Fillament drying

Posted by Darathy

|

Re: Fillament drying May 22, 2015 02:05PM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Fillament drying May 22, 2015 02:06PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Darathy

should i increase? i have it set to 5mm

5mm should be plenty, I still use 4mm. What retraction speed do you use?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fillament drying May 22, 2015 02:07PM |

Registered: 9 years ago Posts: 177 |

Stringing can be caused from your temp being too high as well. And if retraction was a serious issue I'd expect to see lots of ooze problems as well.

I too am using 5mm retraction (at 60mm/s speed), so that's likely not your problem, but you could always increase and see if it helps you're likely using different PLA than I am.

I'd also check what your 'Minimum travel after retraction is' mine is set to 2mm. This controls the travel threshold that triggers a retraction, i.e. a 1mm travel won't retract but a 3mm travel will.

I too am using 5mm retraction (at 60mm/s speed), so that's likely not your problem, but you could always increase and see if it helps you're likely using different PLA than I am.

I'd also check what your 'Minimum travel after retraction is' mine is set to 2mm. This controls the travel threshold that triggers a retraction, i.e. a 1mm travel won't retract but a 3mm travel will.

|

Re: Fillament drying May 22, 2015 03:11PM |

Registered: 9 years ago Posts: 638 |

|

Re: Fillament drying May 23, 2015 07:12AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Darathy

yes i have it set to 5mm/60mm/s and 2mm minimum travel .i will increase it to 7mm and see if it changes. as i said i have tried lowering it from my usual 185 to 175 and not much diferance

Increasing above 4mm is unlikely to make any difference - in fact it may make things worse because of the longer delay during retraction. Temperature and speed are more likely to do the trick.

Dave

|

Re: Fillament drying May 23, 2015 12:10PM |

Registered: 9 years ago Posts: 638 |

7mm with 65mm/s didnt make any diference  , also i print at 180C unless this pla has way lower melting point then most pla...

, also i print at 180C unless this pla has way lower melting point then most pla...

Dont know if you can see but had trouble finding focus a lot of stringing going on

a lot of stringing going on

Edited 1 time(s). Last edit at 05/23/2015 12:21PM by Darathy.

, also i print at 180C unless this pla has way lower melting point then most pla...

, also i print at 180C unless this pla has way lower melting point then most pla...Dont know if you can see but had trouble finding focus

a lot of stringing going on

a lot of stringing going onEdited 1 time(s). Last edit at 05/23/2015 12:21PM by Darathy.

|

Re: Fillament drying May 23, 2015 01:39PM |

Registered: 9 years ago Posts: 177 |

well, I guess keep trying to reduce the temperature, either till the stringing stops or the extruder starts skipping steps. Maybe the color additives or this brand have a lower Tm.... I'm not sure what else could be causing it.

You might be able to find some sort of 2 tower calibration print that changes temperature every so many layers.

You might be able to find some sort of 2 tower calibration print that changes temperature every so many layers.

|

Re: Fillament drying May 23, 2015 04:19PM |

Registered: 10 years ago Posts: 51 |

I find I have to print PLA at much cooler temperatures than people on the net generally recommend.

Not sure if SA's sunny weather or my 1 339m above sea level has an effect, or whether my printer's thermistor just overshoots, but I print my black PLA at 185, and my see-through blue at 175-180.

Not sure if SA's sunny weather or my 1 339m above sea level has an effect, or whether my printer's thermistor just overshoots, but I print my black PLA at 185, and my see-through blue at 175-180.

|

Re: Fillament drying May 24, 2015 04:56AM |

Registered: 9 years ago Posts: 638 |

|

Re: Fillament drying May 24, 2015 08:10AM |

Registered: 13 years ago Posts: 1,611 |

Which firmware version do you have? If you send M302 (firmware 1.04) or M302 P1 (firmware 1.09 and dc42 firmware), it will allow cold extrusion. See [reprap.org]

Though 160C is surprisingly low for PLA!

Ian

RepRapPro tech support

Though 160C is surprisingly low for PLA!

Ian

RepRapPro tech support

|

Re: Fillament drying May 24, 2015 08:21AM |

Registered: 9 years ago Posts: 638 |

i know ,i am really surprised that this filament is going so low... but i have no other choice i bought 2kg of it lol for being so satisfied with the samples ,altho i bought diferent colors then the ones the samples were ,they did not seem to string so much. I would guess they have lower glass transition temperature(normal is 60-65) aswell. Did notice it was more elastic then other PLA i was using(it did not break imedietly with bending but seemed to stretch a bit before breaking).

i'm using DC's 1.04f .

Edited 1 time(s). Last edit at 05/24/2015 08:22AM by Darathy.

i'm using DC's 1.04f .

Edited 1 time(s). Last edit at 05/24/2015 08:22AM by Darathy.

|

Re: Fillament drying May 24, 2015 08:33AM |

Registered: 9 years ago Posts: 638 |

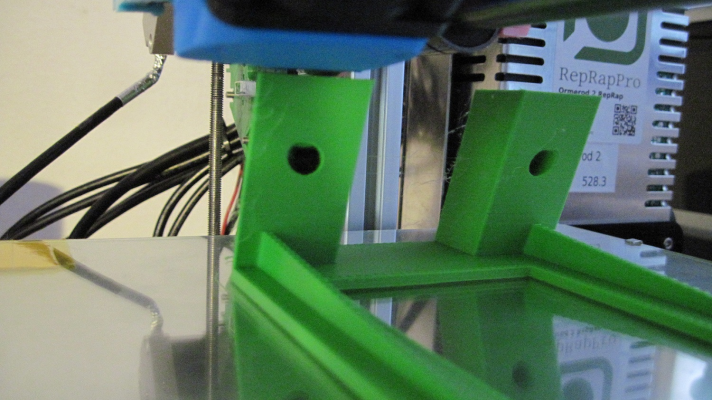

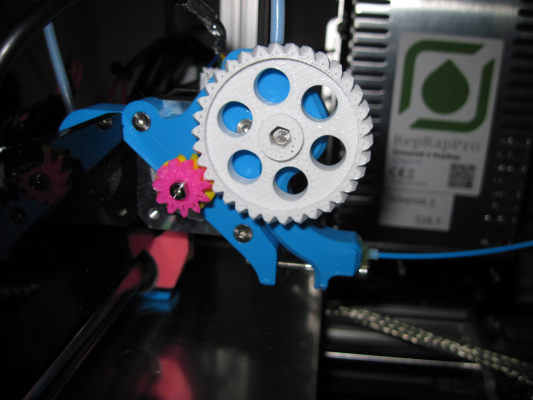

print temperature of 180 and retraction speed 80mm/s have helped a bit ,also probably retraction isnt as effective becouse of my tongue that holds the bowden tube on the extruder has abaut 2-3mm gap, I am printig masonstonehenge's springloaded extruder with the tongue screw holder.I modified the motor side to fit Ormerod 2. I will post this mod for Ormerod 2 if it will work.

|

Re: Fillament drying May 24, 2015 08:57AM |

Registered: 9 years ago Posts: 1,699 |

|

Re: Fillament drying May 24, 2015 10:00AM |

Registered: 9 years ago Posts: 638 |

|

Re: Fillament drying May 26, 2015 10:00AM |

Registered: 9 years ago Posts: 20 |

Quote

Darathy

....also probably retraction isnt as effective becouse of my tongue that holds the bowden tube on the extruder has abaut 2-3mm gap,

...

It sounds like you need this...which fixed that for me on the ormerod (1) extruder..

[www.thingiverse.com]

|

Re: Fillament drying May 26, 2015 02:22PM |

Registered: 9 years ago Posts: 638 |

i solved it with this:

untill i find a pneumatic fitting i will use the screw to hold it in place

untill i find a pneumatic fitting i will use the screw to hold it in place

|

Re: Fillament drying May 27, 2015 07:34AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Darathy

i know ,i am really surprised that this filament is going so low....

It is always possible that the temperature reading is inaccurate, so the nozzle is in reality far hotter than it is reporting. If you can get hold of a wire type thermocouple thermometer, you can push it through the Bowden tube in place of the filament until it hits the inside of the nozzle, and get an extremely accurate temperature reading. Many multimeters have a temperature setting and just need you to plug in a thermocouple, which are not very expensive even from RS - e.g. [uk.rs-online.com]

Dave

|

Re: Fillament drying May 28, 2015 06:30AM |

Registered: 10 years ago Posts: 176 |

I find that I get stringing when my temperature is set too low for the filament.

I use Kisslicer for slicing for the Ormerod - it does a good job, and the only major difference between professional and free version is that the pro supports multiple extruders.

I'm interested by that Cura screenshot. My Cura preview doesn't look like that at all - is there a setting I'm missing I wonder?

I like the look of that extruder you've got there Darathy.. why don't you add the pictures to thingiverse?

Edited 2 time(s). Last edit at 05/28/2015 06:43AM by VortyZA.

I use Kisslicer for slicing for the Ormerod - it does a good job, and the only major difference between professional and free version is that the pro supports multiple extruders.

I'm interested by that Cura screenshot. My Cura preview doesn't look like that at all - is there a setting I'm missing I wonder?

I like the look of that extruder you've got there Darathy.. why don't you add the pictures to thingiverse?

Edited 2 time(s). Last edit at 05/28/2015 06:43AM by VortyZA.

|

Re: Fillament drying May 28, 2015 07:54AM |

Registered: 10 years ago Posts: 2,472 |

Quote

VortyZA

I'm interested by that Cura screenshot. My Cura preview doesn't look like that at all - is there a setting I'm missing I wonder?

I don't think it was taken from Cura. You can take the G-code file that is produced by Cura (or any other slicing application) and load it into a g-code viewer. Note however that no standalone G-code viewer I am familiar with will accurately depict the width of the extrusion (because there is insufficient information in the G-codes to determine the width), so it may look as if there are gaps or overlaps between lines or perimeter/infill that will not occur when you print.

Dave

|

Re: Fillament drying May 28, 2015 08:31AM |

Registered: 9 years ago Posts: 1,699 |

Quote

VortyZA

I use Kisslicer for slicing for the Ormerod - it does a good job, and the only major difference between professional and free version is that the pro supports multiple extruders.

The free version also does not support multiple objects so if you like to print some different parts at once you will need the pro version. I also do not like the appearence and usibility, but that is formerly my personell opinion.

BTT Yesterday I tested drying ABS filament in the oven at 75°C As I opened the door after roughly 45 minutes (I did not look at the start time) it sounded like making popcorn. One hour later the filament was finished and could be served. It really worked.

|

Re: Fillament drying May 28, 2015 11:33AM |

Registered: 10 years ago Posts: 176 |

Ahh - the multiple objects thing.. OK I forgot that after I bought the Pro version. If you were of a mind to try it out and got used to it, there are many ways of laying out the objects and saving them as one composite object which Kisslicer will happily load.

I found that the support generated by Kisslicer beats Cura and (used to beat) Slic3r hands down.. I couldn't remove the support from the objects I printed with slic3r and the Cura support was just so rudimentary that quite often it would not support an object at all.

I found that the support generated by Kisslicer beats Cura and (used to beat) Slic3r hands down.. I couldn't remove the support from the objects I printed with slic3r and the Cura support was just so rudimentary that quite often it would not support an object at all.

|

Re: Fillament drying May 28, 2015 12:55PM |

Registered: 9 years ago Posts: 1,699 |

Of course there is a way putting multiple objects in one file, but Cura and Slic3r have the possibility to rearrange these objects for optimal printing position.

I did not test generating support by slicing yet. I would prefer to have the support directly at the component inside the .stl file like the sping loaded extruder. Otherwise I try to print without. Kisslicer is the youngest one of this three so I think it has the possibility to provide better support for the objects because the author could see the problems at the other two programs and fix this. However the usage and the look is in my opinion not good at Kisslicer. it looks like a program from the 90's. Finding and using the options is also not good. Why I have a pulldown menu when I cannot change the content? And the arrangement of the single tabs - it is hard to find something and you easily can miss something. As I said that is my opinion. And for me the most important thing is that I got the best print results with Slic3r at the moment.

Edited 1 time(s). Last edit at 05/28/2015 01:40PM by Treito.

I did not test generating support by slicing yet. I would prefer to have the support directly at the component inside the .stl file like the sping loaded extruder. Otherwise I try to print without. Kisslicer is the youngest one of this three so I think it has the possibility to provide better support for the objects because the author could see the problems at the other two programs and fix this. However the usage and the look is in my opinion not good at Kisslicer. it looks like a program from the 90's. Finding and using the options is also not good. Why I have a pulldown menu when I cannot change the content? And the arrangement of the single tabs - it is hard to find something and you easily can miss something. As I said that is my opinion. And for me the most important thing is that I got the best print results with Slic3r at the moment.

Edited 1 time(s). Last edit at 05/28/2015 01:40PM by Treito.

|

Re: Fillament drying May 29, 2015 09:19PM |

Registered: 9 years ago Posts: 1,699 |

In some points I have to update my opinion.

There is a newer beta version of Kisslicer available. I did not test it but I took one short look. It looks a little bit fresher. And you can change and handle profiles somehow but this is a little bit tricky (not tested yet). You have first to copy an existing profile rename it and then you can make changes. In my opinion is the handling in Slic3r much better.

It seems that there is no difference in printing quality except of one thing:I am still trying to print an extruder. There is one problem. The holes for the filament guidance are in the X- /Z-dimension (or Y/Z depending on the rotation. So when the top layer is printed that closes the path I am getting Blobs with Slic3r and Kisslicer. Cura produces also some blobs but they are much smaller.

There is a newer beta version of Kisslicer available. I did not test it but I took one short look. It looks a little bit fresher. And you can change and handle profiles somehow but this is a little bit tricky (not tested yet). You have first to copy an existing profile rename it and then you can make changes. In my opinion is the handling in Slic3r much better.

It seems that there is no difference in printing quality except of one thing:I am still trying to print an extruder. There is one problem. The holes for the filament guidance are in the X- /Z-dimension (or Y/Z depending on the rotation. So when the top layer is printed that closes the path I am getting Blobs with Slic3r and Kisslicer. Cura produces also some blobs but they are much smaller.

Sorry, only registered users may post in this forum.