First layers problem

Posted by helidave1

|

First layers problem September 09, 2015 11:12AM |

Registered: 8 years ago Posts: 9 |

Hi All,

I have a Ormerod 2 V528.4. Had it about a week and installed the latest firmware as advised. Its my first attempt at 3d printing so apologies in advance if I am missing something obvious.

I have printed out some of the test pieces that come with the software (snowman, coat-hanger and the axis test piece). All the prints are 95% successful however I have 2 problems which I believe are linked.

1) I never get a complete skirt printed out. Its always a partial skirt (about 60 to 70% complete I guess).

2) The first few layers do not seem to properly merge, they are "stringy" I guess is the best way to put it. I can separate them with a fingernail after the item has cooled. This means the bottom few layers are slightly deformed.

I also notice the same effect on a simple design of my own however I also noticed that the overall height of the completed item seems to be out by 0.9mm or so. When I looked at the height from the top of the item back down to the first good layer, the height seems correct. Almost as if its printing a couple of extra layers although when I check it on Slicr3 it is correct.

The Z height has been checked and reset several times to see if this is my problem. The bed has been levelled as described (and re-checked 3 times). The filament is the one supplied with the kit (white PLA). I clean the bed with Acetone prior to a print.

I can attach a photo if that would make it clearer.

Thanks in advance

I have a Ormerod 2 V528.4. Had it about a week and installed the latest firmware as advised. Its my first attempt at 3d printing so apologies in advance if I am missing something obvious.

I have printed out some of the test pieces that come with the software (snowman, coat-hanger and the axis test piece). All the prints are 95% successful however I have 2 problems which I believe are linked.

1) I never get a complete skirt printed out. Its always a partial skirt (about 60 to 70% complete I guess).

2) The first few layers do not seem to properly merge, they are "stringy" I guess is the best way to put it. I can separate them with a fingernail after the item has cooled. This means the bottom few layers are slightly deformed.

I also notice the same effect on a simple design of my own however I also noticed that the overall height of the completed item seems to be out by 0.9mm or so. When I looked at the height from the top of the item back down to the first good layer, the height seems correct. Almost as if its printing a couple of extra layers although when I check it on Slicr3 it is correct.

The Z height has been checked and reset several times to see if this is my problem. The bed has been levelled as described (and re-checked 3 times). The filament is the one supplied with the kit (white PLA). I clean the bed with Acetone prior to a print.

I can attach a photo if that would make it clearer.

Thanks in advance

|

Re: First layers problem September 09, 2015 11:24AM |

Registered: 10 years ago Posts: 14,672 |

When you say you get a partial skirt, what exactly do you mean? It's normal for the filament flow not to really get going until several cm of skirt have been printed, that's why there is a "Minimum extrusion for skirt" parameter in slic3r. OTOH if you mean the skirt prints on one side but not on the other, that suggests that either the bed is not level, or you are using auto bed compensation but it is making things worse.

A photo would help to identify the other problem.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

A photo would help to identify the other problem.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First layers problem September 09, 2015 01:10PM |

Registered: 8 years ago Posts: 9 |

Hi,

Apologies, I should have made myself clearer. The skirt prints and looks good but It never goes completely around the object. There is always quite a significant gap The actual extrusion looks good however. I did look at the minimum extrusion setting but I thought that the example files provided would have already had that set so I discounted it.

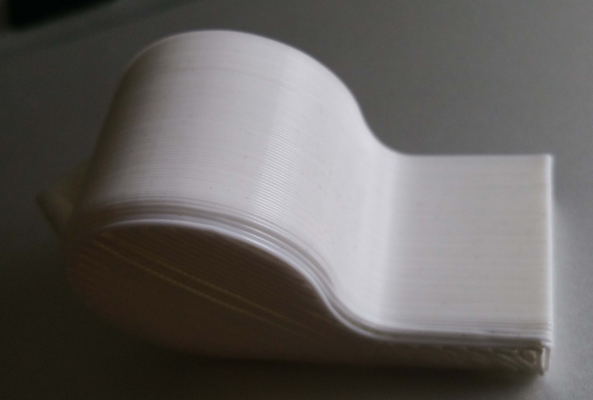

I have attached a photo showing the whistle print. It looks excellent apart from the first few layers.

Thanks

David

Apologies, I should have made myself clearer. The skirt prints and looks good but It never goes completely around the object. There is always quite a significant gap The actual extrusion looks good however. I did look at the minimum extrusion setting but I thought that the example files provided would have already had that set so I discounted it.

I have attached a photo showing the whistle print. It looks excellent apart from the first few layers.

Thanks

David

|

Re: First layers problem September 09, 2015 02:02PM |

Registered: 10 years ago Posts: 14,672 |

Quote

helidave1

The skirt prints and looks good but It never goes completely around the object. There is always quite a significant gap

Do you mean that it does several skirt loops, and the gap is present at the same point in each loop? If so, that is a sign of the bed not being level.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First layers problem September 09, 2015 02:46PM |

Registered: 9 years ago Posts: 1,699 |

I would also guess that the bed is not leveled correctly. For us it is the easiest way to see a picture of the skirt together with the printing option (material, layer height especially first layer height, skirt values like minimum length, count of loops etc.).

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: First layers problem September 09, 2015 03:18PM |

Registered: 8 years ago Posts: 9 |

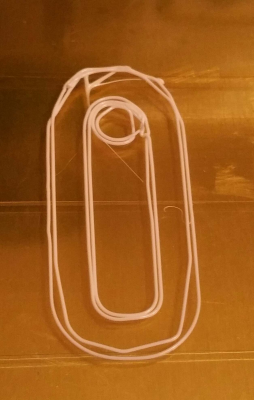

I rechecked the bed again as per the instructions and it looks fine. If I alter the skirt value from 1 to 3 in slic3r I get the result shown in the photo. Nothing (or almost nothing) gets printed on the first circuit, then I get 2 complete skirts but they are not uniform, then it starts on the object base. Bed temperature is 57, Extruder temperature is 200. It seems to settle down after the first few layers and then I get a fantastic print.

Regards

David

Regards

David

|

Re: First layers problem September 09, 2015 03:21PM |

Registered: 10 years ago Posts: 1,230 |

this print has a very small foot print, only covers a small area of the bed, so bed leveling is not that important but zeroing the nozzle is, and as far as I can see you are starting the print way too high

howto post pictures:

Attach a file

Choose...(will send to your pc's filesystem, find the file, chose "open file")

Attach

Create link in message (first, place the cursor in the message window where you want the picture to appear)

Erik

howto post pictures:

Attach a file

Choose...(will send to your pc's filesystem, find the file, chose "open file")

Attach

Create link in message (first, place the cursor in the message window where you want the picture to appear)

Erik

|

Re: First layers problem September 09, 2015 03:37PM |

Registered: 10 years ago Posts: 14,672 |

I concur, it looks to me that the print is starting too high.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First layers problem September 09, 2015 03:38PM |

Registered: 10 years ago Posts: 1,230 |

Quote

helidave1

I rechecked the bed again as per the instructions and it looks fine. If I alter the skirt value from 1 to 3 in slic3r I get the result shown in the photo....

again, you start the print with the nozzle way too high, the filament is slip-sliding around, zero the nozzle correctly - like toothpaste on a brush, it won't stick if not pressed down properly, the filament should be squished against the bed, you can ad 125-150% to first layer width to make sure of that (it cant expand without back pressure from the bed surface) but it wont help much if the nozzle hight is off

Erik

|

Re: First layers problem September 09, 2015 03:50PM |

Registered: 8 years ago Posts: 9 |

Thanks All,

I checked and rechecked my Z home position because I thought I might be too high and was concerned about striking the bed if I was too low. It looks right to me but I am starting to wonder if I'm doing it correctly. I followed the instructions for the first time zero given in the manual and I rechecked it before I started the print. As it is set now I am just trapping a piece of paper. Is there an alternative method I should be using?

Regards

David

I checked and rechecked my Z home position because I thought I might be too high and was concerned about striking the bed if I was too low. It looks right to me but I am starting to wonder if I'm doing it correctly. I followed the instructions for the first time zero given in the manual and I rechecked it before I started the print. As it is set now I am just trapping a piece of paper. Is there an alternative method I should be using?

Regards

David

|

Re: First layers problem September 09, 2015 03:51PM |

Registered: 8 years ago Posts: 9 |

|

Re: First layers problem September 09, 2015 04:52PM |

Registered: 8 years ago Posts: 9 |

I checked the nozzle Z0 height again and its just less than the thickness of a sheet of paper. I went back to Slic3r and adjusted the layer height to 125% and tried again. I achieved a better skirt detail, more uniform but had the same problem with the first few layers. I then tried changing the layer height and first layer height from 0.3mm to 0.4mm. This gave more or less the same result. How does slic3r treat the first and last 3 layers when the horizontal shells setting is set to 3 ? I ask because it seems to me that the first 3 layers are not extruded as solid whereas the last three layers seem to be. It seems to lay down 3 open layers before laying down the three solid layers. After this is done the print is fine.

David

David

|

Re: First layers problem September 09, 2015 05:20PM |

Registered: 8 years ago Posts: 9 |

|

Re: First layers problem September 09, 2015 06:15PM |

Registered: 10 years ago Posts: 14,672 |

The nozzle Z=0 height should be zero, not anything higher. One of the problems is that getting the Z=0 height right when you home the axis in the corner doesn't necessarily mean it is right at the centre of the bed.

One solution is to use one of my IR sensor boards, which lets you home the Z axis in the centre of the bed. Another is to use the following procedure. Home the printer, then heat the bed and hot end to operating temperature. Move the head over the centre of the bed, put a piece of ordinary 80gsm copier paper under it, then lower rhe head until it just grips the paper. Then send G92 Z0. If you remove the paper then the nozzle should be just touching the bed. Raise the nozzle, then print. Make sure that the gcode file does not have a G28 command at the start, otherwise it will undo the height setting.

Edited 1 time(s). Last edit at 09/09/2015 06:16PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

One solution is to use one of my IR sensor boards, which lets you home the Z axis in the centre of the bed. Another is to use the following procedure. Home the printer, then heat the bed and hot end to operating temperature. Move the head over the centre of the bed, put a piece of ordinary 80gsm copier paper under it, then lower rhe head until it just grips the paper. Then send G92 Z0. If you remove the paper then the nozzle should be just touching the bed. Raise the nozzle, then print. Make sure that the gcode file does not have a G28 command at the start, otherwise it will undo the height setting.

Edited 1 time(s). Last edit at 09/09/2015 06:16PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First layers problem September 09, 2015 08:10PM |

Registered: 9 years ago Posts: 1,699 |

Normally it is a good way to lower the z-axis slowly (by 0.1 mm or even 0.05 mm) and to watch the skirt and the Extruder. If you are getting too low in this way no damage occurs as you will only have slightly touching the bed. The worst case would be damaged Kapton tape.

Back to the watching: If you are getting too deep the Extruder motor may skip or you get blobs at the skirt, but if you start with a first layer height of 150% for the beginning you should not get any problems if you are carefully. You then have to watch if the skirt is all the way round the same width except for a area around the bginning as it may take some time before filament leaves the hot-end. And that is when the harmless skipping and blobbing occurs as the nozzle does not touch the bed and you are (depending on the layer height) something about 0.1 mm - 0.3 mm over the bed.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Back to the watching: If you are getting too deep the Extruder motor may skip or you get blobs at the skirt, but if you start with a first layer height of 150% for the beginning you should not get any problems if you are carefully. You then have to watch if the skirt is all the way round the same width except for a area around the bginning as it may take some time before filament leaves the hot-end. And that is when the harmless skipping and blobbing occurs as the nozzle does not touch the bed and you are (depending on the layer height) something about 0.1 mm - 0.3 mm over the bed.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: First layers problem September 10, 2015 05:53AM |

Registered: 8 years ago Posts: 9 |

|

Re: First layers problem September 10, 2015 11:58AM |

Registered: 10 years ago Posts: 2,472 |

Don't use a Z offset, just ensure that the Z axis has been correctly zeroed. After homing in the way you usually do, heat the bed to its normal print temperature but leave the nozzle cold, raise the nozzle to around 5mm, put a sheet of A4 paper on the bed and send the command

"G1 X100 Y100 Z0"

Check that the paper is gripped firmly but can be pushed and pulled with some resistance. Hold the paper by the edge and ensure you are not pushing down on the bed. If it is not right, move the Z height in very small steps (0.05mm or 0.1mm) using the web or Pronterface buttons, and when it is right send "G92 Z0" Then send your print file in the normal way. NOTE - ensure the print file does not include any homing commands at the start.

IMPORTANT - before homing or checking as described, make sure that the nozzle is clean. A small blob of plastic on the nozzle will cause you to set the Z zero height far too high.

Dave

"G1 X100 Y100 Z0"

Check that the paper is gripped firmly but can be pushed and pulled with some resistance. Hold the paper by the edge and ensure you are not pushing down on the bed. If it is not right, move the Z height in very small steps (0.05mm or 0.1mm) using the web or Pronterface buttons, and when it is right send "G92 Z0" Then send your print file in the normal way. NOTE - ensure the print file does not include any homing commands at the start.

IMPORTANT - before homing or checking as described, make sure that the nozzle is clean. A small blob of plastic on the nozzle will cause you to set the Z zero height far too high.

Dave

|

Re: First layers problem September 10, 2015 12:53PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

Don't use a Z offset, just ensure that the Z axis has been correctly zeroed. After homing in the way you usually do, heat the bed to its normal print temperature but leave the nozzle cold, raise the nozzle to around 5mm, put a sheet of A4 paper on the bed and send the command

"G1 X100 Y100 Z0"

Check that the paper is gripped firmly but can be pushed and pulled with some resistance. Hold the paper by the edge and ensure you are not pushing down on the bed. If it is not right,move the Z height in very small steps (0.05mm or 0.1mm) using the web or Pronterface buttons, and when it is right send "G92 Z0" Then send your print file in the normal way. NOTE - ensure the print file does not include any homing commands at the start.

IMPORTANT - before homing or checking as described, make sure that the nozzle is clean. A small blob of plastic on the nozzle will cause you to set the Z zero height far too high.

Dave

Great advice as always - as an alternative to the in bold quoted text you can adjust the treaded rod, the upside: even smaller adjusting steps, no re-zeroing, and you don't risk dam busting the bed if your should choose the wrong button in web or pronterface

One turn of the treaded rod will move the hotend 0,8mm, every feel able click will move the hotend 0,8/50 = 0,016mm

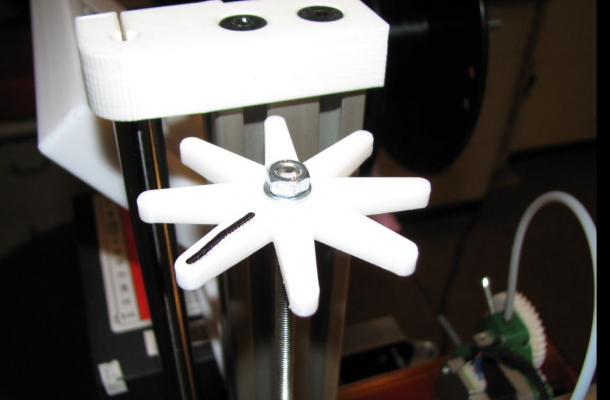

To turn the rod, grab one of the gears or mount and use a star wheel at the top (attached)

Erik

|

Re: First layers problem September 10, 2015 03:45PM |

Registered: 8 years ago Posts: 9 |

Hi,

Thank you to everybody who offered advise - you were all on the money with your answers, the nozzle was too high. I followed the instructions posted above and its printing out as I type and it looks very good indeed.

Sorry, forgot to add my thanks to omerod168 for adding the file for the manual adjust star - much appreciated and it will be my next print this evening.

David

Edited 2 time(s). Last edit at 09/10/2015 04:11PM by helidave1.

Thank you to everybody who offered advise - you were all on the money with your answers, the nozzle was too high. I followed the instructions posted above and its printing out as I type and it looks very good indeed.

Sorry, forgot to add my thanks to omerod168 for adding the file for the manual adjust star - much appreciated and it will be my next print this evening.

David

Edited 2 time(s). Last edit at 09/10/2015 04:11PM by helidave1.

|

Re: First layers problem October 01, 2015 03:18PM |

Registered: 10 years ago Posts: 54 |

I have recently started having the same problems - my prints were ok on objects with a small surface area nut i cant print larger models.

i am getting the same high extruder results as ormerod 168. I run the G92 Z0 command with the print head just touching the glass bed, I run the print and the first layer is being printed at 0.36 - but the first layer did not "squish" as it did previosly... I got my printer working properly 2 weeks ago and have only recently encountered this problem.

My gcode has a G28 Z0 command near the start, but should that not take the z probe to my decided z0 value? or does it override the z0 value and set it to default?

i am getting the same high extruder results as ormerod 168. I run the G92 Z0 command with the print head just touching the glass bed, I run the print and the first layer is being printed at 0.36 - but the first layer did not "squish" as it did previosly... I got my printer working properly 2 weeks ago and have only recently encountered this problem.

My gcode has a G28 Z0 command near the start, but should that not take the z probe to my decided z0 value? or does it override the z0 value and set it to default?

|

Re: First layers problem October 01, 2015 03:47PM |

Registered: 10 years ago Posts: 14,672 |

G28 Z0 will home the Z axis only, by running sys/homez.g.

Edited 1 time(s). Last edit at 10/02/2015 01:35PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 10/02/2015 01:35PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First layers problem October 02, 2015 07:25AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Ecko

I have recently started having the same problems - my prints were ok on objects with a small surface area nut i cant print larger models.

i am getting the same high extruder results as ormerod 168. I run the G92 Z0 command with the print head just touching the glass bed, I run the print and the first layer is being printed at 0.36 - but the first layer did not "squish" as it did previosly... I got my printer working properly 2 weeks ago and have only recently encountered this problem.

My gcode has a G28 Z0 command near the start, but should that not take the z probe to my decided z0 value? or does it override the z0 value and set it to default?

That command will re-home the Z height and thus over-ride your manual adjustment, so remove it from the G-code file (you can use a simple text editor). If you slice your own files, do not have any Z homing commands in the start code of the slicing software. I use DC42's Z sensor which is far more accurate than the supplied sensor, but even that does not reliably set Z height correctly every time (probably does so 90% of the time), so I always check manually which means that I cannot have a Z homing command in my print files.

Dave

|

Re: First layers problem October 02, 2015 12:35PM |

Registered: 9 years ago Posts: 395 |

are you using the standard sensors using white paper at the corners (and kapton on it)?

I ask because I run in the same situation and it is due to the difference in height induced by the paper and the kapton. Follow,the advices above or in slic3r make the first layer thinner than the rest to compensate.

Also the standard reprap settings have a firs layers that is nut really filled ... You might want to change that as well.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

I ask because I run in the same situation and it is due to the difference in height induced by the paper and the kapton. Follow,the advices above or in slic3r make the first layer thinner than the rest to compensate.

Also the standard reprap settings have a firs layers that is nut really filled ... You might want to change that as well.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: First layers problem October 02, 2015 05:18PM |

Registered: 10 years ago Posts: 54 |

I am using a glass print bed, standard sensors and white paper with kapton tape (only on the corners). I tried making the first layer thinner in Sli3r but i got results similar to ormerod168 skirt jpeg image. I am trying to get a "squished" first layer - will have a go at removing the G28 Command from my gcodes. the funny thing was it worked perfectly for a week.. then it started messing up (not sure why)

.

.

|

Re: First layers problem October 03, 2015 02:17AM |

Registered: 9 years ago Posts: 395 |

Change of light affecting bed calibration?

White paper peeling off from the bed?

Bed was bumped against?

New filament with irregulars section causing irregular slow?

The z axis starter to lean in the opposite direction (did you add a screen or a spool holder to it)?

Crack in the z axis motor?

These are all things I would also check. But removing the g28 and setting the initial z position by hand will work ... But you need to do it before any new print.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

White paper peeling off from the bed?

Bed was bumped against?

New filament with irregulars section causing irregular slow?

The z axis starter to lean in the opposite direction (did you add a screen or a spool holder to it)?

Crack in the z axis motor?

These are all things I would also check. But removing the g28 and setting the initial z position by hand will work ... But you need to do it before any new print.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: First layers problem October 05, 2015 10:43AM |

Registered: 10 years ago Posts: 54 |

Happy to say removing g28 z0 from the gcode worked. But I do wonder - if I have just set zero by sending g92 z0 to the duet - why does it seem yo ignore my zero reading and default to a standard reading every time I run the bed compensation (I am using zpl 1.6 web interface). Anyway it works - yay.

|

Re: First layers problem October 05, 2015 01:20PM |

Registered: 9 years ago Posts: 638 |

Quote

Ecko

Happy to say removing g28 z0 from the gcode worked. But I do wonder - if I have just set zero by sending g92 z0 to the duet - why does it seem yo ignore my zero reading and default to a standard reading every time I run the bed compensation (I am using zpl 1.6 web interface). Anyway it works - yay.

I seem to have the same issue ,i home my Z so it catches a peice of paper under the nozzle , then i run bed compensation(5 point with DCs sensor) and send G1 Z0 and nozzle does not catch the paper again.

|

Re: First layers problem October 05, 2015 01:26PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Darathy

Quote

Ecko

Happy to say removing g28 z0 from the gcode worked. But I do wonder - if I have just set zero by sending g92 z0 to the duet - why does it seem yo ignore my zero reading and default to a standard reading every time I run the bed compensation (I am using zpl 1.6 web interface). Anyway it works - yay.

I seem to have the same issue ,i home my Z so it catches a peice of paper under the nozzle , then i run bed compensation(5 point with DCs sensor) and send G1 Z0 and nozzle does not catch the paper again.

Do you home the Z axis at the bed centre, or somewhere else?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: First layers problem October 05, 2015 02:37PM |

Registered: 9 years ago Posts: 638 |

|

Re: First layers problem October 05, 2015 03:25PM |

Registered: 10 years ago Posts: 14,672 |

In theory, if your last bed compensation point of the 5 has the same XY coordinates as the Z homing point at the centre of the bed, then after running bed compensation, the Z=0 height at the centre of the bed should be exactly the same as if you just ran Z homing. But I think I saw an effect similar to your report some time ago, so I'll do some tests.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.