Y axis microswitch EMI issue

Posted by tig124

|

Y axis microswitch EMI issue December 04, 2015 04:39AM |

Registered: 8 years ago Posts: 38 |

Hello All,

Looking on here there was talk about the need to separate the wiring of the Y axis microswitch from the stepper motor due to EMI noise from the stepper motor causing false steps on the y axis in your prints.

My solution has been to add a clip on ferrite onto the wiring of the Steppermotor (y axis one) which sucks all the EMI noise from the stepper motor wiring and turns this into heat.. This ferrite should be put as close to the controller board as possible.

Hope this helps others out??

Tom

[techyman3d.blogspot.co.uk]

Engineers solutions are generally the best

[techyman3d.blogspot.co.uk]

Looking on here there was talk about the need to separate the wiring of the Y axis microswitch from the stepper motor due to EMI noise from the stepper motor causing false steps on the y axis in your prints.

My solution has been to add a clip on ferrite onto the wiring of the Steppermotor (y axis one) which sucks all the EMI noise from the stepper motor wiring and turns this into heat.. This ferrite should be put as close to the controller board as possible.

Hope this helps others out??

Tom

[techyman3d.blogspot.co.uk]

Engineers solutions are generally the best

[techyman3d.blogspot.co.uk]

|

Re: Y axis microswitch EMI issue December 04, 2015 05:02AM |

Registered: 10 years ago Posts: 14,672 |

There isn't any need to separate the Y axis microswitch from the stepper motor cables. There might be if it were using a normally open microswitch instead of normally closed.

Using a ferrite bead as you suggest will only take care of common mode EMI such as may be generated by the switching regulator. It won't do anything for EMI or capacitive coupling into the microswitch cable caused by the stepper motor phases switching.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Using a ferrite bead as you suggest will only take care of common mode EMI such as may be generated by the switching regulator. It won't do anything for EMI or capacitive coupling into the microswitch cable caused by the stepper motor phases switching.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Y axis microswitch EMI issue December 04, 2015 06:19AM |

Registered: 8 years ago Posts: 38 |

|

Re: Y axis microswitch EMI issue December 04, 2015 07:10AM |

Registered: 10 years ago Posts: 2,472 |

No, there has never been any talk about a need to separate motor and switch wiring on this forum. Perhaps you have a different printer?

Noise on the microswitch input cannot possibly affect the print. The only thing that could be affected is the Y homing operation, and I would be extremely surprised if it was an issue given the low impedance of the switch input, which also has a bypass cap on the Duet. Any problems homing are more likely to be caused by a loose connection to the switch.

Once the Ormerod is printing, the controller never looks at the switch state so it won't matter how much noise it has on it.

Dave

Noise on the microswitch input cannot possibly affect the print. The only thing that could be affected is the Y homing operation, and I would be extremely surprised if it was an issue given the low impedance of the switch input, which also has a bypass cap on the Duet. Any problems homing are more likely to be caused by a loose connection to the switch.

Once the Ormerod is printing, the controller never looks at the switch state so it won't matter how much noise it has on it.

Dave

|

Re: Y axis microswitch EMI issue December 04, 2015 01:51PM |

Registered: 9 years ago Posts: 638 |

|

Re: Y axis microswitch EMI issue December 04, 2015 01:59PM |

Registered: 10 years ago Posts: 14,672 |

The push-on connectors don't fit the microswitch tags properly and tend to fall off. I soldered some standard 0.1" header pins to the microswitch tags, insulated the soldered bits with heatshrink, and slipped the push-on connectors on them. That was over a year ago, and they have not fallen off since then.

Edited 2 time(s). Last edit at 12/04/2015 02:00PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 2 time(s). Last edit at 12/04/2015 02:00PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Y axis microswitch EMI issue December 04, 2015 03:30PM |

Registered: 8 years ago Posts: 38 |

|

Re: Y axis microswitch EMI issue December 05, 2015 02:23AM |

Registered: 9 years ago Posts: 1,699 |

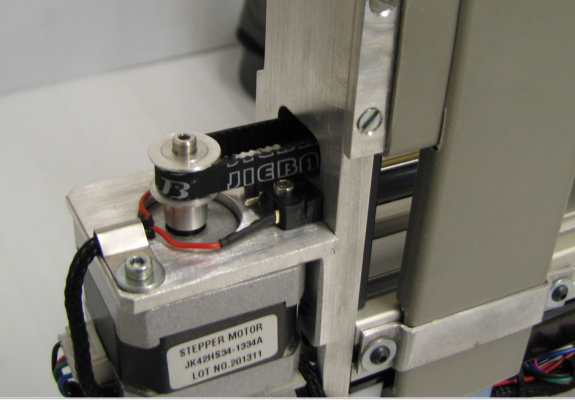

Can you post a picture of the switch?

@dmould Interesting. This aspect I have never considered. But if I rethink of it this is definitely an advantage to use a NC contact with GND.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

@dmould Interesting. This aspect I have never considered. But if I rethink of it this is definitely an advantage to use a NC contact with GND.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Y axis microswitch EMI issue December 05, 2015 05:39AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Darathy

Only Problem that annoys me with Ormerod 2's microswitch is the position of it. It gets disconected a lot of times becouse the connectors dont hold on to the pins anaugh and soldering would complicate disasembeling the printer.

Connectors might not be perfect but OK if you secure the cables

Erik

|

Re: Y axis microswitch EMI issue December 06, 2015 04:51AM |

Registered: 9 years ago Posts: 638 |

Quote

dc42

The push-on connectors don't fit the microswitch tags properly and tend to fall off. I soldered some standard 0.1" header pins to the microswitch tags, insulated the soldered bits with heatshrink, and slipped the push-on connectors on them. That was over a year ago, and they have not fallen off since then.

you mean this:[www.pololu.com] to the switch?

|

Re: Y axis microswitch EMI issue December 06, 2015 06:37AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Darathy

Quote

dc42

The push-on connectors don't fit the microswitch tags properly and tend to fall off. I soldered some standard 0.1" header pins to the microswitch tags, insulated the soldered bits with heatshrink, and slipped the push-on connectors on them. That was over a year ago, and they have not fallen off since then.

you mean this:[www.pololu.com] to the switch?

Yes.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Y axis microswitch EMI issue December 07, 2015 06:54AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Darathy

Only Problem that annoys me with Ormerod 2's microswitch is the position of it. It gets disconected a lot of times becouse the connectors dont hold on to the pins anaugh and soldering would complicate disasembeling the printer.

Yes, that annoys me as well, though it's only because I've been too lazy to fix it. What I've been intending to do is solder a pair of short wires to the switch that terminate in a small in-line connector. The short wires should however be fastened mechanically, otherwise the vibration of the printer in operation is likely to result in a fracture at the solder joints sooner or later. I've asked Santa for a round tooit, so maybe it will be done by January.

Dave

|

Re: Y axis microswitch EMI issue December 07, 2015 11:45AM |

Registered: 9 years ago Posts: 44 |

|

Re: Y axis microswitch EMI issue December 07, 2015 03:56PM |

Registered: 9 years ago Posts: 1,699 |

Regarding the Ormerod 2 only a short distance is needed. So I directly soldered mine to the switch (not the original one). In my eyes is does not make any sense to use an additional connector at this short distance. But how do you avoid that the wires of the cables could get in touch with the rotary parts that means with the pulley?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Y axis microswitch EMI issue December 08, 2015 06:52AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

Regarding the Ormerod 2 only a short distance is needed. So I directly soldered mine to the switch (not the original one). In my eyes is does not make any sense to use an additional connector at this short distance. But how do you avoid that the wires of the cables could get in touch with the rotary parts that means with the pulley?

Just route them around the pulley and they should stay out of the way. It's not a particularly elegant design, but it would work OK if the connectors had fitted the switch properly. If you want to do a "proper job" you could remove the switch and cut down the connector tags after soldering wires to them, then route the lower wire against the switch body to exit next to the upper wire, and pop some large diameter heat-shrink or self-amalgamating tape over the switch body to hold the wires neatly in place and prevent vibration at the solder joints. Which is what I plan to do when Santa brings me a round tooit.

Dave

|

Re: Y axis microswitch EMI issue December 08, 2015 11:21PM |

Registered: 9 years ago Posts: 1,699 |

Hello Dave,

my Ormerod 2 do not use original cables. However luckily I use cable where the isolation is not very flexible (sorry I do not have the word in moment), but this does not prevent the cable to move. I screwed a short screw into the upper right hole of the motor to fix the cable here with a cable tie, but this connection got loose with the bed movement and the cable for the heated bed.

I use this type of microswitch, but mine is without NO contact (the connection is of course soldered with this model):

[uk.rs-online.com]

I got it very cheap for only 0,10€ per piece.

One wire passes the pulley underneath and one cable above the pulley. Unfortunately I use a wrong pulley at the moment (replacement is already here) so mine is a little bit bigger (20 teeth instead of 18).

I am looking for a more stable and safe construction. Erik's solution looks indeed very good.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

my Ormerod 2 do not use original cables. However luckily I use cable where the isolation is not very flexible (sorry I do not have the word in moment), but this does not prevent the cable to move. I screwed a short screw into the upper right hole of the motor to fix the cable here with a cable tie, but this connection got loose with the bed movement and the cable for the heated bed.

I use this type of microswitch, but mine is without NO contact (the connection is of course soldered with this model):

[uk.rs-online.com]

I got it very cheap for only 0,10€ per piece.

One wire passes the pulley underneath and one cable above the pulley. Unfortunately I use a wrong pulley at the moment (replacement is already here) so mine is a little bit bigger (20 teeth instead of 18).

I am looking for a more stable and safe construction. Erik's solution looks indeed very good.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.