a broken extrusion or curl-up that I know will get worse and worse, but I have saved the print by slowing down to 30% or so for the following few layers.

Overhangs always curl up to some extent, and getting a good overhang print requires adjusting several factors. I suggest however that you first get your non-overhanging prints to come out satisfactorily before looking at improving the overhangs, otherwise you are juggling too many variables at once.

Dave

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 29, 2015 10:48AM |

Registered: 9 years ago Posts: 106 |

Hi Dave,

Thanks for that. I've set my Z=0 position to be 0.2 mm higher than it really is (by way of the G31 command in config.sys), this seems to have improved the situation for the first layers, but then the problem reoccurs around layers 3 or 4 or so. I guess I'm onto something here. As you said, speed might be an issue too, when I slow the external perimeter printing speed down, the overhangs come out slightly better. I'll have to play around with the speeds a bit. As for looking up the parameters in the supplied G code, why didn't I think of that myself... Had a quick look and yes, all speeds seem slower. I'll play around with these settings and probably report back here when everything has gone pear-shaped again.

Incidentally, Slic3er doesn't seem to recognize some perimeters as being external ones. For the Massive_Overhang_Test_Light, the distal perimeters of the two longer prongs print at normal fast speed and it's only those of the two shorter prongs that slow down (noticed this when I set external perimeter printing speed to rather low but left the other perimeter speeds high).

Another issue I observed during infill printing: on a few occasions the printer crossed over its own trace on the same layer, i.e. something like a figure of 8. This obviously resulted in bumps which then caused problems and head crashes in the next layers. Although this might be an ooze/speed issue...

So many variables, so little patience...

Thanks everyone for your replies! :-)

Bart

Thanks for that. I've set my Z=0 position to be 0.2 mm higher than it really is (by way of the G31 command in config.sys), this seems to have improved the situation for the first layers, but then the problem reoccurs around layers 3 or 4 or so. I guess I'm onto something here. As you said, speed might be an issue too, when I slow the external perimeter printing speed down, the overhangs come out slightly better. I'll have to play around with the speeds a bit. As for looking up the parameters in the supplied G code, why didn't I think of that myself... Had a quick look and yes, all speeds seem slower. I'll play around with these settings and probably report back here when everything has gone pear-shaped again.

Incidentally, Slic3er doesn't seem to recognize some perimeters as being external ones. For the Massive_Overhang_Test_Light, the distal perimeters of the two longer prongs print at normal fast speed and it's only those of the two shorter prongs that slow down (noticed this when I set external perimeter printing speed to rather low but left the other perimeter speeds high).

Another issue I observed during infill printing: on a few occasions the printer crossed over its own trace on the same layer, i.e. something like a figure of 8. This obviously resulted in bumps which then caused problems and head crashes in the next layers. Although this might be an ooze/speed issue...

So many variables, so little patience...

Thanks everyone for your replies! :-)

Bart

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 29, 2015 11:14AM |

Registered: 10 years ago Posts: 2,472 |

Quote

bartdietrich

Incidentally, Slic3er doesn't seem to recognize some perimeters as being external ones. For the Massive_Overhang_Test_Light, the distal perimeters of the two longer prongs print at normal fast speed and it's only those of the two shorter prongs that slow down (noticed this when I set external perimeter printing speed to rather low but left the other perimeter speeds high).

Look at the setting "Detect bridging perimeters" in the Print Settings tab. That may affect this (I'm guessing).

Quote

bartdietrich

Another issue I observed during infill printing: on a few occasions the printer crossed over its own trace on the same layer, i.e. something like a figure of 8. This obviously resulted in bumps which then caused problems and head crashes in the next layers. Although this might be an ooze/speed issue...

The method of printing infill changes as you go below a certain percentage. Higher percentage infill prints in alternate directions on each layer, but below a certain amount (not sure exactly what amount, maybe 30%?), the method changes to printing in both directions on every layer and having the extrusions crossing each other. The crossover points should squash down on the next layer and not be a problem, though with very sparse infill you can get problems with the top solid layer which has quite long bridges between the infill lines, and I need to slow down the first solid top layer by quite a bit if I have a low infill percentage. If you are finding they don't squash down too well, maybe try increasing your extruder temperature.

Dave

Edited 1 time(s). Last edit at 04/29/2015 11:15AM by dmould.

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 29, 2015 01:05PM |

Registered: 10 years ago Posts: 1,230 |

Quote

bartdietrich

... I'm having problems with Massive_Overhang_Test_Light (got this off the internet, don't know where it's been and what's in it)...

Yes one never can be too careful, some models have been around (LOL), but my guess is you got it from here:

[forums.reprap.org]

Here's the original uncut version:

[www.thingiverse.com]

I have attached the two (in simplify3d sliced) gcode files used, they may not fit your printer and could make it go bananas, but at least you can see and compare setting in a file viewer - if you do use the files for printing, make sure to heat up the nozzle first, I always do that and AFAIR dont have a wait command

..and you can always adjust the extrusion multiplier on the fly with M221 Sxx

..also note that the "detect bridging perimeters" setting can make slic3r use your bridging speed setting also when printing overhangs (so I'm told)

BTW, here's some links you may find usefull:

nophead's thoughts on overhangs

[forums.reprap.org]

Print Troubleshooting Pictorial Guide

[www.reprap.org]

A visual Ultimaker troubleshooting guide

[support.3dverkstan.se]

Erik

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 29, 2015 03:49PM |

Registered: 9 years ago Posts: 34 |

Quote

bartdietrich

The problem is that, after a few layers, the nozzle starts riding over and bumping into material it has already printed. After a sufficient number of layers this gets so bad that the nozzle either detaches the print from the bed and drags it around or gets stuck in parts of the print and makes the x,y motors skip.

Is this a Z-Scar Issue like this?

[support.3dverkstan.se]

I try to solve this since I own Ormerod. Had too many hours invested without luck. Now I'm experimenting with a E3d replica for improvements, but this has no much improvment so far. My theory is, this may appear on bowden extruder or too less cooling on the nozzle. A direct extruder cannot be used. A new experiment is to build a super cooling duct onto the e3d, powered by a 10W Fan. Haven't finished the buildup yet.....

By the way: What about the Z heights 0,24 / 0,12mm. Why are those measures used instead of 0,10; 0,15; 0,2; 0,25 ? Are there technical reason for favouring? Should the other be avoid?

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints April 30, 2015 07:52AM |

Registered: 10 years ago Posts: 2,472 |

Quote

gazoox

By the way: What about the Z heights 0,24 / 0,12mm. Why are those measures used instead of 0,10; 0,15; 0,2; 0,25 ? Are there technical reason for favouring? Should the other be avoid?

This was discussed here: [forums.reprap.org]

The Ormerod Z axis uses 4000 steps per mm, so a single step is a small enough unit that it is not really important to ensure that layer height is an exact number of steps. The firmware will use the closest step which means that you might have regularly spaced layers that are 1 step different in height to the rest, which means they will differ in height by 0.00025mm which is not big enough to worry about (though it may show slight banding effects on a printer that is extremely well adjusted, so make layer heights a multiple of 0.00025mm if that is an issue).

You should ideally use a layer height that is an exact division of all Z dimensions in the original design so all Z measurements end up being exact. If, for example, the design has a base thickness of 2.5mm but you print it with a layer height of 0.2mm, then the base will actually turn out with a thickness of either 2.4mm or 2.6mm (depending whether the slicing software has rounded up or down). It is worth carefully considering what layer height to use if the original design used imperial measurements. Perhaps use a layer height of 0.254mm to suit such models, though if the original design had measurements that included 1/8th inches or 1/16th inches, a layer height of 0.26458mm would fit those dimensions better.

Dave

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 11:07AM |

Registered: 9 years ago Posts: 106 |

Thanks for the replies everyone.

I copied what settings there were in the supplied G code files into Slic3r and this resulted in immediate improvement of prints (although also in a marked slowing down). You were right Dave, (much) slower printing speeds do make a big difference. Although the massive overhang test is still a disaster (on the two most inclined prongs at least): no issue with the infill now, but with curling up. But I'll deal with this at some other point...

Thanks Ormerod186 for the attachments and links, I'll look at them later. Right now, I need to print a spool holder. Bought 1 kg filament rolls which don't fit on the one that came with the printer. Was trying to print something the other day with the spool lying next to the printer. I made sure I had unrolled sufficient filament and it was lying a loose and unentangled pile. So I left it overnight. The next morning I came back to see that some of the filament had somehow fallen off the work surface, which caused a shift in the remainder of it, that, coupled with the spring inherent in it etc etc etc resulted in the bed and x axis getting totally entangled in a mess of filament. The print obviously failed and I had to cut the bed free. :-) Everything still works though. First priority therefore is the bigger spool holder. Deigned one and was going to print it yesterday but then realised that with my new and improved but slower settings it would take some 6 hours. Didn't feel like babysitting the spool for that long into the night...

Just realised: this bloody printer is starting to take over my life! :-)

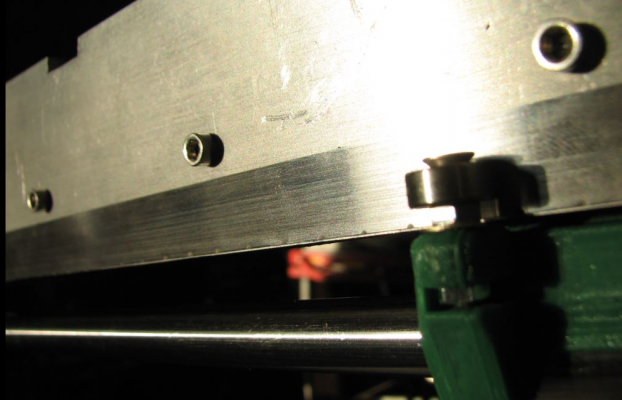

Oh, another thing. My x carriage was not completely level, it was leaning just a tiny tiny little bit forward. I was however unable to adjust this with the supplied 9 mm bearing/screw on the back of the carriage: it was at the far end of its adjustment range already. So I ordered some 10 mm bearings and will see if I can use those to position the head exactly level (starting at the other end of movement range for the adjustment screw obviously).

Bart

I copied what settings there were in the supplied G code files into Slic3r and this resulted in immediate improvement of prints (although also in a marked slowing down). You were right Dave, (much) slower printing speeds do make a big difference. Although the massive overhang test is still a disaster (on the two most inclined prongs at least): no issue with the infill now, but with curling up. But I'll deal with this at some other point...

Thanks Ormerod186 for the attachments and links, I'll look at them later. Right now, I need to print a spool holder. Bought 1 kg filament rolls which don't fit on the one that came with the printer. Was trying to print something the other day with the spool lying next to the printer. I made sure I had unrolled sufficient filament and it was lying a loose and unentangled pile. So I left it overnight. The next morning I came back to see that some of the filament had somehow fallen off the work surface, which caused a shift in the remainder of it, that, coupled with the spring inherent in it etc etc etc resulted in the bed and x axis getting totally entangled in a mess of filament. The print obviously failed and I had to cut the bed free. :-) Everything still works though. First priority therefore is the bigger spool holder. Deigned one and was going to print it yesterday but then realised that with my new and improved but slower settings it would take some 6 hours. Didn't feel like babysitting the spool for that long into the night...

Just realised: this bloody printer is starting to take over my life! :-)

Oh, another thing. My x carriage was not completely level, it was leaning just a tiny tiny little bit forward. I was however unable to adjust this with the supplied 9 mm bearing/screw on the back of the carriage: it was at the far end of its adjustment range already. So I ordered some 10 mm bearings and will see if I can use those to position the head exactly level (starting at the other end of movement range for the adjustment screw obviously).

Bart

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 11:34AM |

Registered: 9 years ago Posts: 638 |

I had simular issues but look at what DC42 wrote on my post: [forums.reprap.org]

I printed the new X-carriage with bearing under the X-Arm ,fixing the bearing in place was a bit tricky but atm i have no sag ,I cant completly tighten the bearing in place becouse of so little space and cant actualy grip the nut so i could but so far it stays in place.

Edit2: Yes i have multicolored Ormerod2 xD

Edited 3 time(s). Last edit at 05/01/2015 11:43AM by Darathy.

I printed the new X-carriage with bearing under the X-Arm ,fixing the bearing in place was a bit tricky but atm i have no sag ,I cant completly tighten the bearing in place becouse of so little space and cant actualy grip the nut so i could but so far it stays in place.

Edit2: Yes i have multicolored Ormerod2 xD

Edited 3 time(s). Last edit at 05/01/2015 11:43AM by Darathy.

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 11:46AM |

Registered: 9 years ago Posts: 106 |

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 12:48PM |

Registered: 9 years ago Posts: 638 |

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 02:12PM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 02:51PM |

Registered: 9 years ago Posts: 638 |

For a spoolholder i found this: [www.thingiverse.com] ,looks awsome!

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 03:36PM |

Registered: 9 years ago Posts: 34 |

Quote

bartdietrich

Just realised: this bloody printer is starting to take over my life! :-)

Bart

Just like me. Don't know if this is good or not. I do experiments since two month nearly every day. But this is my engineers nature

[www.thingiverse.com]

-> I'm using the same! Very good. Also I cut down a plastic bucket in size to fit over the holder like a hat to protect the filament from direct (sun-)light. Smal cut window as filament outlet For very light filament rolls, the holder can slide away from extruder force, so you should add some sort of heavy metal onto top or glue the thing onto a slippy free base plate.

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 08:11PM |

Registered: 9 years ago Posts: 106 |

Quote

As a temporary measure while you are printing a spool holder, just put the spool on a broomstick resting horizontally between a couple of piles of books, buckets, bricks or similar with something to stop the broomstick from rolling off.

Thanks Dave. I have books, I have one bucket, I can probably source some bricks (lots of building work around where I work) but I don't have a broom. I do have a mop though (goes with the bucket mentioned earlier). Thing is, cutting the mop handle to size (the printer shares a very limited space with lots of other kit) would mean I would become mop-less (for all practical purposes) and I don't like that idea. It's not that I like mopping, but sometimes you just gotta do what you gotta do. So therefore my mop stays untouched. I do like the general idea of taking an offensive weapon to it though.

Quote

How u mean entangled with the bed and X axis? X Axis will bend only slightly ,it will break or crack sooner since the acrylic is very fragile.

What do I know! The build instructions say not to bend the x axis parts or else. Makes sense. As to your original question: easy, a filament loop caught the edge of the bed and tightened its grip as the extruder kept working. Thankfully, the print was around 3/4 way through when I went to sleep so the belts didn't get as much of a skipping workout as they otherwise might have and the whole bed-bit lifts up quite easily. When the motors start trying to bend the glass, the motors lose.

Quote

Just like me. Don't know if this is good or not. I do experiments since two month nearly every day. But this is my engineers nature eye rolling smiley

Probably not good but in a good way! I've wanted a 3D printer for a while but could never really justify the expense. Until the new job (I'm a research chemist, I do materials chemistry now, no longer organics/pharmaceuticals) made me realise a 3D printer might actually be useful for work (official justification for buying it: making a customised UV cuvette holder with inert gas inlet and Peltier cooling for irradiation experiments). That's what the gods invented credit cards for... :-)

Bart

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 01, 2015 08:24PM |

Registered: 9 years ago Posts: 106 |

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 02, 2015 08:25AM |

Registered: 10 years ago Posts: 1,230 |

Quote

bartdietrich

I copied what settings there were in the supplied G code files into Slic3r and this resulted in immediate improvement of prints

The nozzle bumping around, could be your infill was too skinny and that made bits of plastic stick up, happened to me, the cure (for me) was to raise the infill extrusion width 150%, notice that the upper speed limit for the ormerod is how fast the extruder can supply the filament

- ; infillExtrusionWidthPercentage,150

Quote

(although also in a marked slowing down). You were right Dave, (much) slower printing speeds do make a big difference.

Yes to a point, things need time to cool, from newly added filament and radiated heat from nozzle, espc. darker color filament absorb a lot of heat - the cure can be to print more than one, placed on the bed with some distance between

Quote

Although the massive overhang test is still a disaster (on the two most inclined prongs at least): no issue with the infill now, but with curling up. But I'll deal with this at some other point...

A bit more cooling will help, and the direction of air should be upskirt, in under the overhangs, placed on the ormerod bed as in my sliced g-file:

..and as noted, I have opened the air slots in the fanduct a lot:

Quote

Just realised: this bloody printer is starting to take over my life! :-)

Oh noes! - resistance is futile! -

Quote

Oh, another thing. My x carriage was not completely level, it was leaning just a tiny tiny little bit forward. I was however unable to adjust this with the supplied 9 mm bearing/screw on the back of the carriage: it was at the far end of its adjustment range already. So I ordered some 10 mm bearings and will see if I can use those to position the head exactly level (starting at the other end of movement range for the adjustment screw obviously).

yes, changing the bearing for a 10 mm was one of the first mods, another fix could be to glue a hacksaw to the x-axis plate as I did on ormerod1a

Erik

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 02, 2015 08:41AM |

Registered: 10 years ago Posts: 1,230 |

Quote

bartdietrich

Thanks Dave. I have books, I have one bucket, I can probably source some bricks (lots of building work around where I work) but I don't have a broom. I do have a mop though (goes with the bucket mentioned earlier). Thing is, cutting the mop handle to size (the printer shares a very limited space with lots of other kit) would mean I would become mop-less (for all practical purposes) and I don't like that idea. It's not that I like mopping, but sometimes you just gotta do what you gotta do. So therefore my mop stays untouched. I do like the general idea of taking an offensive weapon to it though.

Agreed, being mop-less is the worst but use your imagination - small three outside house needs pruning? - blind man with white stick (easy pray, just chat them up so they cant here you hacking away) - drunken sailer with a wooden leg (watch them going round in circles, its a laugh!)

Erik (LOL)

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 06, 2015 06:51AM |

Registered: 9 years ago Posts: 106 |

Thanks for the input everyone!

Does indeed look pretty cool! In the meantime, I designed my own (see photo). Nothing ground braking but functional. Am a bit concerned about the weight the triangular bit that holds the spool has to support now (the spool is sagging a tiny bit) but it's good enough for the time being.

Quote

Darathy

For a spoolholder i found this: [www.thingiverse.com] ,looks awsome!

Does indeed look pretty cool! In the meantime, I designed my own (see photo). Nothing ground braking but functional. Am a bit concerned about the weight the triangular bit that holds the spool has to support now (the spool is sagging a tiny bit) but it's good enough for the time being.

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 06, 2015 06:56AM |

Registered: 9 years ago Posts: 106 |

Quote

ormerod168

yes, changing the bearing for a 10 mm was one of the first mods, another fix could be to glue a hacksaw to the x-axis plate as I did on ormerod1a

Hi Erik,

I thought of doing something similar but being lazy, I'd rather disassemble as little as possible so the 10 mm bearing seemed like the easiest way out. And it seems to do the job. :-)

Quote

ormerod168

Agreed, being mop-less is the worst but use your imagination - small three outside house needs pruning? - blind man with white stick (easy pray, just chat them up so they cant here you hacking away) - drunken sailer with a wooden leg (watch them going round in circles, its a laugh!)

There's also nicking a loo roll holder from work...

Bart

Edited 1 time(s). Last edit at 05/06/2015 06:58AM by bartdietrich.

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 06, 2015 01:42PM |

Registered: 9 years ago Posts: 34 |

|

Re: Slic3r profile for Ormerod 2 results in rubbish prints May 06, 2015 02:56PM |

Registered: 9 years ago Posts: 638 |

Quote

bartdietrich

Thanks for the input everyone!

Quote

Darathy

For a spoolholder i found this: [www.thingiverse.com] ,looks awsome!

Does indeed look pretty cool! In the meantime, I designed my own (see photo). Nothing ground braking but functional. Am a bit concerned about the weight the triangular bit that holds the spool has to support now (the spool is sagging a tiny bit) but it's good enough for the time being.

oh cool i havent thought of actualy using the same place reprap had it placed ,it seemed to me completely wrong side to put a spoolholder xD , very awkward to get the fillament to the extruder.

Quote

gazoox

Hey Barddietrich.

The foil on your acrylic Ormerod parts should be removed. I made same mistake first, but then recognized that this is not part of the design

I actualy thought there was no foil on them at start. but later when i was loooking closely i notice it was a foil XD

Edited 1 time(s). Last edit at 05/06/2015 02:58PM by Darathy.

Sorry, only registered users may post in this forum.