Clogged nozzle just won't clear

Posted by static65

|

Clogged nozzle just won't clear March 12, 2016 05:25AM |

Registered: 10 years ago Posts: 66 |

Hi again.

Cat woke me up at 6:30 this morning so I went and checked my overnight print and discovered it had come off the bed and formed a giant blob around the nozzle. Spent half an hour or more cleaning that, put the hot end back on the printer and discovered it had developed a significant sag, so fixed that with a spacer and a bigger bearing on the back of the X arm. By 8:30 I was doing a test print, only to find the nozzle has now developed a clog!

I changed filament to one that I know is good quality just in case it was the cheap white filament that caused the clog. I've now done about 8 or 9 cycles of heating the PLA to 190, extruding a bit by hand, cooling to 120 (thats the lowest I could get it to retract), retracting by hand and removing 20mm or so from the end of the filament. Each time I think I've got it because it extrudes anywhere between 50 and 150mm of filament before it clogs again.

What's the next step? I saw a post on using a heat gun and compressed air to clean a quick-set nozzle, but I don't have any air tools (also it's an Ormerod 1 so not quick-set). I've ordered some 0.5mm drill bits to see if I can clear it from the other side but not sure if that's a good idea.

By this point I would normally have bought a new nozzle but I can't find any non-quick set ones available. Might be time to get a printer that still has support...

Many thanks in advance!

Cat woke me up at 6:30 this morning so I went and checked my overnight print and discovered it had come off the bed and formed a giant blob around the nozzle. Spent half an hour or more cleaning that, put the hot end back on the printer and discovered it had developed a significant sag, so fixed that with a spacer and a bigger bearing on the back of the X arm. By 8:30 I was doing a test print, only to find the nozzle has now developed a clog!

I changed filament to one that I know is good quality just in case it was the cheap white filament that caused the clog. I've now done about 8 or 9 cycles of heating the PLA to 190, extruding a bit by hand, cooling to 120 (thats the lowest I could get it to retract), retracting by hand and removing 20mm or so from the end of the filament. Each time I think I've got it because it extrudes anywhere between 50 and 150mm of filament before it clogs again.

What's the next step? I saw a post on using a heat gun and compressed air to clean a quick-set nozzle, but I don't have any air tools (also it's an Ormerod 1 so not quick-set). I've ordered some 0.5mm drill bits to see if I can clear it from the other side but not sure if that's a good idea.

By this point I would normally have bought a new nozzle but I can't find any non-quick set ones available. Might be time to get a printer that still has support...

Many thanks in advance!

|

Re: Clogged nozzle just won't clear March 12, 2016 06:58AM |

Registered: 9 years ago Posts: 1,699 |

You can use the original or cheap Chinese E3D-printheads. The Chinese clones starts at 5$.

If you have PLA only it is no problem to use temperatures of 230°C which could help cleaning the nozzle. If you have ABS you could use this instead, but be careful not to raise the temperature of the nozzle above 250°C.

I built an Ormerod 2 by my own using a Chineses E3D-clone and I am getting much better printouts compared to the non-quick set hot-end. So I decided to exchange the nozzle of my Ormerod 1 soon. I would suggest that you should use the E3D-clone as well if you have someone who could help you with printing the necessary mounting parts.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

If you have PLA only it is no problem to use temperatures of 230°C which could help cleaning the nozzle. If you have ABS you could use this instead, but be careful not to raise the temperature of the nozzle above 250°C.

I built an Ormerod 2 by my own using a Chineses E3D-clone and I am getting much better printouts compared to the non-quick set hot-end. So I decided to exchange the nozzle of my Ormerod 1 soon. I would suggest that you should use the E3D-clone as well if you have someone who could help you with printing the necessary mounting parts.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Clogged nozzle just won't clear March 12, 2016 07:55AM |

Registered: 10 years ago Posts: 1,230 |

Quote

static65

What's the next step? I saw a post on using a heat gun and compressed air to clean a quick-set nozzle, but I don't have any air tools (also it's an Ormerod 1 so not quick-set). I've ordered some 0.5mm drill bits to see if I can clear it from the other side but not sure if that's a good idea.

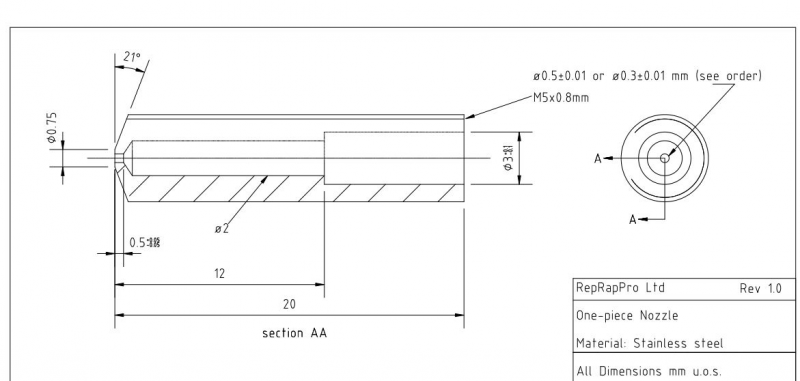

1) clear the first part with a 3mm drill bit, hand held so you can feel the drill bit follow the path of the hole without damaging the inner surface of the nozzle

2) clear the second part with a 2mm drill bit, same procedure

3) clear the 0,5mm hole, notice this part is only 0.5mm deep so you should be able to push that out even while cold, e.g pull a single wire form a wire brush, these are usually 0.4mm thick and very stiff, fingerspitzgefühl is important at this point, do not damage the the tip of the nozzle

3a) heat the nozzle with a heat gun, suck the last D0.5x0.5mm out with a "spring-loaded-solder-sucking-thingie" whatever its called :-)

3b) heat the nozzle and blow the last part out with a spring loaded or pre-charged pneumatic air gun

Quote

By this point I would normally have bought a new nozzle but I can't find any non-quick set ones available. Might be time to get a printer that still has support...

You can get a 0.3mm one-piece-nozzle at emakershop here...

[www.emakershop.com]

..and you have ordered a 0.5mm drill already so should not be a problem

Erik

|

Re: Clogged nozzle just won't clear March 12, 2016 09:27AM |

Registered: 9 years ago Posts: 1,699 |

That one works with the Ormerod hot end without the brass nozzle of course, but I doubt you could get the nozzle deep enough without further modifications.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Clogged nozzle just won't clear March 12, 2016 11:26AM |

Registered: 9 years ago Posts: 638 |

|

Re: Clogged nozzle just won't clear March 12, 2016 02:22PM |

Registered: 10 years ago Posts: 66 |

Quote

ormerod168

Quote

static65

What's the next step? I saw a post on using a heat gun and compressed air to clean a quick-set nozzle, but I don't have any air tools (also it's an Ormerod 1 so not quick-set). I've ordered some 0.5mm drill bits to see if I can clear it from the other side but not sure if that's a good idea.

[attachment 74408 one-piece-nozzle.JPG]

1) clear the first part with a 3mm drill bit, hand held so you can feel the drill bit follow the path of the hole without damaging the inner surface of the nozzle

2) clear the second part with a 2mm drill bit, same procedure

3) clear the 0,5mm hole, notice this part is only 0.5mm deep so you should be able to push that out even while cold, e.g pull a single wire form a wire brush, these are usually 0.4mm thick and very stiff, fingerspitzgefühl is important at this point, do not damage the the tip of the nozzle

3a) heat the nozzle with a heat gun, suck the last D0.5x0.5mm out with a "spring-loaded-solder-sucking-thingie" whatever its called :-)

3b) heat the nozzle and blow the last part out with a spring loaded or pre-charged pneumatic air gun

Quote

By this point I would normally have bought a new nozzle but I can't find any non-quick set ones available. Might be time to get a printer that still has support...

You can get a 0.3mm one-piece-nozzle at emakershop here...

[www.emakershop.com]

..and you have ordered a 0.5mm drill already so should not be a problem

Erik

Thanks Erik, that's cleared it out nicely. Used a 2mm drill bit to remove all the plastic down to the nozzle by hand, then I went for the heat gun and solder-sucker approach. I had to look up a translation for "fingerspitzgefühl" but other than that your instructions were most excellent

Hopefully I can get this part printed for a 3DHubs customer tonight, it was starting to look like I'd have to cancel on him.

Hopefully I can get this part printed for a 3DHubs customer tonight, it was starting to look like I'd have to cancel on him.Thanks again!

|

Re: Clogged nozzle just won't clear March 13, 2016 01:26AM |

Registered: 8 years ago Posts: 164 |

|

Re: Clogged nozzle just won't clear March 13, 2016 01:52AM |

Registered: 9 years ago Posts: 1,699 |

Static65, you are from Germany, too?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Clogged nozzle just won't clear March 13, 2016 03:24AM |

Registered: 9 years ago Posts: 1,699 |

Quote

static65

I had to look up a translation for "fingerspitzgefühl" but other than that your instructions were most excellent

[dict.leo.org]

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Clogged nozzle just won't clear March 13, 2016 06:17AM |

Registered: 10 years ago Posts: 66 |

Treito, I'm from the UK  Regards your earlier post, I do have an original E3D V6 hot end but I couldn't get it to stop stringing everywhere. It's also got a 24V cartridge and fans, and my 24V power supply blew up, so that's on hold until I get another one.

Regards your earlier post, I do have an original E3D V6 hot end but I couldn't get it to stop stringing everywhere. It's also got a 24V cartridge and fans, and my 24V power supply blew up, so that's on hold until I get another one.

0x0000, thats good to know! In this case I needed to get the print done ASAP so the drill bit approach would still have been quickest.

Regards your earlier post, I do have an original E3D V6 hot end but I couldn't get it to stop stringing everywhere. It's also got a 24V cartridge and fans, and my 24V power supply blew up, so that's on hold until I get another one.

Regards your earlier post, I do have an original E3D V6 hot end but I couldn't get it to stop stringing everywhere. It's also got a 24V cartridge and fans, and my 24V power supply blew up, so that's on hold until I get another one.0x0000, thats good to know! In this case I needed to get the print done ASAP so the drill bit approach would still have been quickest.

|

Re: Clogged nozzle just won't clear March 13, 2016 07:59AM |

Registered: 9 years ago Posts: 106 |

PLA residues can also be dissolved with sodium hydroxide solution ("caustic soda"). This is corrosive to skin and especially eyes so take care. As opposed to dichloromethane or chloroform, used sodium hydroxide solution can be safely disposed of down the drain (flush with lots of water).

Neither of these will do anything for charred plastic residues in the nozzle though. Sonication can help in that case: this dislodges residues mechanically and breaks them up into tiny particles which can then be flushed out. Ultrasonic cleaning baths can be bought on eBay from about £20-30. Place nozzle into small beaker with sodium hydroxide solution and put the beaker into the ultrasonic bath (filled with water of course). Do not pour sodium hydroxide solution directly into the ultrasonic cleaner: the containers are usually aluminium and will be eroded by sodium hydroxide!

Bart

Neither of these will do anything for charred plastic residues in the nozzle though. Sonication can help in that case: this dislodges residues mechanically and breaks them up into tiny particles which can then be flushed out. Ultrasonic cleaning baths can be bought on eBay from about £20-30. Place nozzle into small beaker with sodium hydroxide solution and put the beaker into the ultrasonic bath (filled with water of course). Do not pour sodium hydroxide solution directly into the ultrasonic cleaner: the containers are usually aluminium and will be eroded by sodium hydroxide!

Bart

Sorry, only registered users may post in this forum.