Levelling your beds! - How do you do yours?

Posted by tig124

|

Levelling your beds! - How do you do yours? December 23, 2015 06:29PM |

Registered: 8 years ago Posts: 38 |

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 01:50AM |

Registered: 9 years ago Posts: 1,699 |

I am planning to do a comparison test soon, but I need some preparations first so that no method gets any disadvantages.

There are several possibilities so far as I know:

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

There are several possibilities so far as I know:

- Using the provided sensor: The worst method. Only works more or less if the bed is nearly leveled and is highly dependent from the be surface.

- dc42's sensor boards: At the moment this seems to be the best option. I did not test them directly but I already ran some test based on the method. They are nearly independent from the surface and contactless. They cost a little bit more and as long as you are not good in electronics the price is fair as every board is tested.

- Tilt method: This uses an effect of the Ormerod 2. If the nozzle hits the bed the device is tilting to one side. This effect is used to trigger a microswitch. However I tested this method and it fails for me. It is only good to home the z-axis but at high X-values there is no support of the bed. I observed that the bed was pushed down before the device tilted. This is not suitable for sensitive surfaces like BuildTak if the nozzle is heated up.

- As I have a chinese replica nozzle (a round one) I use at the moment a method based on the tilt method: If the nozzle hits the surface the nozzle will be pushed up and triggers a microswitch. At the moment this is the best method. You have no offset and it is very accurate how my prints also shows. But it is not compatible with sensitive surfaces like BuildTak if the nozzle is hot. The design of the nozzle holder is not provided yet. I am not a fan of levers at microswitches but here I should use one together with a smaller microswitch, so I have to change my design if I keep with this method.

- I will try to exchange the mircoswitch with an optical sensor or a FSR to increase the accuracy. Especially the FSR shows highly potential and it may be converted to the standard nozzle. However and that is the problem why I did not run any tests so far: It is not possible to directly connect the FSR to the Duet board. A small signal converting is needed either using a transistor or more likely an opAmp. So I will need to do some calculations and further tests. But it seems to be very accurate. I am only afraid that the travel may result in triggering and I maybe need to add some weak springs but how and where?

- FSR with standard nozzle may end in some trouble as it may dependent on how tighten you screw your screws for example.

- Leveling the bed by hand. Here you can try to use the provided sensor board, using the paper method (which did not work for me) or use a measuring device like a dial indicator. I have one but not yet used.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 01:58AM |

Registered: 9 years ago Posts: 395 |

Despite all ... I find the manual way the easiest and I hate the auto bed levelling of the ormerod ( am using the standard o2 one). I wish it were not there as it messes things up for me more than help.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 02:19AM |

Registered: 9 years ago Posts: 1,699 |

I am happy that this exists otherwise I could not use my microswitch method. It is very accurate with roughly 0.05mm,

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 02:50AM |

Registered: 10 years ago Posts: 14,672 |

I use the nuts on the 3-point bed support to level the bed as far as possible. I don't have any problem with using a spanner for this and it only needs to be re-done if I move the printer. There is a slight twist in my Y axis that I haven't corrected yet, so when doing large prints I enable bed compensation.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 06:03AM |

Registered: 10 years ago Posts: 1,230 |

Yes those small 3mm nut can be a pain to adjust but if you bolt you printer down to something solid you will only have to do it once

Erik

Erik

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 06:16AM |

Registered: 8 years ago Posts: 38 |

Quote

ormerod168

Yes those small 3mm nut can be a pain to adjust but if you bolt you printer down to something solid you will only have to do it once

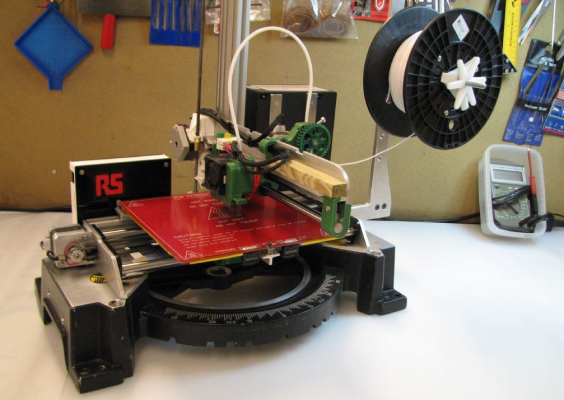

[attachment 68256 bigfoot8.JPG]

Erik

Ah yes that would do the job eric....Mind you I need it to be more portable! and Compact!!! I was thinking of ditching the nuts and inserting a spring mechanism in there somehow (need to switch my brain into mechanical mode and figure this out) then at least the bed could have final adjustments made if the printer gets moved!

I have seen bed compensation - But not tried it yet - What does that require?

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 07:11AM |

Registered: 10 years ago Posts: 14,672 |

If you use springs between the PCB bed heater and the bed support, then you could use a singe nyloc nut underneath the bed support on each of the three screws for levelling, which would make adjustment a little easier. I tried this, but the springs I had were not strong enough.

Bed compensation requires a working Z probe. It's OK for compensating small levelling errors, although it increases wear on the Z threaded rod and nut.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Bed compensation requires a working Z probe. It's OK for compensating small levelling errors, although it increases wear on the Z threaded rod and nut.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 08:49AM |

Registered: 10 years ago Posts: 293 |

|

Re: Levelling your beds! - How do you do yours? December 24, 2015 09:50AM |

Registered: 9 years ago Posts: 1,699 |

The values highly depends on the installation and my aim is to get the best possible signal so I will do this on my own. An installation at another printer gives an other signal. I simply was too busy and a first test showed me that there is a highly potential which I want to use.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.